4 D2 | Fixed Prosth | Metal Alloys and Casting

1/35

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

36 Terms

what is an alloy?

mixture of two or more metals/metalloids that are mutually soluble in the molten state

- alloying metals are added to alter hardness, strength, and toughness of a metallic element, thus obtaining properties not found in a pure metal

general requirements of dental alloy include: ________

- not harmful or allergic

- chemical properties provide resistance to corrosion and physical changes when in the oral cavity

- technical expertise needed for fabrication and use should be feasible

- metals/alloys should be plentiful, relatively inexpensive, and readily available

T/F type 0 metal is extremely rigid and stiff with high stress... all the way to type 5 metal which is pretty malleable, and low stress

FALSE

type 0 - low stress, pretty malleable

type 5 - high stress, high stiffness/rigidity

T/F noble metals, base metals, and precious metals are all defined based on their chemical properties

FALSE

noble metals and base metals are based on chemical properties

precious metals are based on cost

general properties of noble metals that make it good for dentistry

reacts with sulfur to make sulfide and thus are resistant to oxidation, tarnish, and corrosion

the term "semiprecious metals" was originally used for ___________

noble metal alloys containing significant amounts of silver

nonprecious alloys are composed of ___________

nonprecious ingredients, with most being based on a combination of nickel and chromium

how do you classify a high noble alloy?

the total noble content is ≥60%, with ≥40% of it being gold

how do you classify a titanium/titanium alloy?

titanium content ≥85%

how do you classify a noble alloy?

total noble content ≥25%

how do you classify a predominantly base metal?

≥25% base metals

all the following are properties to consider when choosing a cast alloy except:

a) noble metal content

b) hardness

c) yield strength

d) precious metal content

e) elongation

f) fusion temperature

d) precious metal content

_________ are properties to consider when choosing alloys for PFM restorations

a) thermal expansion

b) fusion temperature

c) bond strength

d) composition

e) hardness

f) yield strength

a) thermal expansion

c) bond strength

d) composition

f) yield strength

why is the composition of metal alloy important when choosing alloys for PFM restorations?

some components can affect the color of the porcelain

why is bond strength important when choosing alloys for PFM restorations?

porcelain-to-metal bond strength ensures retention of porcelain to the metal both in the oral environment and during thermal processing

why is thermal expansion important when choosing alloys for PFM restorations?

ensures the porcelain and metal don't cause irregular expansion that distorts PFM restoration

slight mismatch between porcelain and metal desirable

which metal causes "greening" of the porcelain color?

a) nickel

b) gold

c) copper

d) silver

e) titanium

d) silver

which of the following are also considered important properties of alloys for PFM restoration?

a) yield strength

b) elastic modulus

c) semi-precious content

d) chemical stability

e) biocompatibility

f) chemical retention

a) yield strength

b) elastic modulus

d) chemical stability

e) biocompatibility

T/F elastic modulus affects the flexibility of a porcelain framework

T/F chemical stability affects the tarnish resistance, corrosion resistance, and thermal stability

T/F yield strength is crucial due to the large cross section of the PFM restoration

FALSE -- elastic modulus affects the flexibility of the metal framework

TRUE

FALSE -- yield strength is crucial due to small x.s. of the PFM restoration

type I dental casting gold alloys are _________, and used for _________

a) extra hard, used for long-span bridges, RPD, etc.

b) medium, used for inlays/onlays including cusp replacement

c) hard, used for crowns and short-span bridges with high stress applications

d) soft, used for inlays with low stress applications

d) soft, used for inlays with low stress applications

type II dental casting gold alloys are _________, and used for _________

a) extra hard, used for long-span bridges, RPD, etc.

b) medium, used for inlays/onlays including cusp replacement

c) hard, used for crowns and short-span bridges with high stress applications

d) soft, used for inlays with low stress applications

b) medium, used for inlays/onlays including cusp replacement

type III dental casting gold alloys are _________, and used for _________

a) extra hard, used for long-span bridges, RPD, etc.

b) medium, used for inlays/onlays including cusp replacement

c) hard, used for crowns and short-span bridges with high stress applications

d) soft, used for inlays with low stress applications

c) hard, used for crowns and short-span bridges with high stress applications

type IV dental casting gold alloys are _________, and used for _________

a) extra hard, used for long-span bridges, RPD, etc.

b) medium, used for inlays/onlays including cusp replacement

c) hard, used for crowns and short-span bridges with high stress applications

d) soft, used for inlays with low stress applications

a) extra hard, used for long-span bridges, RPD, etc.

yield strength

the point at which a material begins to deform permanently

T/F softer metals = lower yield strength. harder metals = higher yield strength

TRUE

why do you want to know what metal is used when you want to add porcelain onto your pfm restoration?

you want to know at what temperature this metal is going to melt, and make sure you dont reach that temp or else your pfm restoration is going to turn to mush

or if there are allergic reactions (like with nickel)

also prices

T/F the lost wax technique is one of the oldest methods of casting available. it is inexpensive and convenient to use even on complicated shapes. its desired accuracy is about 0.1%

