Nature of Metals and Alloys

1/116

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

117 Terms

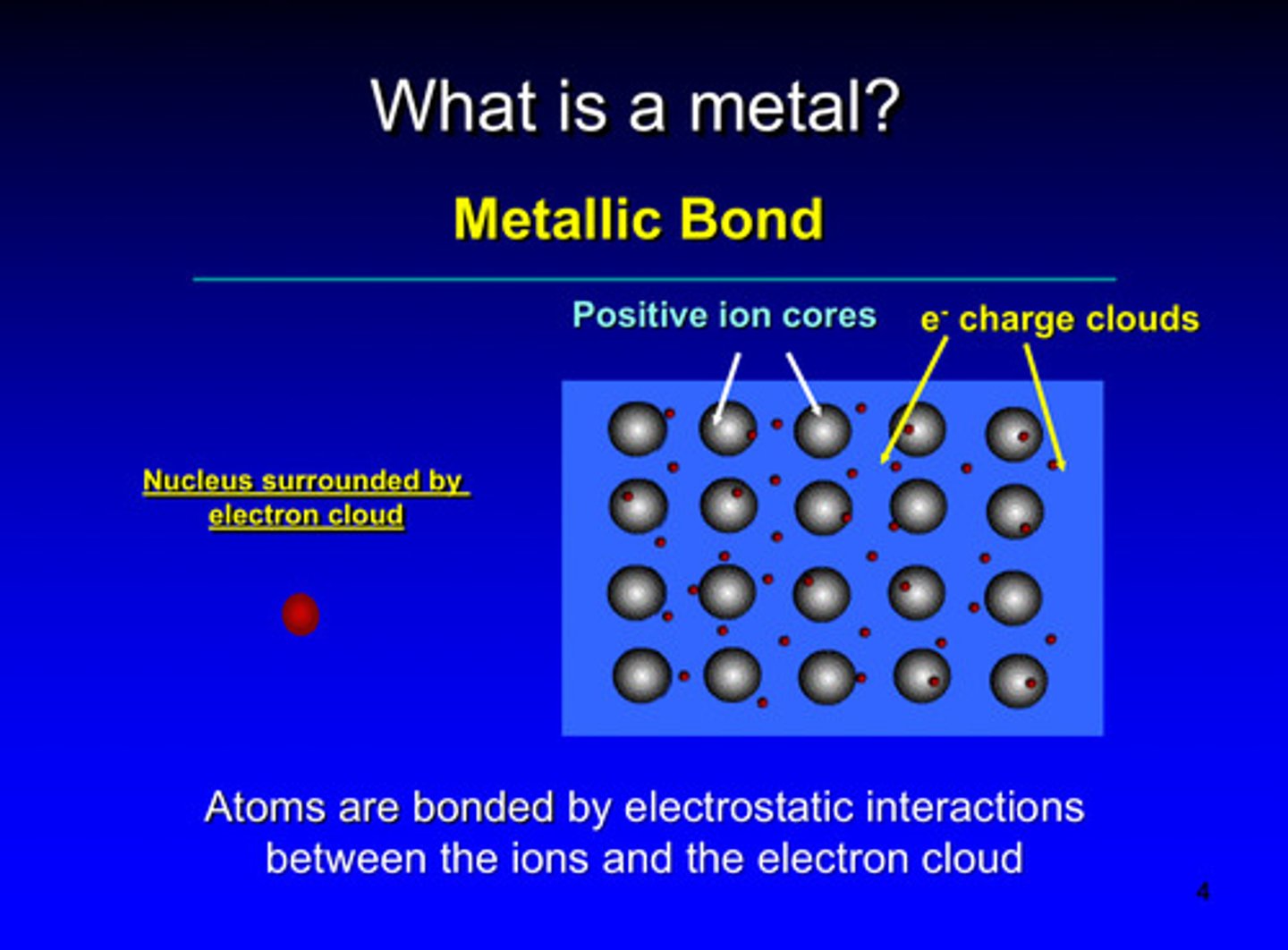

what kind of bonds to metals have

metallic bonds

in metallic bonds, atoms are bonded by ____________ interactions between the ______ and the _________ ________

electrostatic; ions and the electron could

the nucleus in metals are surrounded by the

electron cloud

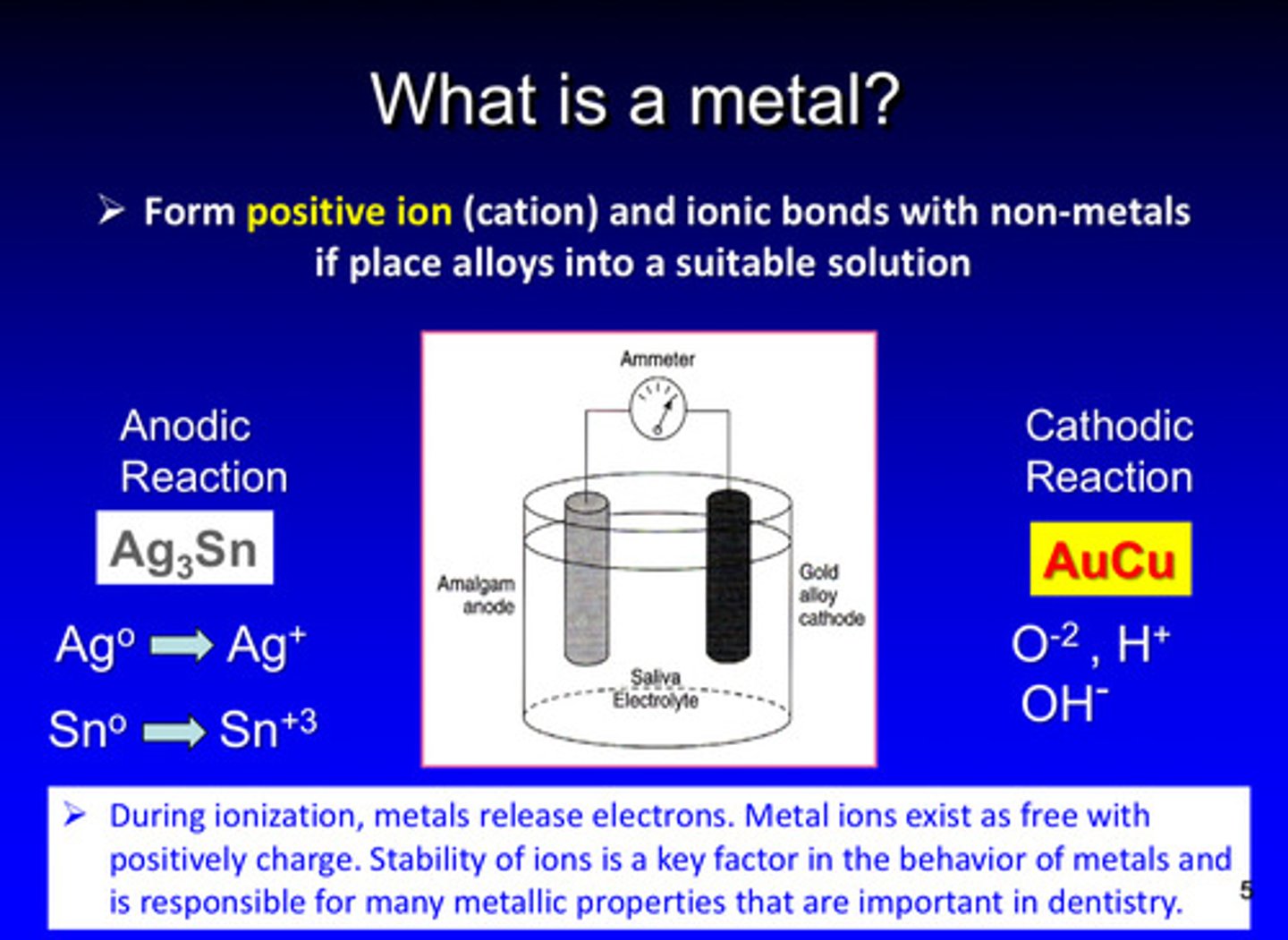

metals form what kind of ions and bonds with non-metals if alloys are placed into a suitable solution

