MECH2305 - Tolerances and Fits

1/42

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

43 Terms

Tolerance

The exact limit allowed within the variation of the size for a component.

High vs Low tolerance

high tolerance costs more to produce, low tolerance parts may not function as expected.

Three methods of tolerance

Limits of size

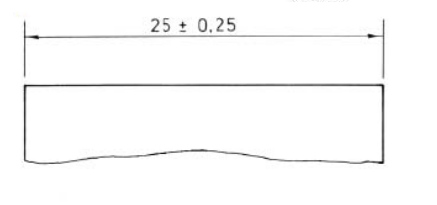

Bilateral Tolerance

Unilateral tolerance

Limits of size

Upper and lower limit is specified.

Bilateral Tolerance

Basic size, and then add/subtract the same value.

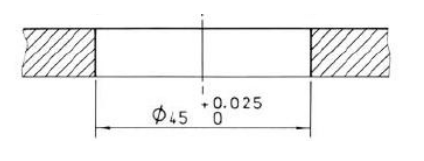

Unilateral tolerance

Only one of the upper or lower limit is specified, with variation only allowed below or above this size.

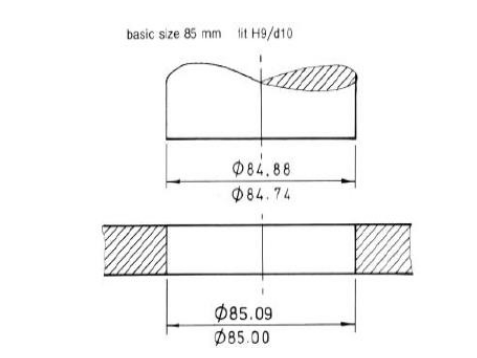

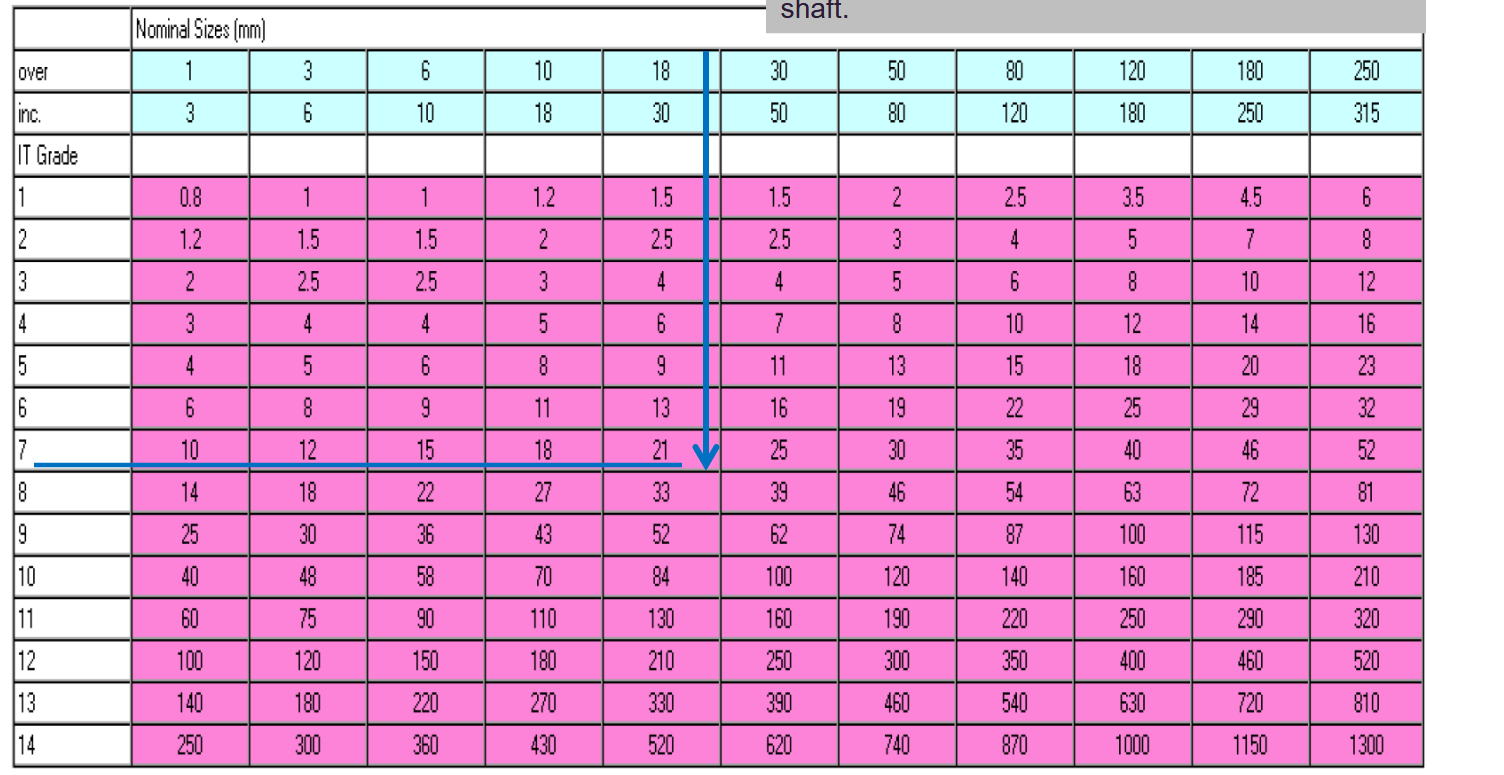

Using the table provided, find the tolerance for

Tolerance = +- 2×10^-6

Basic Size

The basic size, i.e. what it is in an ideal world.

