Product Design and Development Exam 1

1/97

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

98 Terms

Product quality

How good is the product resulting from the development effort? Satisfies customer needs? Robust and reliable? Ultimately reflected in market share and the price customers pay.

Product cost:

What is the manufacturing cost? Cost includes spending on capital, equipment, and cost of producing each unit of product. Determines how much profit accrues to the firm for a particular sales volume and a particular sales price.

Development time:

How quickly did the team complete the product development effort? Determines how responsive firm can be to competitive forces and to technological developments, as well as how quickly the firm receives the economic returns from the team’s efforts.

Development cost

How much did the firm have to spend to develop the product? Is usually a significant fraction of the investment required to achieve the profits.

Development capability

Are the team and the firm better able to develop future products as a result of their experience with a product development project? Is an asset the firm can use to develop products more effectively and economically in the future.

Characteristics of Successful Product Development

Product Quality

Product Cost

Development Time

Development Cost

Development Capability

Who designs and develops products

Marketing

Design

Manufacturing

Challenges of Product Development

Trade-offs

Dynamics

Details

Time Pressure

Economics

Appeals of Product Development

Creation

Satisfaction of societal and individual needs

Team diversity

Team spirit

Organizational realities

Lack of empowerment of team

Functional allegiances transcending project goals

Inadequate resources

Lack of cross-functional representation on the project team

Well-defined product development process is useful for the following reasons

Quality assurance

Coordination

Planning

Management

Improvement

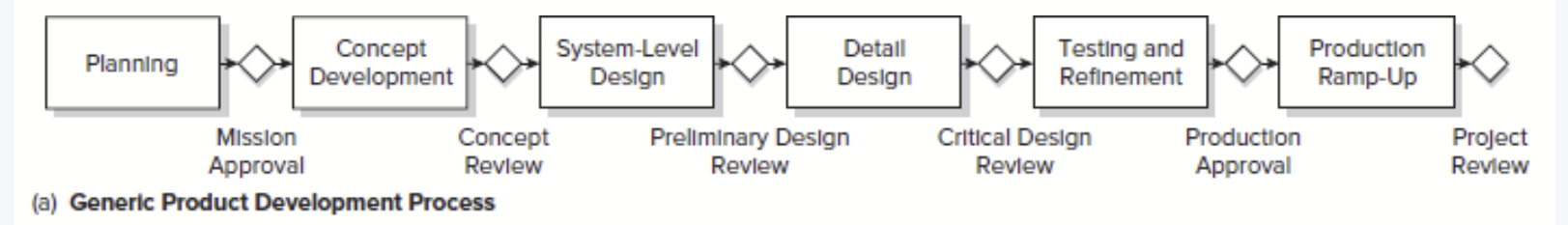

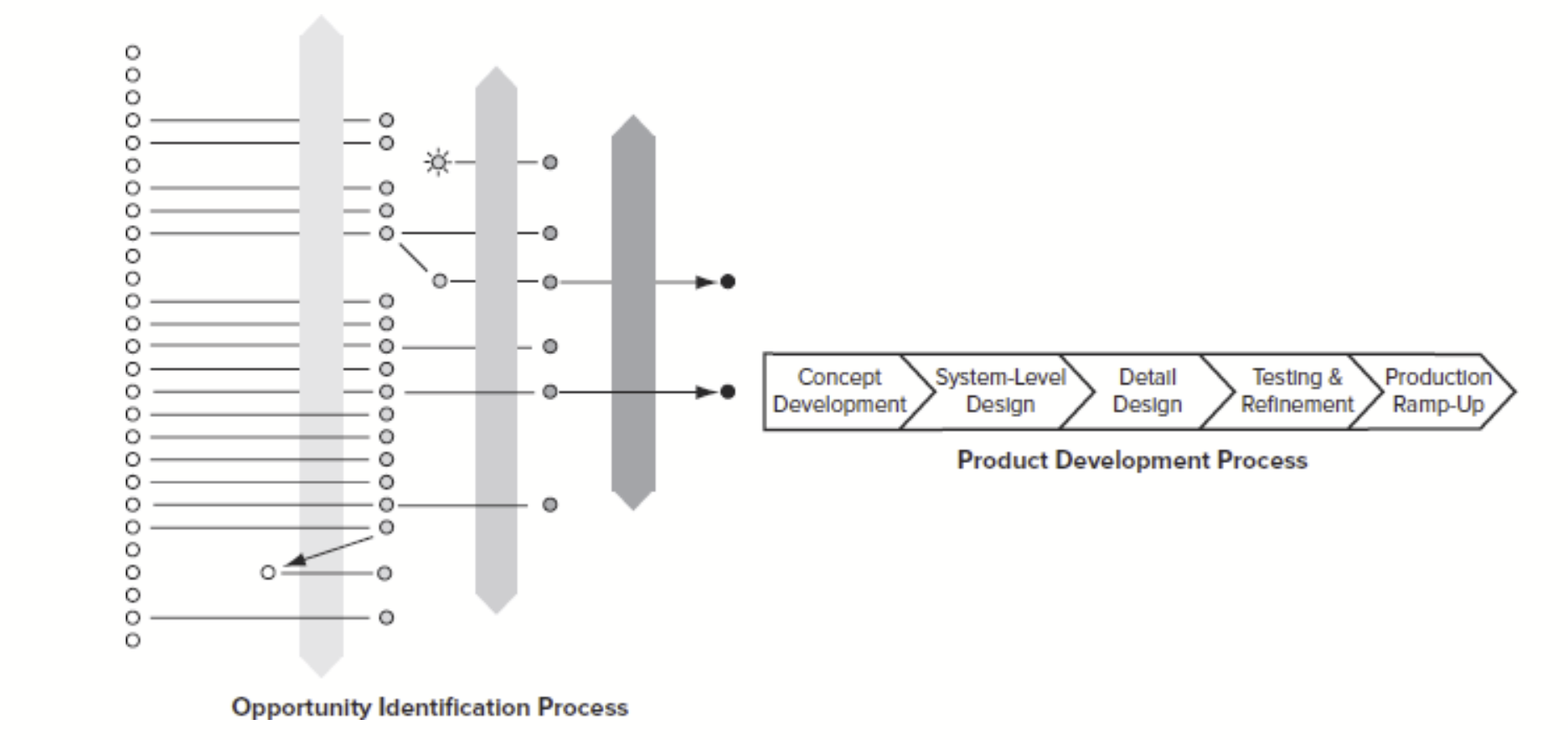

Phases of generic product development

Planning

Concept development

System-level design

Detail design

Testing and refinement

Production ramp-up

Planning

Precedes the approval and launch of development process. Begins with opportunity identification. Includes assessment of technology developments and market objectives. Output is mission statement.