form positive ions (cations) and ionic bonds with non metals

during ionization, metals release what

release electrons

metal ions exist as free with ________ charges

positive

what is a key factor in the behavior of metals and is responsible for many metallic properties that are important in dentistry

stability of ions

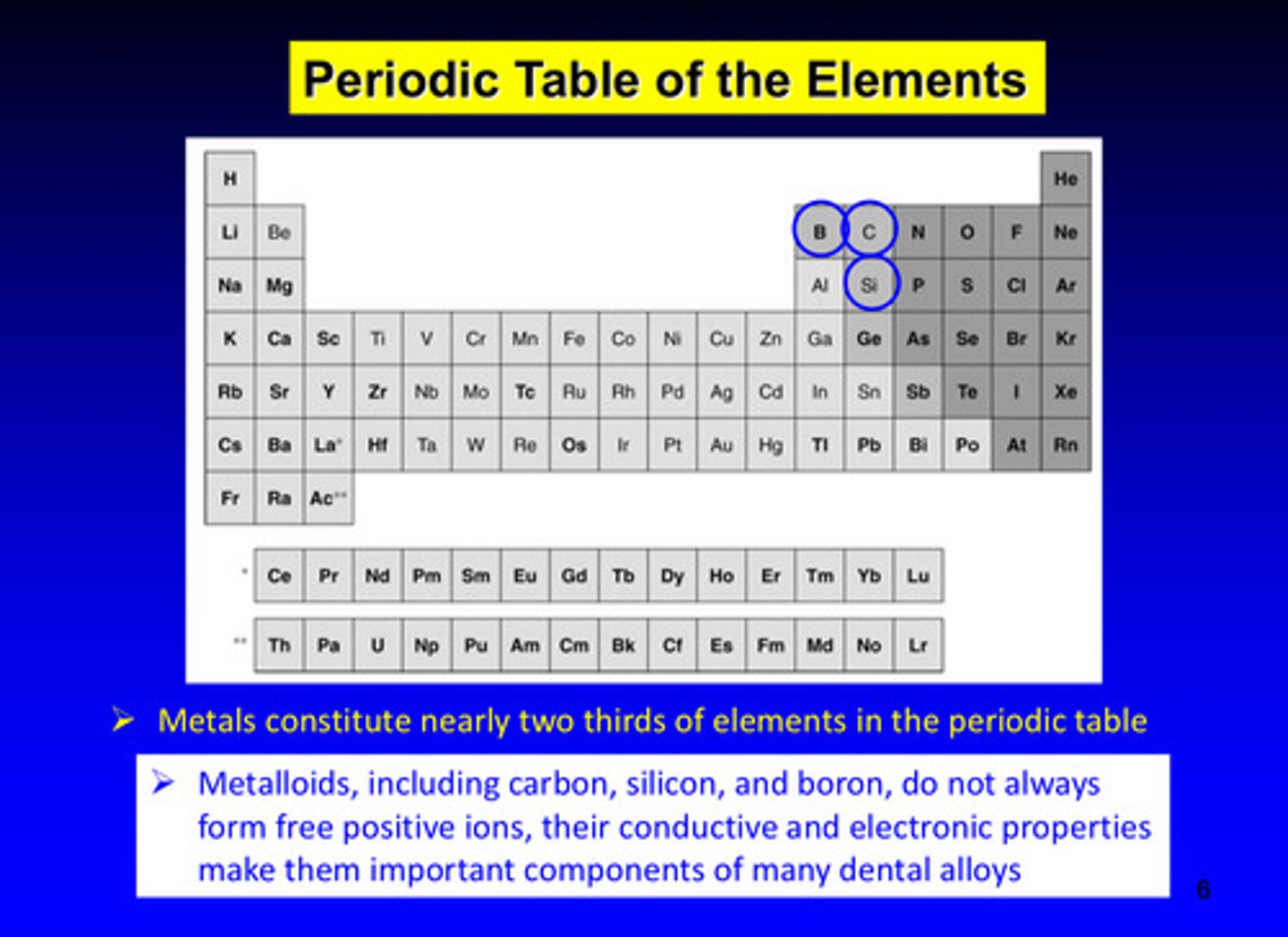

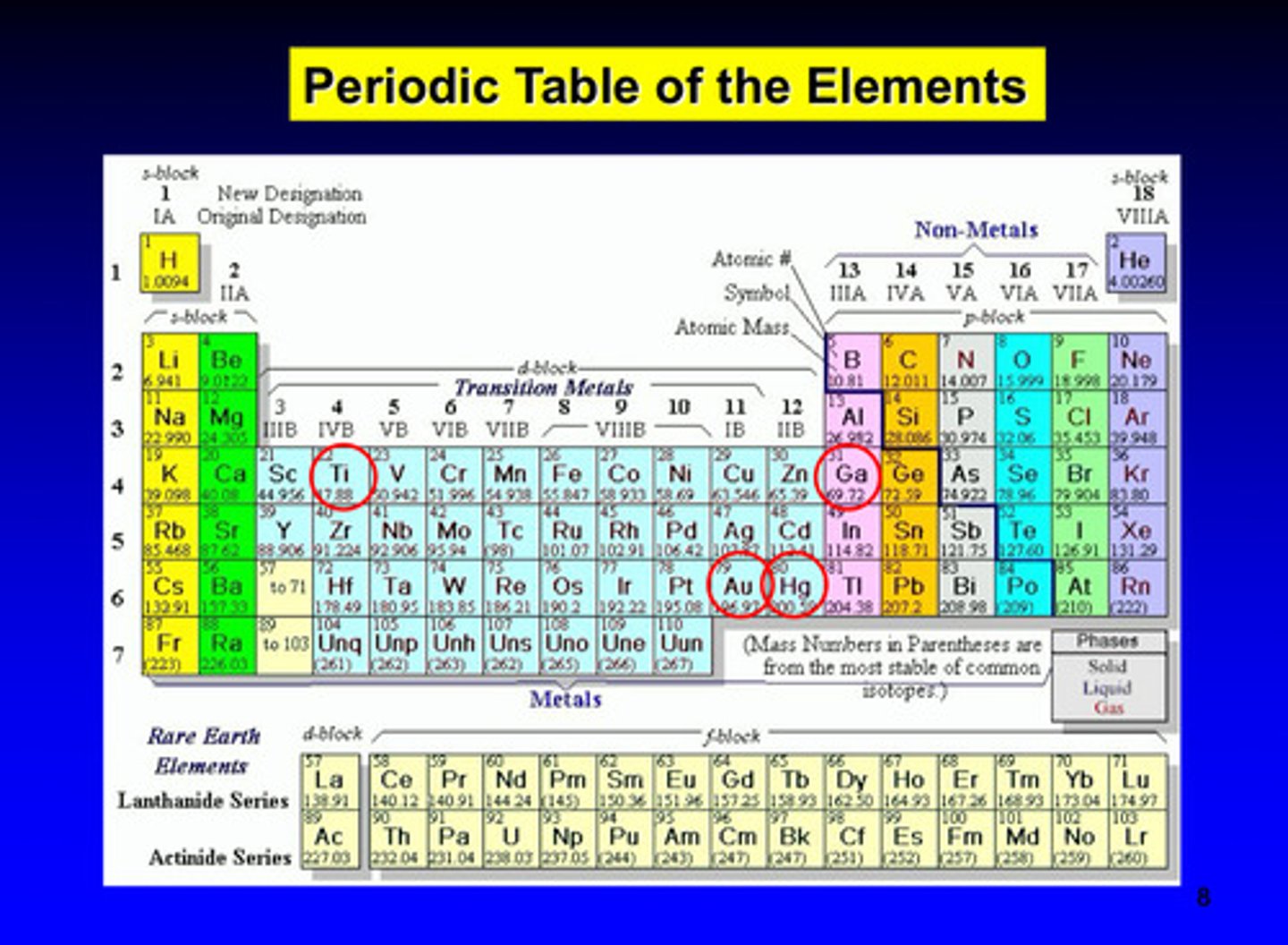

metals constitute nearly _____ of elements in the periodic table

2/3

metalloids, including carbon, silicon, and boron, do not always form ______ _______ ions, but their _________ and __________ properties make them important components of many dental alloys