Tolerance

Difference between max and minimum sizes.

Allowance

Difference between the mating parts.

Limits of size

The absolute maximum and minimum size possible.

Maximum/minimum material conditions

When external feature is at its upper/lowest limit, and internal is at its lowest/highest.

Fit

A fit between two parts is defined as the difference between their sizes before assembly.

3 Types of fits

Clearance fit

Interference fit

Transition fit

Clearance fit

There is always space between the shaft and the hole.

Interference fit

The shaft is always larger than the hole.

Transition fit

The shaft may be in either clearance or interference.

Hole basis system

Hole size is fixed and shaft size is varied to give different fits.

Shaft basis system

Shaft size is fixed and hole size is varied to give different fits

Geometric dimensioning and tolerancing

Worries about the shape, not the size of said shape.

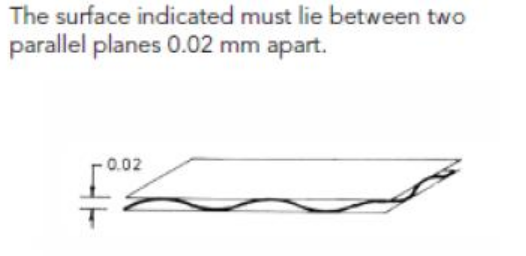

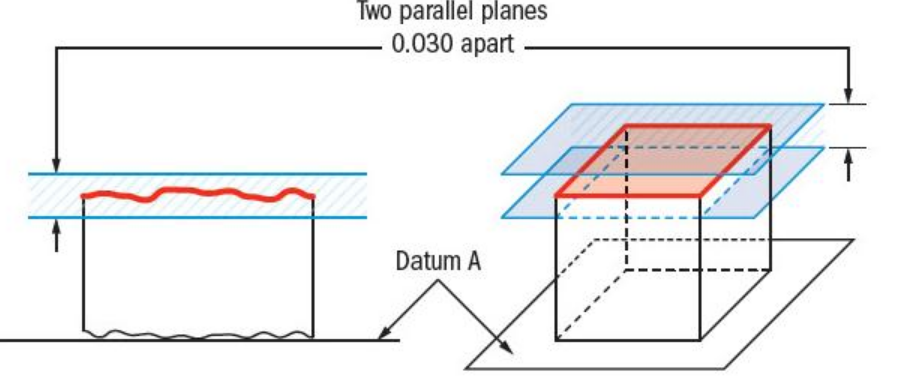

Flatness

Shape must fit between two parallel planes.

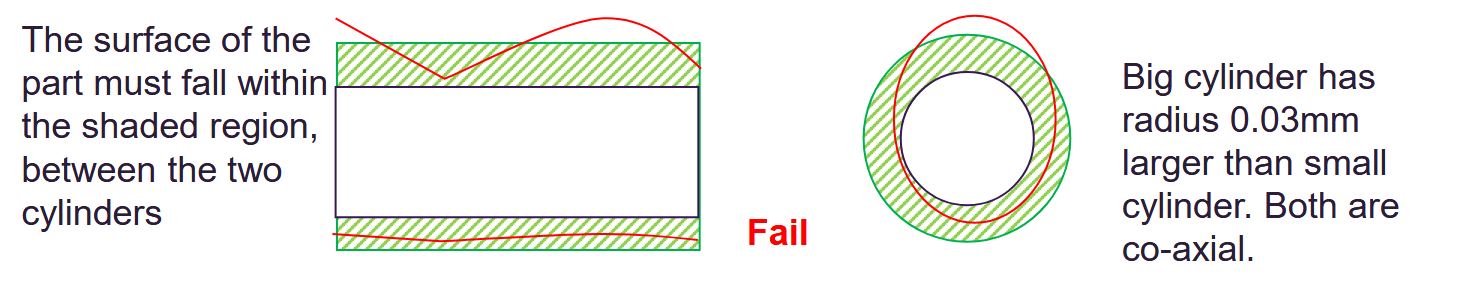

Cylindricity

Shape must fit between two cylinders, both the circles and lengthways

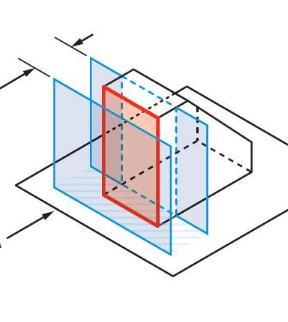

Perpendicularity

The shape must fit between two planes 90 degrees to the axis.

