Wastewater Treatment - Midterm 2

1/73

Earn XP

Description and Tags

Mostly conceptual. Some practice of variables

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

74 Terms

Purpose of primary treatment

removal of suspended solids by sedimentation

Types of settling and sedimentation

•Type 1: Discrete particle settling

•Type 2: Flocculant settling

•Type 3: Hindered or zone settling

•Type 4: Compression settling

Discrete particle settling (key characteristics)

particles settle as individual entities. particles in low solids concentration.

Application of discrete particle settling

observed in grit chambers and presedimentation tanks

Flocculant settling (key characteristics)

In dilute suspensions of particles that coalesce (flocculate). This increases the mass of particles and settling speed.

Application of flocculant settling

In sedimentation tanks or seen in flocculant removal in clarifiers after chemical coagulation-flocculation

Hindered or zone settling (key characteristics)

in intermediate concentrations, inter-particle forces hinder settling. particles settle as a unit.

application of hindered or zone settling

in secondary clarifiers after biological treatment

compression settling (key characteristics)

high concentration of particles leads to formation of a structure. compression is required which comes from the growing weight of the structure

application of compression settling

bottom of secondary clarifiers and sludge thickeners

Sum of forces in the y direction for Discrete Particle Settling

FD = Fg - Fb = (pb - pw)gVp

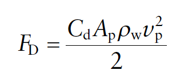

Drag Force Equation

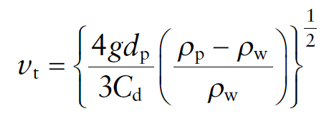

Terminal Velocity Equation

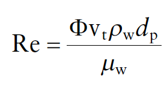

Reynolds number Equation. Phi is the particle shape factor, uw is the dynamic viscosity of water.

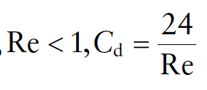

Laminar Flow

Transitional Flow

Turbulent Flow

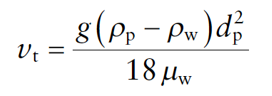

Stokes Equation. Use when flow is laminar and particles are spherical.

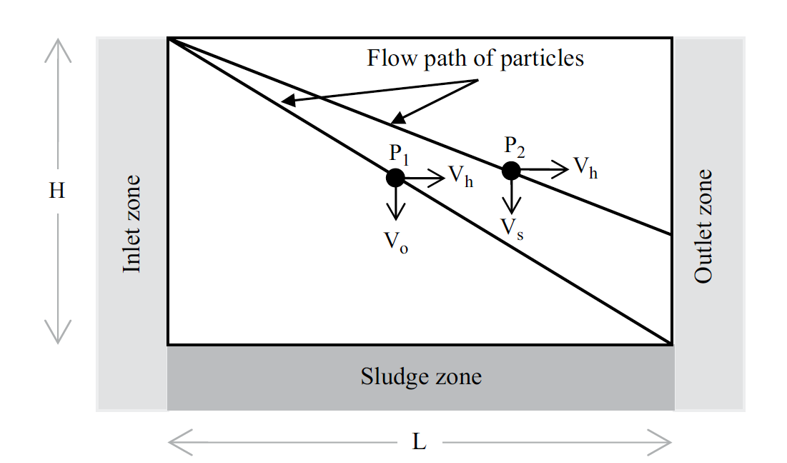

Describe the Ideal Design of a Sedimentation tank

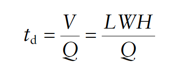

How to find detention time

What is design settling velocity, how do you find it?

Same as Surface Overflow Rate (SOR)

100% of particles will be removed if

settling velocity, vs > vo

Particles will be removed partially if

If vs < vo, percent of vs/vo

Steps for finding percent removal of particles if 100% is removed for a different size.

Assume laminar flow and calculate vt for known particle size. Check Re and recalculate if necessary until values converge.

Assume laminar flow for new particle size. find vt through the same guess and check. use vt2/vt1

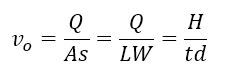

Weir Loading Rate

What happens in Secondary Treatment

Biological treatment of primary effluent wastewater

Purpose of secondary treatment

reduce BOD and suspended solids to acceptable levels. nutrients may also be removed.

