Polymer Processing (L9 & 10)

1/65

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

66 Terms

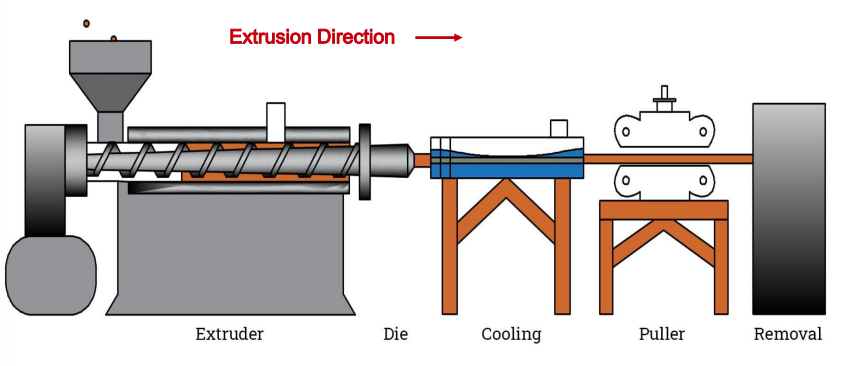

Extrusion

Material is forced to flow through a die orifice to provide long continuous product whose cross section is determined by the shape of the orifice

Which type of plastics are most commonly used in extrusion?

thermoplastics and elastomers

extrudate

extruded product

Extrusion Process

Screw/heaters are used to melt & blend thermoplastic pellets in barrel (very similar to injection molding)

Screw rotates at constant rate to supply polymer melt through die opening

Screw is profiled to supply sufficient pressure for proper extrusion

Extruded part cooled using air or water

Cooling and stretching minimizes shrinkage and disortion

Components of an extruder

Barrel and Screw

*The die is NOT an extruder component

Sections of the screw

Feed section, compression section, metering section

Feed Section

feedstock is moved from hopper and preheated

Compression section

polymer is transformed into thick fluid, air mixed with pellets is extracted from melt, and material is compressed

Metering Section

melt is homogenized and sufficient pressure developed to pump it through die opening

Increase in polymer melt pressure is largely determine by the ___

Channel depth

What is the principle transport mechanism of the screw

drag flow

screen pack

series of wire meshes supported by a stiff plate containing small axial holes

Before reaching the die, the melt passes through a _____

Screen Pack

Functions of screen pack

Filters out contaminants and hard lumps

▪ Builds pressure in metering section

▪ Straightens flow of polymer melt and removes its "memory" of circular motion from screw

Viscoelastic Property

“Memory” of a polymer. if the flow were left unstraightened, the polymer would play back its history of turning inside the extrusion chamber, tending to twist and distort the extrudate.

What determines the cross-sectional shape of the extrudate?

The shape of the die orifice

What is required to form hollow shapes?

Mandrel.

Mandrel held in place using spider legs

▪ Polymer melt flows around legs supporting the mandrel to reunite into a monolithic tube wall

▪ Mandrel often includes an air channel for blowing air to maintain hollow form of extrudate

Crosshead Die

Extrudate direction perpendicular to extruder barrel

Typical Extrusion Line Layout

Film

thickness below 0.5 mm

Sheet

thickness from 0.5 mm (0.020 in) to about 12.5 mm (0.5 in)

Slit-Die Extrusion of Sheet and Film

Conventional extrusion, using a narrow slit as the die opening ▪ Slit may be up to 3 m (10 ft) wide and as narrow as around 0.4 mm (0.015 in)

Common Problems of Slit-Die Extrusion of Sheet and Film

thickness uniformity throughout width due to drastic shape change of polymer melt as it flows through die

Chill Rolls

achieve fast solidification of the molten film after extrusion.