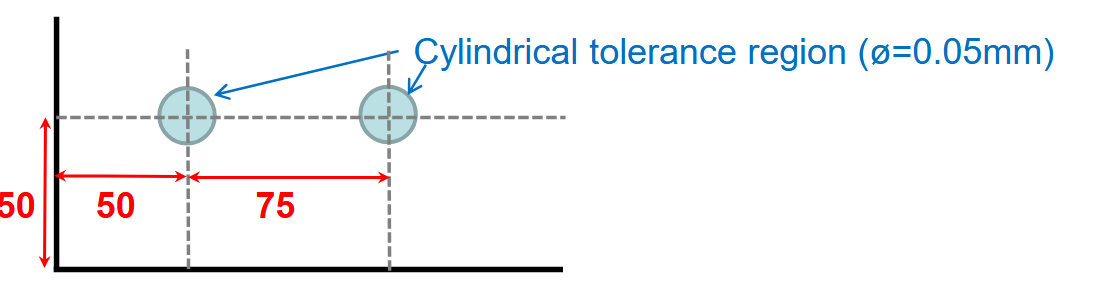

Position

Used to control location of a feature

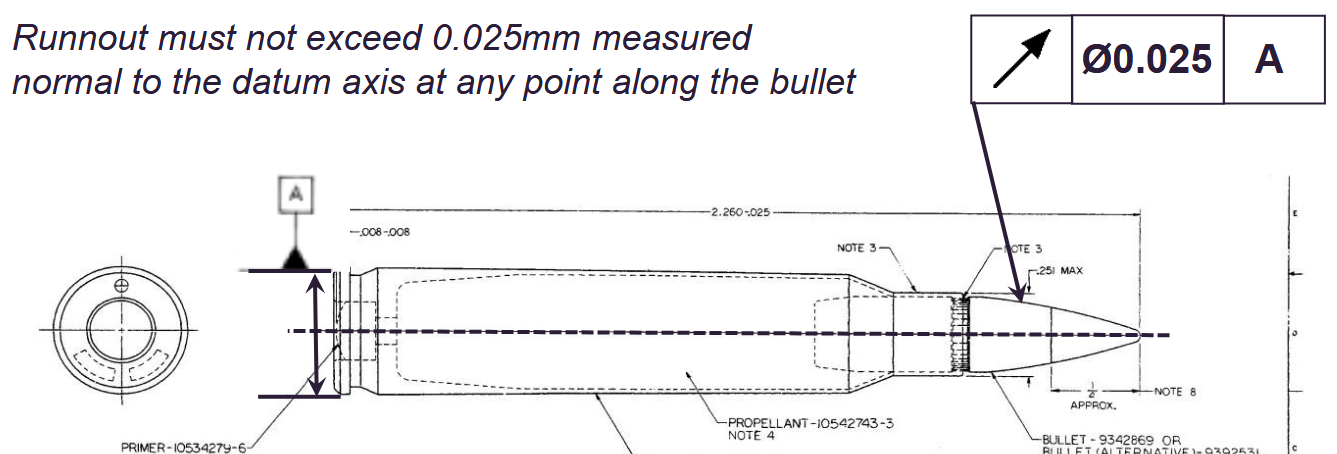

Run out tolerance

Very easy to apply, used to control location of circular part relative to its axis

Parallelism

Surface must be equidistant form planes at all times.

Flatness symbol

Parrellelogram

Cylindricity symbol

Circle between two sticks

Perpendicularity symbol

Two lines perpendicular

Position symbol

Circle with lines through middle

Concentricity symbol

Two circles around eachother

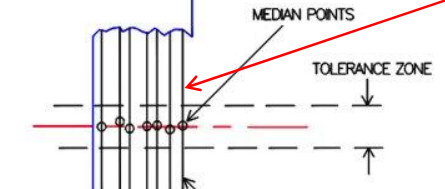

Concentricity

Used to establish a tolerance zone for median points

Run out tolerance symbol

Arrow

Parralellism symbol

two parrallel lines

Angularity

Must be between two perpendicular, bent planes.

Angularity symbol

A little angle

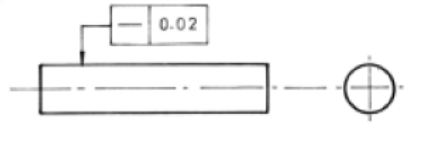

Straightness

Must fit within two straight lines

Straightness symbol

Flat, singular line

Maximum material condition

Tolerance only applies when feature is at its maximum size, i.e. if lower, tolerance can be increased to what the greatest would actually be.

Least material condition

Tolerance applies when at minimum size, i.e. if actual size is larger the minimum size, can go further below the tolerance.

Basic Surface Texture

The part may be produced by any method

Material removal by machinig is required

Machining must be applied to the surface to reach the desired surface quality

Material Removal Prohibited

No metal is to be removed, the surface is produced by casting, forging, hot or cold forming etc.