Mission statement

Specifies target market for the product, business goals, key assumptions, and constraints.

Concept development: (pg. 15)

Needs of the target market are identified. Alternative product concepts generated and evaluated. 1 or more concepts selected for further development and testing

Concept

Description of the form, function, and features of a product. Usually accompanied by a set of specifications, and analysis of competitive products, and an economic justification.

System-level design

Includes definition of product architecture, decomposition of product into subsystems and components, preliminary design of key components, and allocation of detail design responsibility to internal and external resources. Initial plans for production system and final assembly are usually defined during this phase as well. Output of this phase usually includes geometric layout of product, functional specification of each subsystem, and preliminary process flow diagram for final assembly process.

Detail design

Includes complete specification of geometry, materials, and tolerances of all unique parts, and identification of all standard parts to be purchased. Process plan is established, tooling designed for each part. Output is control documentation.

Control documentation

Drawings or computer files describing geometry of each part and its tooling, spec’s of purchased parts, production supply chain, and process plans for fabrication and performance.

Testing and refinement

Involves the construction and evaluation of multiple pre-production versions of product.

Alpha prototype

Usually built with production-intent parts—parts with the same geometry and material properties as intended for the production version of the product but not necessarily fabricated with the actual processes to be used in production. Tested to determine if the product will work as designed and if it satisfies key customer needs.

Beta prototype

Usually built with parts supplied by the intended production processes but may not be assembled with final assembly process. Are extensively evaluated internally and also tested by customers in their own use environment. Goal is usually to answer questions about performance and reliability, and to identify necessary engineering changes for final product.

Production ramp-up: (pg. 15)

Product is made using intended production system. Purpose is to train workforce and work out any remaining problems in production process. Products produced during this are sometimes supplied to preferred customers and carefully evaluated to identify any remaining flaws.

Concept Development process

Identify customer needs

Establish target specifications

Concept generation

Concept selection

Concept testing

Setting final specifications

Project planning

Economic analysis

Benchmarking of competitive products

Modeling and prototyping

Technology-push products

New proprietary technology pushes product development

Generic market-pull products

Market opportunity drives product development.

Platform products

Product is built around preexisting technological subsystem.

Process-intensive products

Characteristics of the product are highly constrained by the production process, so that product design cannot be separated from production process design.

Customized products: (pg. 20)

Slight variations on standard products. Typically developed in response to a specific order by a customer. Development consists primarily of setting values of design variables such as physical dimensions and materials.

High-risk products

Addresses many types of risk including technical risk, market risk, budget, and schedule risk. These products entail unusually large uncertainties of tech or market so that there is large tech or market risk. (Generic product development process is modified by taking steps to address the largest risks in the early stages of product development.)

Quick-build products

Design-build-test cycle is repeated many times. Has high-, medium-, and low- priority features. Uses the result of each cycle to learn how to modify the priorities of the next cycle. Customers may even be involved in the testing process after one or more cycles.

Digital products: (pg. 21)

Developed using a highly-iterative product development process. Often developed incrementally, beginning with basic functions and building up to the complete system with many iterations.

Product-service systems: (pg. 21)

Often provided in conjunction with tangible products. Largely developed using the standard product development methods, however, design teams pay careful attention to the range of customer needs and timing of key touch points.

Complex systems: (pg. 22)

Modifications to the generic product development process address a number of system-level issues. The concept development phase considers the architecture of the entire system, and multiple architectures may be considered as competing concepts for the overall system. The system-level design is critical, decomposing into subsystems and further into many components.

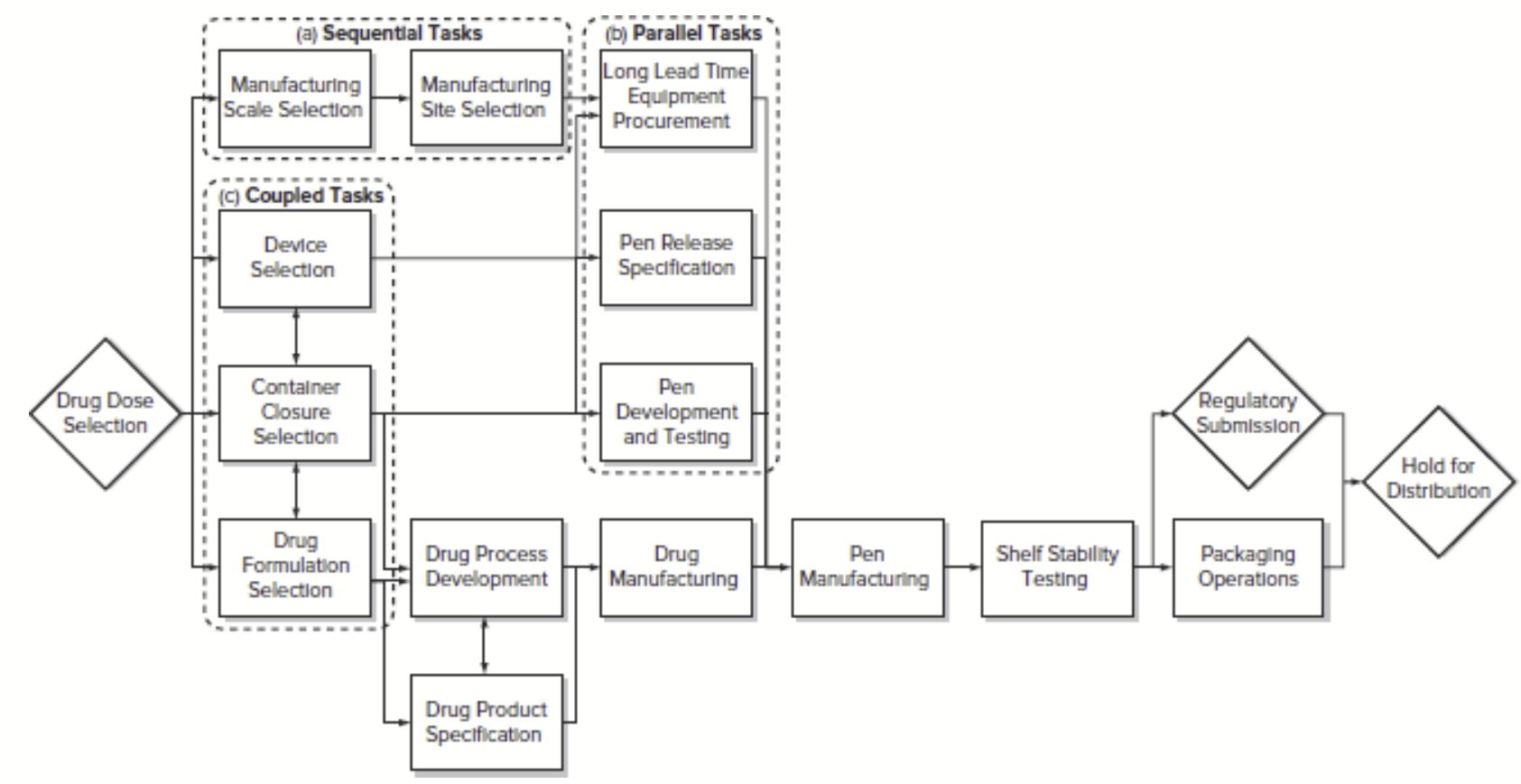

Process flow diagrams: (pg. 22)

