HL DT - Topic 4 (part 1)

1/81

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

82 Terms

Physical Properties

characteristics of materials that can be identified through non-destructive testing, describes the state of materials

Mass

the amount of matter contained in a material

Weight

a measure of the force applied by a material due to gravity

Volume

the quantity of three-dimensional space enclosed in a material

Density

the mass per unit volume of a material

Electrical Resistivity

a material's ability to conduct electricity

Thermal Conductivity

the rate at which heat is transferred through a material at a specific temperature

Hardness

a material's resistance to penetration or scratching

Mechanical Properties

how a material performs/reacts to applied force

Tensile Strength

a material's ability to withstand pulling forces

Compressive Strength

a material's ability to withstand squashing forces

Stiffness

an elastic body’s resistance to deflection

Toughness

the ability of a material to resist cracks

Ductility

the ability of a material to be drawn into a wire

Elasticity

the ability of a material to return to its original shape after being deformed

Plasticity

the ability of a material to change shape permanently under stress

Strain

the change in length caused by an applied force divided by the original length

Young's Modulus

a measure of stiffness for an elastic material, equal to stress divided by strain

Aesthetic Characteristics

aspects of a product relating to taste, texture, smell, and appearance

Smart Materials

materials that have properties that change when subjected to external stimuli

Piezoelectricity

a material that generates an electrical charge when deformed

Shape Memory Alloy

metals that can return to their original shape after being deformed (used in braces, stents in arteries, etc)

Photochromicity

a material that changes color in response to light (used in sunglasses/glasses)

Magneto Rheostatic

a fluid that undergoes a drastic change in viscosity when exposed to a magnetic field

Electro Rheostatic

a fluid that undergoes a drastic change in viscosity when exposed to an electric field

Aluminium Extraction

the process of extracting aluminium from bauxite ore through electrolysis (very costly and needs lots of energy)

Steel Extraction

the process of producing steel using a blast furnace, allows for recycling (oxygen furnace and electric arc furnace)

Grain Size

metals are crystalline structures with individual grains, grain size is determined by heat treatment

Alloy

a mixture that contains at least one metal

Work Hardening / Strain Hardening / Cold Working

the process of increasing a metal's hardness through plastic deformation

Tempering

increasing the toughness of a ferrous metal by heating it and allowing it to cool in air (increases ductility and decreases hardness/brittleness)

Super Alloys

alloys that exhibit good mechanical strength, resistance to thermal creep, surface stability, and resistance to corrosion

Creep

the gradual extension of a material under a constant force over time, dependent on temperature

Ferrous Metals

metals that contain iron (iron, stainless steel, mild steel, high speed steel)

Non-Ferrous Metals

metals that do not contain iron (brass, copper, tin, zinc, zluminium)

Hardwood (tree, properties, forest, eg)

wood from deciduous trees

good strength, hardness, and durability

found in tropical and temperate forests

beech, teak, oak

Softwood (tree, properties, forest, eg)

wood from coniferous trees

less dense and prone to water damage and color changes

found in temperate forests

pine, spruce, redwood

Air Seasoning

the process of drying fresh timber in the open or a large shed to reduce moisture content (less costly, but little control over drying process)

Kiln Seasoning

the process of drying fresh timber in a temperature and humidity controlled chamber system (expensive)

Man-Made Timber

made by binding strands or particles of fiber/veneers/boards together

Laminate Timber

timber made from thin layers of wood veneer glued together (grain rotated 90 degrees every layer)

Particle Board

made from wood chips and synthetic resin

Finishing Timbers

using additive preservatives to improve a timber’s natural resistance and improve durability

Glass

material made by rapidly cooling a mixture of sand, soda, and lime

Thermal Shock

cracking or shattering of glass due to rapid temperature changes

Tempered/Toughned Glass

glass that is heated to its almost melting point then chilled to make it impact resistance

Plastics

synthetic materials derived from natural resources, such as crude oil

Thermo Plastics

plastics that can be remolded when heated (eg. polypropylene, HDPE, HIPS, ABS, PET, PVC)

Thermosetting Plastics

plastics that cannot be remolded after their initial heat-forming (polyurethane, epoxy resin, melamine resin)

Bioplastics

plastics derived from renewable sources, such as vegetable fats/oils, corn starch, microbiota, etc

Fibers

elongated hair-like strands used in textiles

Weaving

the process of forming a sheet like material by interlacing long threads passing in one direction with others at right angle (done on a loom)

Knitting

the process of creating fabric by interlocking loops of yarn

Felting

the process of matting tarn together to create fabric

Composites

materials made from two or more different materials combined to enhance properties

CNC (Computer Numerical Control)

A manufacturing process controlled by computers for precision.

