Lab 01: Lab Safety

1/36

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

37 Terms

safety officer

critical part of lab safety program

labelling all chemicals

providing supplies for the proper handling and disposal of biohazardous materials

Occupational Safety and Health Administration

OSHA stands for

Occupational Safety and Health Administration Acts and Standards

standards include provisions for warning labels or other appropriate forms of warning to alert all workers to potential hazards, suitable protective equipment, exposure control procedures, and implementation of training and education programs

Occupational Safety and Health Administration

primary purpose is to ensure safe and healthful working conditions for every US worker

1970

OSHA was created

Occupational Safety and Health Administration Acts and Standards

formal safety program

w/ specifically mandated plans

identification of various hazards

Centers for Disease Control and Prevention

CDC stands for

1991

OSHA mandated that all clinical laboratories must implement a chemical hygiene plan and exposure control plan and a copy of MSDS must be readily accessible and available to all employees at all times

September 30, 2009

OSHA published the long-awaited Proposed Rule to modify the Hazard Communication Standard (HCS) to conform with UN’s Globally Harmonized System (GHS) of Classification and Labeling of Chemicals

chemical hazard communication (HAZCOM)

it includes:

revised criteria for classification of chemical hazards

revised labelling provisions that include requirements for use of standardized signal words, pictograms, hazard statements, and precautionary statements

material safety data sheets

MSDS

Occupational Exposure to Bloodborne Pathogens

this regulation requires that laboratories develop, implement, and comply with a plan that ensures the protective safety of laboratory staff to potential infectious bloodborne pathogens, hepatitis B virus, and human immunodeficiency virus

OSHA

educate and train all healthcare workers in standard precaution and preventing bloodborne infections

provide proper equipment and supplies

monitor compliance with the protective biosafety policies

Safety Manual Policies and Practices

Standard Precautions

Handwashing

Personal

Protective Equipment

Safe Work Practices and Protective Techniques for Infection Control includes:

needlestick prevention

sharps prevention

Preventing Occupational Transmission of HBV and HIV through

1:10

dilution of bleach

hypochlorite

most widely used of the chlorine disinfectants

nonanalytical factors

analysis of quantitative data (quality control)

quality assessment system is divided into 2 major components:

test request procedures

patient identification

specimen procurement

specimen labeling

specimen transportation and processing procedures

laboratory personnel performance

laboratory instrumentation, reagents and analytical test procedures

turnaround times

accuracy of the final result

quality assessment in the hematology laboratory:

qualified personnel

laboratory policies

laboratory procedure manual

test requisitioning

patient identification and specimen procurement and labeling

specimen collection, transport, processing, and storage

preventive maintenance of equipment

appropriate methodology

accuracy in reporting results and documentation

variance

a general term that describes the factors or fluctuations that affect the measurement, in operator performance

providing a guide to the functioning of equipment, reagents, and individual technique

confirming the accuracy of testing when compared with reference values

correcting an increase in the frequency of both high and low manually acceptable value (dispersion)

detecting any progressive shift of values to one side of the average value for at least 3 days (trend)

demonstrating an abrupt shift or change from the established average value for 3 days in a row (shift)

