BBE 4302 midterm 4

1/86

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

87 Terms

what is an enzyme

macromolecular biological catalysts that accelerate chemical reactions.

positive characteristics of enzymes

1. highly selective in what they react with

2. generally non-toxic

3. often do not produce by-products

EC tree of enzymes

3 Hydrolases

3.2 Glycosylases

3.2.1 Glycosidases, i.e. enzymes that hydrolyse O- and S-glycosyl compounds

3.2.1.91 cellulose 1,4-beta-cellobiosidase (non-reducing end)

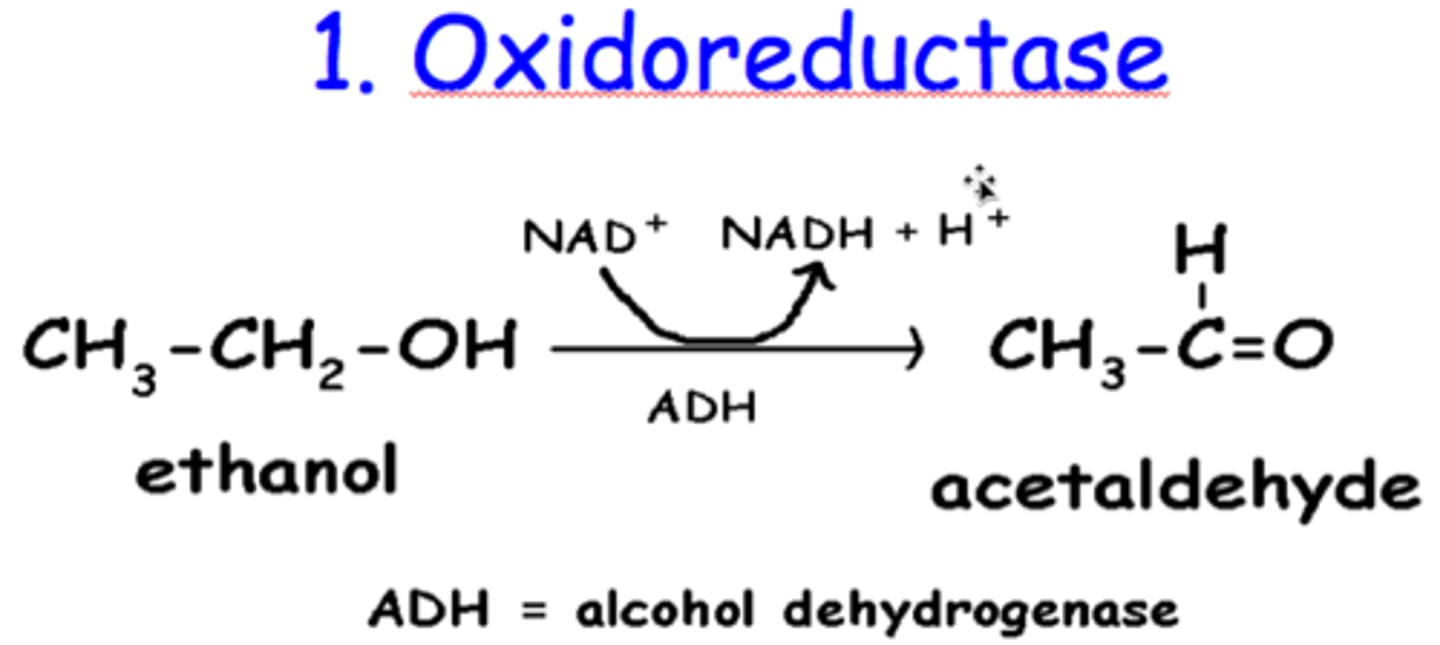

EC 1, Oxidoreductases:

catalyze oxidation/reduction reactions

can break down C-C bonds

A- + B → A + B-, usually uses NADP+ or NAD+ as cofactors.