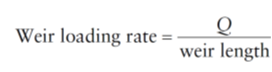

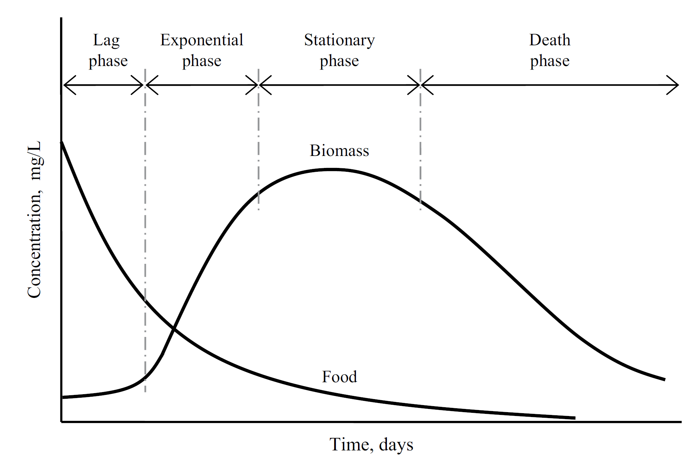

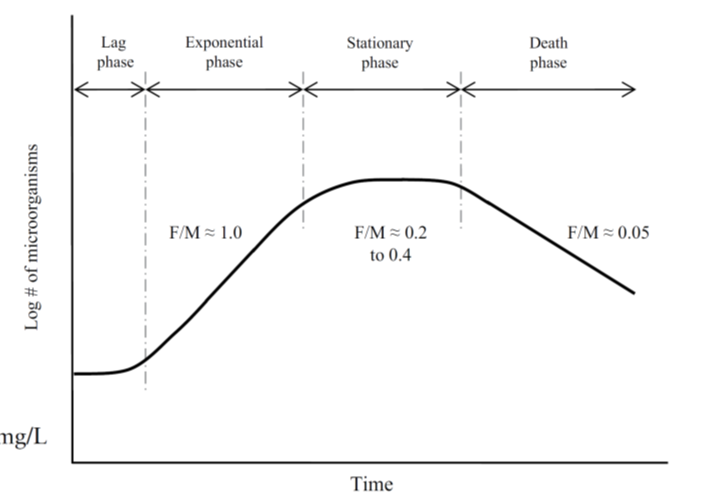

phases of biomass yield

what relationship does this curve show

microbial growth and substrate utilization

aerobic

requiring oxygen

anaerobic

no oxygen

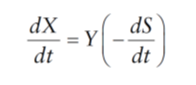

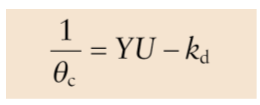

variables in this equation

biomass growth rate, biomass yield, substrate (food) utilization

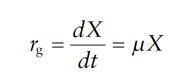

how to find biomass yield

what are the ranges for biomass yield

aerobic: 0.4 < Y < 0.8

anaerobic: 0.08 < Y < 0.2

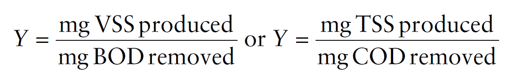

how to find biomass growth rate using specific growth rate

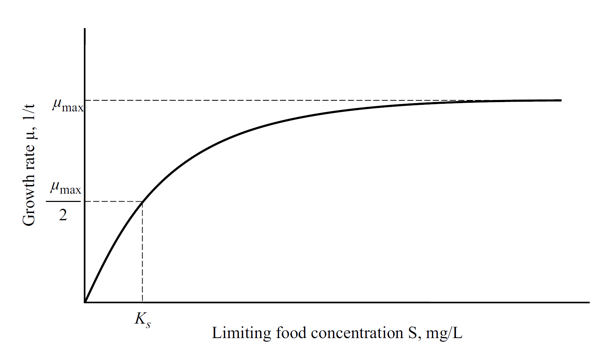

describe/draw the Monod Model

describe the variables in this equation

maximum specific growth rate, 1/days

substrate concentration, mg/L

half-saturation coefficient

the monod model at high substrate concentrations

(S » Ks) u=umax

the Monod model at low substrate concentrations

(S « Ks)

what is endogenous decay

kd, 1/days

rate of microorganisms breaking down on their own during the death and decay phase

how to find a microorganism net growth rate constant

use the net growth rate equation and divide by concentration, X to get a value in the units 1/days

what do umax and Ks describe

the organisms ability to function in the environment

High umax means

the organism will take up substrate very fast

low Ks means

the organism will take up substrate very efficiently

how to check efficiency of organisms based on umax and Ks

compare specific growth rate at initial concentration and goal concentration for both organisms