dispersion

increase in the frequency of both high and low manually acceptable value

trend

progressive shift of values to one side of the average value for at least 3 days

shift

abrupt shift or change from the established average value for 3 days in a row

Levey-Jennings chart

Power functions

The cumulative sum (Cusum) method

trend line analysis

methods in quality assessment

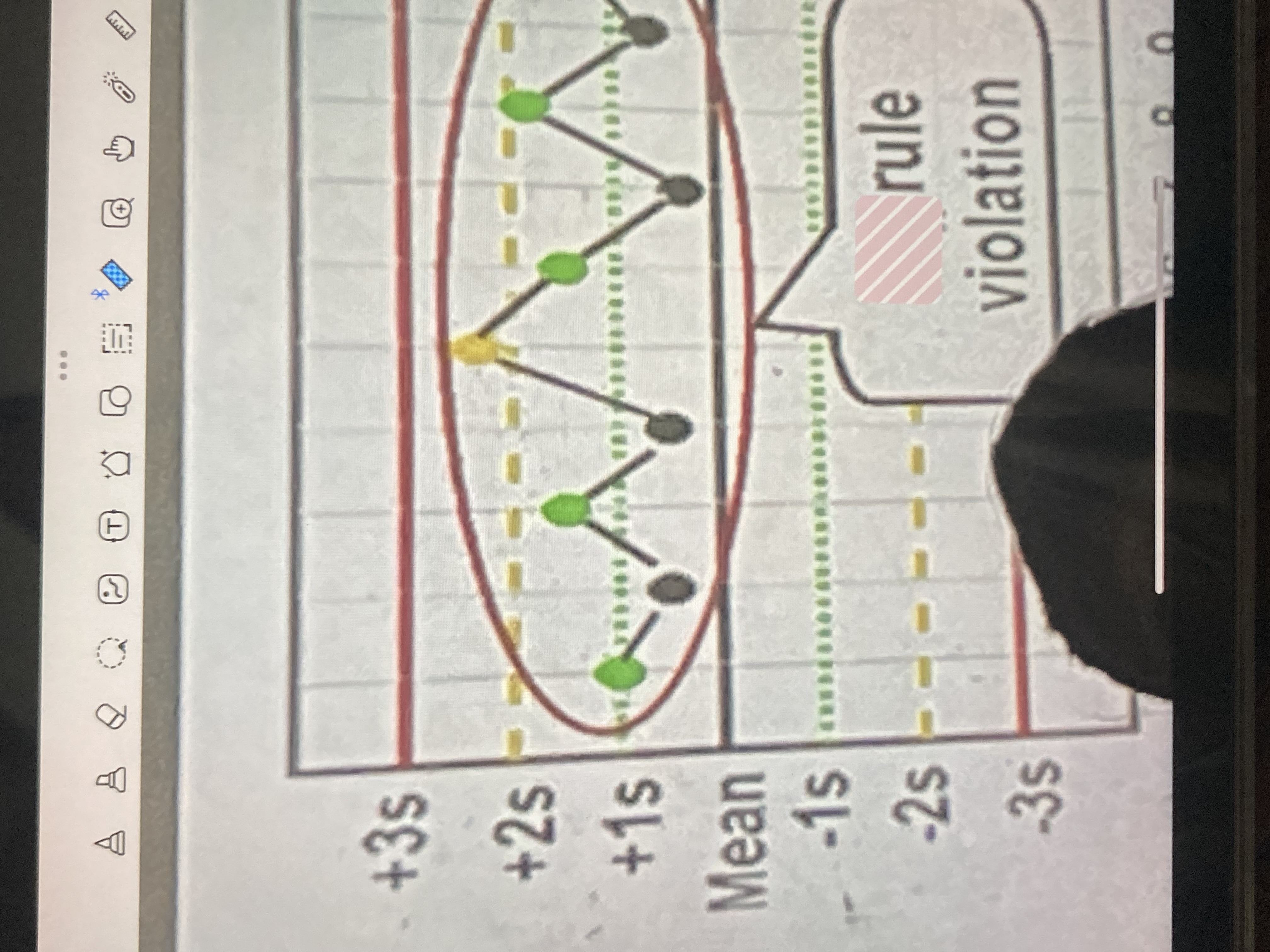

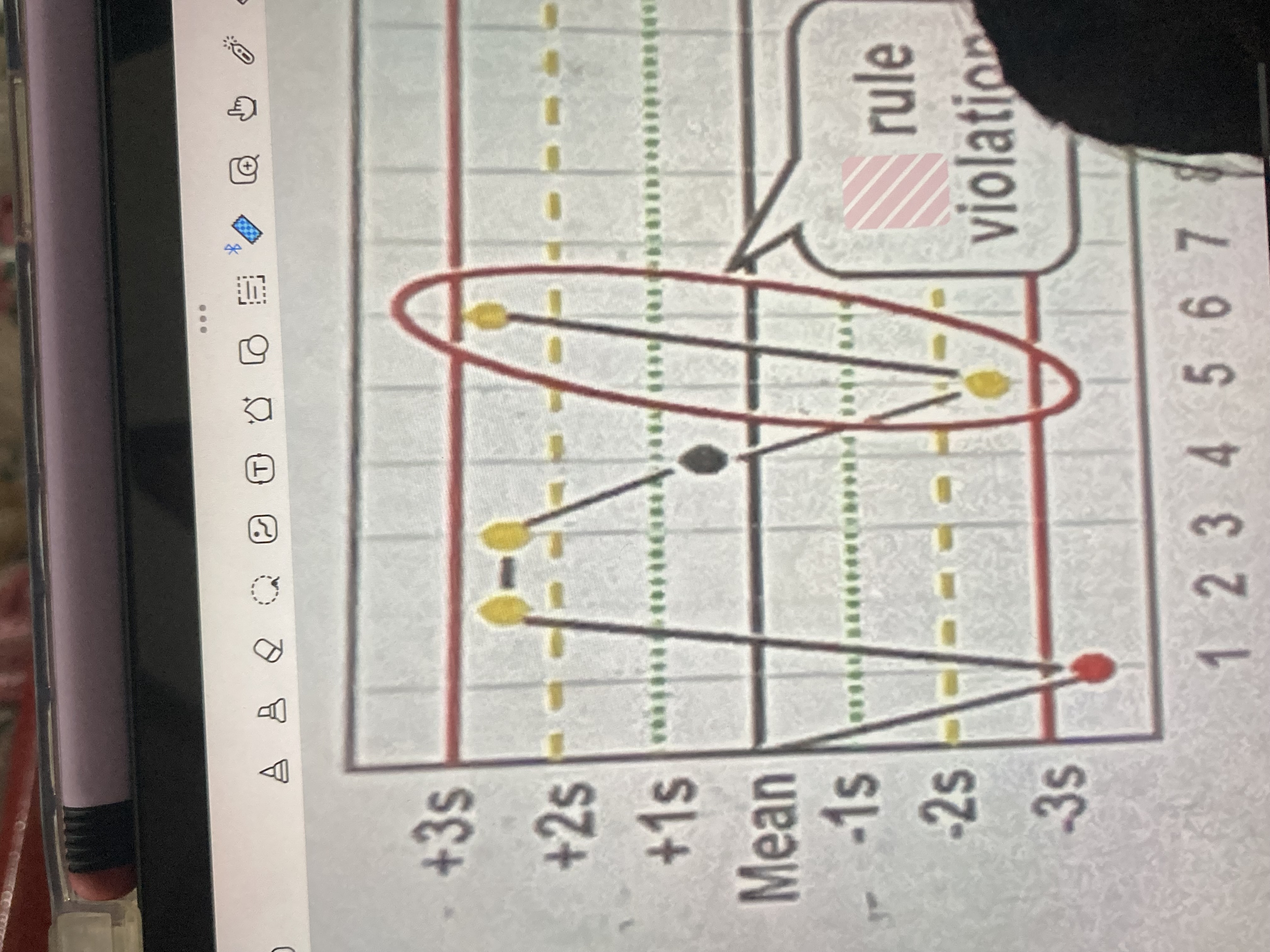

12s

one measurement exceeds 2 standard deviations either above or below the mean of the reference range

