Food Science Exam 2

1/32

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

33 Terms

Categories of Lipids

Triglycerides

Phospholipids

Sterols

Basic structure of a fatty acid

Chain of carbons with a carboxyl (hydrophilic) group on one end, methyl (hydrophobic) group on other end.

saturated vs monounsat vs polyunsat vs cis vs trans fatty acid structures

saturated: carbon chain with NO double bonds. Fully occupied by H atoms.

monounsaturated: one double bond

polyunsaturated: two or more double bonds

trans fatty acid: hydrogens are on opposite sides around the CC double bond

cis fatty acid: hydrogens are on the same side around CC bond (creates a kink in the chain)

common dietary sources of sat, unsat, trans fatty acids, and cholesterol

sat: beef, pork, dairy products, palm & coconut oil

unsat: vegetable oil, nuts, fish

trans fatty acid: dairy, milk, meat, margarine, cookies

cholesterol: only in animal products

effects of saturation on the physical state of fatty acids at room temperature

Hydrogenation makes trans fatty acids (adds hydrogen to unsat) solid at room temp

saturated is solid at room temp

mono and poly unsaturated is liquid at room temp

Two essential fatty acids and dietary sources

Omega-6 (Linoleic acid): canola oil, walnuts, soybeans

Omega-3 (Linolenic acid): flaxseed, chia seeds, walnuts

Lipid function in body and in foods

Body: Organ protection, flavor and satiety, storage of energy as fat tissue, steroid hormone production, cell membrane structure, primary energy source for heart.

In foods: effects mouthfeel and texture, flavor compounds interact with fat molecules in food

fat and oil properties that impact function in products

Properties of fats and oils that impact their function in food products include their melting point, which determines a product's texture and mouthfeel, and plasticity, which affects spreadability. Other key properties are their role in emulsification, heat transfer, flavor enhancement

Apply what you know about the functions of fats and oils in foods to hypothesize how foods and beverages may change if fats and oils are eliminated or reduced in their formulation

The removal of fats and oils would profoundly impact the texture and mouthfeel of many foods: without fat foods are drier, less creamy, and have less flavor.

Food Processing vs Processed Food definition

Food Processing: use of methods and techniques involving equipment, energy, and tools to transform agricultural products into food products

Processed Food: food material has been changed in some way through a combo of ingredients together with processing steps to make food safe to eat, shelf-stable

Processed Foods: Pros vs Cons

Pros:

food safety

convenience

availability

food preservation

Cons:

higher levels of fats, sugars, salt

lower fiber

health risks

Main points for and against food processing

For:

help long term fuel/endurance(ex: gel for marathons)

plant based food can’t be made without processing

natural isnt always good (ex: folate vs folic acid)

Against:

excess calories, causing obesity

higher sugars, fat, and salts but lower fiber

Objectives of food processing

ensure food safety, extend shelf life,

improve convenience, affordability

Ultra-Processed food definition

foods comprised of industrially produced ingredients

Value added ingredients vs. processed/formulated foods

Value added ingredients: agricultural commodities that have been processed or modified for specific functional/nutritional benefits. EX: Flour, milk powder, liquid eggs

Processed foods: food that has been changed to preserve it for convenience, etc. EX: potato chips, cereals, cheese dip

Definition of pathogen, spoilage microorganism, D-Value, and temp danger zone

Pathogen: a microorganism that harms human health

Spoilage microorganism: microorganisms that cause spoilage or disease (some contain enzyme pectin esterase that rot fruits/veggies)

D-value: decimal reduction time, time required at given condition to achieve a log reduction (kill 90%) of microorganisms

Temp danger zone: temperatures that cause microorganisms to grow and multiply (foods stored warmer that 41F and reheated to cooler than 140F)

Conditions that affect bacterial multiplication in foods

Food - nutrients (carbs/protein)

Acidity (neutral to low acid)

Temperature ( 41-135)

Time, bacteria double every 20 mins

Oxygen (anaerobic vs aerobic)

Moisture (high water activity: adding salt or sugar)

How can you modify those conditions to slow bacterial growth?

store foods out of danger zone, keep water activity low

5 bacteria & viruses that cause most illness, hospitalizations and deaths in US each year

Norovirus, Salmonella, Campylobacter, E. coli, and Listeria

Different routes foodborne illness may occur

Contamination: -can occur during harvest or food prep

Incorrect Storage: allows for growth of bacteria or toxin production

Not processed/cooked right: allowing bacteria/toxin to survive before food is eaten

Bacteria and Virus table: food/bev association, incubation time, and prevention

see paper

Diff types of contaminants that make a food unsafe

Biological, Physical, and Chemical

Pop groups at highest risk of foodborne illness and why?

ages 65+

children less than 5 yrs old

ppl with weak immune systems

pregnant women

ALL DUE TO ALTERED IMMUNE SYSTEMS

Explain how groups at risk of foodborne illness can reduce their risk of foodborne illness through food selection, food preparation, and food storage

Groups at risk can reduce foodborne illness by selecting safer foods, practicing safe preparation, and following proper storage guidelines. When shopping, choose undamaged products and keep raw items separate from other groceries. thoroughly cook all food