TRUE

sprue

channel or hole through which plastic or metal is poured or cast into a gate or reservoir and then into a mold

all the following statements of the sprue are correct except:

a) sprue must be large enough to remain open until casting solidifies

b) sprue must be short enough to allow rapid filling of the mold

c) sprue should attach to the thinnest part of the pattern

d) wax sprues are the most common

c) sprue should attach to the thinnest part of the pattern

- they should attach to the thickest part of the pattern

all the following statements of spruing are correct except:

a) forms a mount for the wax pattern and fixes the pattern in space so a mold can be made

b) creates a channel for elimination of wax during burnout

c) allows for molten metal to enter the mold

d) sprue button is the excess metal remaining at the base of a mold after dental casting

e) you want at least 3mm of excess clearance from the sprue to the mold

e) you want at least 3mm of excess clearance from the sprue to the mold

- you want 6mm of excess clearance from sprue to mold to allow space for gas to escape

______ of new gold alloy must be used for each new casting

a) 1/4

b) 1/3

c) 1/2

d) 2/3

b) 1/3 (by weight) -- to try to maintain gold content

what is the most common way of melting the gold alloy?

natural gas/air method (torch)

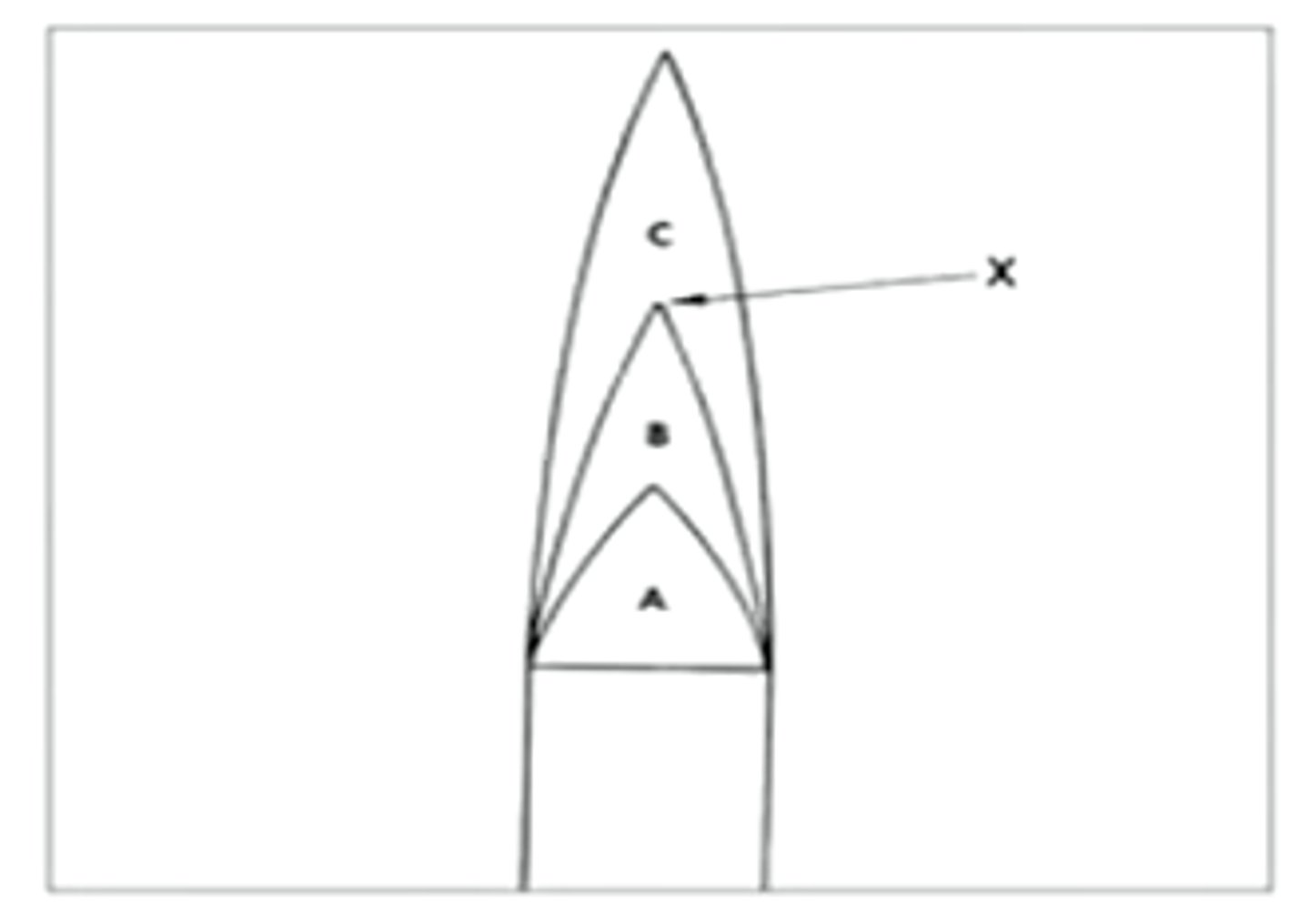

when using a torch, which part of the flame is the best part to melt the gold with?

point x is the hottest zone of the flame

(b) is blue with burning gases and forms a reducing atmosphere

(a) consists of unburnt gases and is not hot enough to melt gold

c) contains burnt gases, and should be avoided bc it forms an oxidizing atmosphere

what are other ways of heating up gold alloys?

- electric resistance

- induction

- electricity

when cleaning and finishing crowns, what types of burs can you use?

heatless stone wheel, green stone, brownie, tripole and brush, greenie, red rouge and brush, supergreenie

if you're making a gold crown for the purpose of a PFM, what would be the changes?

- it would be much smaller (to allow fitting of porcelain)

- would have less contouring bc it needs more oxidation to help with mechanical bonding of ceramic and metal