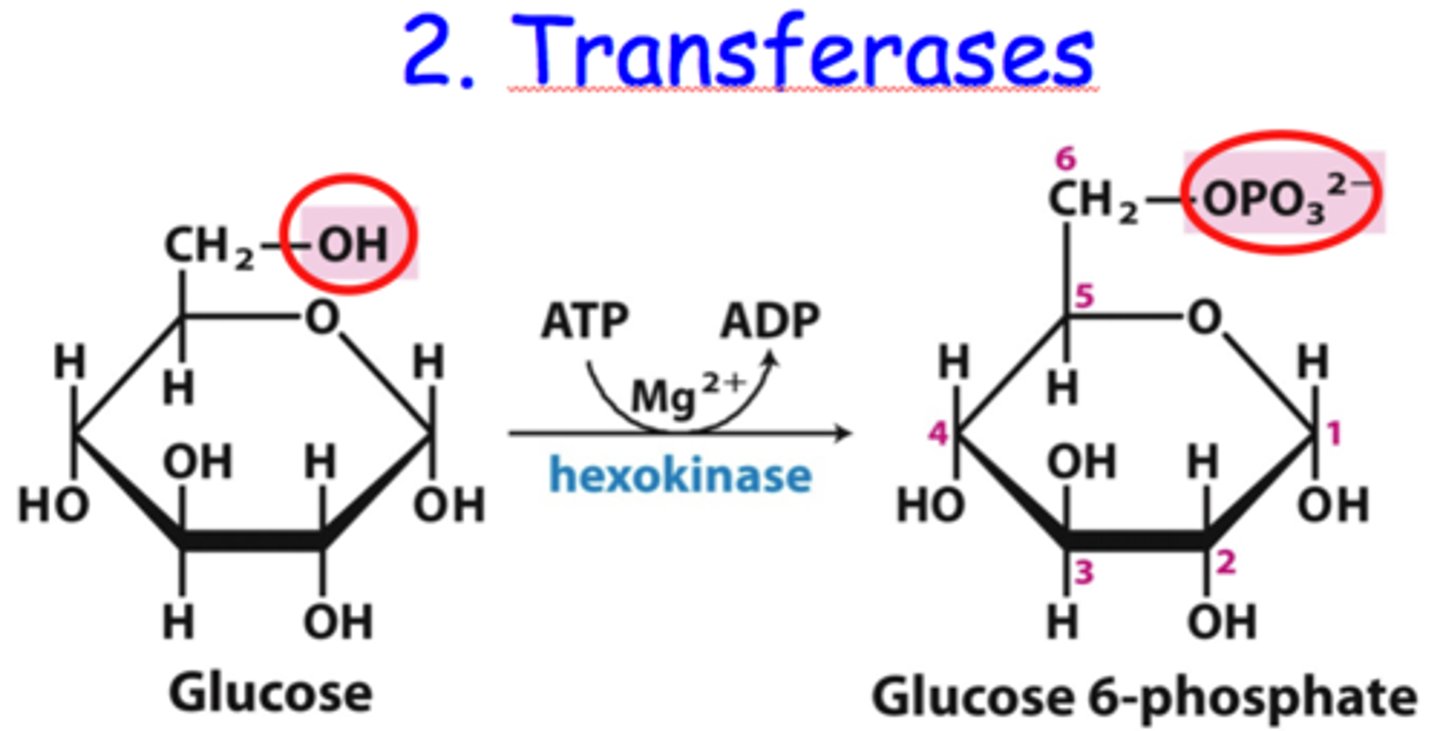

EC 2, Transferases

transfer a functional group (e.g. a methyl or phosphate group)

