2. GERTC MSTC Looksfam: Nunnally

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

51 Terms

40%

Find the swell of a soil that weighs 1661 kg/m3 in its natural state and 1186 kg/m3 after excavation.

20%

Find the shrinkage of a soil that weighs 1661 kg/m3 in its natural state and 2077 kg/m3 after compaction.

Load factor = 0.70, Shrinkage factor = 0.80

A soil weighs 1163 kg/LCM, 1661 kg/BCM, and 2077 kg/CCM. Find the load factor and shrinkage factor for the soil.

415,310 BCM, 332,248 CCM

CE Board Nov 2018 A soil weighs 1163 kg/LCM, 1661 kg/BCM, and 2077 kg/CCM. How many bank cubic meters (BCM) and compacted cubic yards meters (CCM) are contained in 593,300 LCM of this soil?

Base width = 7.45 m, Height = 2.80 m

CE Board May 2019 Find the base width and height of a triangular spoil bank containing 76.5 BCM if the pile length is 9.14 m, the soil’s angle of repose is 37°, and its swell is 25%.

Base diameter = 10.16 m, Height = 3.17 m

Find the base diameter and height of a conical spoil pile that will contain 76.5 BCM of excavation if the soil's angle of repose is 32° and its swell is 12%.

146.6 BCM

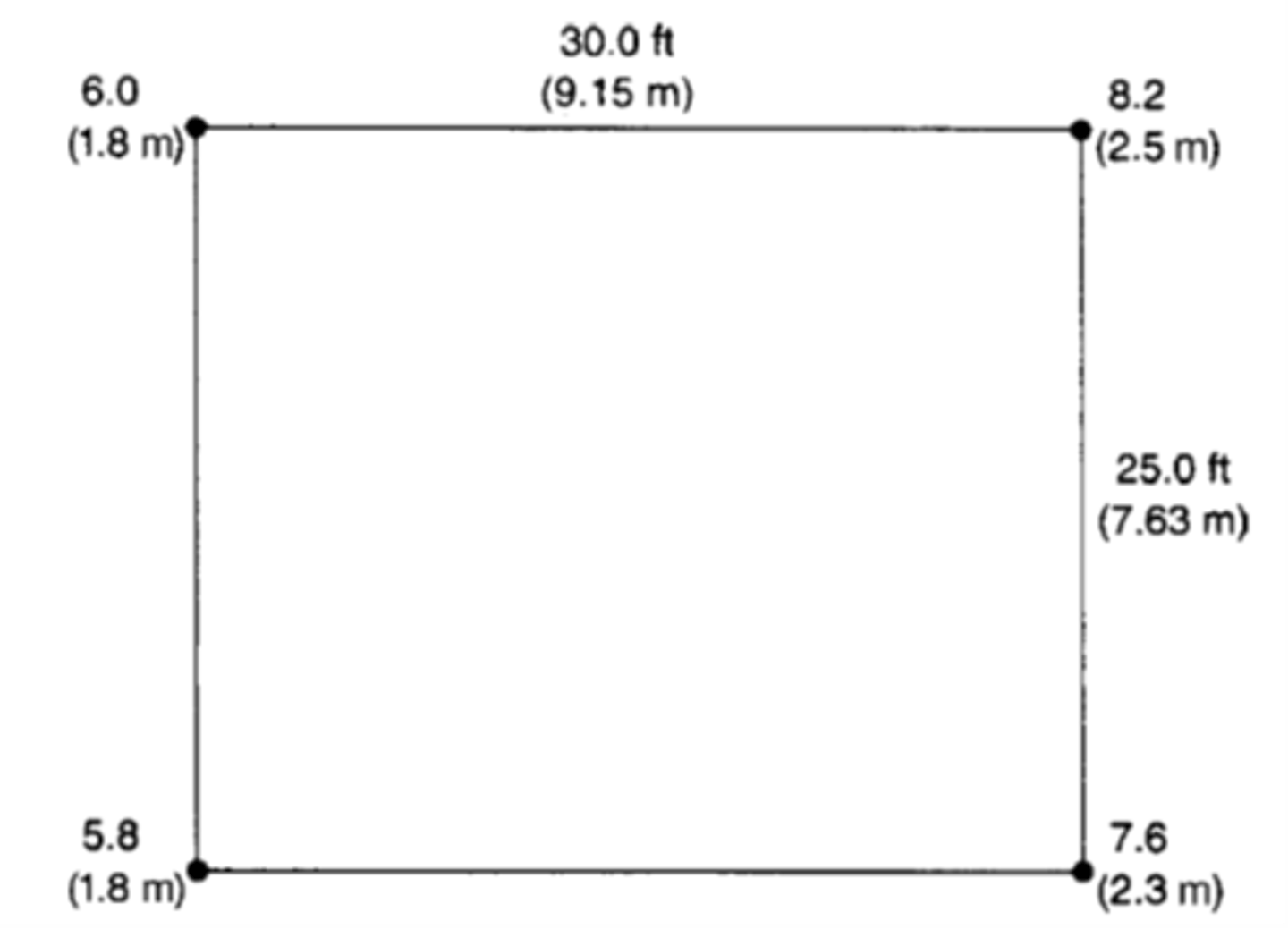

Estimate the volume of excavation required (bank measure) for the basement shown. Values shown at each corner are depths of excavation. All values are in feet (m).

255 BCM

Find the volume (bank measure) of excavation required for a trench 0.92 m wide, 1.83 m deep, and 152 m long. Assume that the trench sides will be approximately vertical.

14,596 BCM

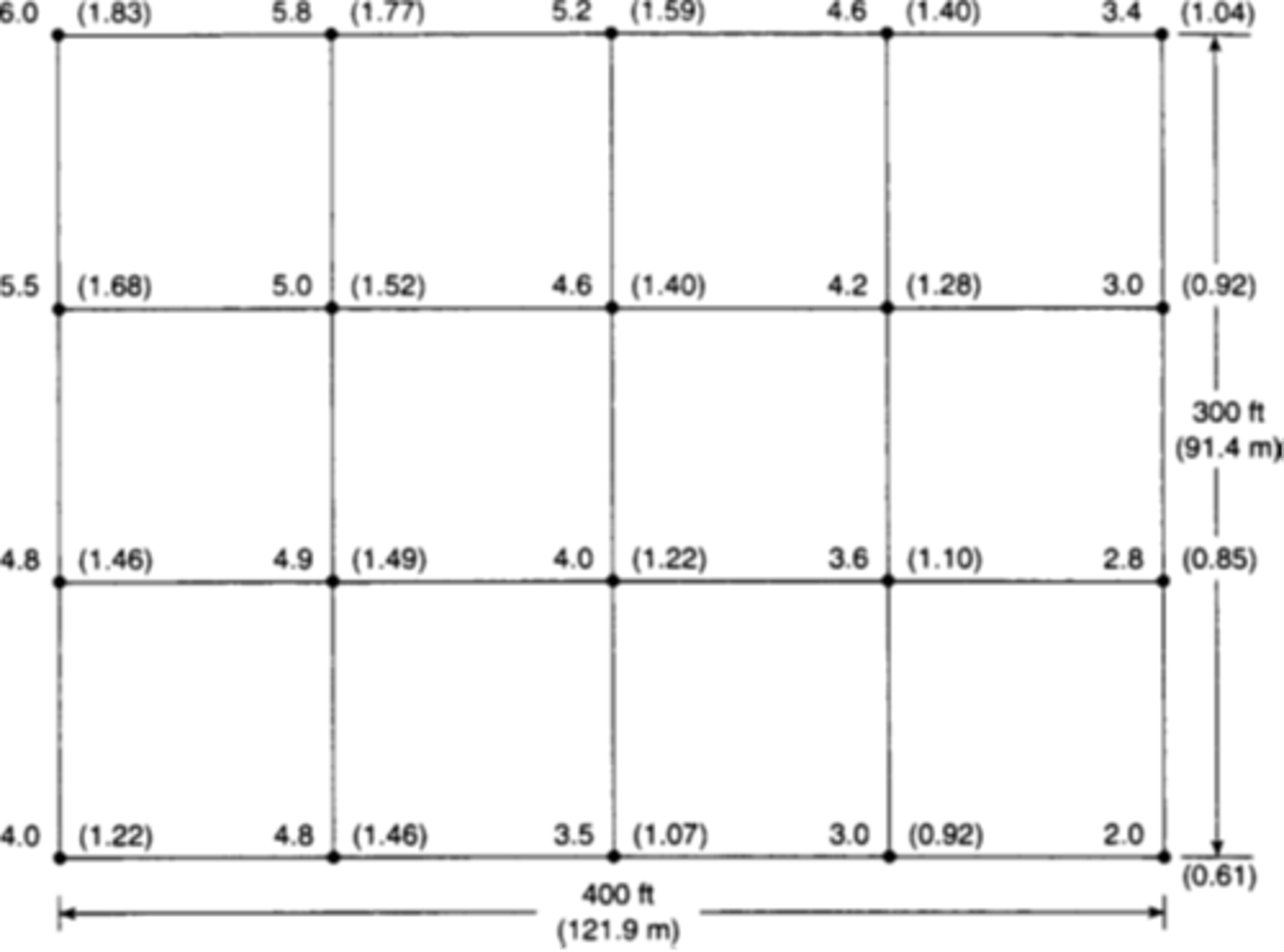

Find the volume of excavation required for the area shown. The figure at each grid intersection represents the depth of cut at that location. Depths in parentheses represent meters.

