CASTING INVESTMENTS AND CASTING PROCEDURES

1/43

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

44 Terms

CASTING

production of a shape by thrusting a molten liquid or plastic material into a mold

INVESTING

process of producing the mold

covering or surrounding something

LOST WAX CASTING TECHNIQUE

Involves creating a mold by coating an expendable wax pattern with a heat-resistant slurry that hardens at room temperature

abutment

what is the tooth that holds the restoration called?

TYPE IV (DIE STONE)

TYPE V (IMPROVED GYPSUM DENTAL STONES)

what types of die stone are commonly used for making dies?

The die

where is the wax pattern made from>?

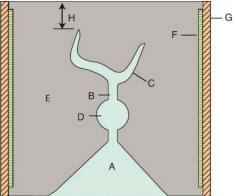

A. CRUCIBLE FORMER SPACE

B. SPRUE

C. “CROWN” SPACE

D. RESERVOIR

E. INVESTMENT MATERIAL

F. CASTING RING LINER

G. CASTING RING

label

WAX PATTERN FABRICATION

wax form that is the positive likeness of the final restoration

form a mount for the wax pattern and fix the pattern in pace so the mold can be made

hold the wax pattern in position

be an avenue where molten metal can go to the mold of the restoration

channel for elimination of wax during burnout procedure

what is the purpose of a sprue?

Shrinks

What happens to molten metal when it sets?

Sprue and reservoir

What are the things that contribute to the compensation for the setting shrinkage of the molten alloy?

same size as the thickest bulk of the pattern

what should the diameter of the sprue be?

“suck-back” porosity

distortion due to pressure

porosity bc of difficulty of metal going through

large sprue + thick wax pattern =

thick sprue + thin wax pattern =

thin sprue + thick wax pattern =

point of greatest bulk in the pattern.

where should the sprue former be placed?

sprue will deform

what happens if you place the sprue on a thin portion of the wax pattern?

it will have a thick clearance

it will have a big space on the top which makes it hard for gasses to escape

\the metal would not flow

What happens if the sprue length is too long?

there is inadequate clearance

there is a short space from the top which makes it easy for gasses to escape

there is a possibility for the material to fracture/break

what happens if the sprue length is too short?

GYPSUM BONDED INVESTMENT - 6mm

PHOSPHATE BONDED INVESTMENT - 3-4mm

what is the clearance needed for the typed of investment materials?

CASTIING RING LINER

lines the interal diameter of the ring

CASTING RING

metal tube in whcih a refractory mold is made for casting dental restorations

CONTAINER for investment material while it sets

COMPLETE RING

SPLIT RING - kayang bumuka without a liner to allow for expansion

What are the kinds of casting rings?

CASTING RING LINER

allows for greater setting expansion in the investment material

has the ability to absorb water especially if cellulose or paper is used

happens when gypsum produce is allowed to set while in contact with water

what is hygroscopic setting expansion?

there will be thin and thick areas that will lead to deformities

what happens if the liner overlaps in the ring?

3mm from the top and bottom of the ring and should be at least 1mm thick for it to allow expansion

what is the clearance for the casting ring liner?

ASBESTOS

traditionally used; carcinogenic

ALUMINOSIICATE CERAMICS

CELLULOSE

light paper; usually used now

what are options for materials to use as a liner?

DRY

uses sticky wax

may involve semi- hygroscopic setting expansion if placed in water after pouring

WET

helps cause semi-hygroscopic setting expansion

uniformly wet

avoid squeezing

what are the casting ring liner technques?

REFRACTORY AND THERMALLY STABLE

NO CHEMICAL INTERACTION WITH METAL SURFACE

EASY TO REMOVE FROM METAL CASTING

requirements for investment material?

for casting GOLD alloys

it cannot be used for other alloys

what are gypsum bonded investments used for?

BINDER

a-hemihydrate of gypsum

FILLERS: silica polymorphs

quartz

tridymite

cristobalite

fused quartz

MODIFYIG AGENTS

COLORING MATTER

REDUCING AGENTS

what is the composition of gypsum bonded investments?

for alloys with a higher melting temperature

what are phosphate bonded investments used for

PHOSPHATE BONDED INVESTMENTS

which investment material should you use if your alloy has a higher melting temperature?

SILICA FILLER: 80% BY WEIGHT

BINDER

magnesium oxide (basic)

monoammonium phosphate (acidic)

composition of phosphate bonded investments?

FILLERS

silica and magnesium oxide

BINDER

silica gel that reverts to silica (cristobalite) on heating

composition of ethyl silicate bonded investments

HAND INVESTING

VACUUM INVESTING

PAINT-OFF TECHNIQUE

Methods of investing?

HAND INVESTING

manual mixing and pouring of investment

VACUUM INVESTING

mixing of material is completed in a vacuum

porosity is reduced

smoother texture and with better detail

tensile strength increased

eliminates porosities and bubbles

PAINT-OFF TECHNIQUE

done after mixing

wax pattern is painted with wet investment material

GYPSUM BONDED INVESTMENT

Hygroscopic expansion technique: 500C

thermal expansion technique: 700C

PHOSPHATE BONDED INVESTMENT

700-1300C

ETHYL SILICATE BONDED INVESTMENT

1090C

burnout temperature for different types of investments

SIZE OF RING

BURNOUT TEMP

NUMBER OF RIGS

TEMP OF OVEN AT THE START OF BURNOUT

factors affecting burnout time

WAX EXPANSION

SETTING EXPANSION

HYGROSCOPIC EXPANSION

THERMAL EXPANSION

compensation for shrinkage of metal after cooling

CASTING

Process of filling the space with molten metal

HEAT SOURCE AND CASTING FORCE

basic requirements of casting

DISTORTION

SURFACE ROUGHNESS, IRREGULARITIES

POROSITY

INCOMPLETE CASTING

defects in casting