A-c + B → A + B-c,

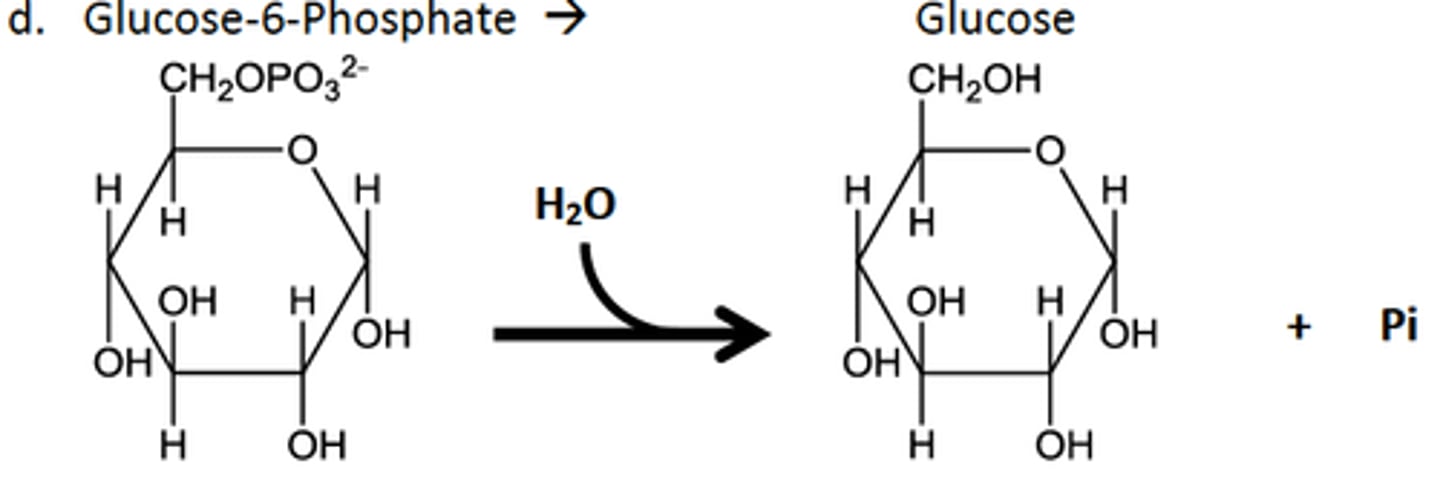

EC 3, Hydrolases

catalyze the hydrolysis of various bonds

A-B + H2O → A-OH + B-H

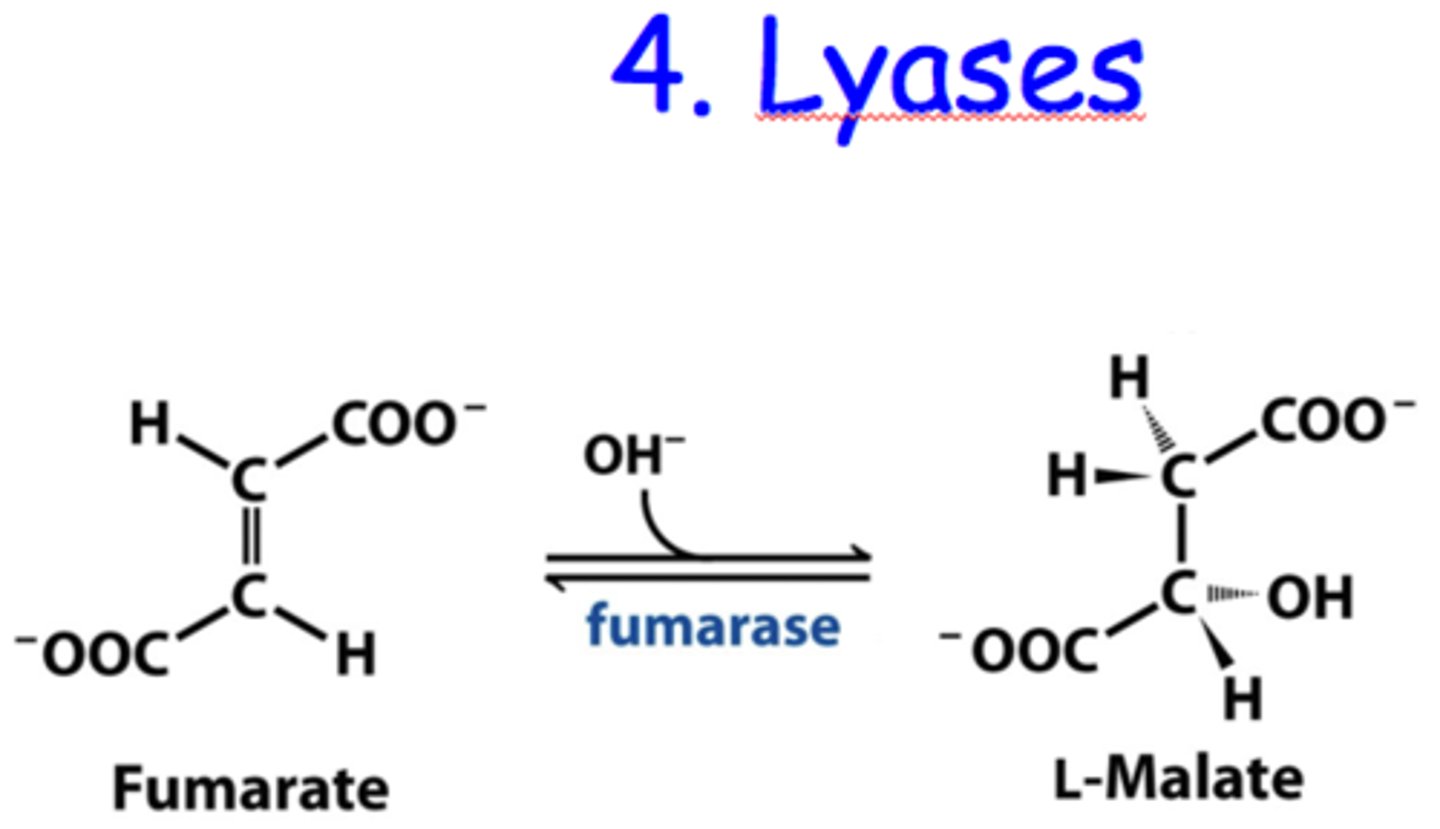