2.75 BCM

CE Board May 2022 Estimate the actual bucket load in bank cubic yards for a loader bucket whose heaped capacity is 3.82 m3. The soil’s bucket fill factor is 0.90 and its load factor is 0.80.

113 LCM/h

CE Board Nov 2021, May 2022, Nov 2023, and April 2024 Find the expected production in loose cubic meters (LCM) per hour of a small hydraulic excavator. Heaped bucket capacity is 0.57 m3. The material is sand and gravel with a bucket fill factor of 0.95. Job efficiency is 50 min/h. Average depth of cut is 4.3 m. Maximum depth of cut is 6.1 m and average swing is 90.

Hint: Production (LCM/h) = C × S × V × B × E, Cycle output = 250 cycles/60 min, Swing-depth factor = 1.00.

290 LCM/h

Find the expected production in loose cubic yards (LCM) per hour of a 2.3-m3 hydraulic shovel equipped with a front-dump bucket. The material is common earth with a bucket fill factor of 1.0. The average angle of swing is 75° and job efficiency is 0.80.

Hint: Production (LCM/h) = C × S × V × B × E, Standard cycles = 150/60 min, Swing factor = 1.05.

165 LCM/h

Determine the expected dragline production in loose cubic yards (LCM) per hour based on the following information:

Dragline size = 1.53 m3

Swing angle = 120°

Average depth of cut = 2.4 m

Material = common earth

Job efficiency = 50 min/h

Soil swell op = 25%

Hint: Production (LCM/h) = I×S×E, Ideal output = 176 BCM/h, Optimum depth of cut = 3.0 m, Swing-depth factor = 0.90

53 LCM/h

Estimate the production in loose cubic meters per hour for a medium-weight clamshell excavating loose earth. Heaped bucket capacity is 0.75 m3. The soil is common earth with a bucket fill factor of 0.95. Estimated cycle time is 40 s. Job efficiency is estimated at 50 min/h.

Hint: Production (LCM/h) = C × V × B × E

9100 kg, 10%

CE Board Nov 2019 and Nov 2022 A wheel tractor-scraper weighing 91 t is being operated on a haul road with a tire penetration of 5 cm. What is the total resistance (kg) and effective grade when the scraper is ascending a slope of 5%.

0 kg, 0%

CE Board Nov 2022 A wheel tractor-scraper weighing 91 t is being operated on a haul road with a tire penetration of 5 cm. What is the total resistance (kg) and effective grade when the scraper is descending a slope of 5%?

5535 kg

CE Board May 2022 crawler tractor weighing 36 t is towing a rubber-tired scraper weighing 45.5 t up a grade of 4%. What is the total resistance (kg) of the combination if the rolling resistance factor is 50 kg/t?

No, because the maximum pull as limited by traction (9000 kg) is less than the required pull (10000 kg).

A four-wheel-drive tractor weighs 20,000 kg and produces a maximum rimpull of 18,160 kg at sea level. The tractor is being operated at an altitude of 3050 m on wet earth. A pull of 10,000 kg is required to move the tractor and its load. Can the tractor perform under these conditions?

Hint: Coefficient of traction = 0.45

2.4 km/h

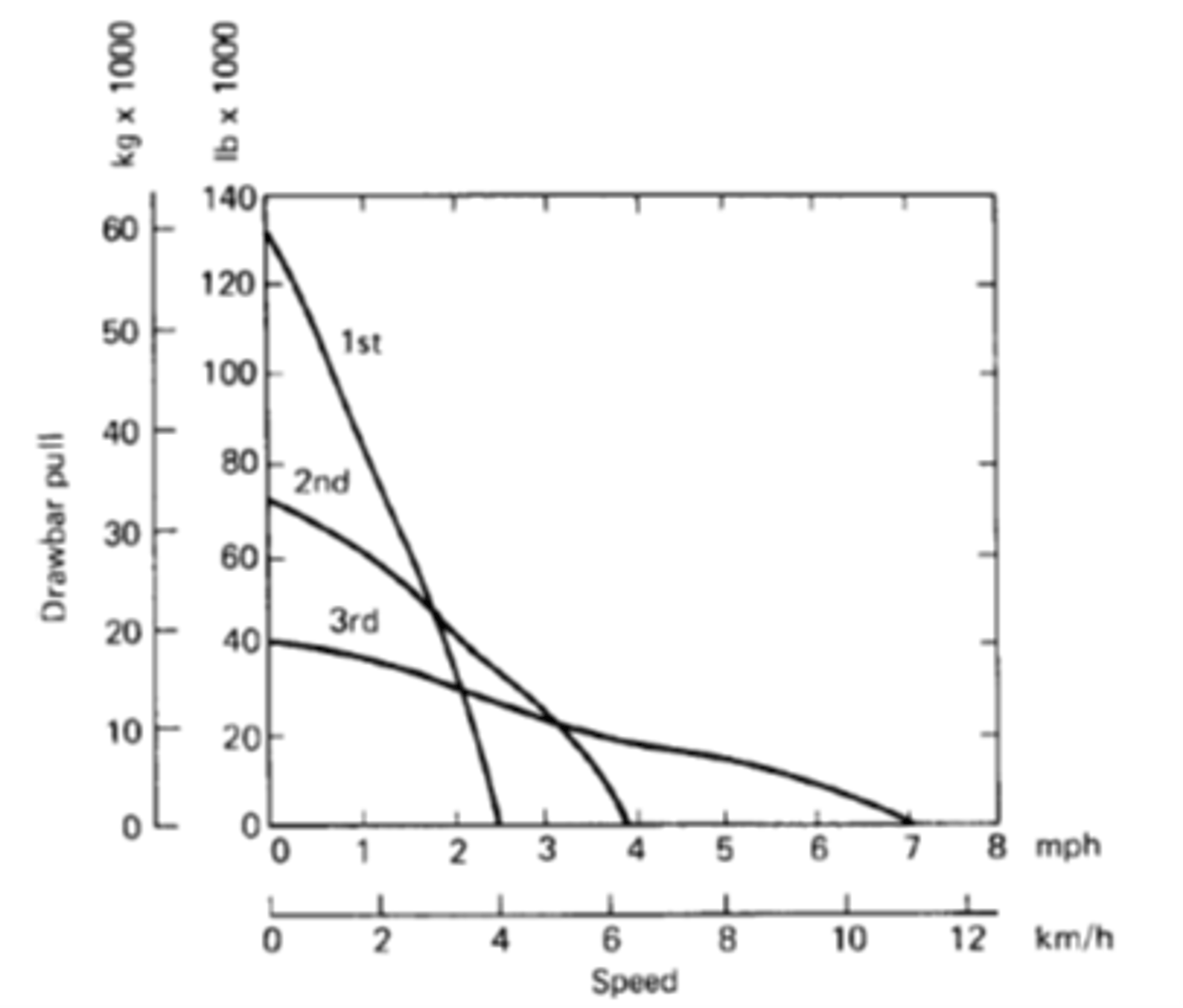

Use the performance curve below to determine the maximum speed of the tractor when the required pull (total resistance) is 27,240 kg.