Depicts the process used to develop the particular product development process adaptation.

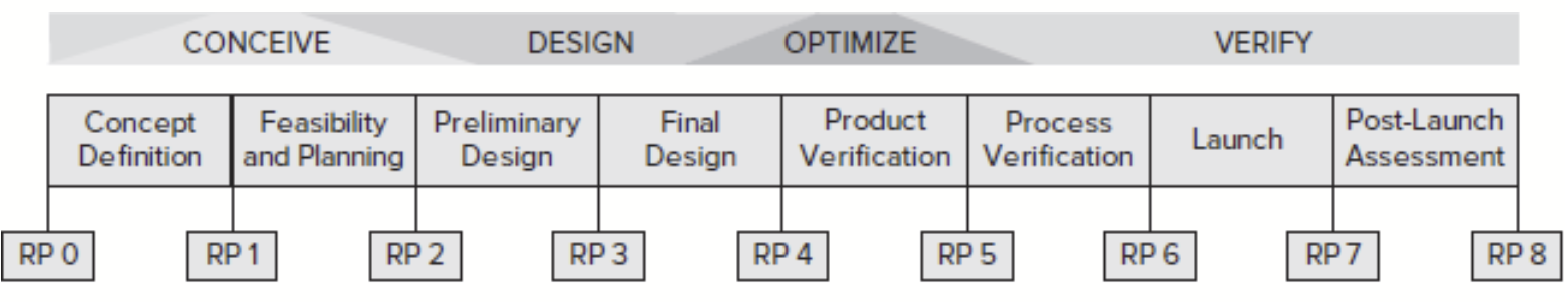

Tyco Rally Point process flow: (pg. 23)

Nine phases, with six phases (from concept definition to process verification) comprising the fundamental product development process. Each phase is followed by a critical review, called a “Rally Point,” which is required to gain approval to proceed to the next phase.

Links among groups like designers and developers, formal or informal: (pg. 24)

Reporting relationships

Financial arrangements

Physical layout

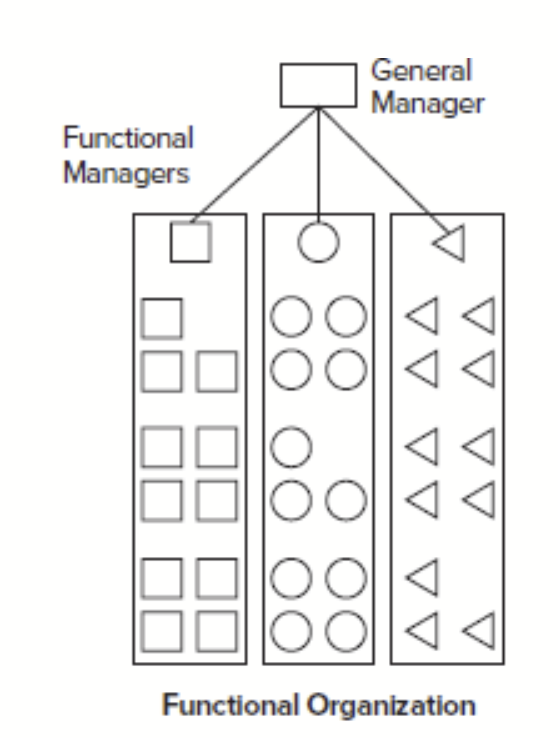

Functional organization: (pg. 26)

Organizational links are primarily among those who perform similar functions.

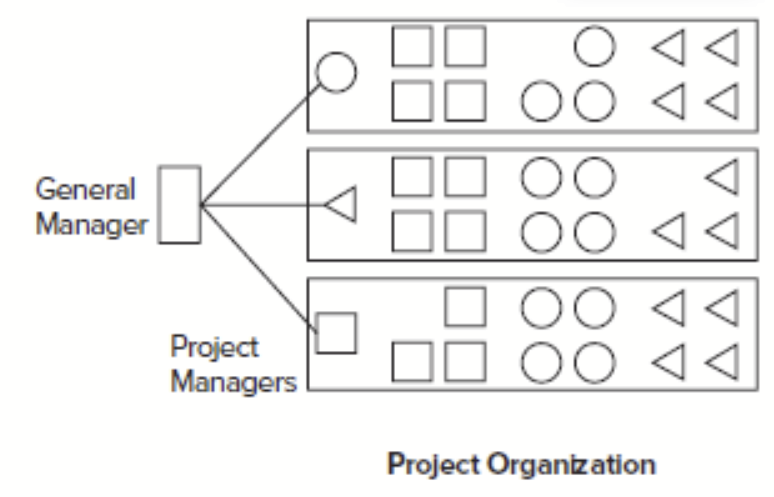

Project organizations: (pg. 26)

The organizational links are primarily among those who work on the same project.