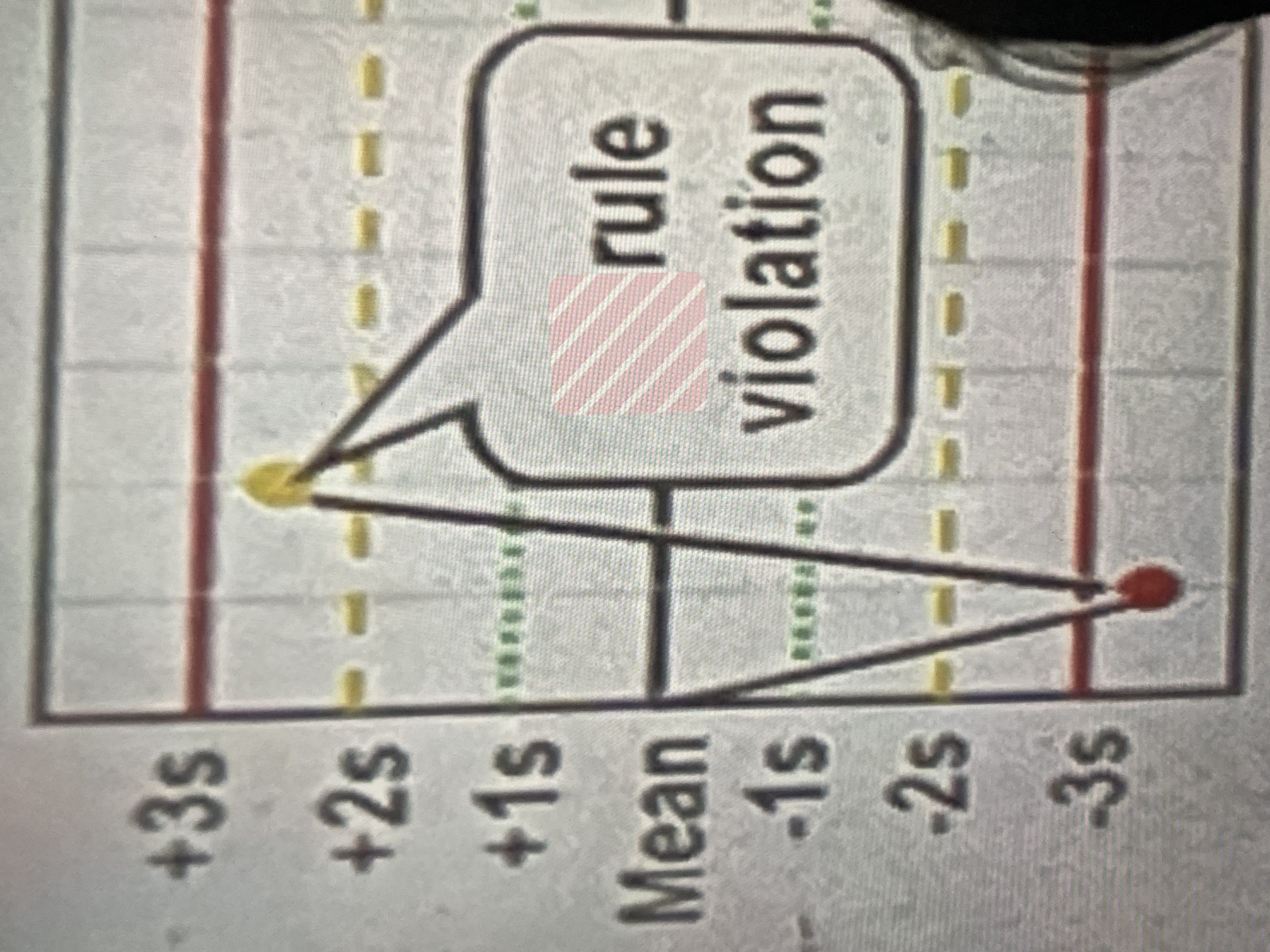

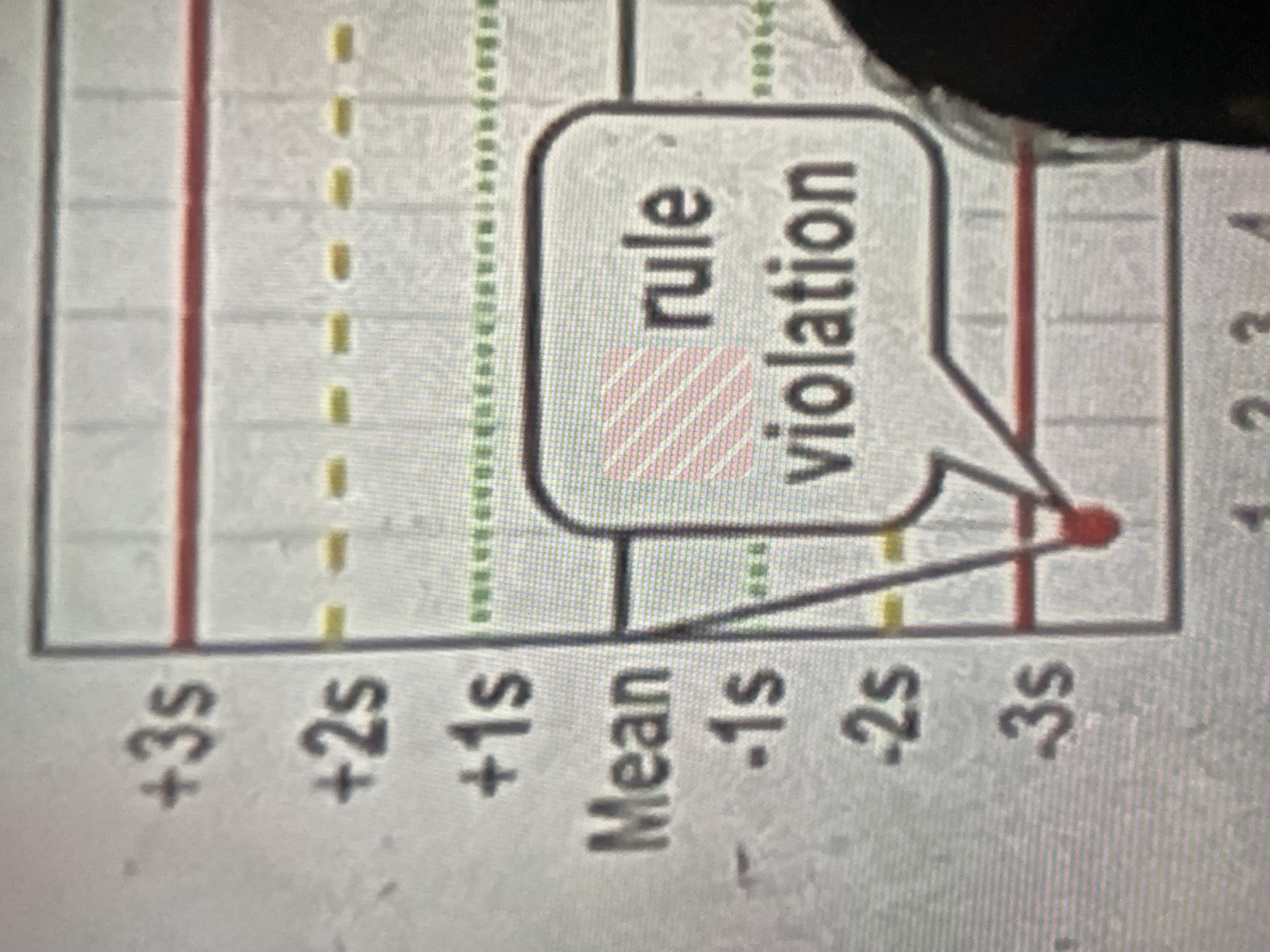

13s

one measurement exceeds 3 standard deviations either above or below the mean of the reference range