10 kph

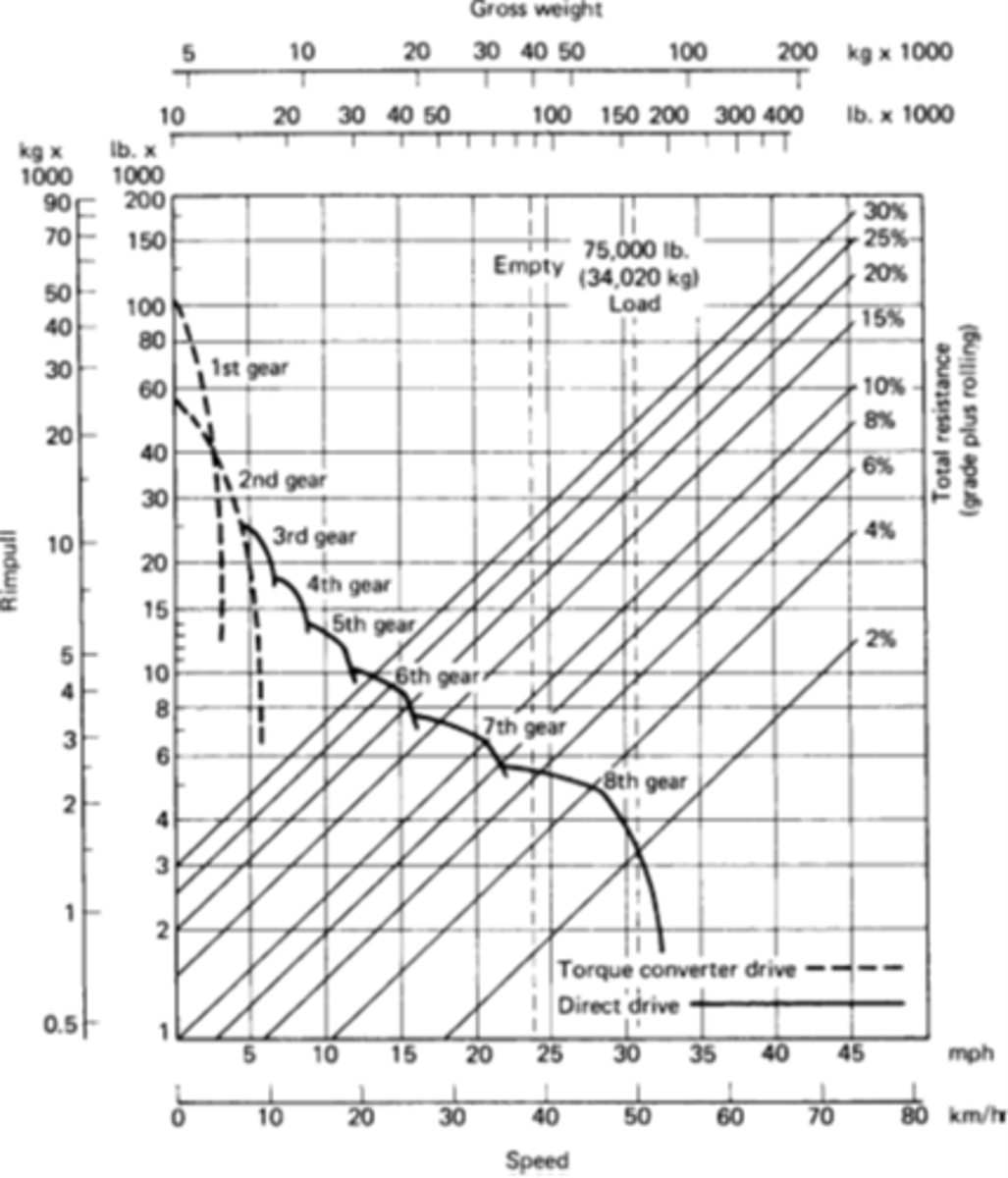

Using the performance curve below, determine the maximum speed of the vehicle if its gross weight is 68,000 kg, the total resistance is 10%, and the altitude derating factor is 25%.

271 LCM/h

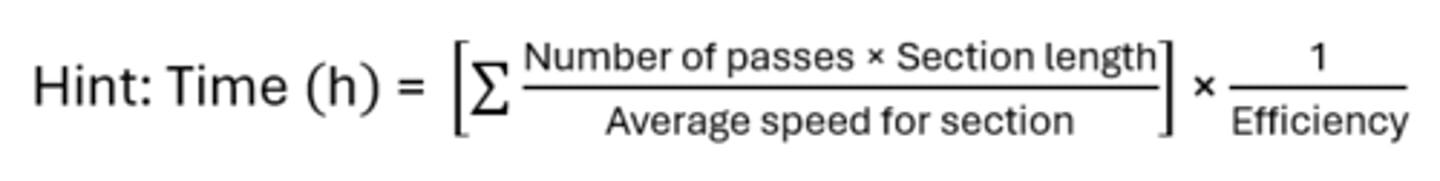

CE Board May 2022 and April 2023 A power-shift crawler tractor has a rated blade capacity of 7.65 LCM. The dozer is excavating loose common earth and pushing it a distance of 61 m. Maximum reverse speed in third range is 8 km/h. Estimate the production of the dozer if job efficiency is 50 min/h.

Hint: Production = volume × cycle per hour, Fixed time = 0.05 min, Dozing speed = 4.0 km/h

168 LCM/h

CE Board Nov 2021 Estimate the hourly production in loose volume (LCM) of a 2.68-m3 wheel loader excavating sand and gravel (average material) from a pit and moving it to a stockpile. The average haul distance is 61 m, the effective grade is 6%, the bucket fill factor is 1.00, and job efficiency is 50 min/h.

Hint: Production = volume × cycle per hour, Basic cycle time = 0.50 min, Travel time = 0.30 min

192 BCM/h

Estimate the production of a single-engine two-axle tractor scraper whose travel-time curves are shown in Figures 4 and 5 based on the following information:

Maximum heaped volume = 24 LCM

Maximum payload = 32,020 kg

Material: Sandy clay, 1898 kg/BCM, 1571 kg/LCM

Rolling resistance = 50 kg/t

Job efficiency = 50 min/h

Operating conditions = average

Single pusher

Haul route:

Section 1. Level loading area

Section 2. Down a 4% grade, 610 m (1.02 min)

Section 3. Level dumping area

Section 4. Up a 4% grade, 610 m (1.60 min)

Section 5. Level turnaround, 183 m (0.45 min)

Hint: Total fixed cycle time = 1.6 min

192 BCM/h

Solve the problem of no. 8 using the average-speed method and the performance curves of Figure 2.

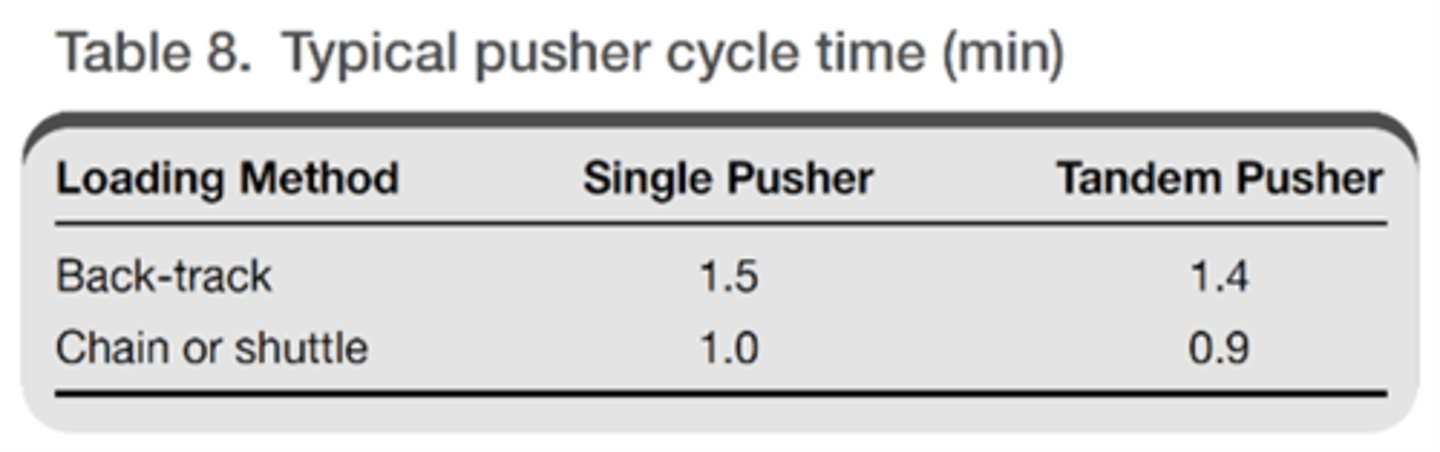

Back-track = 3, Chain = 2

The estimated cycle time for a wheel scraper is 6.5 min. Calculate the number of pushers required to serve a fleet of nine scrapers using single pushers. Determine the result for both backtrack and chain-loading methods.

1112 BCM/h

Find the expected production of the scraper fleet of no. 10 if only one pusher is available, and the chain-loading method is used. Expected production of a single scraper assuming adequate pusher support is 173 BCM/h.

11

Given the following information on a shovel/truck operation:

Shovel production at 100% efficiency = 283 BCM/h

Job efficiency = 0.75

Truck capacity = 15.3 BCM

Truck cycle time, excluding loading = 0.5 h

Calculate the number of trucks theoretically required and the production of this combination.

186 BCM/h

Given the following information on a shovel/truck operation:

Shovel production at 100% efficiency = 283 BCM/h

Job efficiency = 0.75

Truck capacity = 15.3 BCM

Truck cycle time, excluding loading = 0.5 h

Calculate the expected production if two trucks are removed from the fleet.

23.1 h

24.1 km of gravel road require reshaping and leveling. You estimate that six passes of a motor grader will be required. Based on operator skill, machine characteristics, and job conditions, you estimate two passes at 6.4 km/h, two passes at 8.0 km/h, and two passes at 9.7 km/h. If job efficiency is 0.80, how many grader hours will be required for this job?