free positive ions; conductive and electronic properties

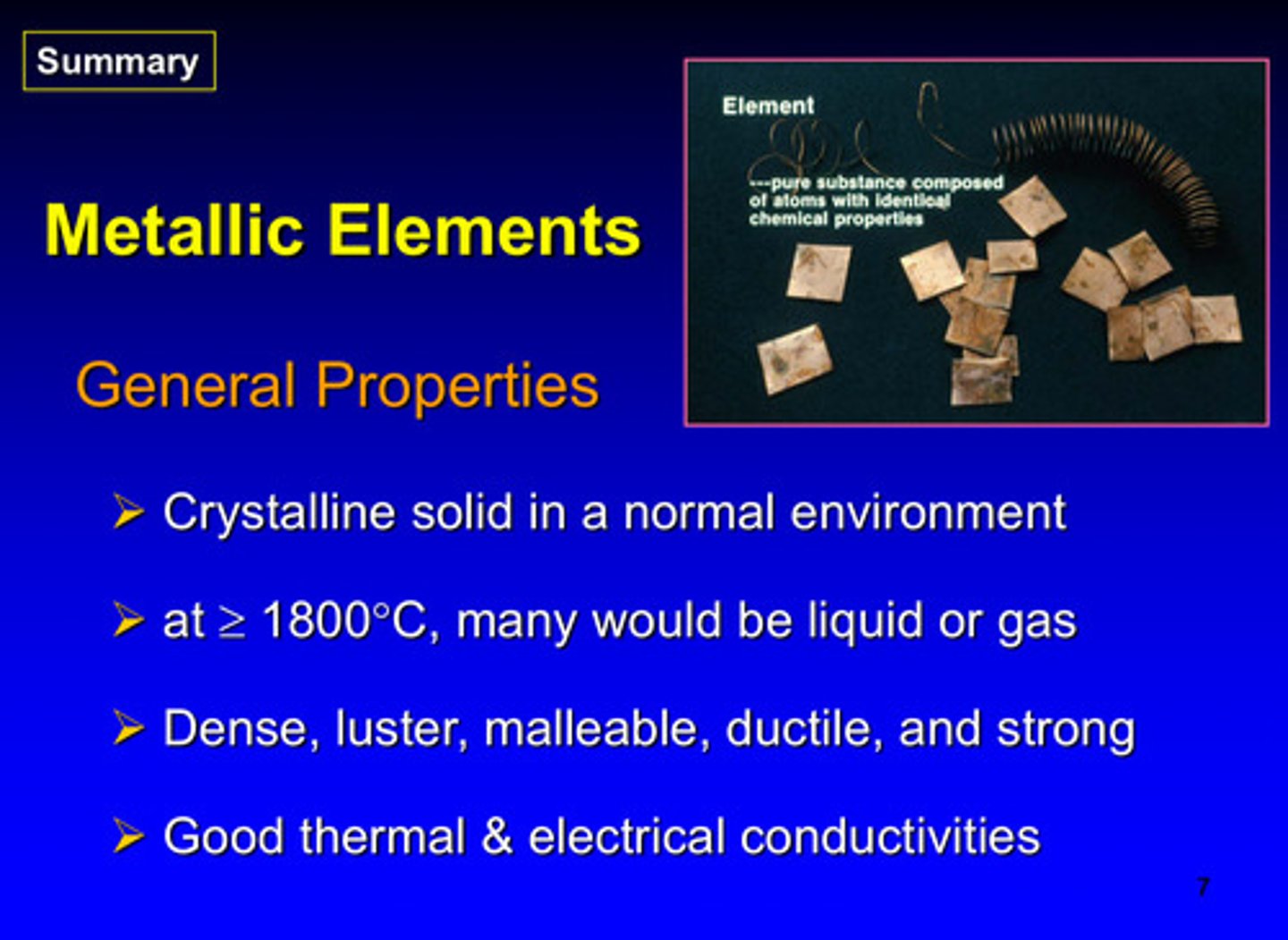

what are the 4 general properties of metallic elements

1) crystalline solid in normal environment

2) at >/= 1800 degrees C, many would be liquid or gas

3) dense, luster, malleable, ductile, and strong

4) good thermal and electrical conductivities

periodic table of the elements image

what is an alloy

a blend of two or more metals in all their possible combinations considered as a whole

in order to form an alloy, the two metals are __________ to a liquid state

heated

when a combination of two metals is completely ________ in the liquid state, the 2 metals can form an alloy

miscible

a binary alloy results from what

two metals and all different possible combinations are considered

what is the goal of alloys and alloy systems

1) to optimize practical properties

2) to form metallic materials with adequate strength, ductility, corrosion resistance, and biocompatibility for application in the oral environment