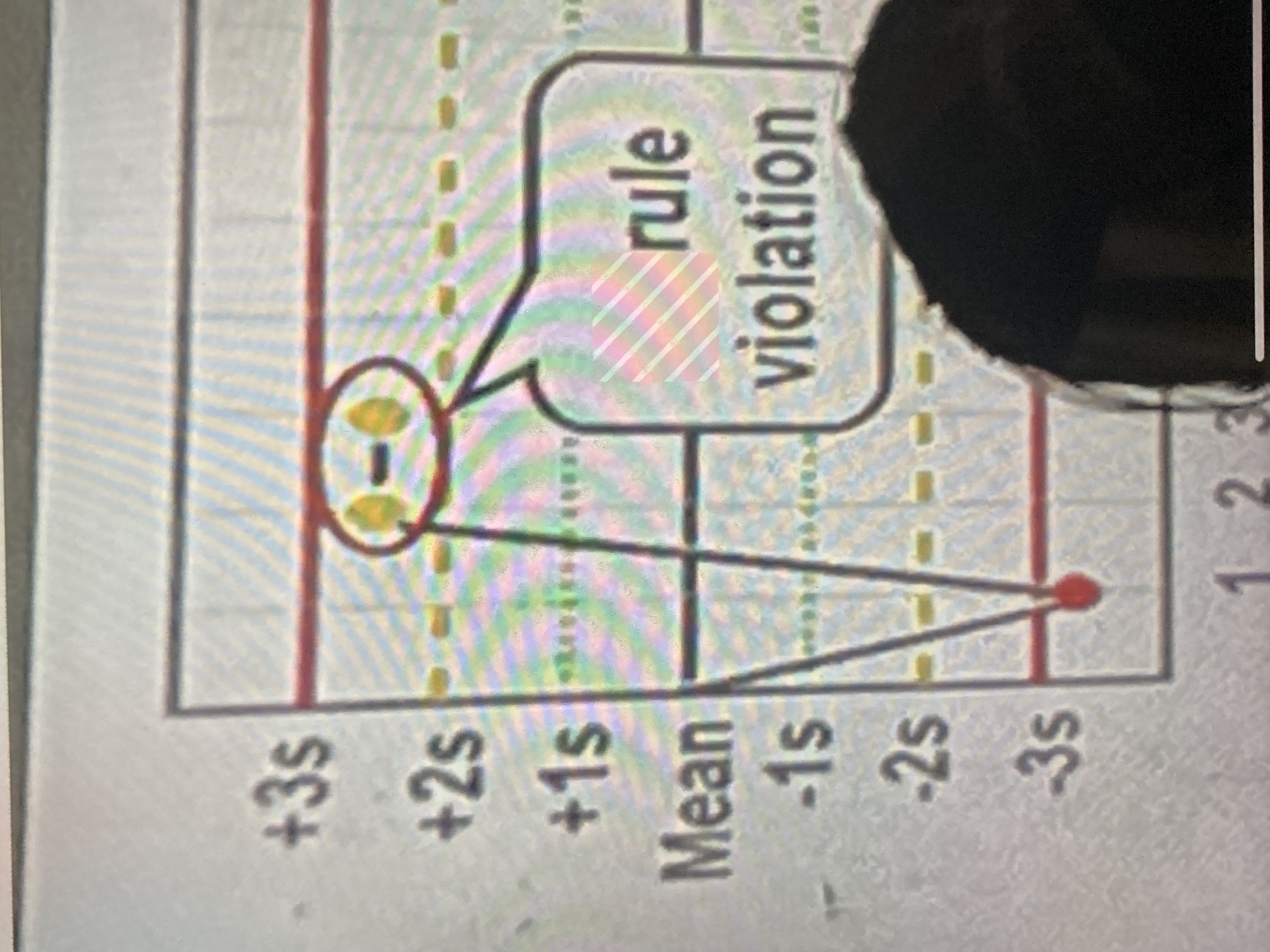

22s

2 consecutive measurements exceed 2 standard deviations of the reference range, and on the same side of the mean

R4s

2 measurements in the same run have a 4 SD difference (such as 1 exceeding 2 above, and another 2 below)

41s

4 consecutive measurements exceed 1 standard deviation on the same side of the mean

10x

10 consecutive measurements are on the same side of the mean

12s

13s

22s

R4s

10x