Materials - Test 5

1/37

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

38 Terms

Strengthening Mechanism - Slip Systems

“The preferred planes and directions along which a crystal will deform and move.”

Planes of the highest density hold together and act like “sheets” of atoms - sliding relative to one another in a single crystal in plastic deformation.

Slip Planes

Shearing occurs on specific atomic planes.

Slip Lines/Luder Bands

When a polished metal surface plastically deforms — it is created, indicating shear.

Planar Density

How many atoms can be packed together on a crystal plane.

Strengthening Mechanism - Dislocations and Defects

An increase of the internal stress of the material results in increased strength and decreased ductility. More dislocations, stronger the material.

Dislocation Density

a measure of the number of dislocations in a unit volume of a crystalline material (total dislocation line length/volume)

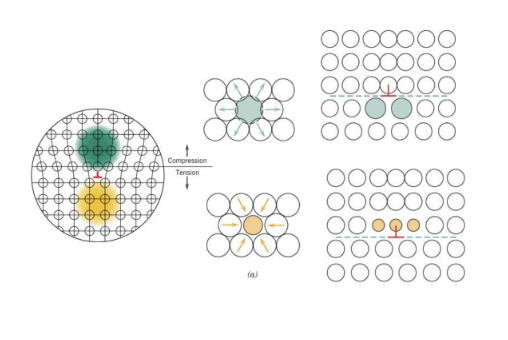

Edge Dislocation

Moves parallel to the applied shear stress. Has tensile and compressive stress fields.

Screw Dislocation

Moves perpendicular to the applied shear stress. Has shear stress fields.

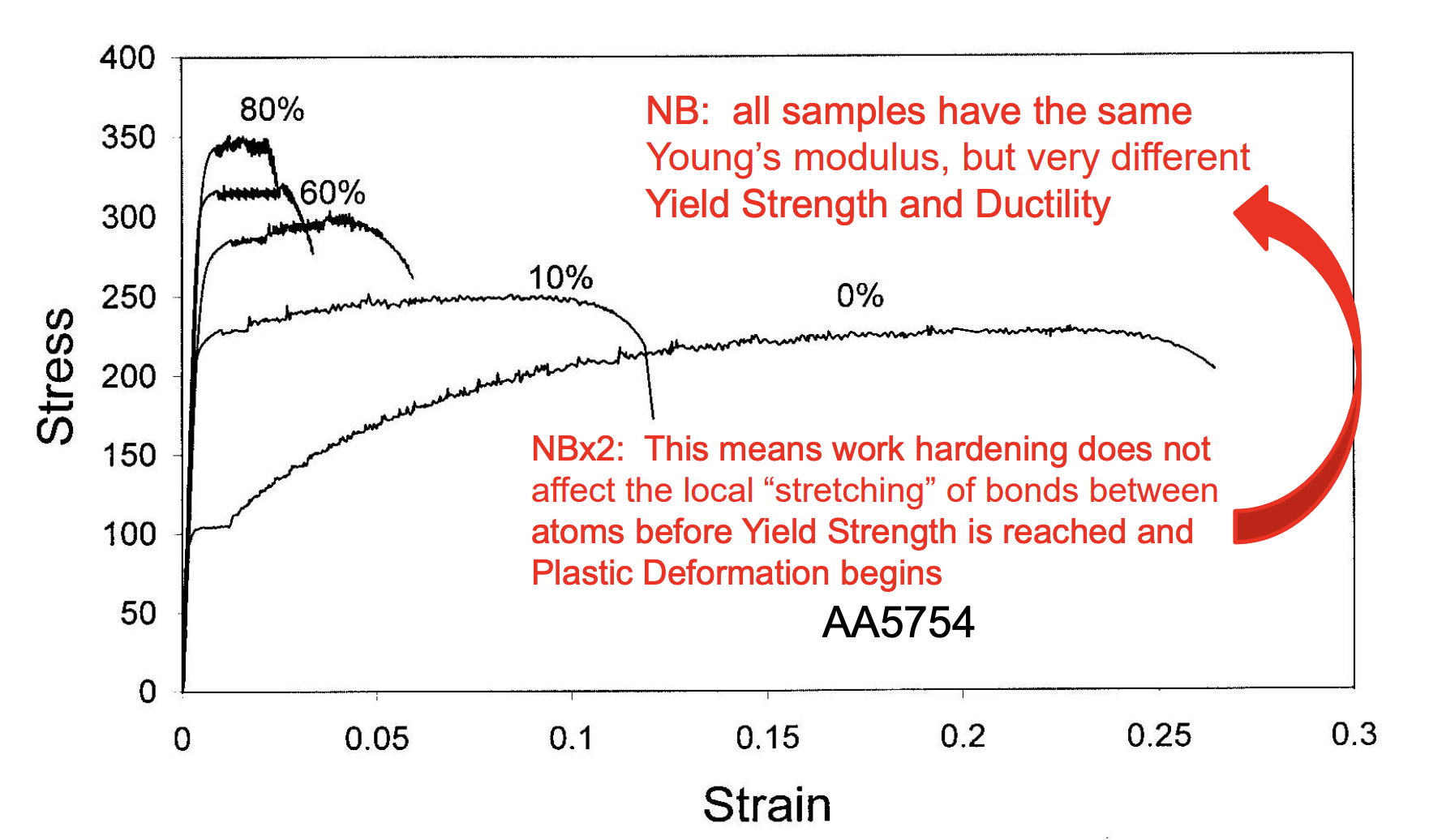

Strengthening Mechanism - Work/Strain Hardening or Cold Working

Introduces dislocations and defects into a materials - reducing/stretching grain sizes at cold temperature (below melting point)

Effects of Work Hardening

It does not affect the local “stretching” of bonds (youngs modulus before) yield strength is reached.