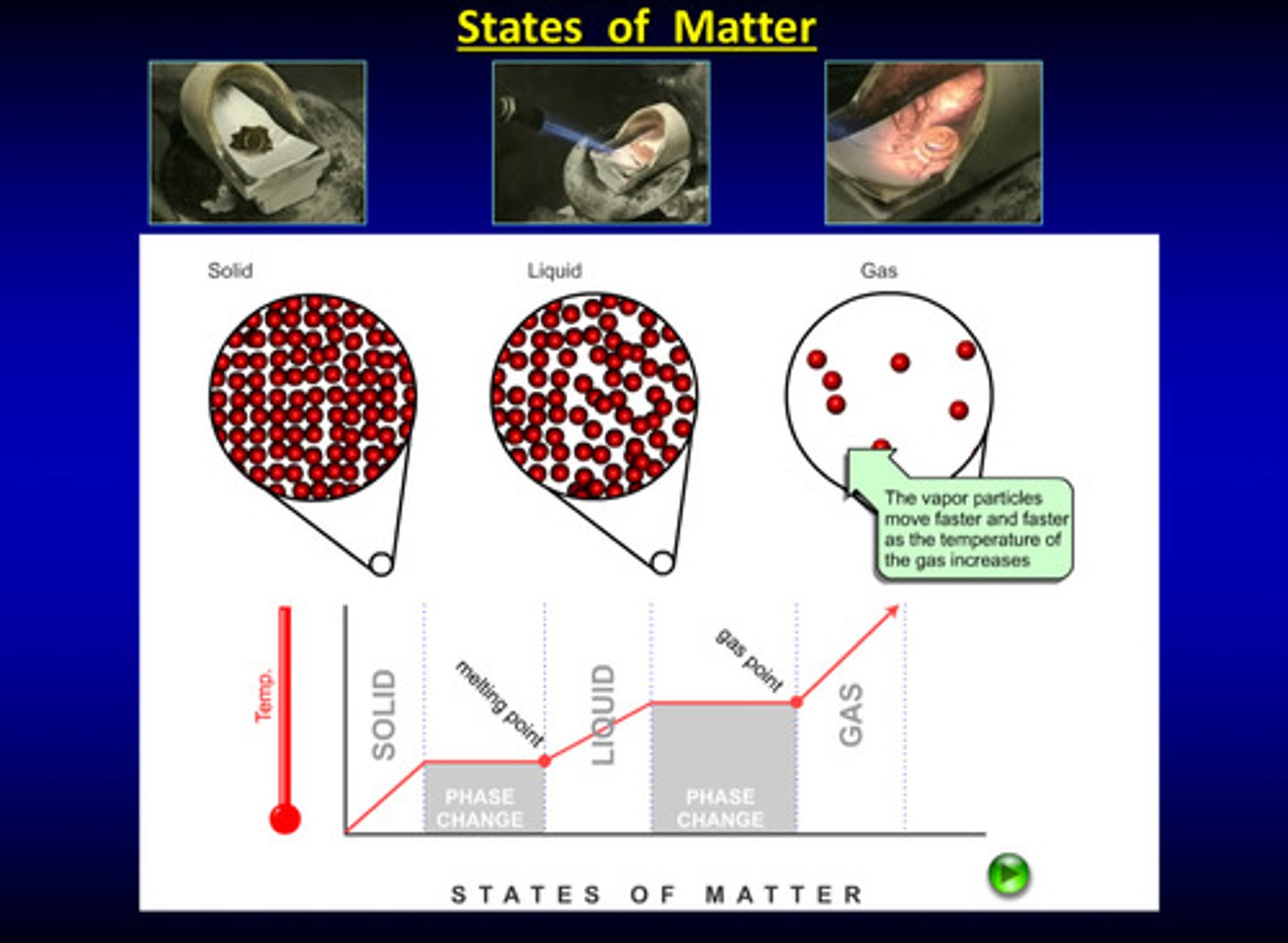

states of matter image

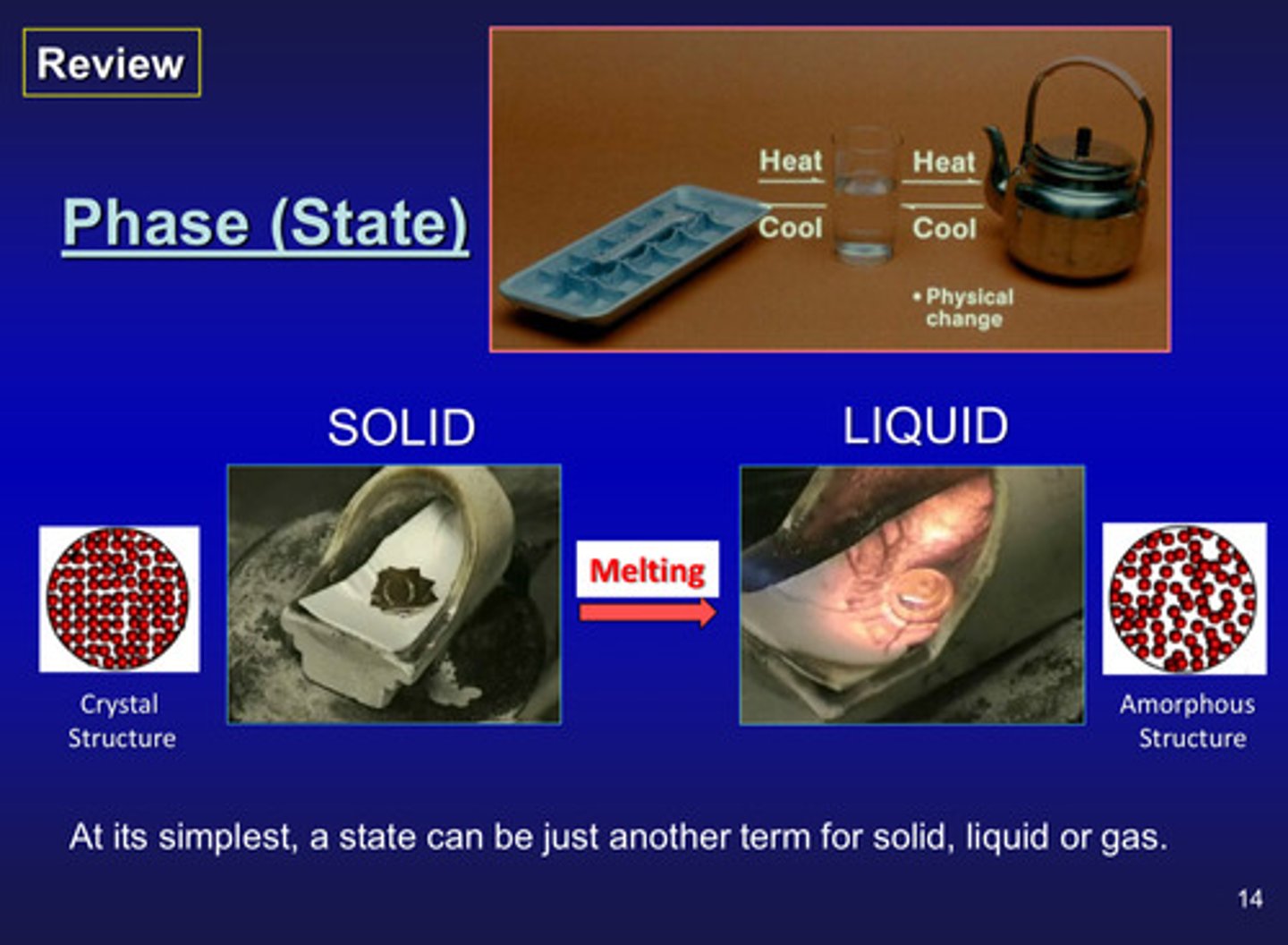

phase changes are _______ changes

physical

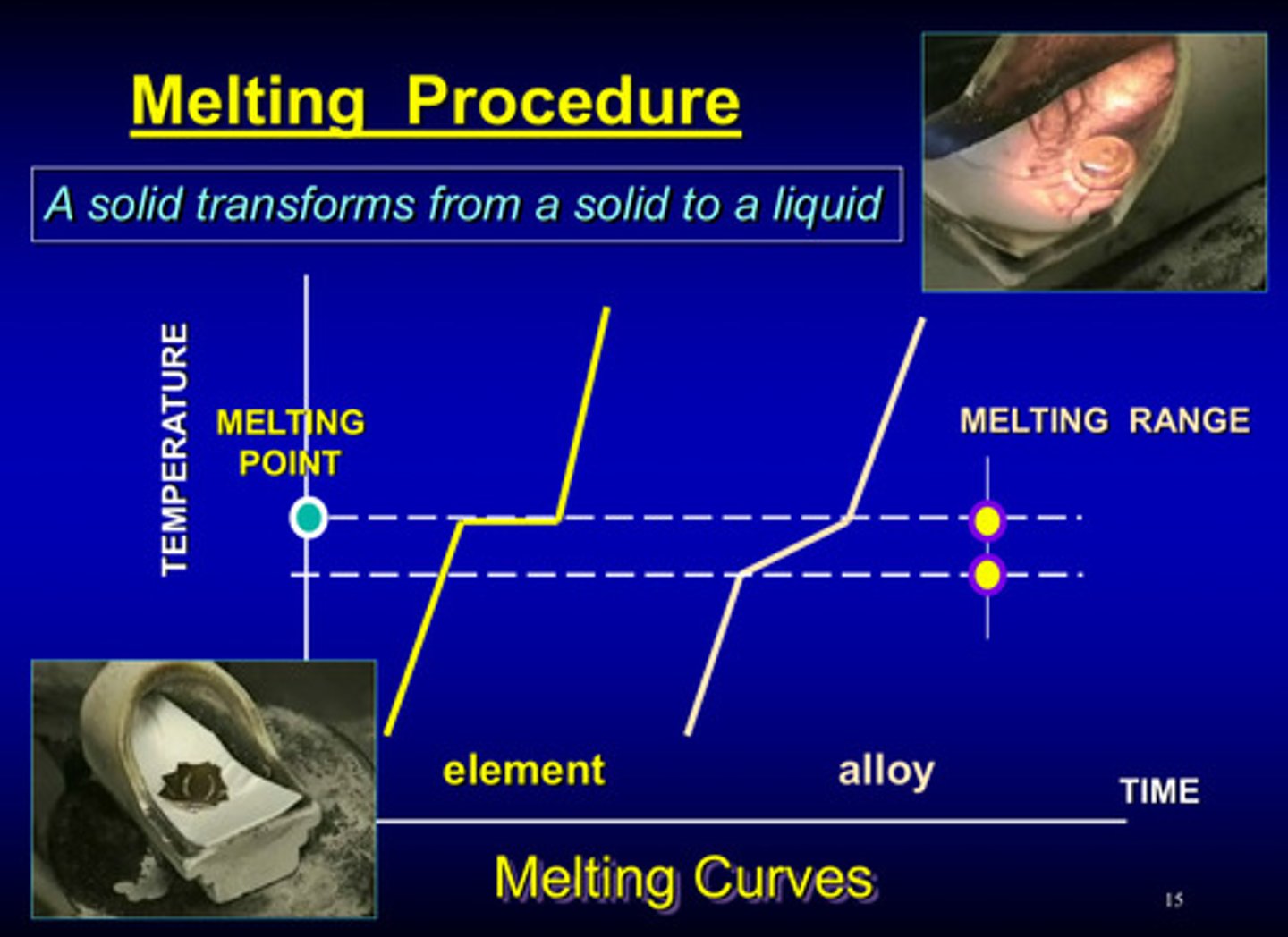

what is melting

solid to liquid

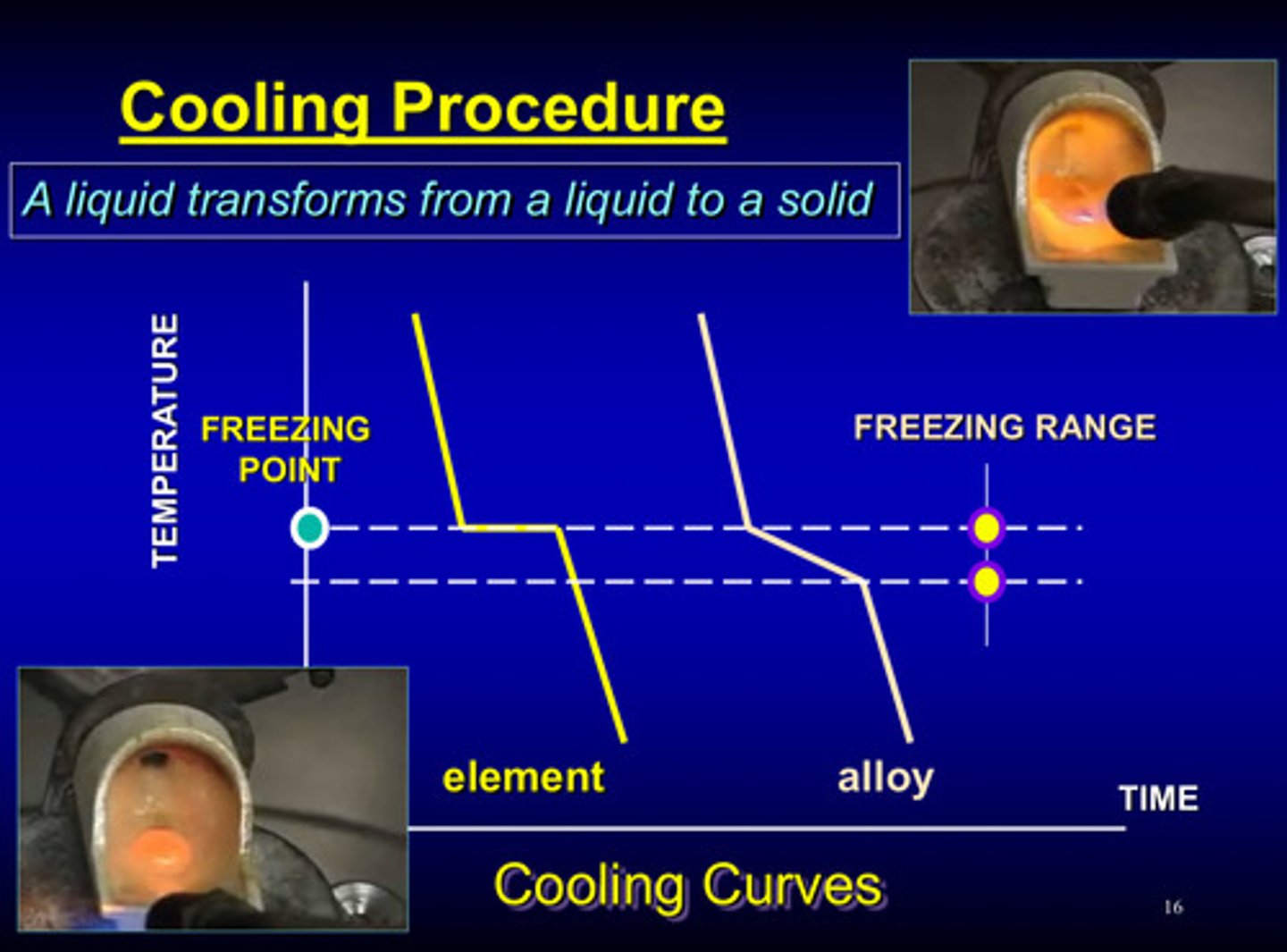

what is cooling