Matrix organization: (pg. 26)

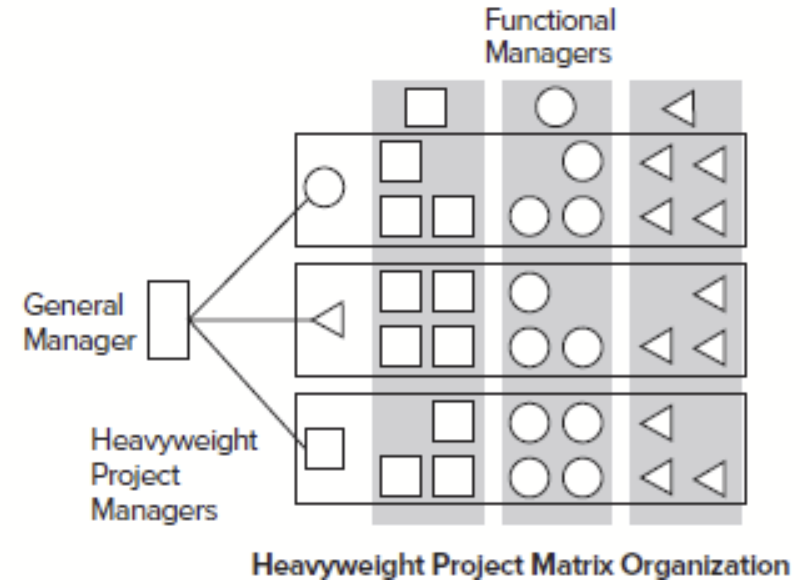

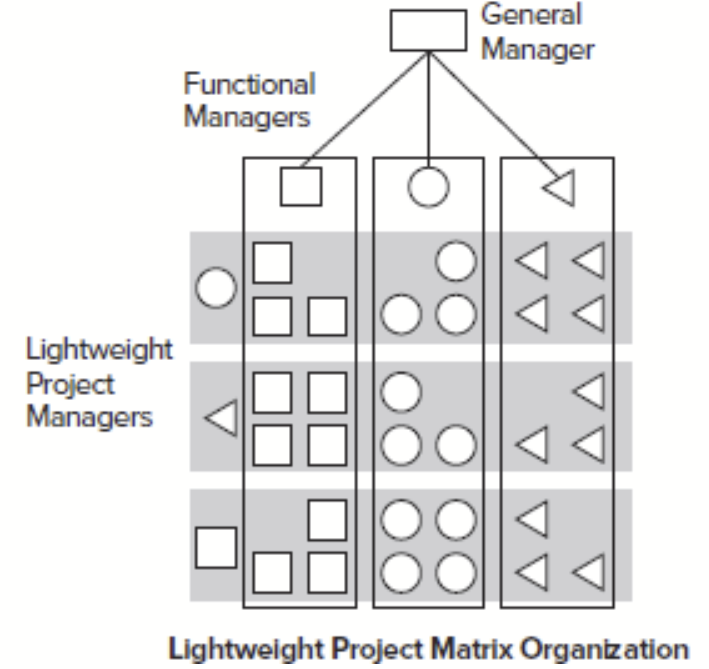

Hybrid of functional and project organizations. In it, individuals are linked to others corresponding to both the project they work on, and their function. Typically, each individual has two supervisors; one project manager and another a functional manager. Practical reality is that either the function or the project tends to have stronger links.

Variants of the matrix organization: (pg. 27)

Heavyweight project organization

Lightweight project organization

Heavyweight project matrix organization: (pg. 27)

Contains strong project links. Project manager has complete budget authority, is heavily involved in performance and evaluation of team members, and makes the most of the major resource allocation decisions.

Heavyweight project team in various industries may be called a: (pg. 27)

Product development team (PDT)

integrated product team (IPT)

Design-build team (DBT)

Lightweight project organization: (pg. 27)

Contains weaker project links and relatively stronger functional links. Project manager is more a coordinator and administrator, updates schedules, arranges meetings, and facilitates coordination, but has no real authority or control in the project organization. The managers are responsible for budgets, hiring, and firing, and performance evaluation.

Opportunity: (pg. 36)

An idea for a new product

Dimensions of opportunity: (pg. 36)

The extent to which the team is familiar with the solution likely to be employed

The extent to which the team is familiar with the need that the solution addresses

Types of opportunity: (p. 37)

Horizon 1

Horizon 2

Horizon 3

Horizon 1 opportunity: (pg. 37)

Improvements, extensions, variants, and cost reductions of existing products.

Horizon 2 opportunity: (pg. 37)

Push out into less known territory in either market or technology

Horizon 3 opportunity: (pg. 37)

Attempts to exploit opportunities that are in some way new to the world

Tournament structure of opportunity identification process

Concept development→system-level design→detail design→testing & refinement→production ramp-up

Ways to increase number of excellent opportunities identified

Generate a large number of opportunities

Seek high quality of the opportunities generated

Create high variance in the quality of opportunities

Opportunity identification process

Establish a charter

Generate and sense many opportunities

Screen opportunities

Develop promising opportunities

Select exceptional opportunities

Reflect on the results and the process

Techniques for generating opportunities

Follow a personal passion

Compile bug lists

Pull opportunities from capabilities

Study customers

Consider implications of trends

Imitate, but better

Mine your sources

VRIN: (pg. 43)

Valuable, Rare, Inimitable, Nonsubstitutional

RWW

Real, Win, Worth it

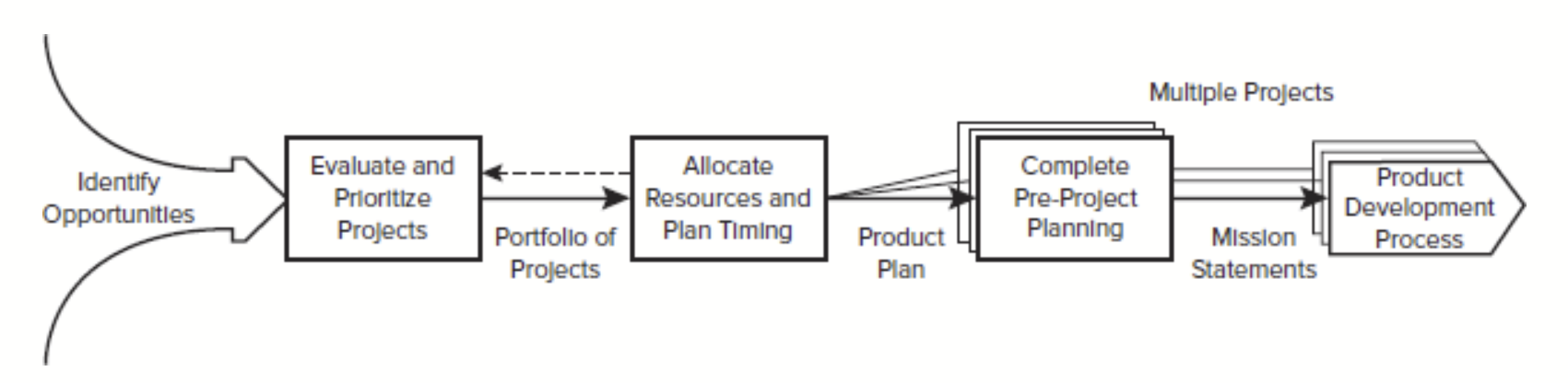

Product plan

Identifies the portfolio of products to be developed by the organization and the timing of their introduction to the market.