Homologous Temperature

A metal or alloy must be below the specified ration (T/Tmelting) in order for cold working to occur.

Strengthening Mechanisms - Grain Size

Reducing the size of grains and increasing grain boundaries increases internal stress.

How to reduce grain size?

Faster rate of cooling, work hardening.

How to increase grain size?

Due to grain boundaries high energy, higher temperatures increase grain sizes - decreases grain boundaries.

Recovery

Reduced internal stress as temperature risers due to dislocation motion.

Strengthening Mechanisms - Solid Solutions

Mixing two or more different atoms to increase internal stresses - have better mechanical properties.

Failure

Occurs at applied stress levels above the yield stress (ductile fracture) or below yield stress (creep, fatigue, or brittle fracture).

Fracture

Catastrophic breaking under constant load.

Ductile Fracture

Stable fractures that resist rupture by hardening and deforming.

Brittle Fracture

Catastrophically breaks under larger stresses.

Ductile to Brittle Transition Temperature

The temperature at which a material changes from a ductile material to a brittle material.

Stress Concentration

The increase in stress is due to cracks, defects or geometry.

Fracture Toughness

Used to combine geometric constraints with material properties to predict whether failure will occur. Measure of stress field at the crack tip.

What is the procedure for estimating whether a crack will lead to failure under an applied load?

Determine the length (a) crack geometry and mode of loading (Y)

Calculate the fracture toughness Kc for the geometry and load

Obtain the Fracture Toughness value KIc of the material

Check if Kc >=KIc

YES: Rapid Crack propagation will likely take place

NO: Check for other modes of failure that can occur (plastic deformation)

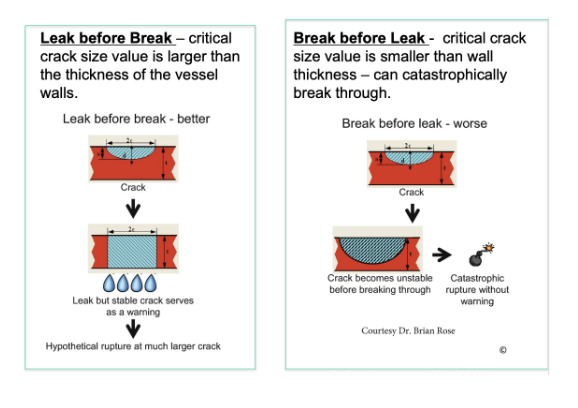

Leak Before Break

We need the critical length of a crack in a pressure vessel wall to be equivalent or greater than the thickness. This is because, it will create a stable fracture where a smaller one could cause an explosion.

Fatigue

A crack grows due to a repeated load of cycling until fracture failure occurs. It is failure that occurs below yield stress levels and is the largest cause of failure.

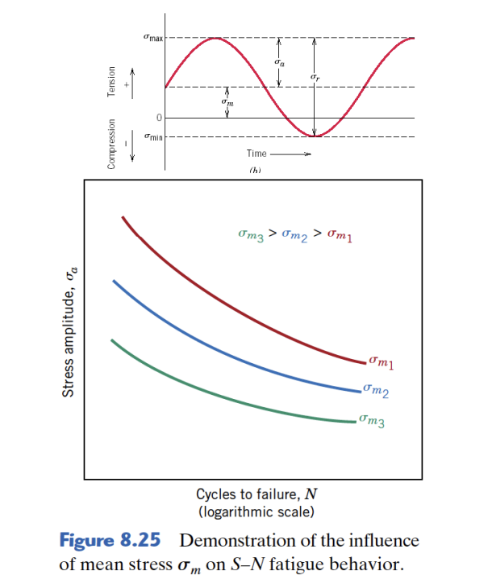

SN Curves

Predicting the operation lifetime of components gives the stress amplitude (max-min/2)

Fatigue Strength

The stress amplitude at the given number of loading cycles.

Fatigue Limit

The horizontal line on the SN graph. the stress amplitude below which fatigue does not occur.

Striations

Microscale features indicating crack origin and growth characteristics. Usually, one striation per load cycle.

Beachmarks

Macroscale feature associated with periodic start up and shut down of operation. DOES NOT reflect load cycles

Factor Affecting Fatigue: Mean Stress

Higher mean stresses have shorter lifetimes.The curve will dip lower, failing at lower stress amplitudes and cycles.

Factor Affecting Fatigue: Surface Treatment

Use Case Hardening (making the surface harder) or Shot Peening (introducing compressive stress to prevent crack propagations)

Factor Affecting Fatigue: Design Factors

Reducing stress concentration areas (ie. fillets)

Creep

Time-dependent plastic deformation at high homologous temperatures - TH > 0.4TMP

What do higher temperatures lead to?

Higher strain rates in secondary creep (2nd regime)

Higher instantaneous strain value at the time of failure

Shorter time to rupture

Higher stress can also lead to higher creep

Why does creep occur?

Stress-Induced Vacancy Diffusion

Grain Boundary Diffusion

Dislocation Motion

Grain Boundary Sliding

Dislocation Line

The boundary between a slip and unslipped portion in a crystal.