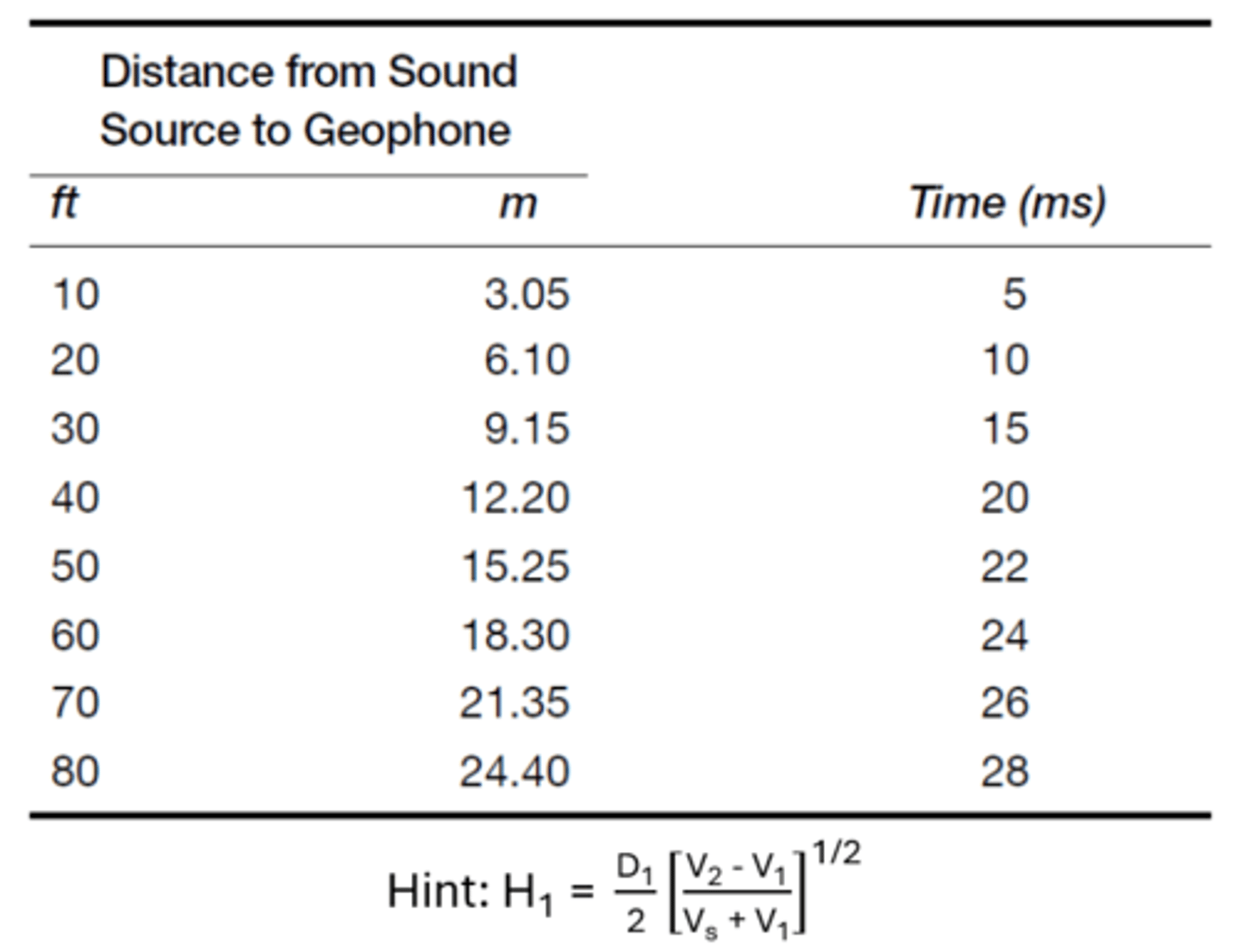

1525 m/s, 4.0 m

CE Board Dec 2024 Find the seismic wave velocity and depth of the upper soil layer based on the following refraction seismograph data:

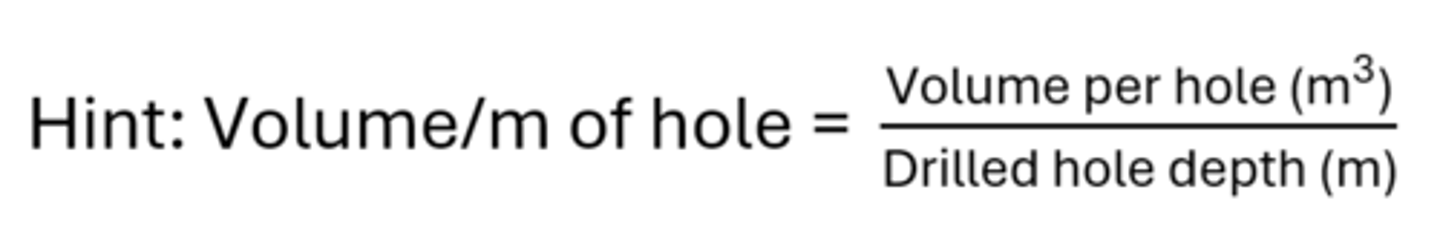

6.8 m3/m

Trial blasting indicates that a rectangular pattern of drilling using 7.6-cm holes spaced on 2.75-m centers and 6.1 m deep will produce a satisfactory rock break with a particular explosive loading. The effective hole depth resulting from the blast is 5.5 m. Determine the rock volume produced per meter of drilling.

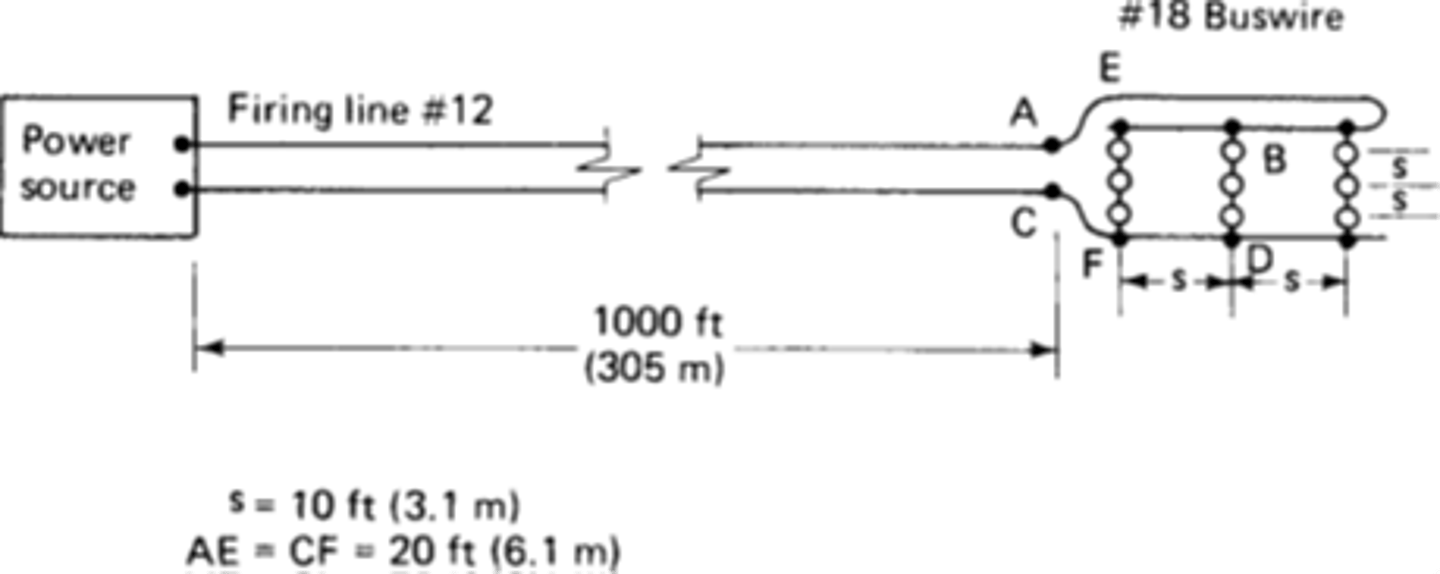

5.89Ω, 26.5 V

Analyze the cap circuit shown to determine circuit resistance and the minimum power source current and voltage necessary to fire the blasts. Caps are equipped with 9.2-m leg wires. Assume normal firing conditions.

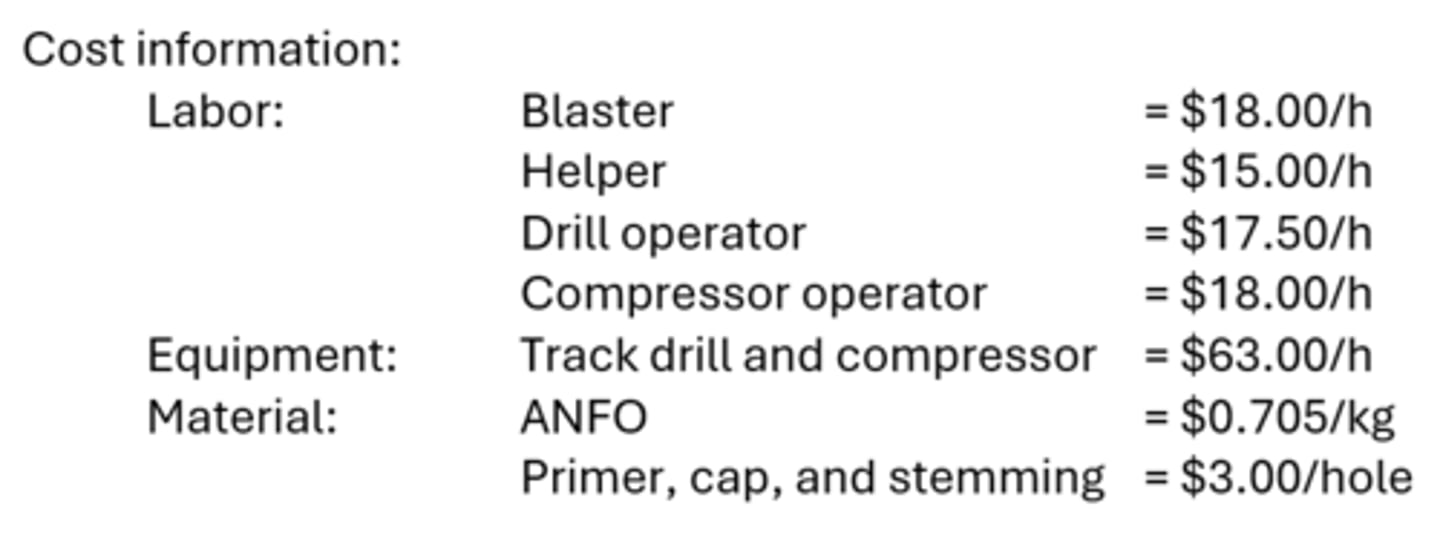

362.3 BCM/h, $0.634/BCM

Estimate the hourly production and the unit cost of the rock excavation involved in preparing an industrial building site by drilling and blasting. The site is 91.4 m by 121.9 m and must be excavated to an average depth of 3.658 m. The material to be excavated is a thinly laminated shale with a sonic velocity of 1220 m/s. The drilling equipment to be used will consist of an air-powered track drill and air compressor. The average drilling rate, including steel changes, moves, and delays, is estimated at 30.5 m/h.