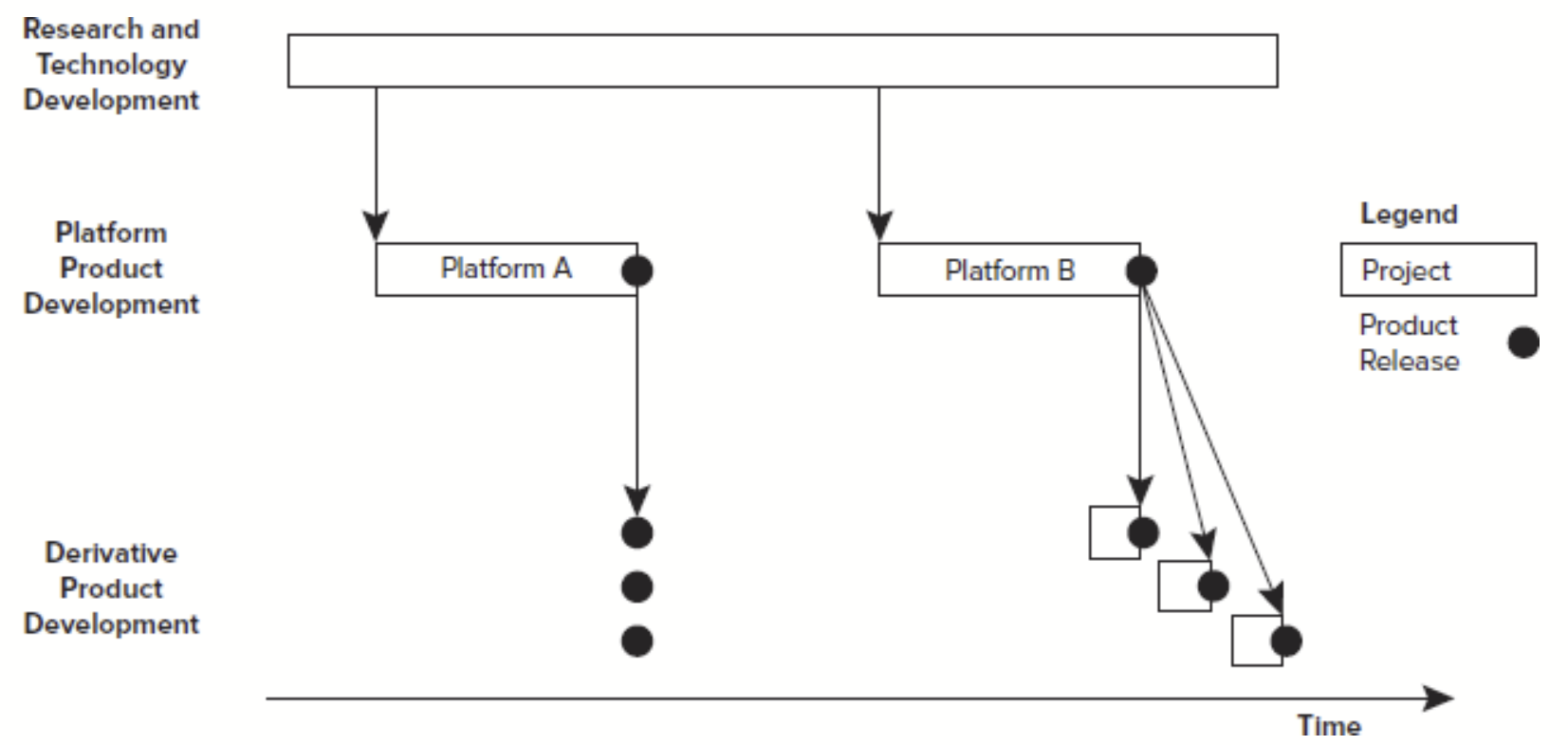

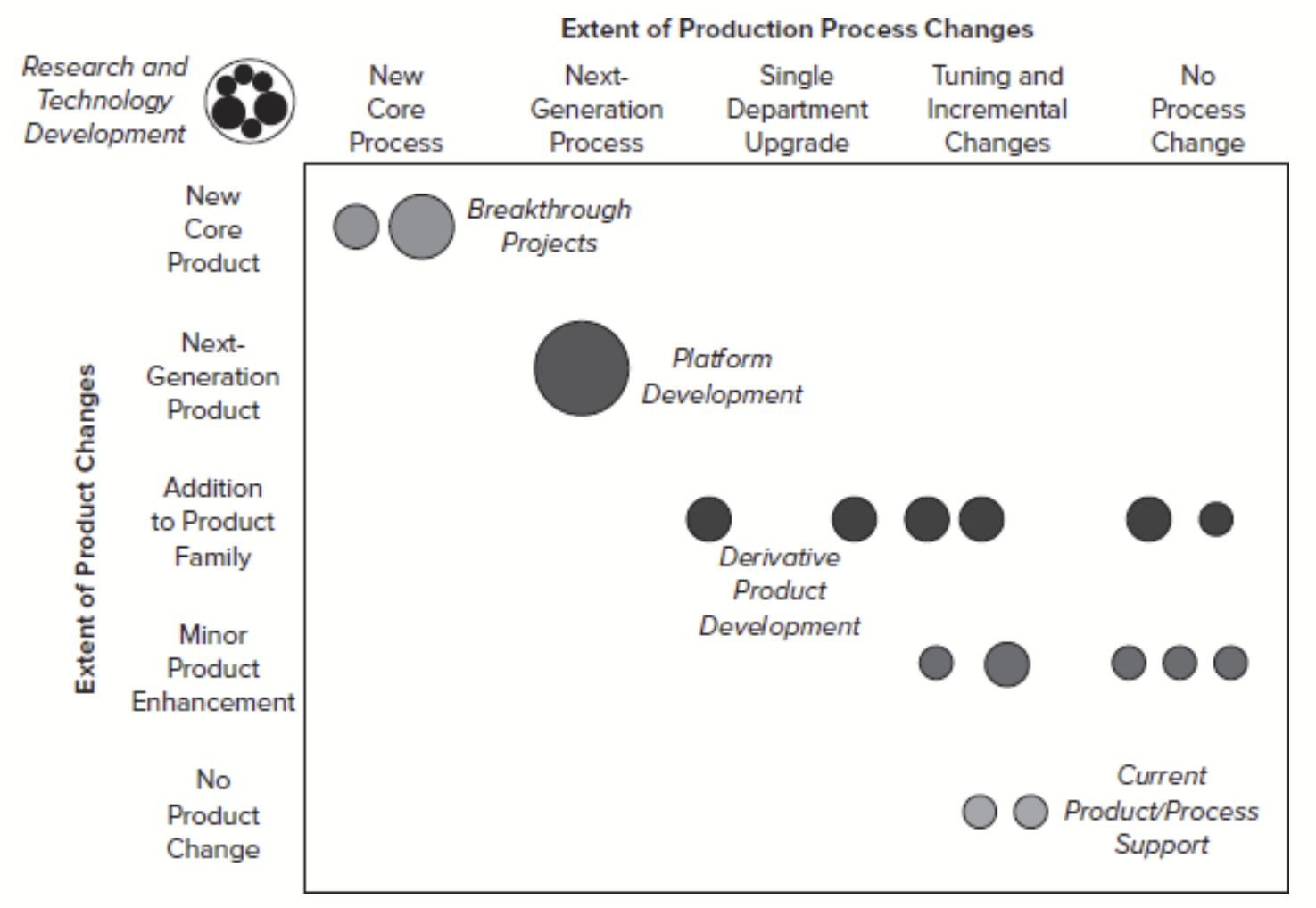

Types of product development projects

New product platforms

Derivatives of existing product platforms

Incremental improvements to existing products

Fundamentally new products

Steps in the product planning process

Identify opportunities→evaluate and prioritize projects→allocate resources and plan timing→complete pre-project planning→product development process

Competitive strategies

Technology leadership

Cost leadership

Customer focus

Imitative

Technology leadership

Great emphasis on research and development of new tech, and on deployment of this tech through product development

Cost leadership

Requires firm to compete on product efficiency, either through economics of scale, use of superior manufacturing methods, low-cost labor, or better management of the production system