Additive manufacturing

Techniques that add material to create a product, such as 3D printing.

Subtractive manufacturing

Techniques that remove material to create a product, such as cutting or drilling.

Stress

force on a material divided by the cross-sectional area of the material

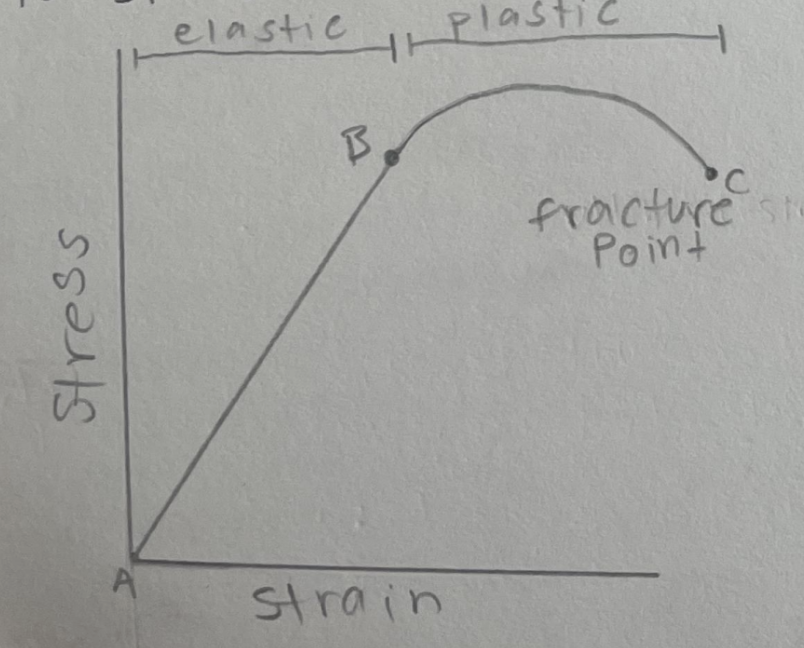

Points on a Stress/Strain Graph

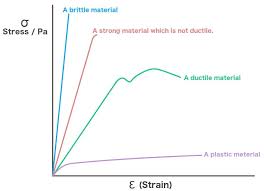

Materials on a Stress/Strain Graph

Small Grain Size

created by quick cooling, higher density/brittleness/hardness

Large Grain Size

created by slow cooling, higher toughness/ductility/flexibility

Timber

a renewable building material that is used directly from the tree after being seasoned

Air Seasoning Advantages

cheap

no equipment

small labour cost

uses little energy

environmentally friendly

Air Seasoning Disdvantages

takes longer

large space needed

Kiln Seasoning Advantages

kills insects

little stacking space

controllable

dries quickly

defects can be controlled

Kiln Seasoning Disadvantages

uses lots of energy

expensive

produces weaker timber

requires a skilled operator

Uses of Recycled Wood

used in panel boars, animal beddings, equestrian landscaping, etc

Characteristics of Glass

amorphous (solid but not crystalline), transparent, chemically inert, non-toxic, brittle, hard, electrical insulator, cheap, biocompatible

Soda Glass

soda lime composition that is cheap but very brittle and has poor thermal shock resistance

Pyrex Glass

glass with improved thermal shock properties and is non potus (reduces cross contamination when cooking)

Laminate Glass

two thin sheets of glass with a sheer of plastic glued in between (plastic retains fragments when it shatters, making it safer)

Recycling Glass

glass products can be broken up and melted back down, not degradation in the quality in this process

Monomer

a relatively small molecule

polymer

monomers joined together (all plastics are polymers)

Natural Plastics

naturally occurring materials that can be shaped and moulded by heat (eg. cellulose amber)

Semi-Synthetic Plastics

made from natural resources but have been mixed with other materials (eg. cellulose acetate)

Synthetic Plastics

made from breaking down/cracking carbon based materials

Natural Fiber

from a plant or animal (silk, cotton, wool)

Synthetic Fibers

created by a chemical process (nylon, polyester, lycra)