CM 3 - Materials, Hardware and Equipment for Prestressing

1/210

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

211 Terms

Short-term or Instantaneous

Long-term or Time dependent

Material Properties that are relevant to Prestressed Concrete Design:

Compressive Strength

Modulus of Elasticity

Modulus of Rupture

Short-term or Instantaneous Properties

Creep

Shrinkage

Long-term or Time dependent Properties

True

The compressive strength, f’c, is measured using a standard 6 in. by 12 in. cylinder.

True

The test cylinders must be cured under standard laboratory conditions before testing

True

Compressive strength is typically tested at 28 days of age.

False

The compressive strength test is done at a random loading rate.

False

The notation f’c represents the flexural strength of concrete.

Compressive strength

The symbol f’c refers to

6 in. × 12 in

Standard compressive strength tests are performed using cylinders with dimensions:

Standard laboratory conditions

Under what conditions are test cylinders cured before compressive strength testing?

28 days

At what age of concrete is compressive strength typically measured?

A specified rate of loading

During compressive strength testing, the cylinders are loaded at:

True

Concrete compressive strength can reach up to 20,000 psi (137.9 MPa) or more depending on mix, aggregate, and curing.

False

The quality of curing does not affect the compressive strength of concrete.

True

Commercial production of concrete with ordinary aggregates is usually between 4,000 to 12,000 psi (27.6 MPa to 82.74 MPa).

True

The most common strength level of concrete is around 6,000 psi (41.4 MPa).

False

Aggregate type has no influence on compressive strength.

20,000 psi (137.9 MPa)

The maximum compressive strength of concrete can reach up to:

4,000 – 12,000 psi

Commercially produced concrete with ordinary aggregates usually falls within what range?

Color of cement

Which of the following factors does NOT directly affect compressive strength?

6,000 psi (41.4 MPa)

The most common compressive strength level of concrete is approximately:

Proper curing practices

Which factor contributes to achieving higher compressive strength in concrete?

True

For prestressed concrete, compressive strength is measured at 28 days of age

True

The required compressive strength range for prestressed concrete is 28 MPa to 70 MPa.

False

Prestressed concrete always requires more than 100 MPa compressive strength.

False

The strength requirement for prestressed concrete is lower than for ordinary concrete.

False

The compressive strength of prestressed concrete is specified at 14 days of curing.

28 – 70 MPa

The compressive strength of prestressed concrete should be within:

28 days

At what age is the compressive strength of prestressed concrete specified?

To resist applied prestressing forces

Why is higher compressive strength needed for prestressed concrete compared to ordinary concrete?

Concrete strengthened by inducing compressive stresses

Which of the following best describes prestressed concrete?

Falls below the requirement

If a prestressed concrete element has a strength of 25 MPa at 28 days, it:

True

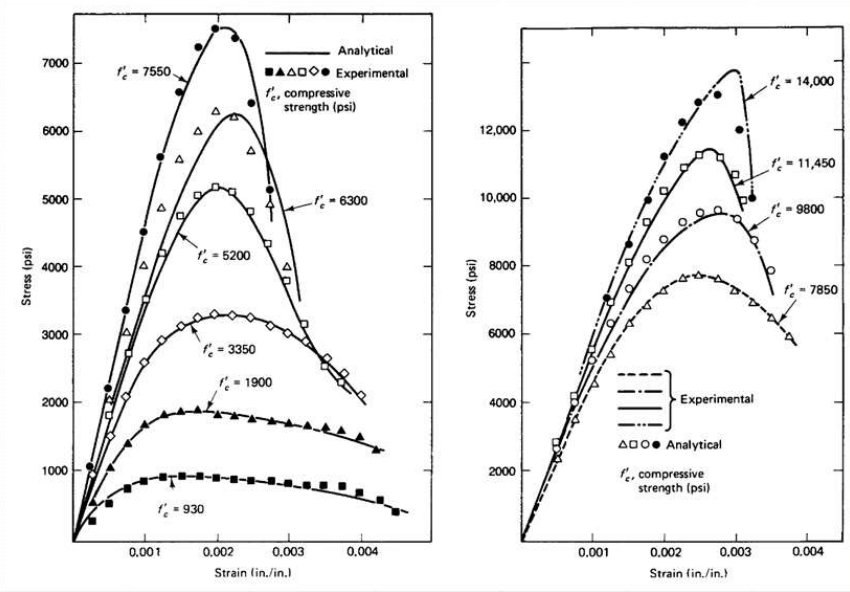

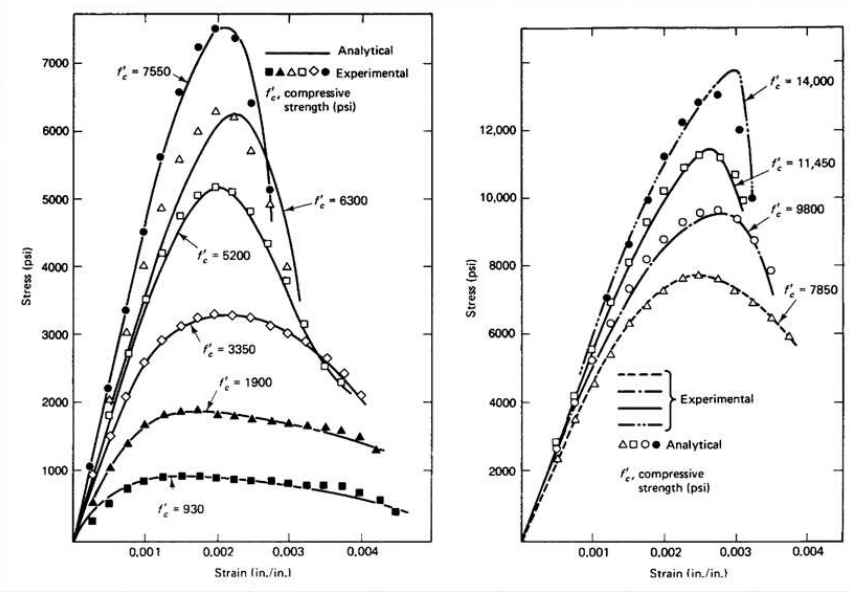

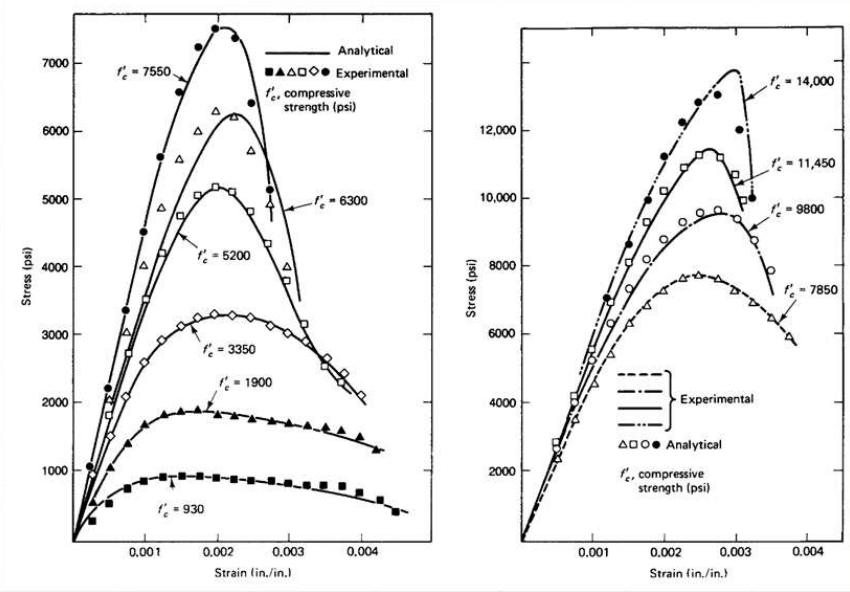

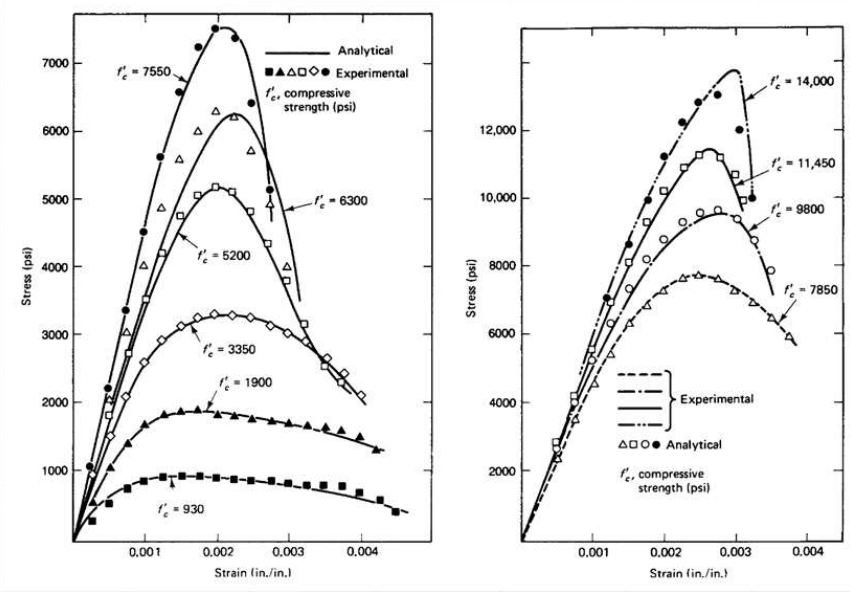

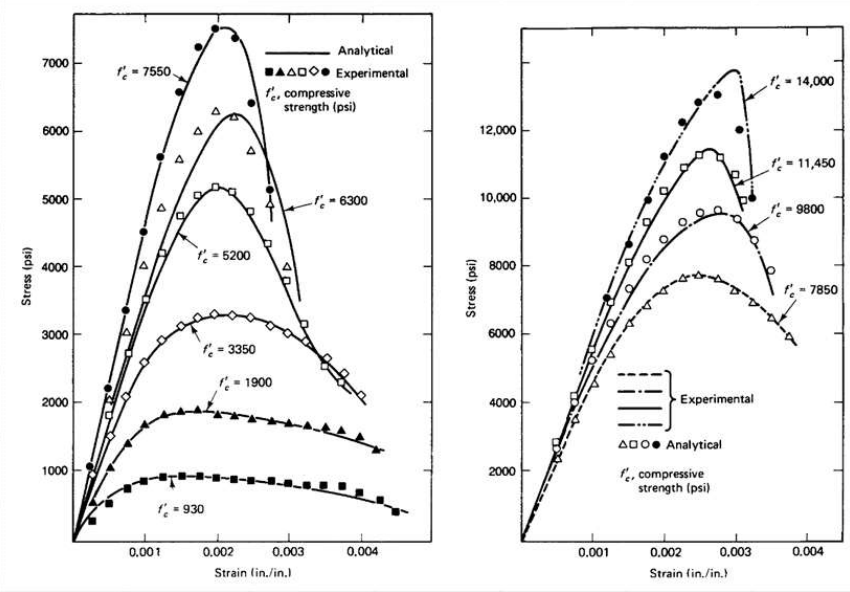

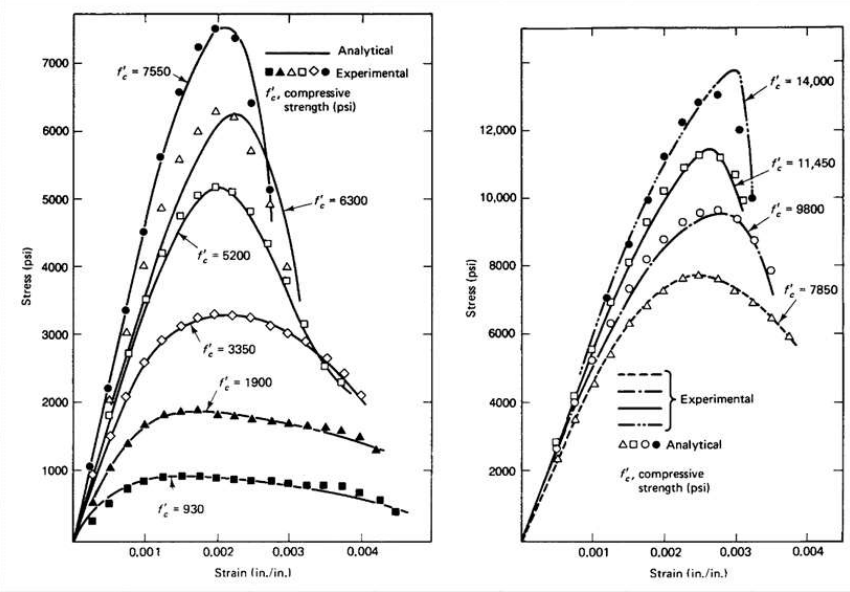

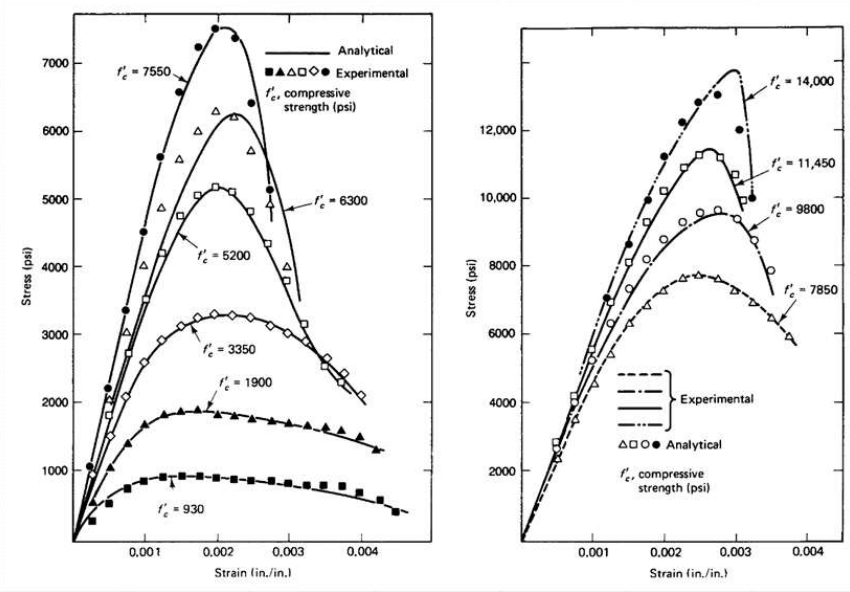

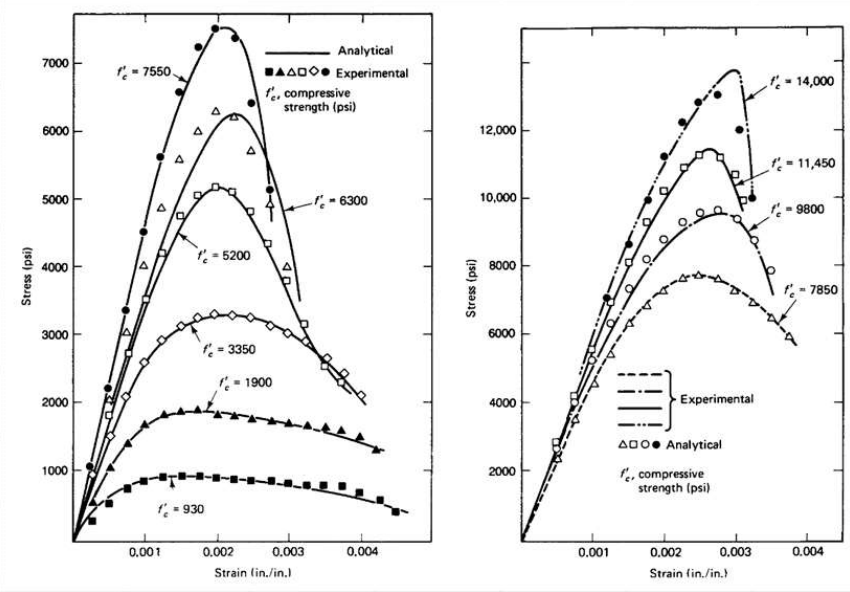

The initial portion of the stress-strain curve of concrete up to about 40% of f’c is considered linear.

False

Concrete behaves elastically all the way up to ultimate strength

True