EC 4, Lyases

cleave various bonds by means other than hydrolysis and oxidation

A-B → A + B

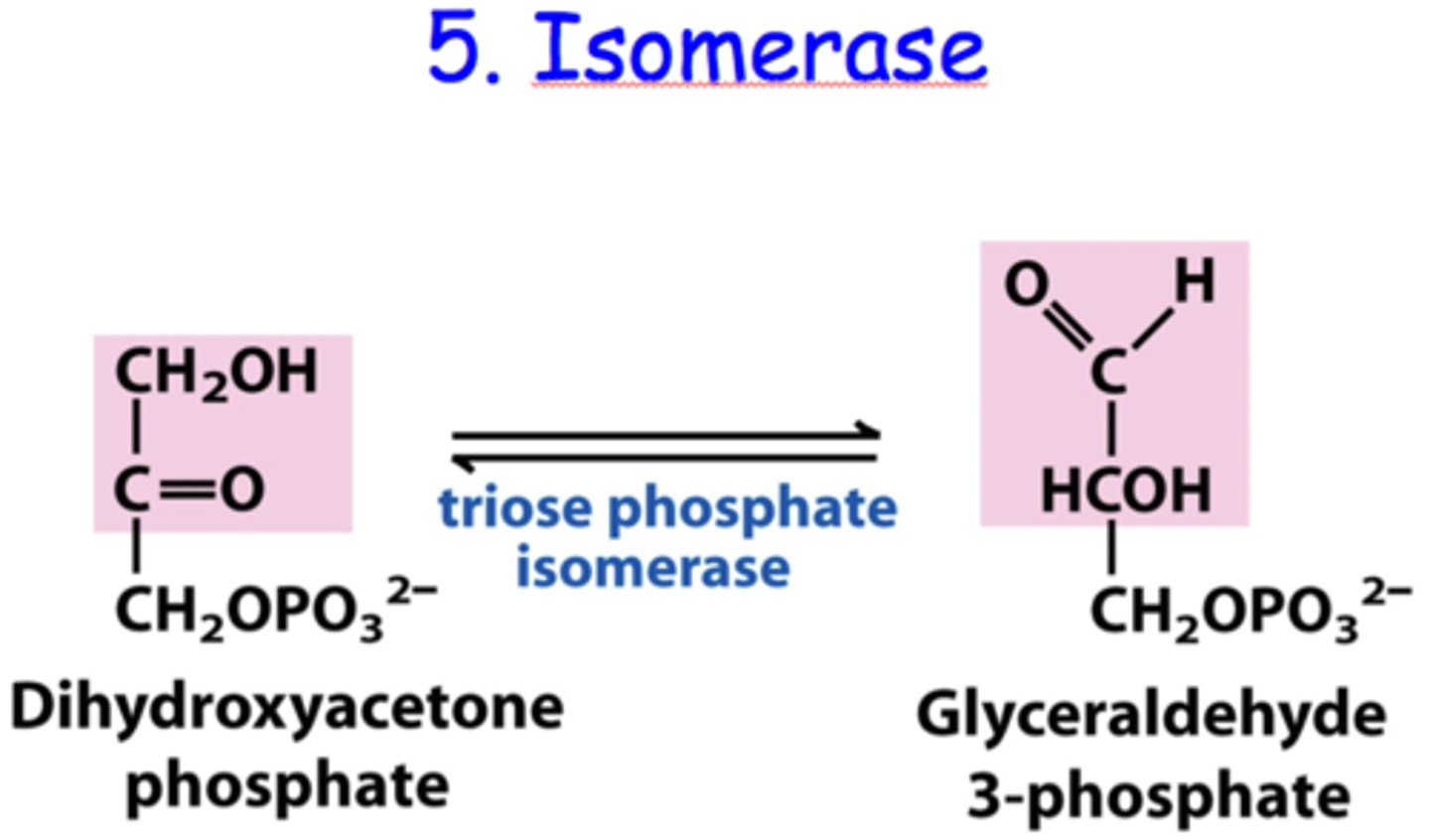

EC 5, Isomerases:

catalyze isomerization changes within a single molecule

A-B → B-A

facilitates rearrangments

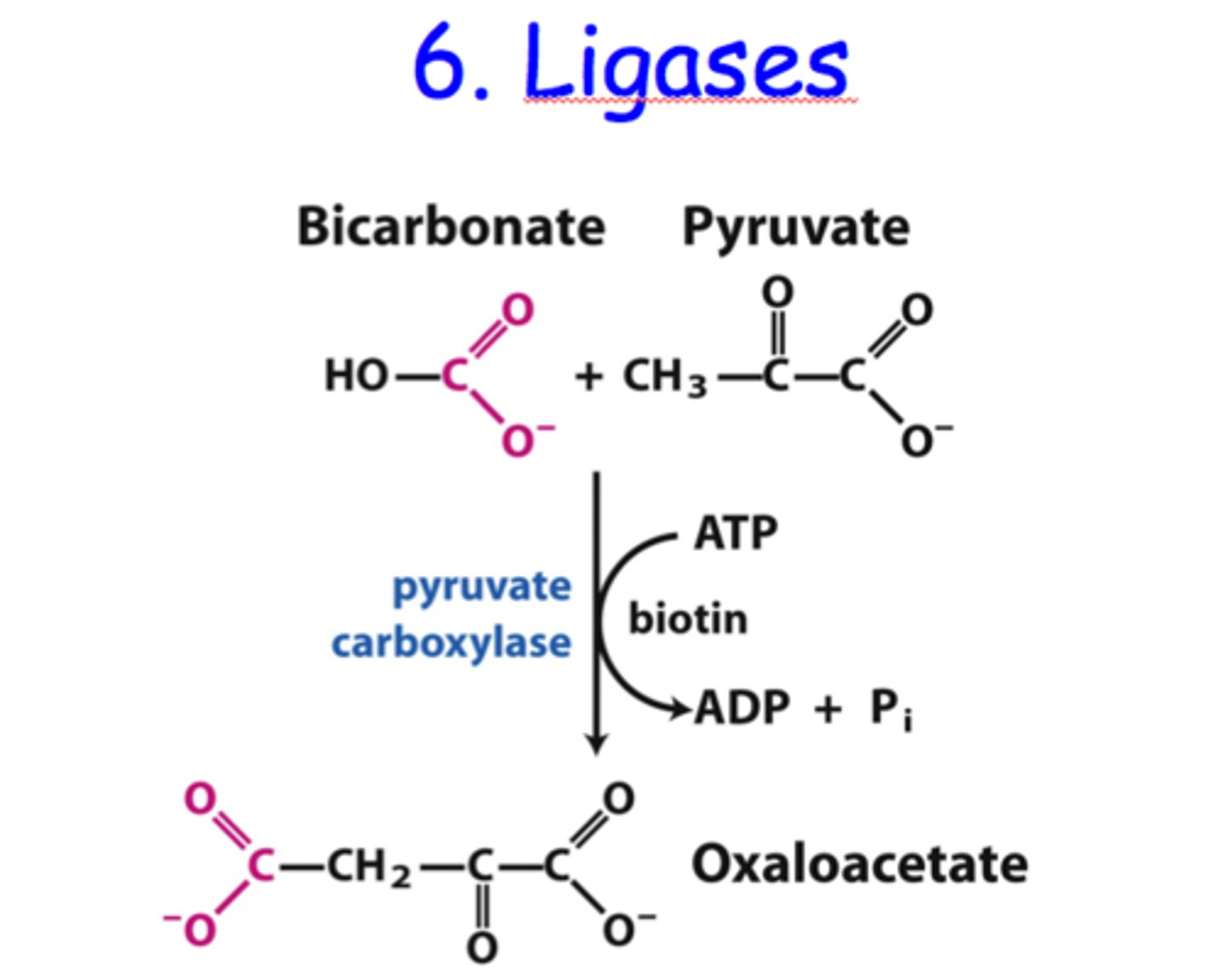

EC 6, Ligases:

join two molecules with covalent bonds.