liquid to solid

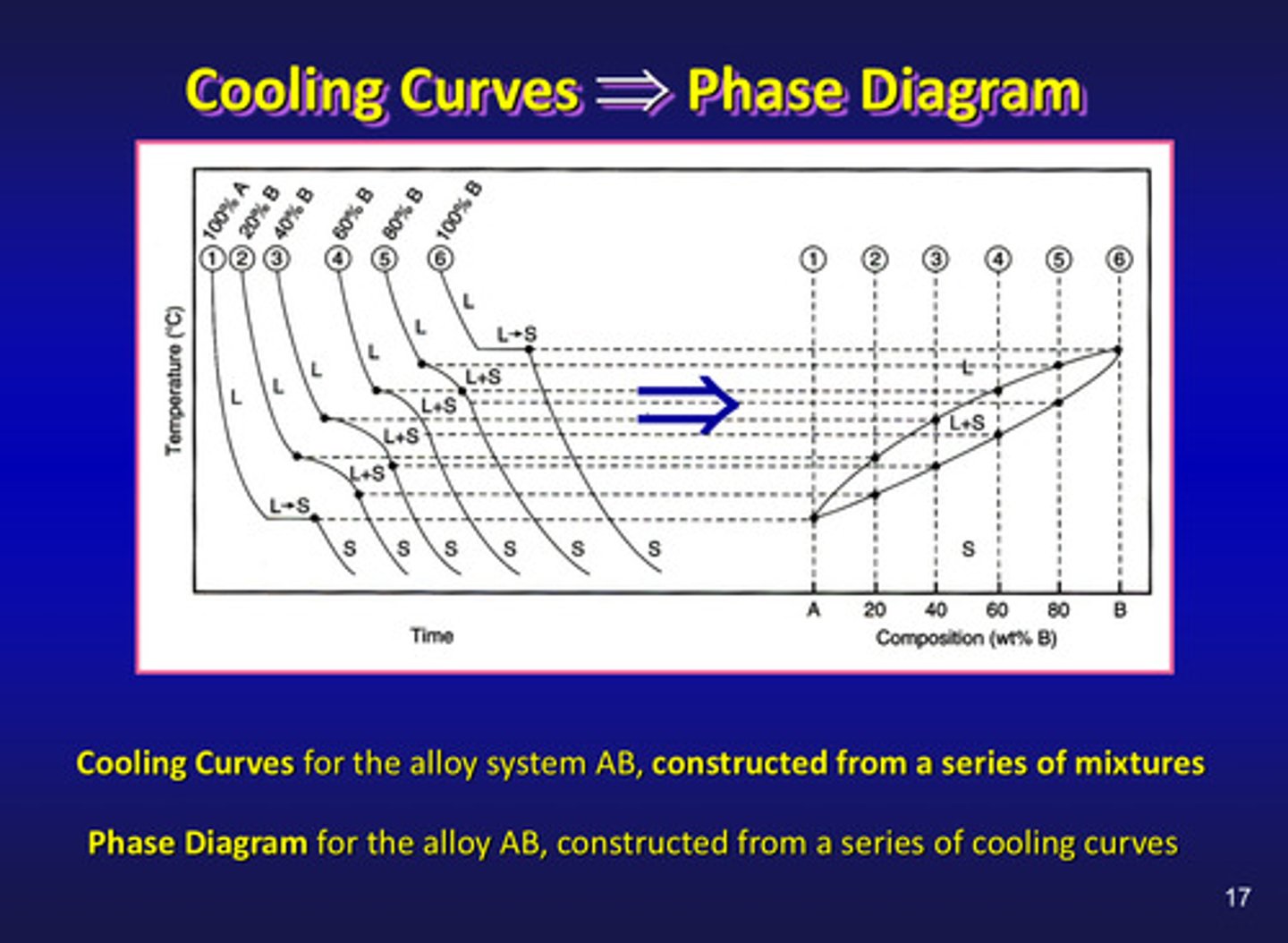

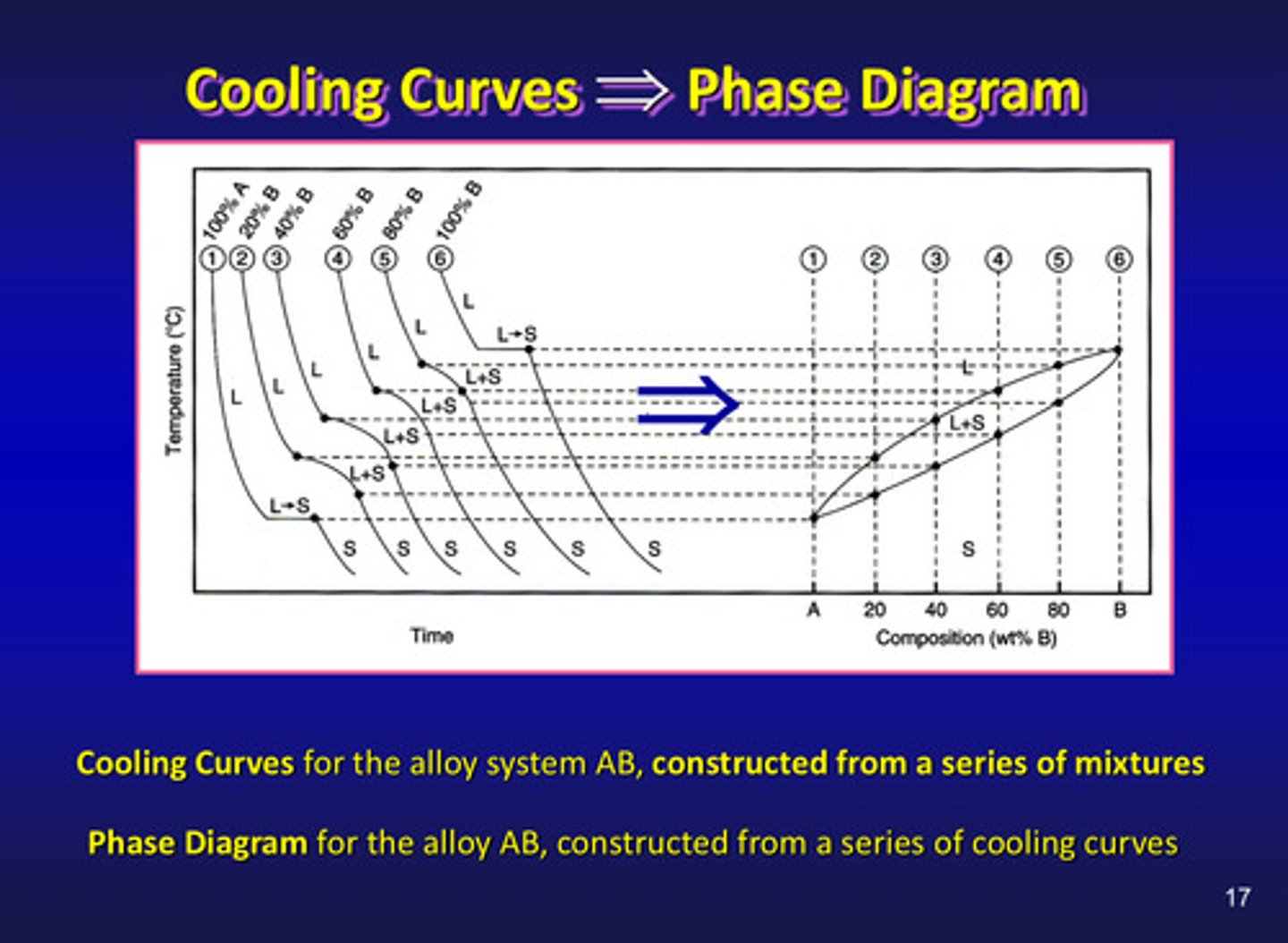

cooling curves for the alloy system AB are constructed from a ?

series of mixtures (left side)

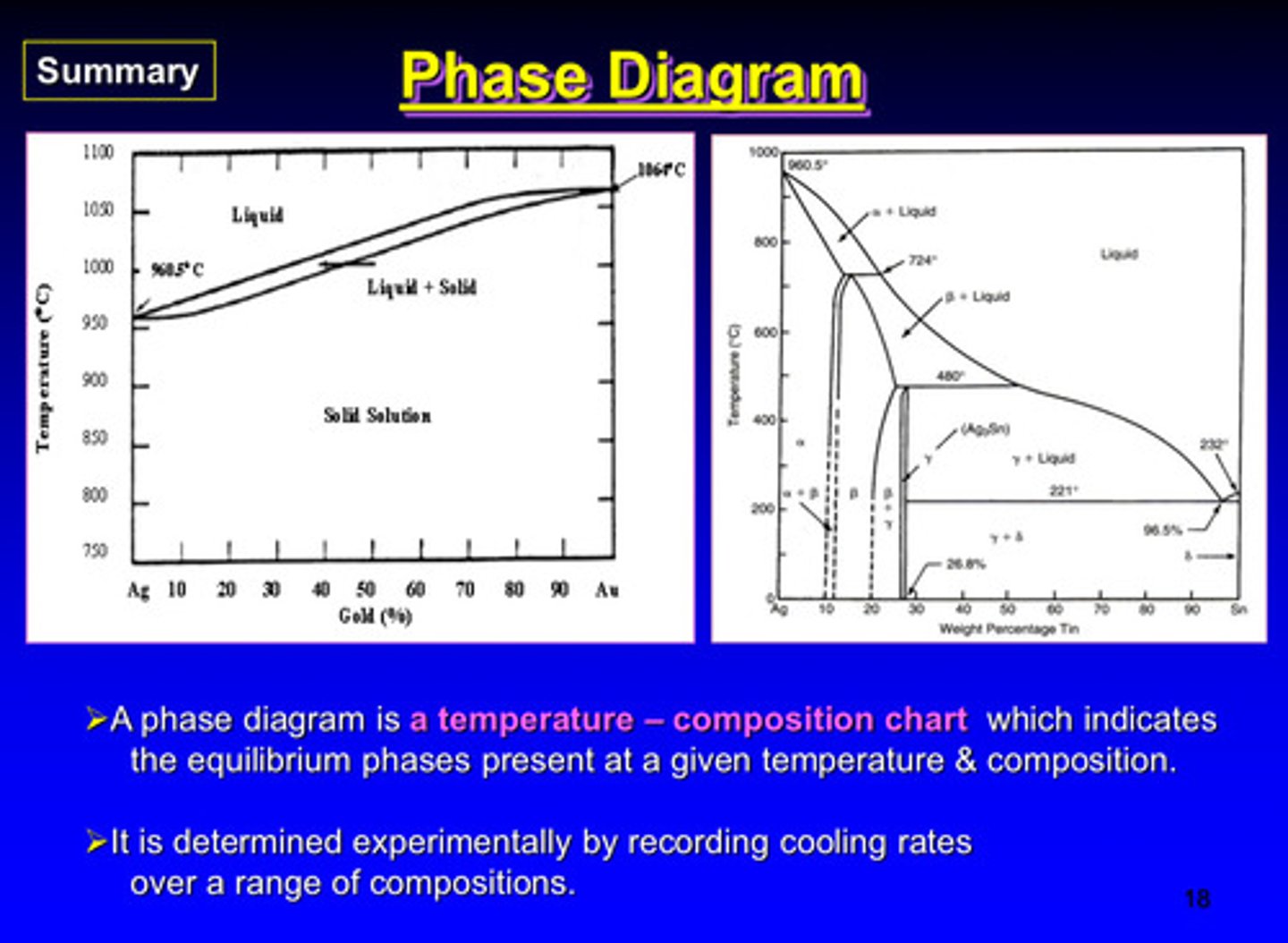

phase diagrams are determined experimentally by recording what

cooling rates over a range of compositions

what is a phase diagram

a temperature - composition chart which indicates the equilibrium phases present at a given temperature and composition

phase diagrams for the alloy AB are constructed from a ?