After about 70% of the failure stress, concrete begins to lose a large portion of its stiffness.

False

The stress-strain curve of concrete is perfectly straight until failure.

True

The modulus of elasticity is related to the slope of the stress-strain curve in the initial linear range

40%

Up to what percentage of ultimate compressive strength (f’c) is the stress-strain curve of concrete essentially linear?

70%

Beyond what approximate percentage of failure stress does concrete lose much of its stiffness?

The slope of the initial straight-line portion

The modulus of elasticity of concrete is most closely associated with:

Loses stiffness and becomes more curved

As concrete approaches 70% of f’c, the stress-strain curve:

Nonlinear and brittle

The stress-strain curve of concrete indicates that concrete is:

True

The stress-strain curves in the figure represent concrete with different compressive strengths.

True

Higher compressive strength concretes (e.g., 14,000 psi) generally reach higher stress values at lower strain levels.

True

The initial slope of each stress-strain curve represents the modulus of elasticity.

False

The strain capacity of low-strength concrete (e.g., 930 psi) is greater than that of high-strength concrete.

930 psi

According to the figure, what is the approximate compressive strength of the lowest strength concrete tested?

14,000 psi

Which concrete compressive strength curve reaches the highest stress value?

Modulus of elasticity

What does the slope of the initial linear portion of the stress-strain curve represent?

Higher strength concretes exhibit steeper initial slopes but lower strain capacity

What trend is observed as concrete compressive strength increases?