Trial blasting indicates that 7.6-cm holes drilled in a 3.658-m rectangular pattern will provide adequate fracturing. A hole depth of 4.115 m must be drilled to yield a 3.658-m effective depth. The blasting agent is ANFO. A 0.23 kg of primer with an electric blasting cap will be used in each hole. The powder factor is 0.297 kg/BCM.

A labor force of one drill operator and one compressor operator will be used for drilling. One blaster and one helper will be employed in blasting.

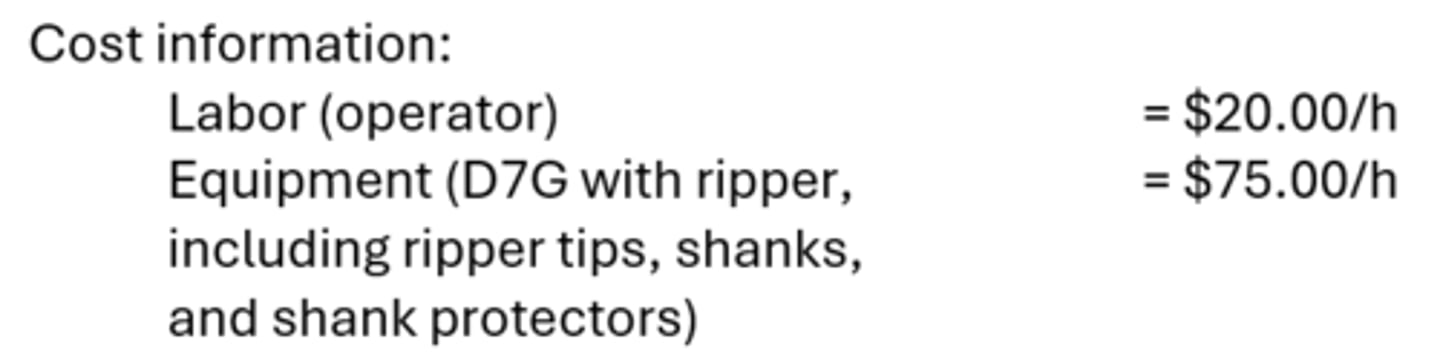

392 BCM/h

Estimate the hourly production and the unit cost of rock excavation by ripping for the problem of no. 4. Field tests indicate that a 7G dozer with ripper can obtain satisfactory rock fracturing to a depth of 0.686 m with two passes of a single ripper shank at 0.914-m intervals. Average speed, including turns, is estimated at 25 m/min.

2.9 m2

A jaw crusher is producing 227 t/h of crushed gravel and discharging it onto a three-screen deck. The top screen in the deck is a 38-mm screen. The gradation of crusher output shows 100% passing 76 mm, 92% passing 38 mm, and 80% passing 19 mm. Material weight is 1842 kg/m3. Find the minimum size of the 38-mm screen to be used. Check both total screen load and screen passing capacity.

181.4 t/h

A primary jaw crusher with a closed setting of 102 mm is producing 181 t/h. The crusher output is to be screened into the following sizes: 51 mm and over, 32 mm to 51 mm, 13 mm to 32 mm, and under 13 mm. A three-deck vibrating screen will be used to separate the stone. Jaw crusher output which does not pass the 51-mm screen will go to a roll crusher set at 51 mm. The output from the roll crusher will be fed back over the 51-mm screen. Determine the output of this plant in t/h for each of the following sizes: 32-51 mm, 13-32 mm, <13 mm.

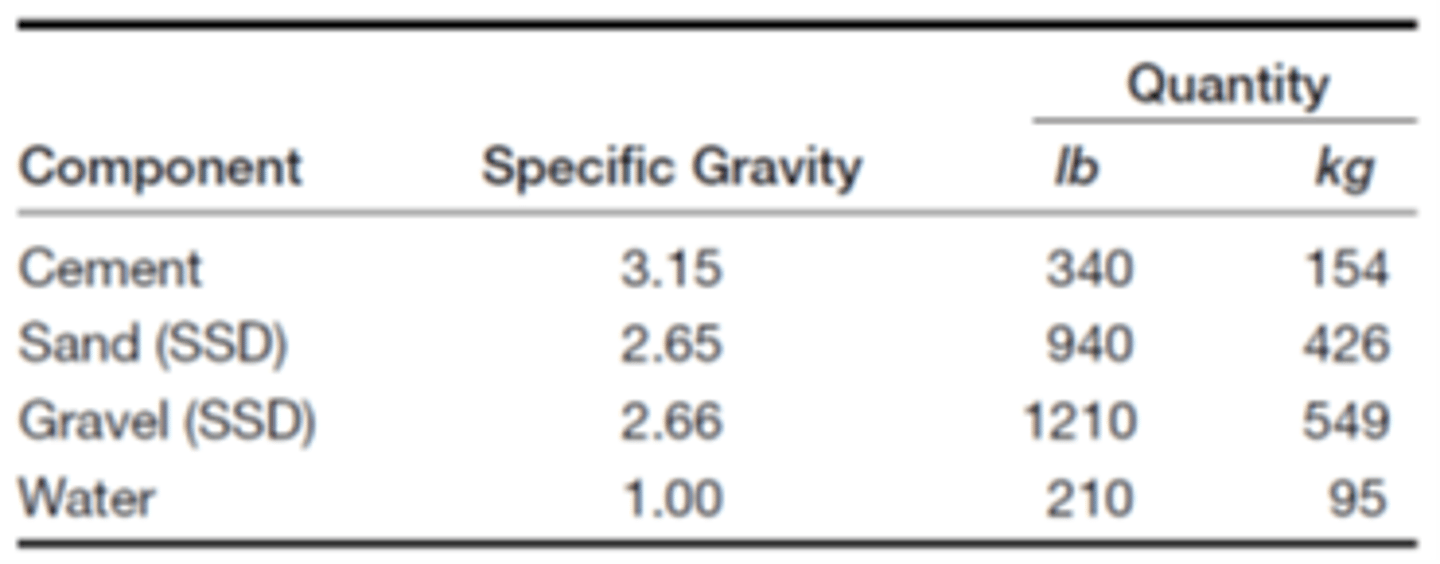

0.51 m3

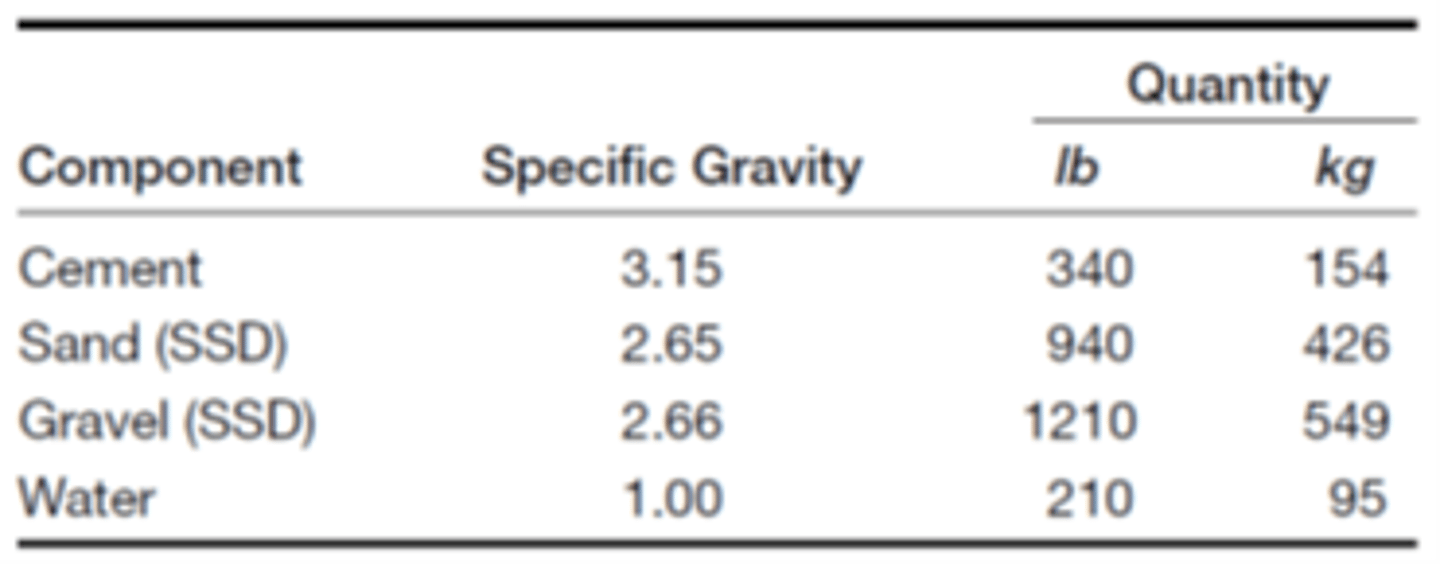

Given the mix design in the following table:

Calculate the volume of plastic concrete.