series of cooling curves (right side)

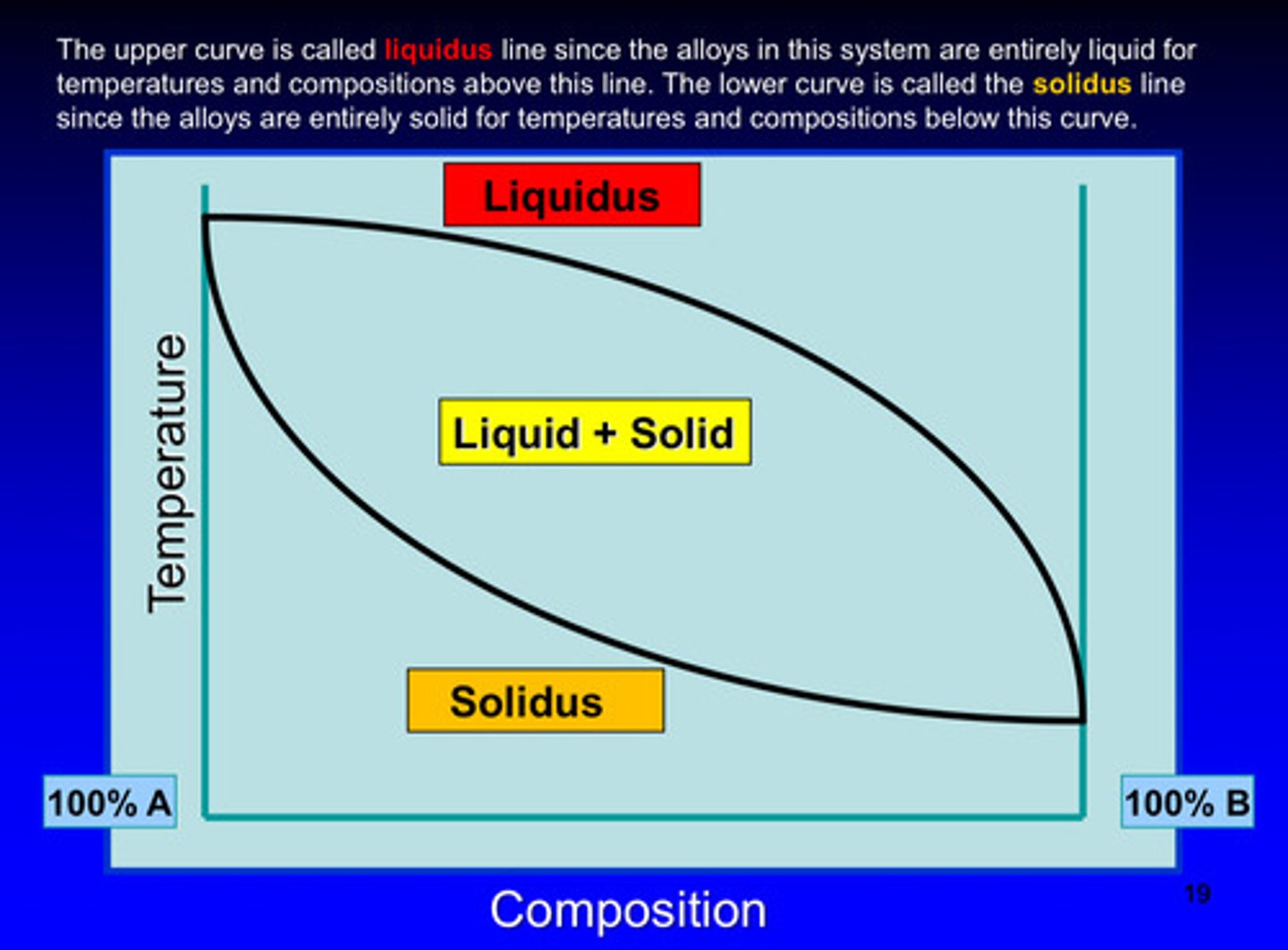

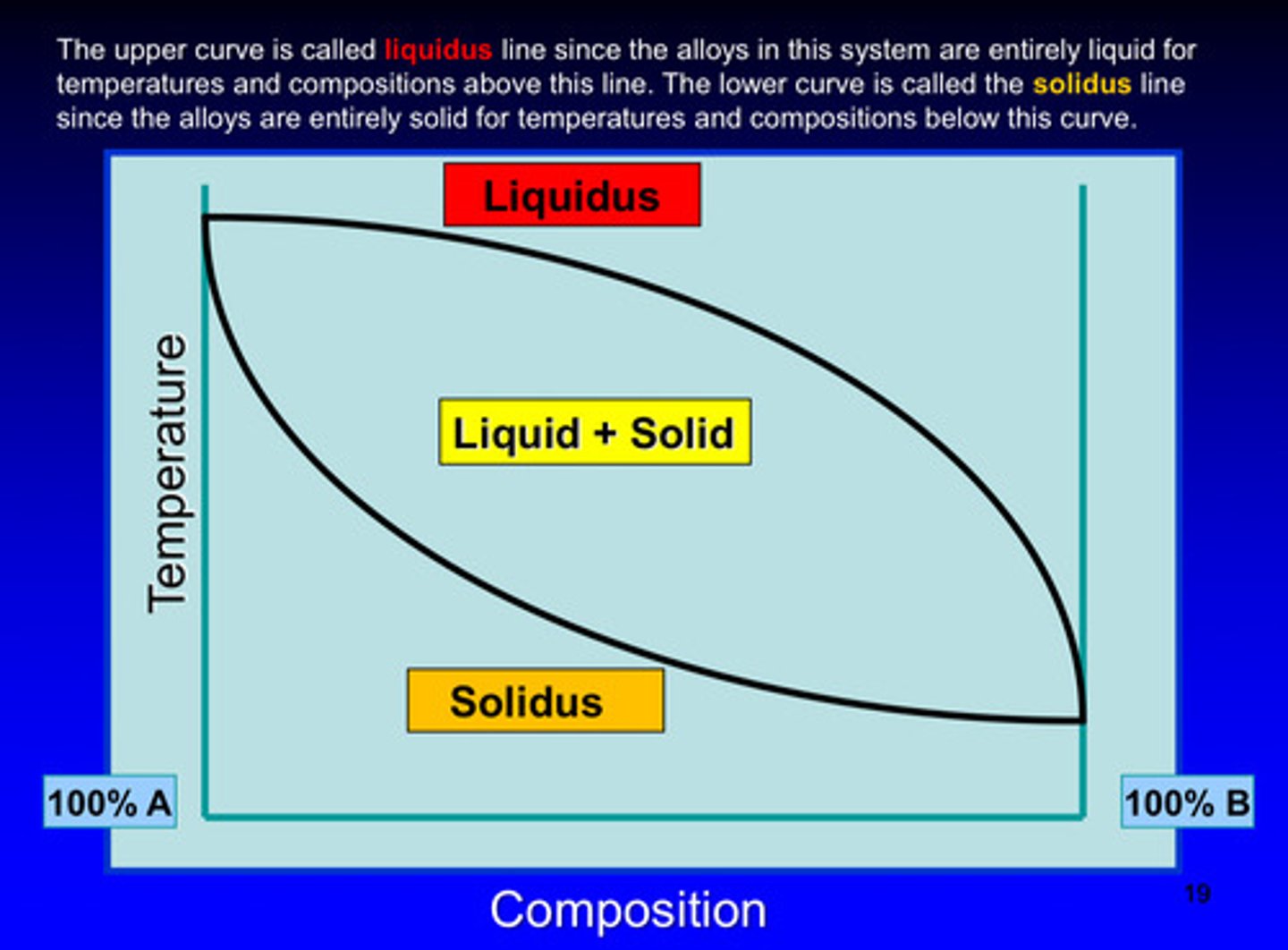

in a phase diagram, the upper curve is called what line

liquidus line since the alloys in this system are entirely liquid for temperatures and compositions above this line

in a phase diagram, the lower curve is called what line

solidus line since the alloys in this system are entirely solid for temperatures and compositions below this curve