Ab + C → A-C + b, e.g. DNA ligase

enzyme structure

50-2,500 amino acids; several to tens of nm;

"Protein size ≈ aa number X 0.11 kDa"

Catalytic/Active domain: binding site and catalytic site

Special binding domain, e.g., CBM (cellulose-binding module)

Linker, maintains the precise orientation and dynamics of the active domain

Cofactor binding domain

which is easier to degrade? starch or cellulose & why?

starch

-components are the same but structures are different

-cellulose = crystallized, more complicated, accessibility is decreased,

cellulose

beta 1,4

starch

alpha 1,6

fermentation

glucose metabolized directly

by Saccharomyces (yeast)

Starch Degradation:

Starch is broken down into simpler sugars like glucose through enzymatic hydrolysis. Amylase enzymes catalyze the hydrolysis of starch.

Glucose isomerase (glucose fructose)

lignocellulose degradation

ligninases(mostly oxidative)

Lignin peroxidase - most prevalent = breaks lignin bonds

Manganese peroxidase - breaks lignin molecule

Versatile peroxidase - breaks lignin molecule, but unclear role.

Laccase - breaks lignin molecule....also builds it...unclear role

Cellulases

produced by major decomposers of cellulose such as fungi and bacteria

must break bonds between β-linked glucose, but

must ALSO penetrate crystalline regions

SYNERGISTIC MIXTURES ARE USED

Hydrolytic enzymes - insert water molecule to break bond

Hemicellulases

degrade hemicellulose which is a complex mixture of polysaccharide polymers

(Hemicellulose = xylan, mannan, galactan)

Endoglucanase

Enzyme responsible for the breakdown of cellulose in fungi and bacteria

cleaves randomly in the middle of polymer chains.

Amorphous cellulose attack, with minor crystalline attack.

Exoglucanase

produces glucose from cellulose

cleaves glucose dimer (cellobiose) from one end

of polymer chain. Crystalline cellulose attack.

ENDO-EXO Synergy

Free ends' created for exo by endo

Crystalline regions 'opened' to endo by exo

What are the two primary enzymes for breaking down starch?

α-amylase and amyloglucsidase

How do α-amylase and amyloglucsidase relate to corn-based ethanol production?

They are crucial in the production process. α-Amylase breaks down starch into smaller polysaccharides, and glucoamylase further hydrolyzes these into glucose for fermentation to ethanol by yeast.

Beta-Glucosidase

converts cellobiose to glucose

three princpal enzymes to break down cellulose

cellulases - are hydrolytic enzymes (insert water molecule to break bond)

*Endoglucananse

*Exoglucanase

*Cellobiohydrolase(CBH I)

which microbe we can use to produce commercial cellulases

Trichoderma reesei

why we must apply pretreatment for lignocellulose conversion

Pretreatment to facilitate Trichoderma enzyme access

is necessary.

majescellulose accessible to enzymes

Are these enzyme-producer microbes good lignocellulose degraders in nature?

Trichoderma is not good in nature at lignocellulose

degradation. It works best on pure cellulose.

ENZYME IMPROVEMENT - traditional mutagenesis

by UV, r-irradiation, linear accelerator, dES (diethyl sulfate), NTG (N-methyl-N0-nitro-N-nitrosoguanidine), etc

Improve cellulase performance, but the genetic background is unknown;

Use comparative genomics to understand the changes relative to WT..

ENZYME IMPROVEMENT - Genetic modification

of the enzyme synthesizing pathways;

ENZYME IMPROVEMENT - Rational design or Directed evolution to

Improve enzyme properties.

ENZYME IMPROVEMENT - optimization of

fermentation conditons

Understand why lignocellulose is one of the great ways to obtain energy - environmentally friendly and sustainable.