Water = 63 kg, Sand = 447 kg, Gravel = 560 kg

Given the mix design in the following table:

Determine the actual weight of each component to be added if the sand contains 5% excess moisture and the gravel contains 2% excess moisture.

Cement = 127.8 kg, Sand = 370 kg, Gravel = 464 kg, Water = 52 kg, Mix volume = 0.42 m3

Given the mix design in the following table:

Determine the weight of each component required to make a three-bag mix and the mix volume.

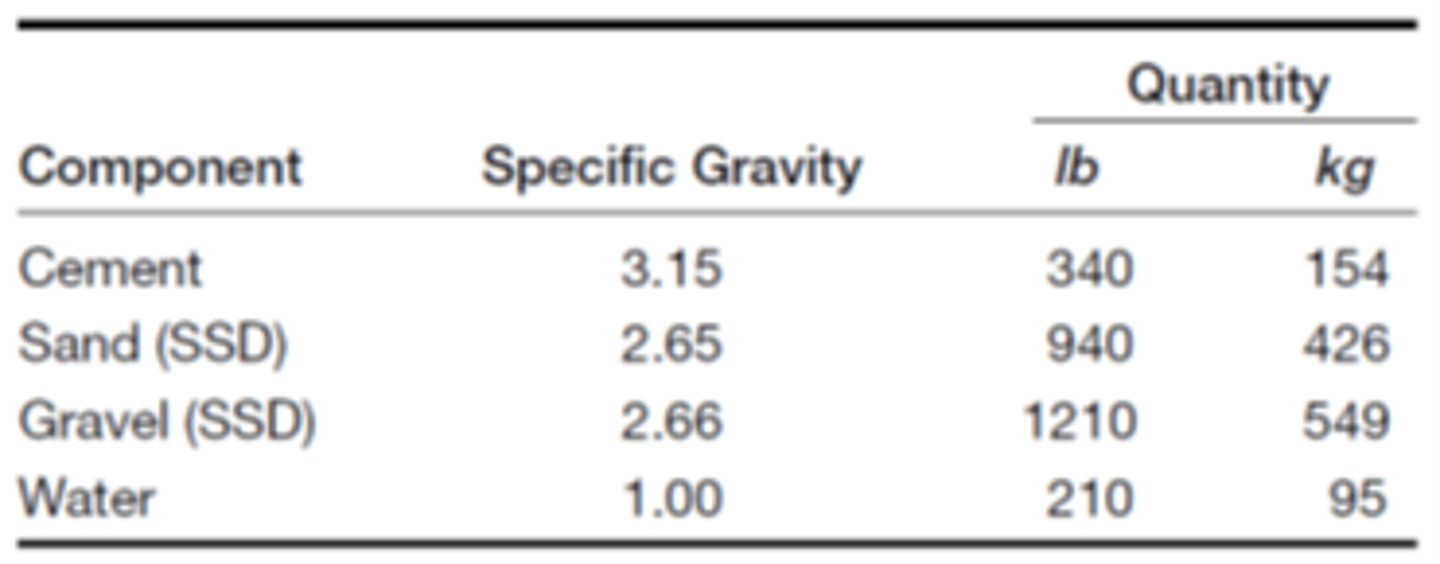

123 ton/h

Calculate the maximum hourly production of an asphalt plant based on the data in the following list.