Customer focus

Firm works closely with new and existing customers to assess their changing needs and preferences.

Imitative

Involves closely following trends in the market, allowing competitors to initially explore which new products are successful for each segment

Perspectives of evaluating and prioritizing projects

Competitive strategy

Market segmentation

Technological trajectories

Product platform planning

Product segment map

Maps competitors’ products and firm’s own products

Technology S-curve

Displays performance of the products in a product category over time

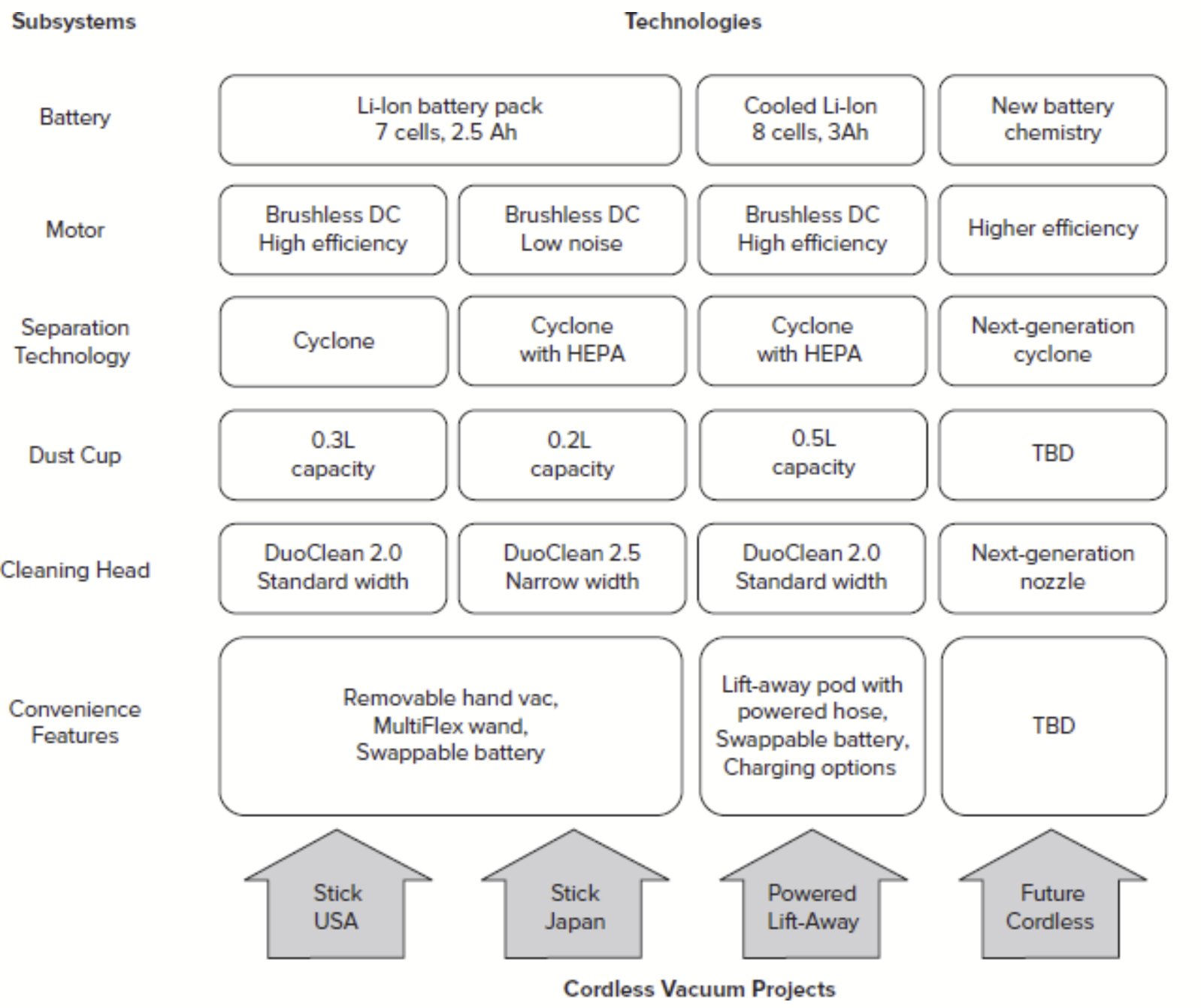

Product platform

The set of assets shared across a set of products

Product platform planning

Technology roadmapping

A way to represent the expected availability and future use of various technologies. Coordinates tech development with product planning.