-Renewable: each 10-1000 years

-Cause less C emission;

-Provide sustainable carbon sources.

LARGE ABUNDANCE

What is the first goal of a suitable biomass 'feedstock'?

Fast Growth - Example: Monterey Pine - Pinus radiata

What is the second goal of a suitable biomass 'feedstock'?

Quality Raw Material - Example: Eucalyptus, long uniform fibers for papermaking

What is the third goal of a suitable biomass 'feedstock' in terms of maintenance?

Low Maintenance Requirements - Example: Switchgrass,Requires very little fertilizer, Drought-tolerant, Pest-resistant, Excellent on 'degraded' soils

What is the fourth goal of a suitable biomass 'feedstock' in terms of environmental impact?

Environmentally-friendly - Example: Mixed Native Prairie-grasses

What is the fifth goal of a suitable biomass 'feedstock' in terms of 'digestibility'?

High 'Digestibility' - Example: Hybrid Poplar

Why has lower-lignin-content plant engineering been explored for 'digestibility,' and why have they had survival problems?

Lowering lignin content in plants improves their digestibility and enhances biomass conversion efficiency.

Plants engineered for lower lignin content have faced survival problems due to compromised structural integrity, susceptibility to pests, and decreased resistance to environmental stressors.

FEEDSTOCK TYPE - Corn stover

(stalk + leaves...no cob!) - Easy transition for near-term cellulosic fuels

FEEDSTOCK TYPE - swithgrass

energy crop Big in the southeast...comes from midwest

FEEDSTOCK TYPE - other

wheat straw

sugar cane

poplar/aspen

municipal waste

Fractionation

separating (refining) the

individual components of

lignocellulose for utilization

biorefinery

a facility that integrates biomass conversion processes and equipment to produce fuels, power, and value-added chemicals from biomass

marketable component of cellulose

a1 - Fiber for paper (longer fibers = better paper)

a2 - Fiber for textiles

a3 - Fiber for strengthening materials (Nanofibers)(Can be used for an absorbent)

a4 - alcohols

marketable component of hemicellulose

b1 - alcohols

b2 - Solvent for fibers during pulping (papermaking)

b3 - Industrially-important chemicals (ex. Furfural)

marketable component of lignin

c1 - Burned for energy

c2 - Thermoplastics, foams, and other materials

c3 - Lignin valorization for producing value-added products (transform into different carbon forms)

marketable component of extractives

d1 - Industrial chemicals (tannins, terpenoids, resin)

d2 - Sap for Latex

marketable component of bark

e1 - cork

e2 - mulch

e3 - charcoal or energy

Goals for Biodegradative Organisms/Systems:

1 - Fast Acting

2 - Highly Selective and Efficient

3 - Robust

4 - Low Cost

5 - Compatible with other Degradative Systems

6 - Multifunctional

Three ways to 'harness' an organism of interest.

Direct Utilization

-Utilization of Native Organism (includes using purified enzymes)

-yeast, sugar to ethanol

Bioengineering

-Take the organism, and change it genetically to make the organisms express the traits you want

Biomimicry

-Use the pathways or systems of an organism as a blueprint to follow during engineering your own system

what are extremphiles & why do we want them for bioenergy

Extremophiles are microorganisms capable of thriving in extreme environments such as high temperatures, acidic pH, or high salinity.

They are of interest in the bioprocessing industry for their potential to perform under harsh conditions and produce valuable enzymes or metabolites.

One-Pot Processes

Integrated bioprocessing systems where multiple steps (e.g., pretreatment, hydrolysis, fermentation) occur in a single reactor or vessel, reducing processing time and cost.

Consortia Bioprocessing

Cooperative interactions between different microorganisms in a bioprocessing system, enhancing overall efficiency and productiv

Bioprospecting

Surveying biological organisms in general for potential utilization (Traditionally referred to surveying plants for medicinal applications)

Bioprocessing Steps for Lignocellulose to Biofuels:

Biomass Collection and Delivery.

Pretreatment to remove lignin and enhance accessibility.

Hydrolysis to break down polysaccharides into fermentable sugars.

Fermentation of sugars to produce biofuels (e.g., ethanol).

Biofuel Processing for purification and quality control.

corn ethanol

Alcohol fermentation in yeast cells.