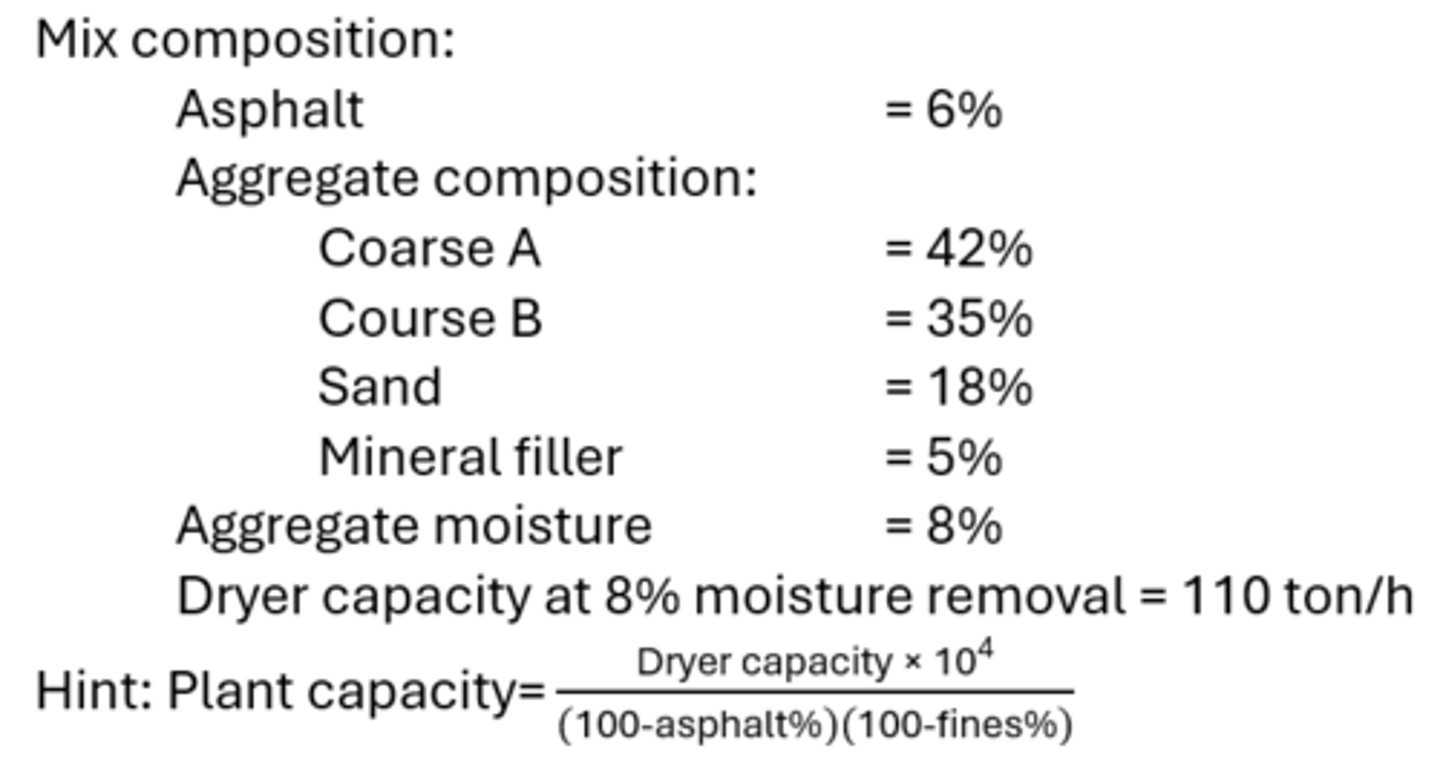

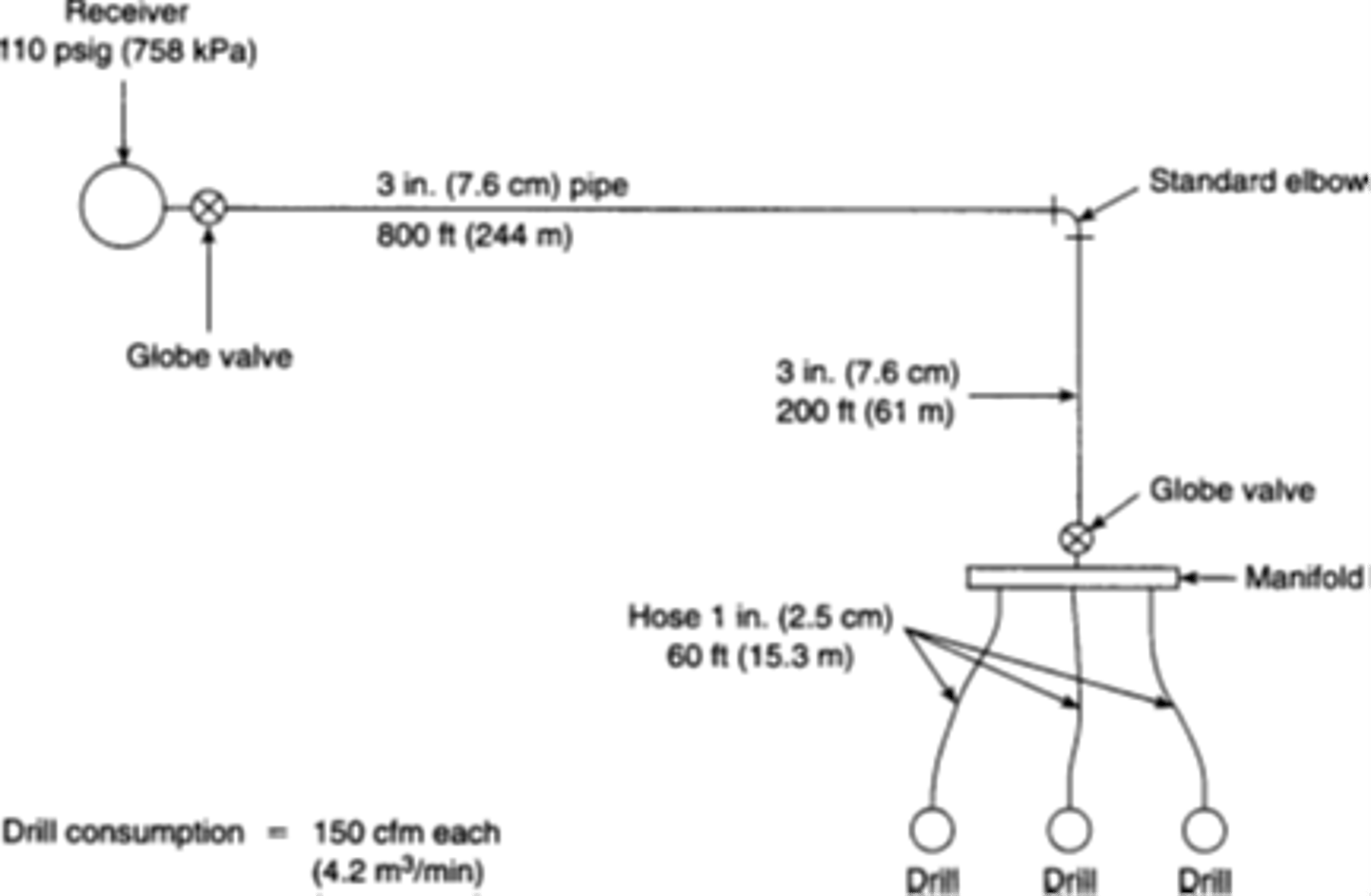

49.1 m3/min

Determine the rated size of air compressor required to operate the following tools at an altitude of 1830 m. Assume a 10% leakage loss and a job load factor of 0.80.

Hint: Altitude adjustment factor = 1.21

708.9 kPa (gauge)

The compressed air system illustrated below is being operated with a receiver pressure of 758 kPa. Pressure drop in the manifold is determined to be 13.8 kPa. If all three drills are operated simultaneously, what is the pressure at the tools? Assume no line leakage.

23.3 m

CE Board Nov 2024 Water must be pumped from a pond to an open discharge 12.2 m above the pump. The line from the pump to discharge consists of 103.7 m of 10.2-cm pipe equipped with a check valve and three standard elbows. The pump is located 3.1 m above the pond water level. The intake line consists of a 6.1-m hose 10.2 cm in diameter equipped with a foot valve. Find the total head that the pump must produce for a flow of 1060 l/min. The equivalent length of the foot valve is 21.4 m.

The 40-M pump is satisfactory.

Determine the minimum size of M-rated centrifugal pump required to pump 1060 l/min through the system of no. 3.

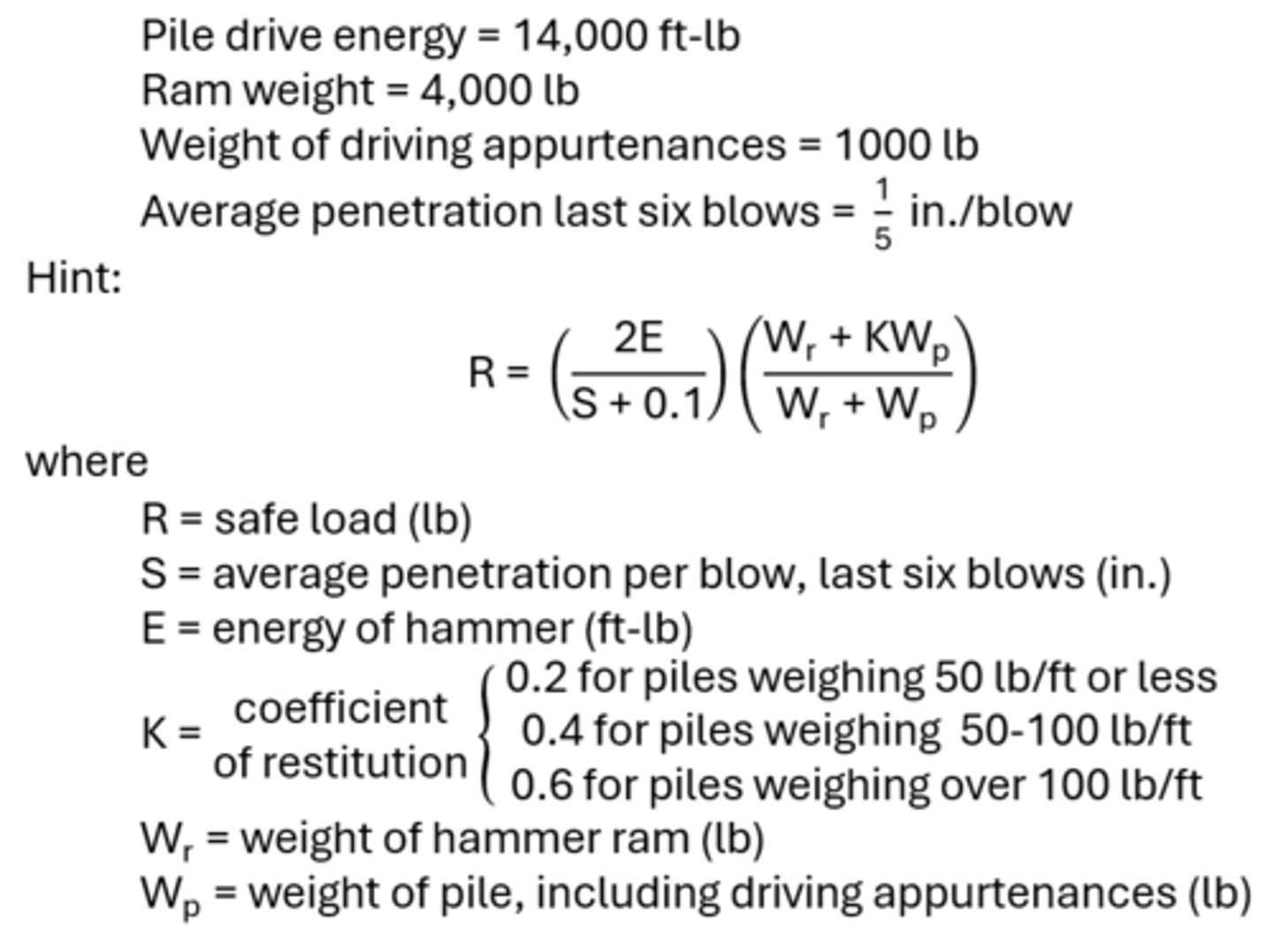

59,862 lb

CE Board April 2023 Determine the safe load capacity of a 6-in.-square concrete pile 60 ft long. Assume that the unit weight of the pile is 150 lb/cu ft.