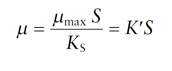

what are the 2 categories of biological treatment

suspended growth

attached growth

what is suspended growth

microorganisms are kept in suspension in a biological reactor to treat organic matter

3 components of suspended growth

a bio reactor with aerated microorganisms in suspension

sedimentation tank or clarifier

recycle system to return settled solids from the clarifier to the reactor

what is MLSS

Mixed Liquor Suspended Solids. Concentration of solids/microorganisms in a reactor (X)

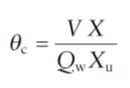

what is SRT

Solids Retention Time (theta c). mass of solids in a reactor divided by the mass of solids wasted per day

what does the F/M ratio describe

The ratio of Food to Microorganisms in a reactor

describe/ draw the F/M ratios during microbial growth

lag phase

exponential phase - F/M = 1

stationary phase - 0.2 < F/M < 0.4

death phase - F/M = 0.05

what is the volumetric loading rate

(VL) is the mass of substrate/food per unit volume

units of volumetric loading rate

kg/m³d

what is HRT

Hydraulic Retention Time: time spent by a fluid particle in a reactor before discharge (theta)

what is the common range of HRT

3-8 hours

describe the graphical representation of this equation

a graph of 1/SRT vs the specific substrate utilization, U, would have a slop of Y and an intercept of kd.

how to find mass and volume of solids wasted per day

mass = Qw x Xu

volume = Qw

Types of suspended growth processes

conventional

oxidation ditch

sequencing batch reactor

membrane biological reactor

types of conventional activated sludge processes

•Step aeration or step feed process

•Tapered aeration process

•Contact stabilization process

•Staged activated sludge process

•Extended aeration process

Describe a Sequencing Batch Reactor (SBR)

A Fill-and -draw-type reactor where all processes (aeration, biodegradation, and settling) occur in a single reactor

Describe a Membrane biological reactor (MBR)

Uses a biological reactor with suspended biomass for BOD and/or nitrogen removal, and uses filtration membranes for solid separation

Advantages of a MBR

Can operate at high MLSS, can handle high volumetric loading and short hydraulic retention times. creates less sludge with a longer SRT and does not require a secondary clarifier. also lowers TSS, BOD, pathogens and turbidity

Disadvantages of a MBR

high capital cost, high membrane replacement cost, high energy cost

Stabilization ponds and lagoons

large earthen basins in which wastewater is retained long enough for natural purification processes to provide the required degree of treatment. Ponds use no mechanical mixing. Lagoons use mechanical mixing

advantages of stabilization ponds and lagoons

low cost, large volume, takes advantage of dilution

disadvantages of stabilization ponds and lagoons

large area is required, odor, high suspended solids in effluent, less effective in colder temperatures

what is attached growth

microorganisms are attached to an inert medium forming a biofilm. wastewater comes in contact and microorganisms degrade the organic matter. a secondary clarifier is used, but sludge recirculation is not necessary.

advantages of attached growth

low cost, low energy, simple operation, low sludge production and sludge bulking

disadvantages of attached growth

less efficient at low temperatures, mass transfer and diffusion limitations can occur, odor, worse effluent condition

3 attached culture systems

trickling filter, bio-tower, rotating biological contractor

Biofilm formation

microorganisms attach to media and grow a biofilm. wastewater passes through and suspended/colloidal particles are absorbed and decomposed into soluble products. O2 from waste and air voids creates aerobic condition.

what is sloughing

when biofilm is pulled off the medium due to the shearing action of wastewater flow.

BOD loading vs loading rate

BOD loading (W1) is QSo, and BOD loading rate is QSo/V. So BOD loading rate is W1/V.