Blown-Film Extrusion Process

Extrusion of polymer tube

2. Tube is drawn upward while still molten and expanded by air inflated into it through die

▪ Air is blown into tube to maintain uniform film thickness and tube diameter

Advantage of Blown-Film Extrusion

Unlike other processes, the material is stretched in both directions. Increased isotropic strength properties

Calendaring

Rubbery TP feedstock is passed through a series of rolls to reduce thickness to desired gage

Strengths of Calendering

Process is noted for good surface finish, high gage accuracy, and production rate (500 ft/min)

Fiber

a long, thin strand whose length is at least 100 times its cross section

Filament

a fiber of continuous length

Spinning

extrusion of polymer melt or solution through a spinneret, then drawing and winding onto a bobbin

Spinneret

die with multiple small holes, the term is a holdover from methods used to draw and twist natural fibers into yarn or thread

Spinning Variations

1. Melt spinning

2. Dry spinning

3. Wet spinning

Melt Spinning

Polymer is heated to molten state and extruded through spinneret

Used for polyester and nylon filaments

Final diameter wound onto bobbin may be only 10% of extruded size

Dry Spinning

Like melt spinning, but starting polymer is in solution and solvent can be separated by evaporation

Pulled through heater chamber

Used for filaments of cellulose acetate and acrylics

Wet Spinning

– Polymer is again in solution, only solvent is non-volatile

– To separate polymer, extrudate is passed through a liquid chemical that precipitates the polymer into strands

– Used to produce rayon

non-volatile

substance does not readily vaporize

Most widely use spinning variation?

Melt Spinning

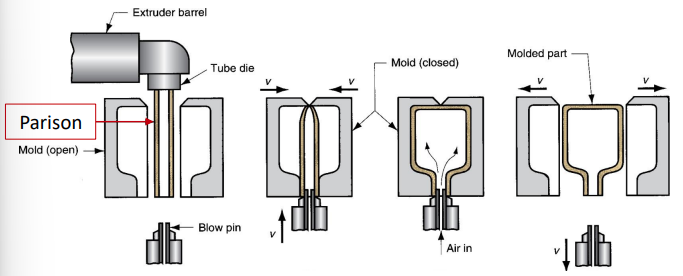

Blow Molding

Molding process in which air pressure is used to inflate soft plastic in a mold cavity

Typical Products of blow molding

one-piece hollow plastic parts with thin walls - from bottles to large storage drums

Production quantity size of blow molding

Very High

Parison

Starting tube used in blow molding. Formed by extrusion or injection molding

Types of blow molding

extrusion, injection

Extrusion Blow Molding

a) Extrusion of parison

b) Parison is pinched at top and sealed at bottom around blow pin as the mold closes

c) Tube is inflated (and cooled)

d) Mold is opened to remove part

e) Excess material trimmed off in secondary op

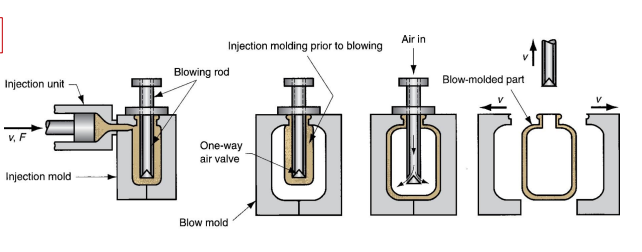

Injection Blow Molding

a) Parison is injected molded around blowing rod

b) Mold is opened and parison is moved to blow mold

c) Soft polymer is inflated

d) Mold is opened to remove part

Advantages of Injection Blow Molding

Higher production rates, greater accuracy, lower scrap rates, less material waste