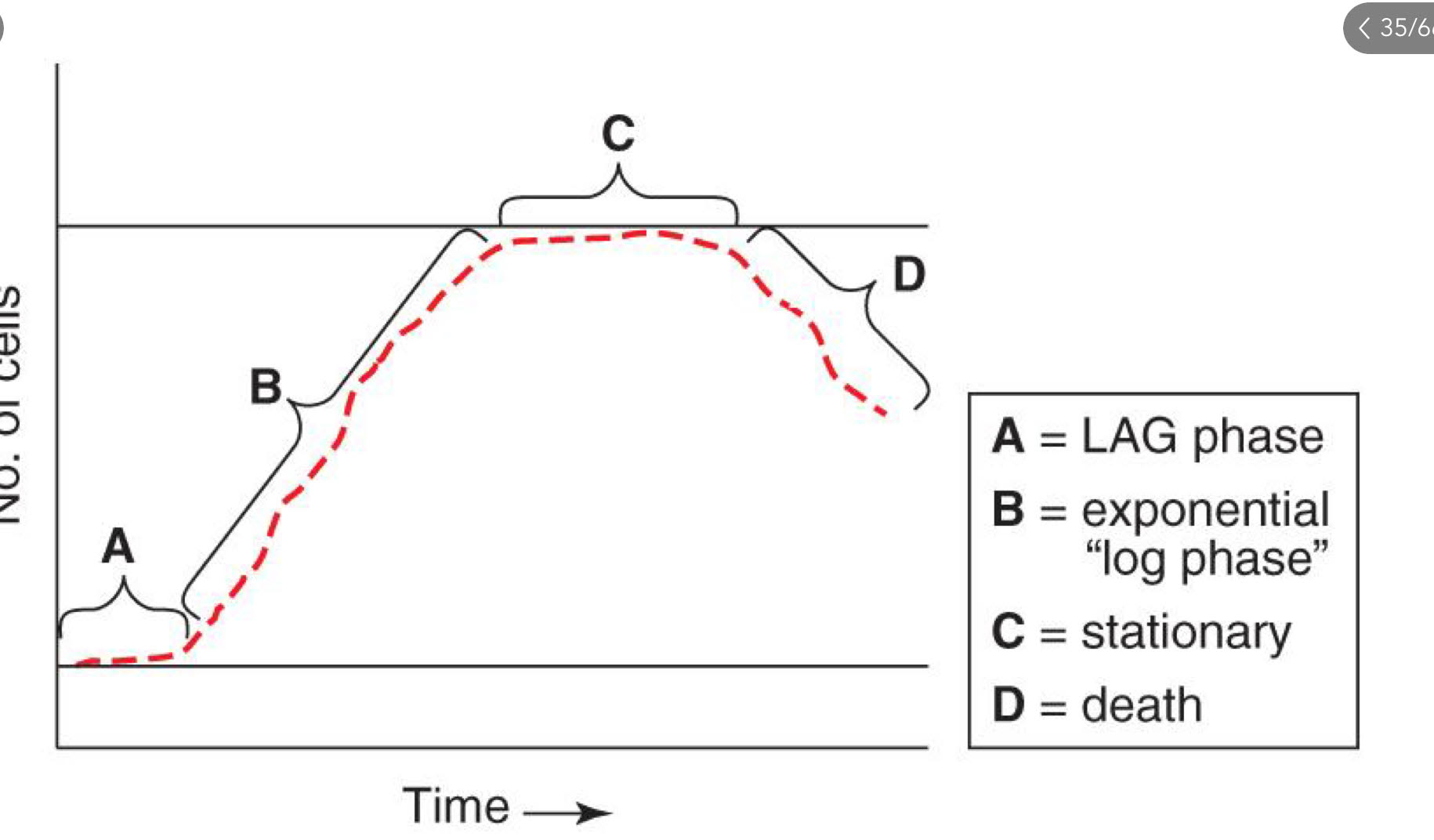

Label each phase of a microbial growth curve and describe what is occurring during each phase.

Quality vs Total Quality Management Definition

Quality: degree to which food product conforms to specifications and consumer expectations

Total Quality Management: company wide system aimed at continuous improvement to ensure regulatory compliance/customer satisfaction

elements of total quality management

Management responsibility, documented procedures, testing, sanitary design, HACCP plan, recall procedures, sustainability, consumer awareness

7 steps of HACCP Plan

Conduct hazard analysis

Identify critical control points

Establish critical limits

Establish monitoring procedures

Corrective actions

Verification procedures

Documentation/record keeping

3 diff types of food/bev recalls

Class I: health hazard w/ reasonable probability of health problems or death

Class II: remote probability of temporary/reversible health consequences

Class III: ingestion of food product is unlikely to cause any adverse health consequences

Market withdrawal: product has minor violation not subject to legal action

List factors/properties of a food product a quality assurance manager may test to

determine final product quality

They may perform physical, chemical, or microbiological (toxins, bacteria) tests. They can do a sensory evaluation (taste/flavor, texture) and test packaging and labeling accuracy.

Which points/unit operations in the ice cream making process may pose a hazard to the final safety level of the ice cream

The pasteurization of milk (being heated to kill bacteria, storage and ingredient sourcing bc of packaging, transport, aging/freezing

Are there any steps taken to control the level of the safety risk? If so, what are the

steps/actions

They perform good hygiene, continuous monitoring, sampling, and temperature management

Beyond food safety, what other factors are taken into consideration when assessing the

overall quality of ice cream? What tests could be performed by a quality assurance

scientist to evaluate the final quality of an ice cream product

Test the composition (butter fat, air percentage), microbial quality, texture, sensory like flavor and mouthfeel, and shelf life