Anaerobic process - 3 general steps

Amylase catalyze the starch degradation to produce glucose.

Advantages of Cellulosic Ethanol

Utilizes non-food feedstocks, reducing competition with food production.

Greater potential for sustainability and environmental benefits.

Diverse biomass sources available, increasing flexibility and scalability of production

Environmental Remediation

detoxification or removal of contaminants/pollutants from an environmental medium (soil, groundwater, etc.)

steps in environmental remediation

1. excavation

2. "ex situ"

2a. pump & treat

3. in situ - detoxificastion

4. vapor extraction

Environmental Remediation Approaches

1) Incineration - high temp combustion = gases, particulates,

ash, heat (most expensive)

2) Thermal desorption - moderate temp volatilization

= off-gas (produced, then treated)

3) Solidification/stabilization - immobilization via

precipitation, complexation, etc. (example, Bentonite)

bioremediation

The use of living organisms to detoxify and restore polluted and degraded ecosystems

Phytoremediation

A method employed to clean up a hazardous waste site that uses plants to absorb and accumulate toxic materials

What is the process involved in PFAS remediation via sequestration and immobilization?

Soil amendment with a sorbent like activated carbon or biochar

What is the function of the sorbent in PFAS remediation?

Binding PFAS and immobilizing it in the environment to reduce escape to groundwater or leachate

What are the advantages of PFAS remediation via sequestration and immobilization?

Readily available commercial sorbents, applicable to various soil types, in-situ or ex-situ treatment, cost-effective

What are the limitations of PFAS remediation via sequestration and immobilization?

Long-term stability of binding is uncertain, does not destroy PFAS, amount of sorbent needed may impact land use management

What is soil washing?

Process: Soil is washed with or without a solvent to transfer contaminants from soil to wash solution.

What are the advantages of soil washing?

Compared to destructive technologies, soil washing has lower infrastructure requirements and can recover treated soils.

What are the limitations of soil washing?

Not applicable to all soil types (e.g., clay-heavy soils), requires excavation of soils making in-situ treatments problematic, and produces contaminated liquid that requires extensive treatment.

What is the process of separation in soil liquefaction?

Soil is mixed with liquid to form a slurry which is fractionated producing a foam. PFAS readily transitions to the air-water interface.

What is the function of PFAS in soil liquefaction?

PFAS readily transitions to the air-water interface (foam) which can then be removed.

What are the advantages of soil liquefaction separation?

Potentially an in-situ treatment, high removal efficiency.

What are the limitations of soil liquefaction separation?

Not applicable to all soil types e.g. clay, high cost, requires secondary treatment of foam fraction.

What is the process of Destruction - Chemical Oxidation?

Pump chemical oxidant (H2O2, persulfate) into soil followed by optional downstream extraction

What is the function of Chemical Oxidation in Destruction?

Oxidant oxidizes PFAS to CO2 or more readily degradable substances

What are the advantages of Chemical Oxidation in Destruction?

Converts PFAS to more biodegradable substrates or directly destroys PFAS

What are the limitations of Chemical Oxidation in Destruction?

Requires large volumes of oxidants, additional safety measures if drinking water could be impacted, inefficient oxidation of many PFAS, requires highly permeable soil, interference from carbonate and organic substances

What is the thermal destruction process for PFAS compounds?

Soil is excavated and treated with high temperatures (>500°C)

What are the advantages of thermal destruction for PFAS compounds?

High degradation rates (>90%), treats a variety of PFAS, potential value-added products like biochar or syngas

What are the limitations of thermal destruction for PFAS compounds?

High disruption of environment, destroys the soil, expensive, production and emission of HF and partially fluorinated compounds, volatilized PFAS

Mycoremediation

using fungi to remove or degrade dangerous chemicals

Why microbes? bioremediation

They are heartless and gutless

They are riddled with mutants

They go to extremes

They are more prolific than "rabbits"

They may already be working for you

Xenobiotic

synthetic, not found in nature

How do we apply the biodegradation process for remediation?

a. Passive in-situ (Natural attenuation)

b. Promoted in-situ

c. Inoculation

d. Ex-situ treatment (solid and slurry)

e. Engineered systems treatment

Hydrophobin

Can enlarge the fungal area of the cells - help elongation & break down surface tension

why fungi are good for biomediation

robust

surface area

hydrophobic

hydrophoobin