Criteria for evaluating fundamentally new product opportunities

Market size

Market growth rate

Competitive intensity

Depth of the firm’s existing knowledge of the market

Depth of the firm’s existing knowledge of the tech

Fit with the firm’s other products

Fit with the firm’s core assets and capabilities

Potential for patents, trade secrets, or other barriers to competition

Existence of a product champion within the firm

Product-process change matrix

Can illuminate imbalances in the portfolio of projects under consideration and in assessing the consistency between a portfolio of projects and the competitive strategy

Determining the project timing

Timing of product introductions

Technology readiness

Market readiness

Competition

The product plan

The set of projects approved by the planning process, sequenced in time

Mission statement

Brief (one sentence) description of product

Benefit proposition

Key business goals

Target market for product

Assumptions and constraints

Stakeholders

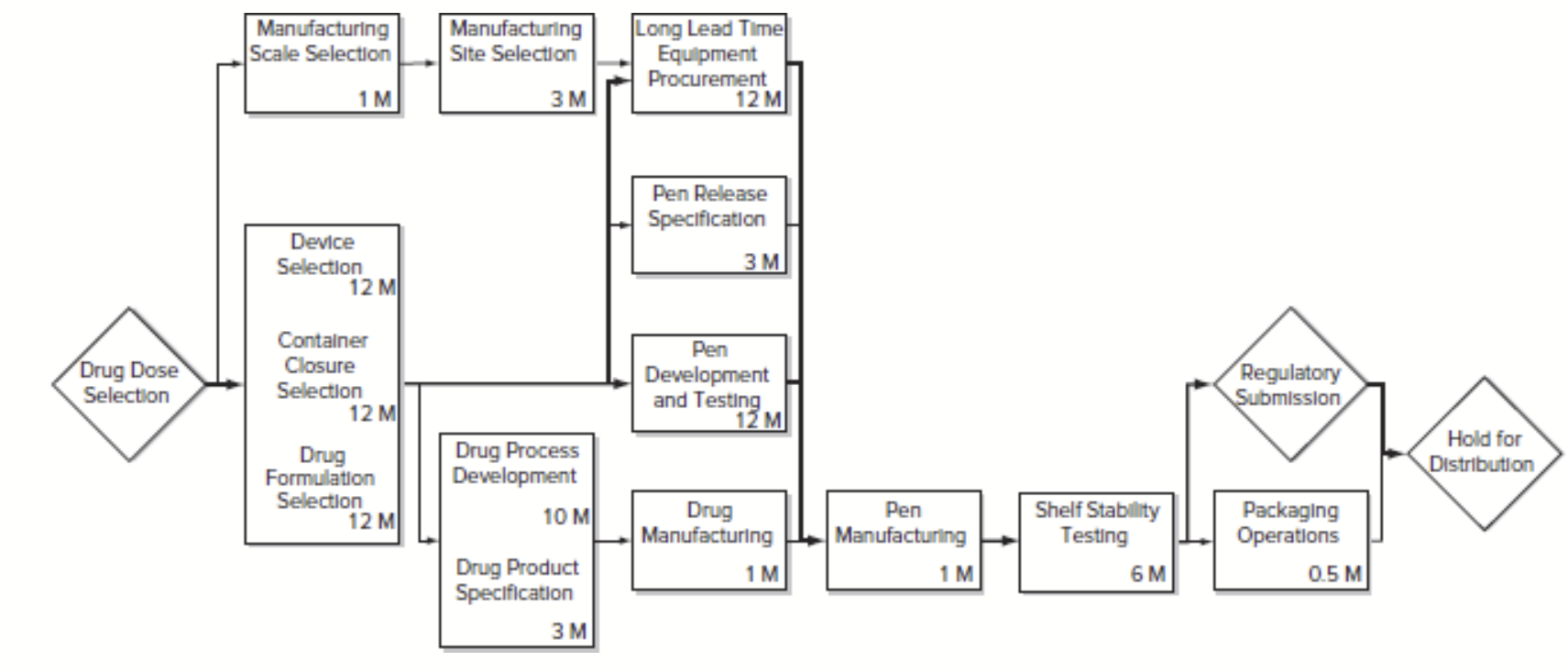

Task network

Represents tasks as coupled, parallel, or dependent.