True

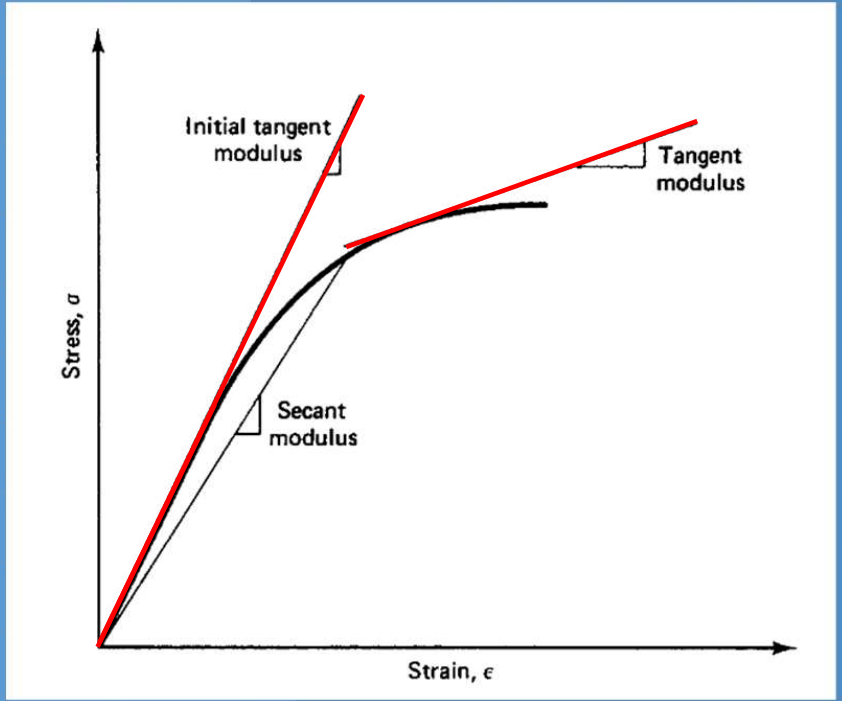

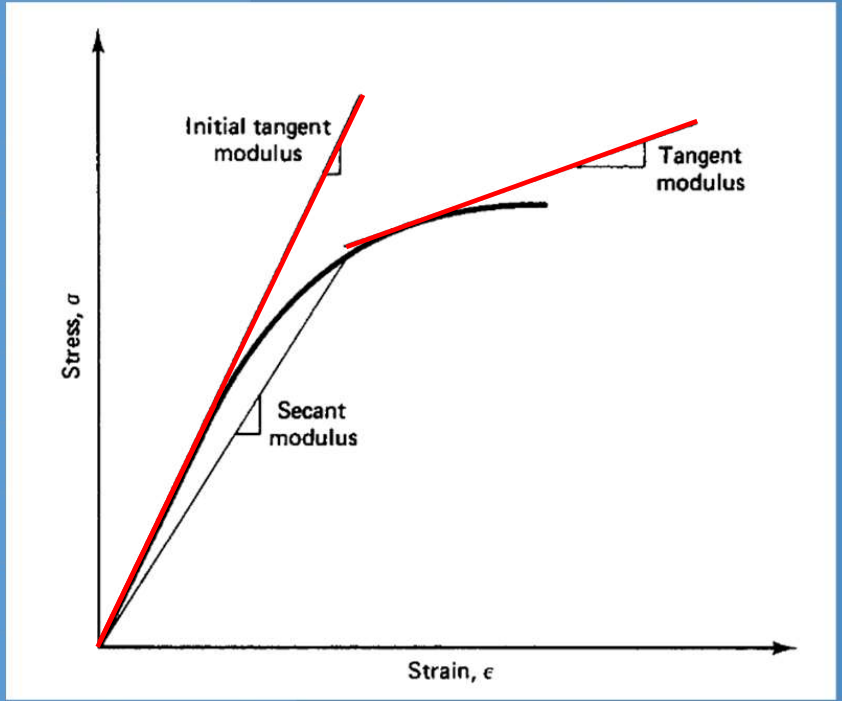

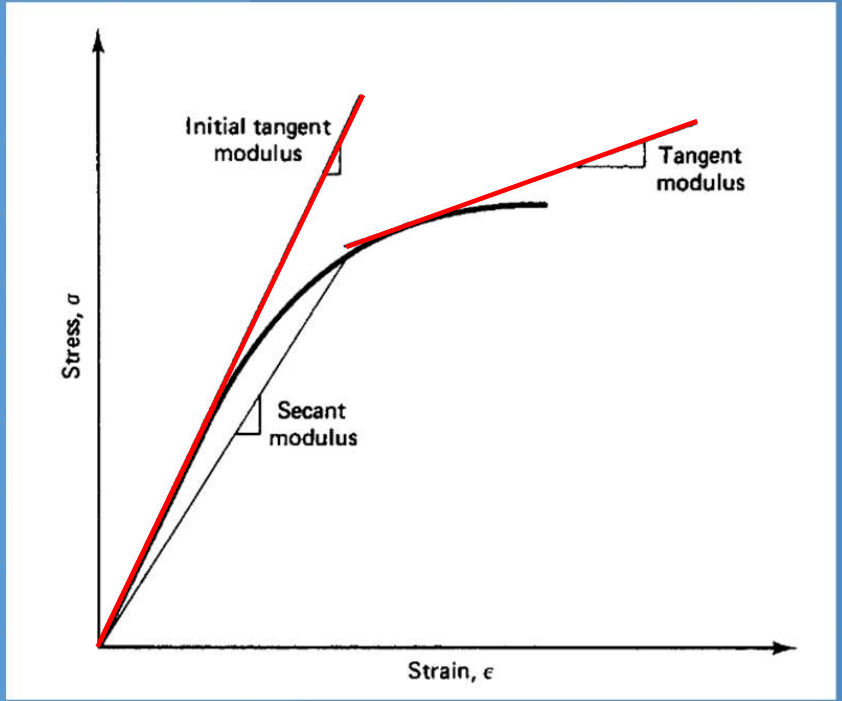

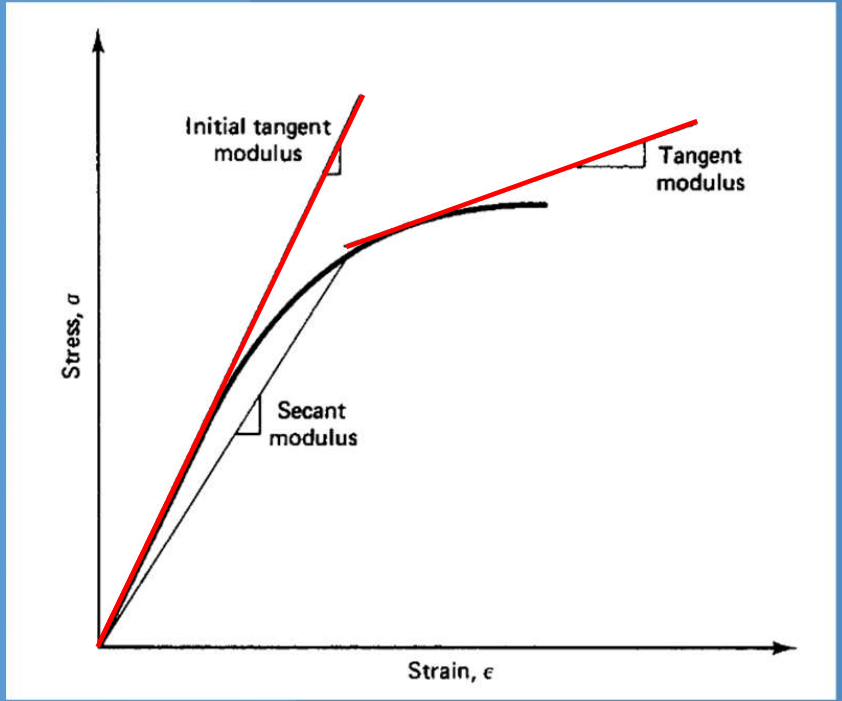

Young’s Modulus of Elasticity is defined as the slope of the stress-strain curve in the elastic (linear) region

True

The initial tangent modulus refers to the slope of the stress-strain curve at the origin

False

The tangent modulus can only be drawn at the ultimate strength of concrete

True

The secant modulus is defined as the slope of a line drawn from the origin to any point on the stress-strain curve.

False

The tangent modulus and initial tangent modulus are always the same

Initial tangent modulus

Which modulus is most often used in design since it represents the initial elastic behavior of concrete?

True

The secant modulus of elasticity is determined from the slope of a line drawn from the origin to a stress level of about 0.4 f’c.

True

In design calculations, the modulus of elasticity of concrete is usually taken as the secant modulus.

True

The modulus of elasticity represents the stiffness of concrete.

False

The tangent modulus is always used in design instead of the secant modulus.

True

The higher the modulus of elasticity, the stiffer the concrete.

The slope of the line from the origin to about 0.4 f’c

The secant modulus of elasticity of concrete is determined by:

Secant modulus

In design calculations, the modulus of elasticity of concrete is usually taken as:

Stiffness

What does the modulus of elasticity of concrete represent?

Stiffer

A higher modulus of elasticity in concrete means the material is:

0.4 f’c

At approximately what stress level is the secant modulus typically evaluated in concrete?