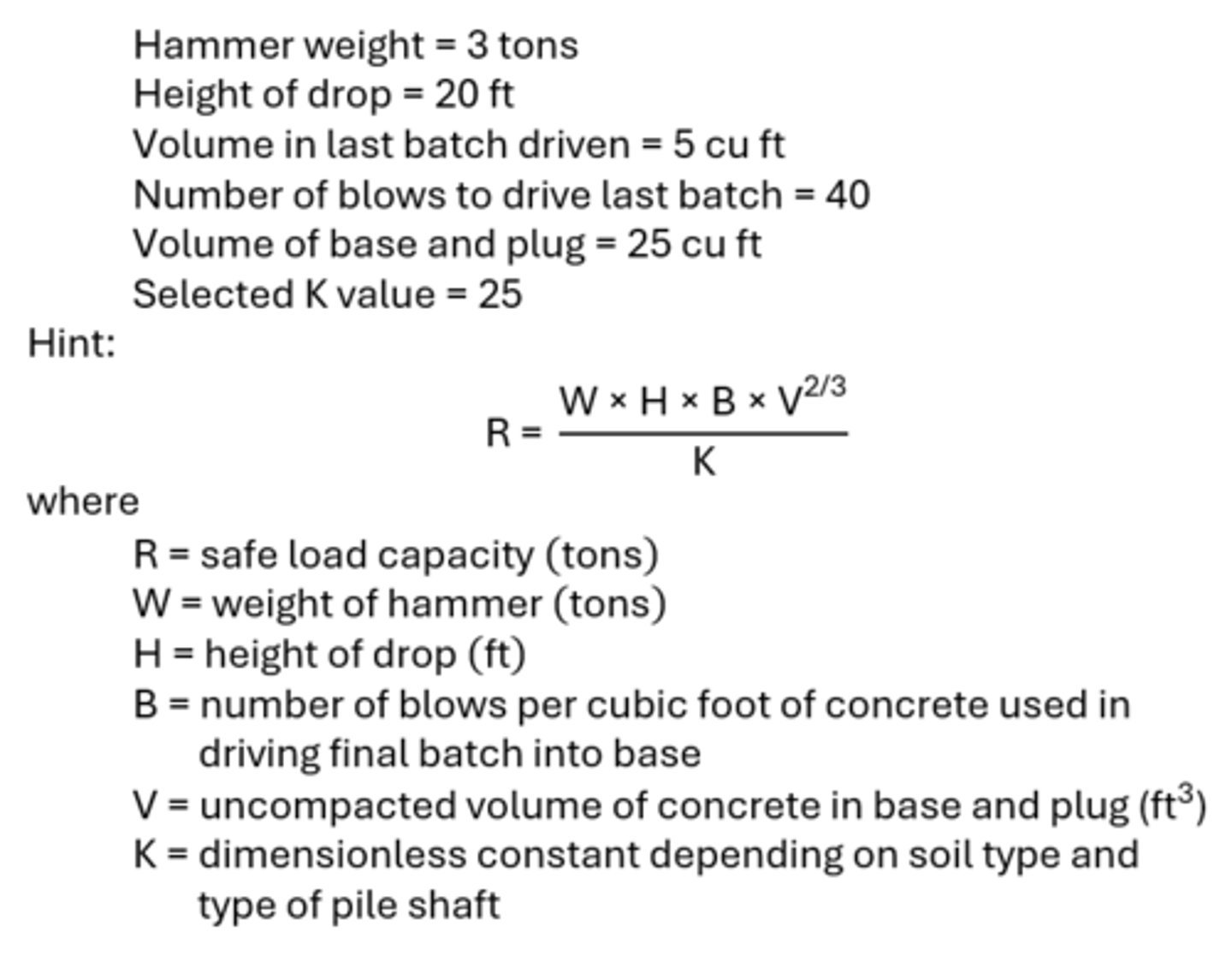

164 tons

Calculate the safe load capacity of a bulb pile based on the following driving data.

981

Calculate the number of bricks 95 × 57 × 203 mm laid in running bond required for a double wythe wall 2.44 × 4.27 m having one opening 1.22 × 1.83 m and one opening 0.81 × 1.22 m. Mortar joints are 13 mm. Allow 3% for brick waste.

0.53 m3

Estimate the quantity of mortar required for the problem of no. 1. The joint thickness between wythes is 13 mm. Assume a 25% waste factor.

1.9 m

Find the maximum safe unsupported height in feet and meters for a 20-cm heavyweight concrete block wall if the maximum expected wind velocity is 80 km/h.

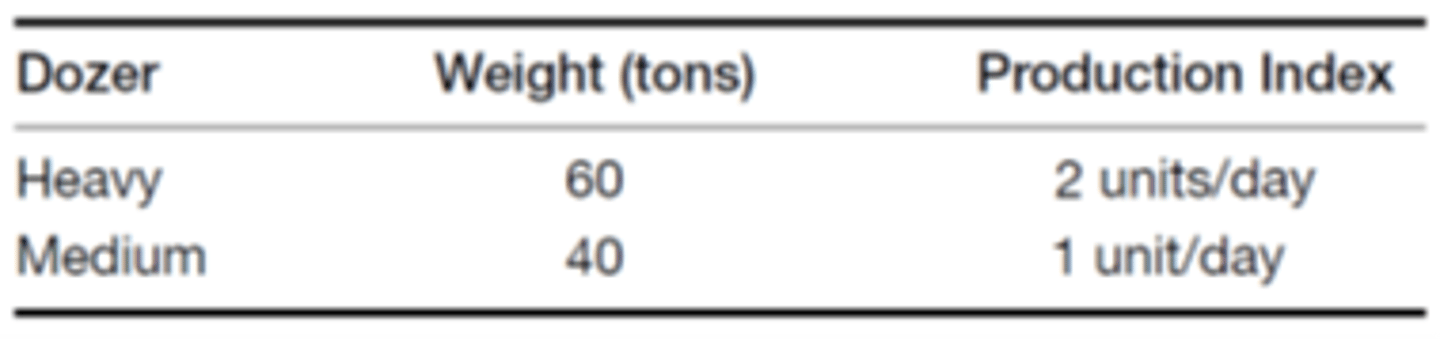

Heavy dozers = 10, Medium dozers = 12, Objective, Function = 32

A project manager for a large earthmoving project is faced with the task of selecting the dozers to be used on a relatively remote project. The project manager is advised by the equipment division manager that both heavy and medium dozers are available for the project. However, only 10 heavy dozers are available. The supply of medium dozers is relatively unlimited. Because of time and transportation limitations, a maximum of 1080 tons of dozers may be transported to the site. The project manager also has the following information on dozer performance and weight.

Plain concrete = 188.235 cu yd, Additive concrete = 282.353 cu yd, Profit = $1600.00

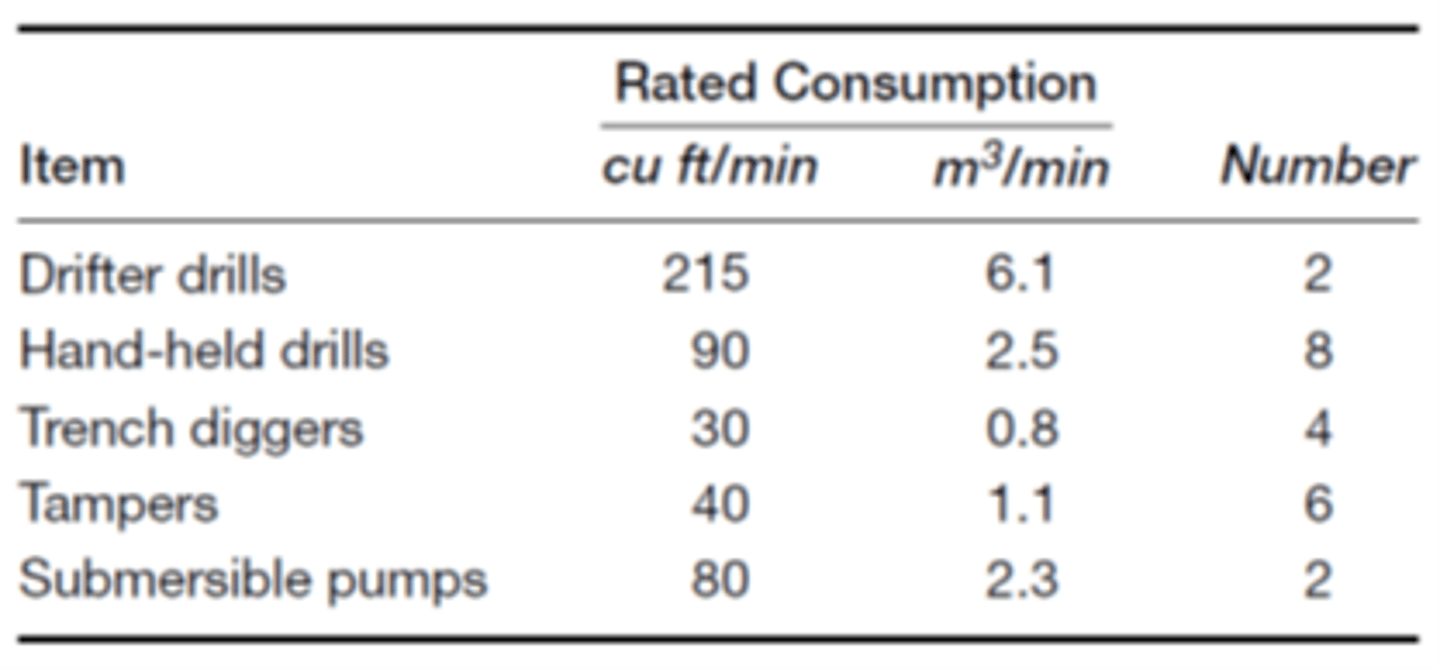

A paving contractor is planning his work schedule for the following week. He has a choice of either of two types of concrete, plain concrete or concrete with an additive. The use of additive concrete reduces concrete finishing time but increases the time required for placement.

Cost records indicate that the contractor can expect a profit of $4 per cubic yard for plain concrete and $3 per cubic yard for additive concrete. Naturally, the objective of the contractor is to maximize his profits. However, he does not want to hire additional workers. Labor requirements [in man-hours per cubic yard (mh/cu yd)] for each type of concrete are given below. Assuming that sufficient demand exists, how many cubic yards of each type of concrete should the contractor

place the following week? The contractor works a 40-h week.

![<p>A paving contractor is planning his work schedule for the following week. He has a choice of either of two types of concrete, plain concrete or concrete with an additive. The use of additive concrete reduces concrete finishing time but increases the time required for placement.</p><p>Cost records indicate that the contractor can expect a profit of $4 per cubic yard for plain concrete and $3 per cubic yard for additive concrete. Naturally, the objective of the contractor is to maximize his profits. However, he does not want to hire additional workers. Labor requirements [in man-hours per cubic yard (mh/cu yd)] for each type of concrete are given below. Assuming that sufficient demand exists, how many cubic yards of each type of concrete should the contractor</p><p>place the following week? The contractor works a 40-h week.</p>](https://knowt-user-attachments.s3.amazonaws.com/aed10eb0-1e5b-47e5-82d1-4a2e217ff401.png)