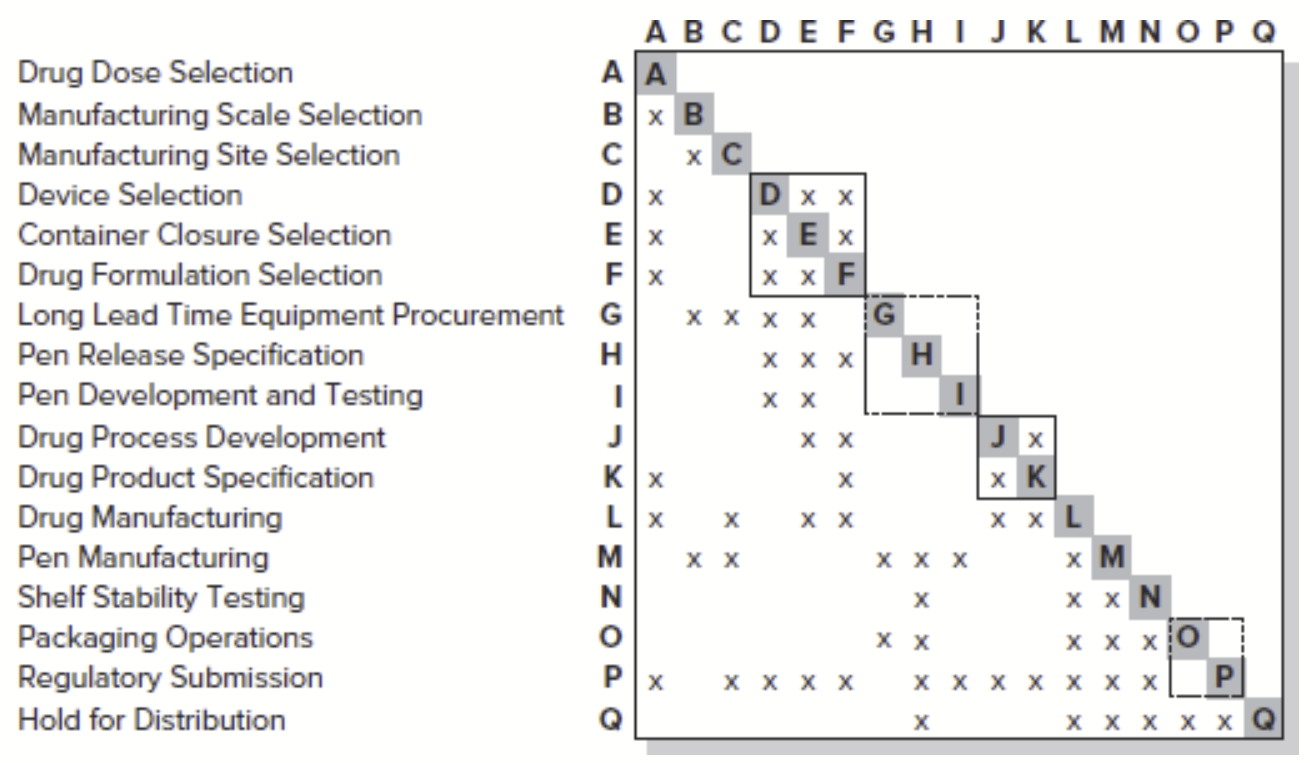

Design structure matrix

Used to analyze development projects modeled at the task level

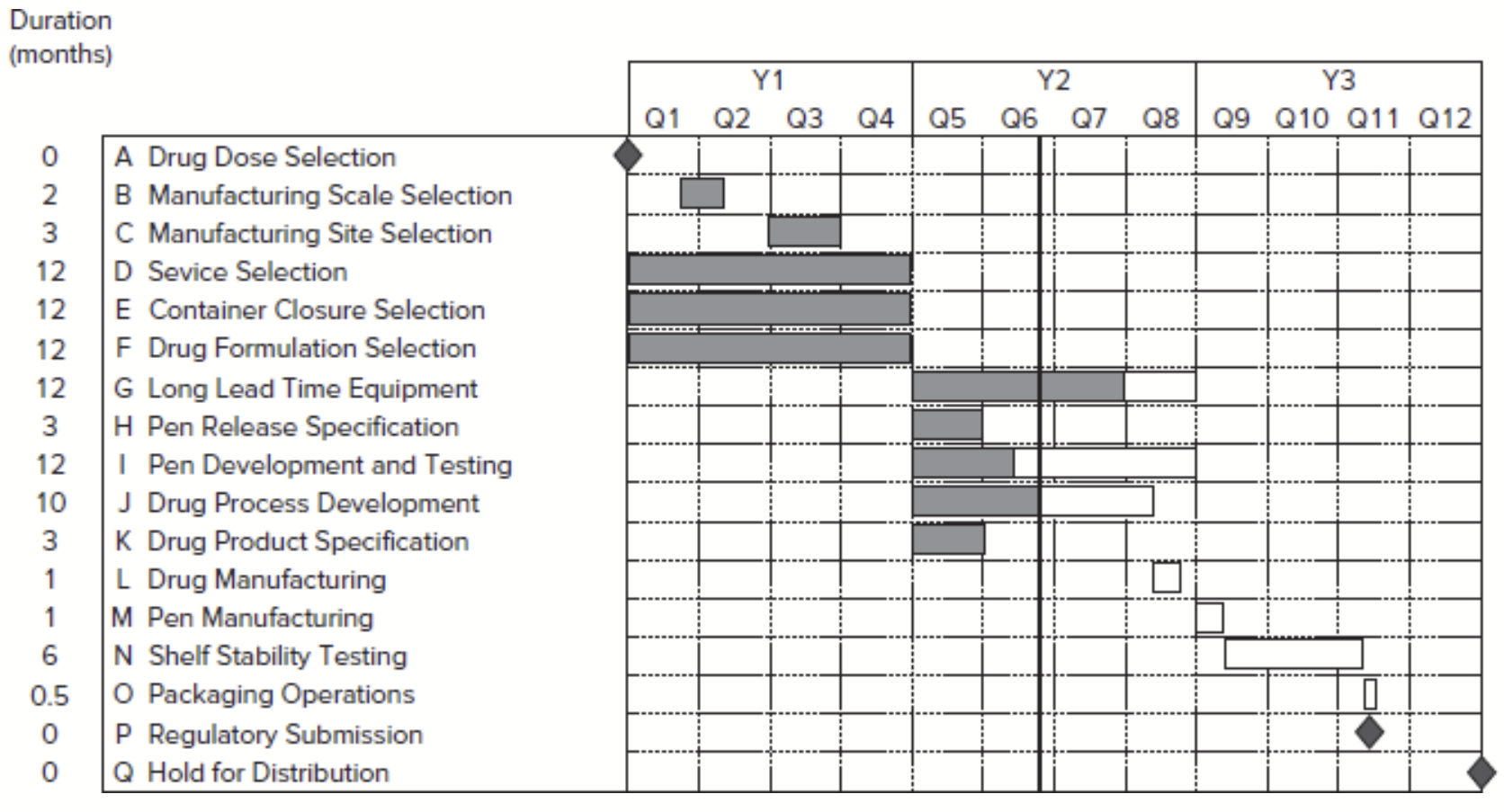

Gantt charts

Represents timing of tasks

PERT chart

Program Evaluation and Review Technique. Represents both dependencies and timing

Critical path

Longest chain of dependent events.

Contract book

Represents an agreement between the development team and senior management about project goals, direction, and resource requirements.

Baseline project planning

Contract book

Task list

Team staffing and organization

Schedule

Budget

Risk plan

Methods of accelerating projects

Start the project early

Manage the project scope

Facilitate exchange of essential information

Decreasing time on critical path

Complete individual tasks on the critical path more quickly

Move tasks off critical path

Eliminate some critical tasks

Aggregate safety times

Eliminate waiting delays for critical path resources

Overlap selected critical tasks

Pipeline large tasks

Outsource some tasks

Complete coupled tasks quicker

Perform more iterations quicker

Decouple tasks to avoid iterations

Consider sets of solutions

Coordination mechanisms

Informal communication

Meetings

Schedule display

Weekly updates

Incentives

Process documents

Scrum teams

Corrective actions

Changing time/frequency of meetings

Changing project staff

Locating team together physically

Soliciting more time/effort from team

Focusing more on critical tasks

Engage outside resources

Change project scope/schedule

Life of a product

Design→production and delivery→use→end of life

Design

Project definition→product definition→conceptual design→product development

Production and delivery

Manufacture→assembly→distribution→installation

Use

Operate in sequence 1…N→clean→maintain (diagnose, test, repair)

End of life

Retirement→disassembly→reuse/recycle

Types of mechanical design problems

Selection

Configuration (packaging)

Parametric

Original

Variant

Redesign

Basic actions of design problem solving

Understand

Develop measures

Generate

Evaluate

Decide

Communicate

Designer’s languages

Semantic

Graphical

Analytical

Physical

Building a project plan

List of tasks

Objectives/deliverables

Estimate resources

Task dependencies

Estimate cost

Project management

The activity of planning and coordinating resources to achieve the goals of the project task deliverables

Product execution (control):

Coordinating and facilitating myriad tasks required to complete the project; to ensure seamless flow of information between tasks.