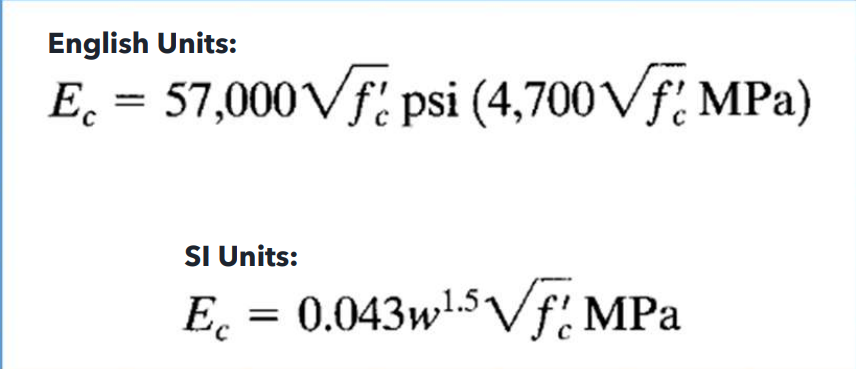

Normal strength concrete

The ACI building code gives the following expressions for calculating the secant modulus of elasticity of Concrete, Ec. This expression only applies to?

True

High Strength Concrete is defined by the ACI Code when cylinder compressive strength exceeds 6000 psi (41.4 MPa).

False

Concrete with compressive strength of 5000 psi (34.5 MPa) is classified as High Strength Concrete.

True

The compressive strength range of 6000 to 12000 psi (42–84 MPa) is considered High Strength Concrete.

False

The modulus of elasticity for High Strength Concrete uses the same expressions as Normal Strength Concrete

True

High Strength Concrete is generally stronger and stiffer compared to Normal Strength Concrete.

6000 psi (41.4 MPa)

According to the ACI Code, High Strength Concrete is defined when compressive strength exceeds:

6000 – 12000 psi (42–84 MPa)

The compressive strength range of High Strength Concrete is:

It uses special modulus expressions for design

High Strength Concrete differs from Normal Strength Concrete because:

AC

Which organization defines High Strength Concrete as having f’c greater than 6000 psi?

Has higher compressive strength and stiffness

Compared to Normal Strength Concrete, High Strength Concrete generally:

True

The modulus of rupture indicates the tensile capacity of concrete under bending.

False

According to ACI, the tensile strength of concrete can be approximated as 50% of its compressive strength.

True

A good approximation of tensile strength is 10–20% of the compressive strength (f’c).

True

The modulus of rupture test is performed using simply supported beams.

True

The modulus of rupture is typically tested under 3-point or 4-point bending configurations

Tensile capacity under bending

The modulus of rupture of concrete represents:

10–20% of f’c

According to ACI, the tensile strength of concrete is approximately:

3-point or 4-point bending test

Which test setup is commonly used to measure the modulus of rupture?

At the midspan of the beam

In the 3-point bending test for modulus of rupture, the load is applied:

Tensile strength of concrete under flexure

The modulus of rupture is generally used to estimate:

True

Time-dependent deformation in concrete is mainly due to creep and shrinkage.

False

Creep refers to the immediate elastic deformation of concrete under load.

True

Shrinkage and creep can cause a partial loss of prestress force

False

Time-dependent deformation has no effect on the deflection of concrete members.

True

Both creep and shrinkage are important factors in the long-term behavior of prestressed concrete structures.

Creep and shrinkage

Time-dependent deformation of concrete primarily results from:

Gradual increase in strain under sustained load

Creep in concrete refers to:

Reduction in volume due to moisture loss

Shrinkage in concrete refers to:

Loss of prestress force

A major consequence of creep and shrinkage in prestressed concrete is:

Change in deflection

One structural effect of time-dependent deformation in concrete is:

True

Creep is the property of materials where they continue to deform over time under constant stress.

True

The initial deformation of concrete under load is called elastic strain.