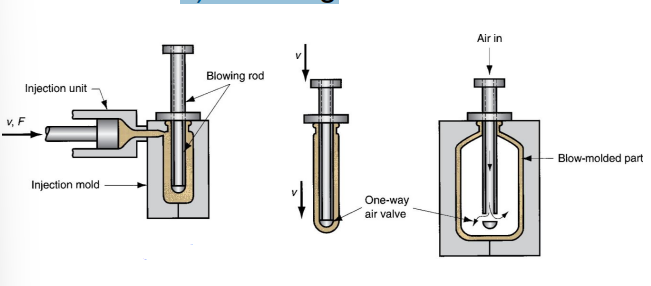

Injection Blow Molding — Stretch

a) Injection molding of parison

b) Stretching

c) Blowing

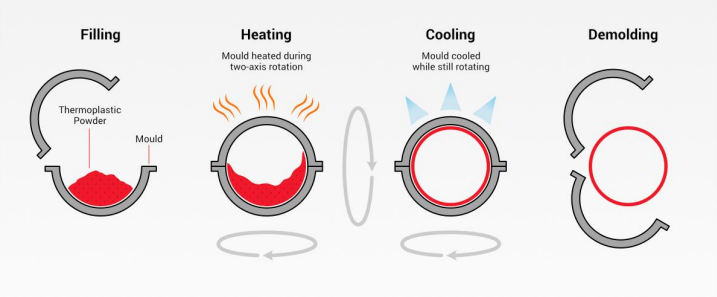

Rotational Molding

Process uses gravity inside a rotating mold to produce a hollow part shape. Alternative to blow molding for larger parts with more complex external geometries

Rotational molding production rates relative to blow molding

Lower production than blow molding

What type of polymers are used in rotational molding?

Mostly for thermoplastic polymers but thermoset and elastomer applications are not uncommon

Rotational Molding Process

Performed on three-station indexing table:

(1) Unload-load

(2) Heat and rotate mold

(3) Cool the mold

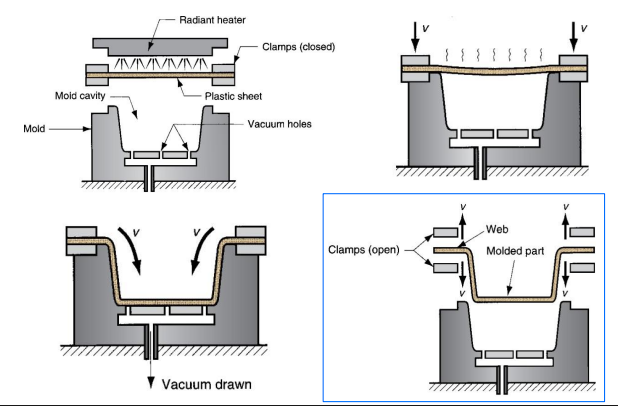

Thermoforming

Flat TP sheet or film is heated and deformed into desired shape using a mold

How is the sheet heated for thermoforming

Heating usually accomplished by radiant electric heaters located on one or both sides of starting plastic sheet or film

What products does thermoforming typically produce?

Widely used in packaging of products and to fabricate large items such as bathtubs, contoured skylights, and internal door liners for refrigerators

Vacuum Thermoforming Process

1. Flat plastic sheet is softened by heating

2. Softened sheet is placed over a mold cavity

3. Vacuum draws the sheet into the cavity

4. Plastic hardens on contact with the cold mold surface, and part is removed and later trimmed

Key process parameters for vacuum thermoforming

Sheet temperature/heating time

Polymer type and thickness

Vacuum pressure/location

Part geometry

What type of polymers are used in thermoforming?

Only thermoplastics can be thermoformed

Sheets of thermosetting or elastomeric polymers have already been cross-linked and cannot be softened by reheating

Thin films

blister packs and skin packs for packaging commodity products such as cosmetics, toiletries, small tools, and fasteners (nails, screws, etc.)

Thicker sheet stock

boat hulls, shower stalls, advertising displays and signs, bathtubs, certain toys,

contoured skylights, internal door liners for refrigerators

Thermoforming applications

thin films, thicker sheet stock

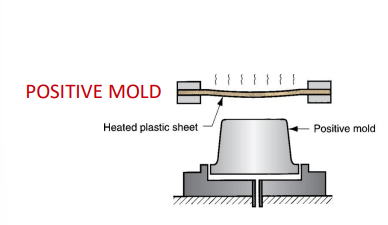

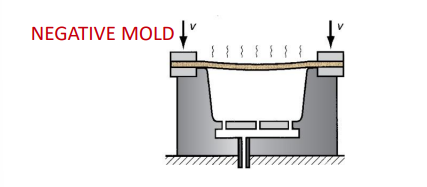

Thermoforming mold types

Positive (male) mold, Negative (female) mold

Positive (male) mold

convex shape

Negative (female) mold

concave shape

Where are the thicker regions of a sheet that is thermoformed?

The product is thickest where ever the sheet first comes in contact with the mold