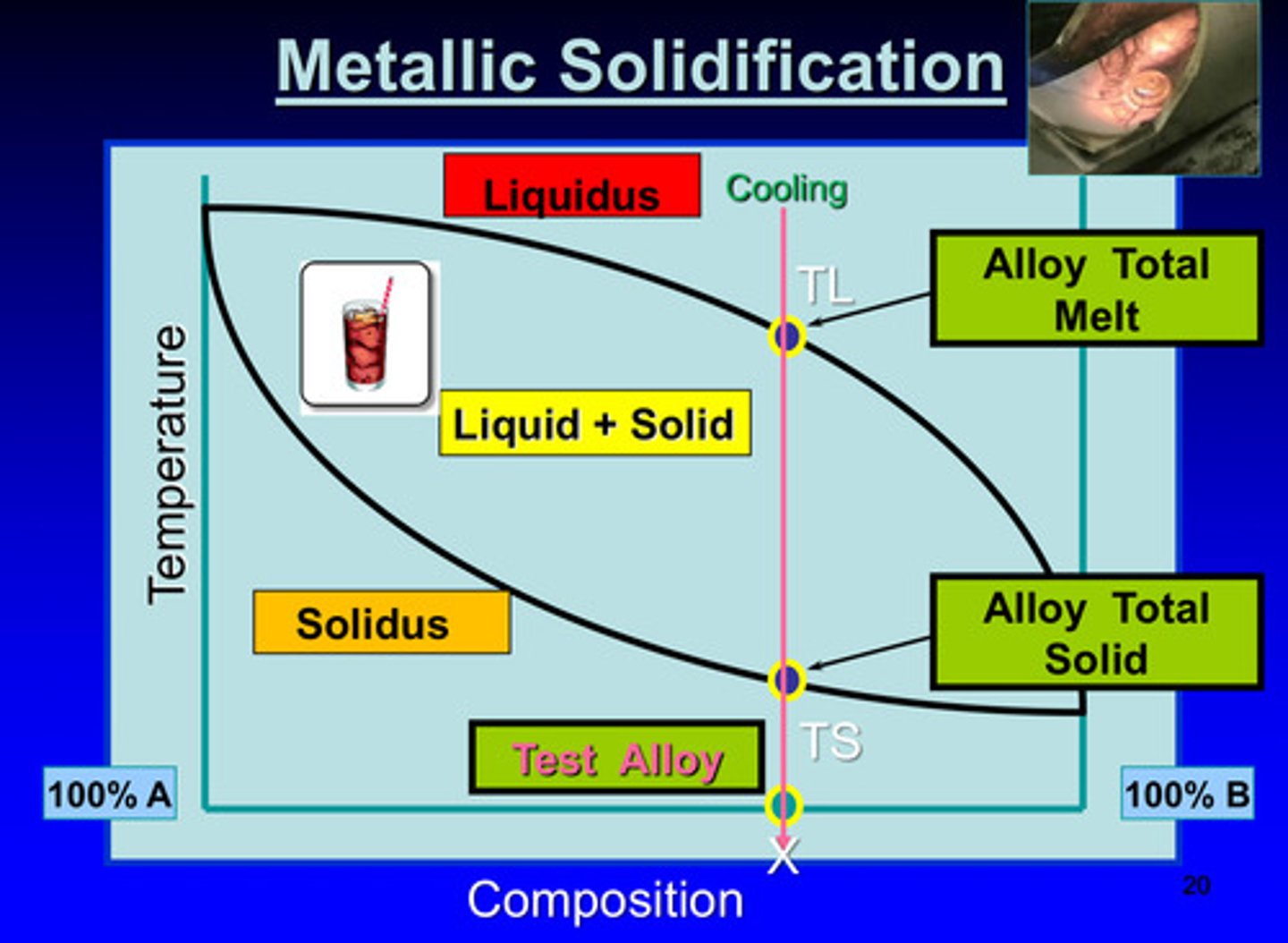

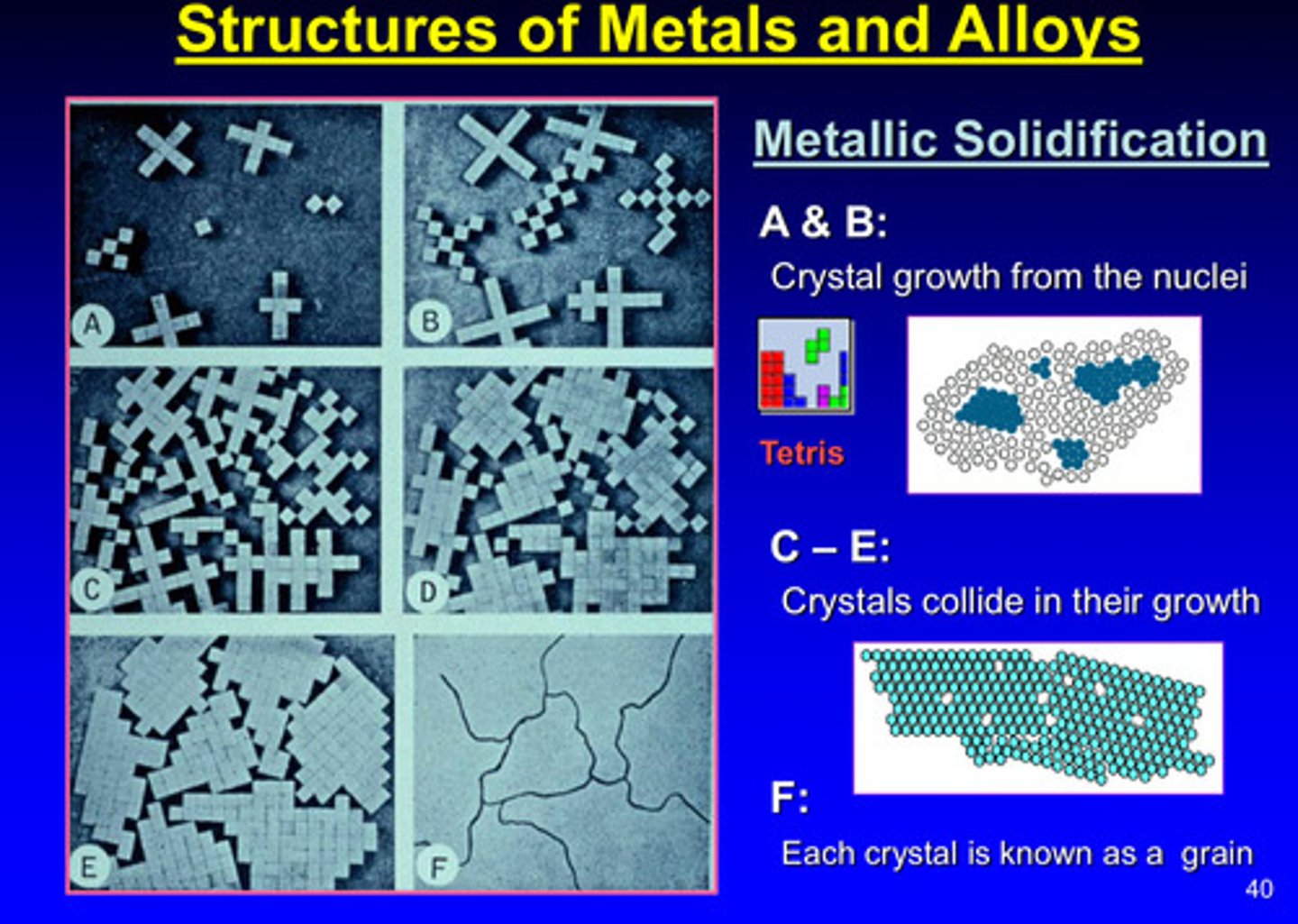

metallic solidification image

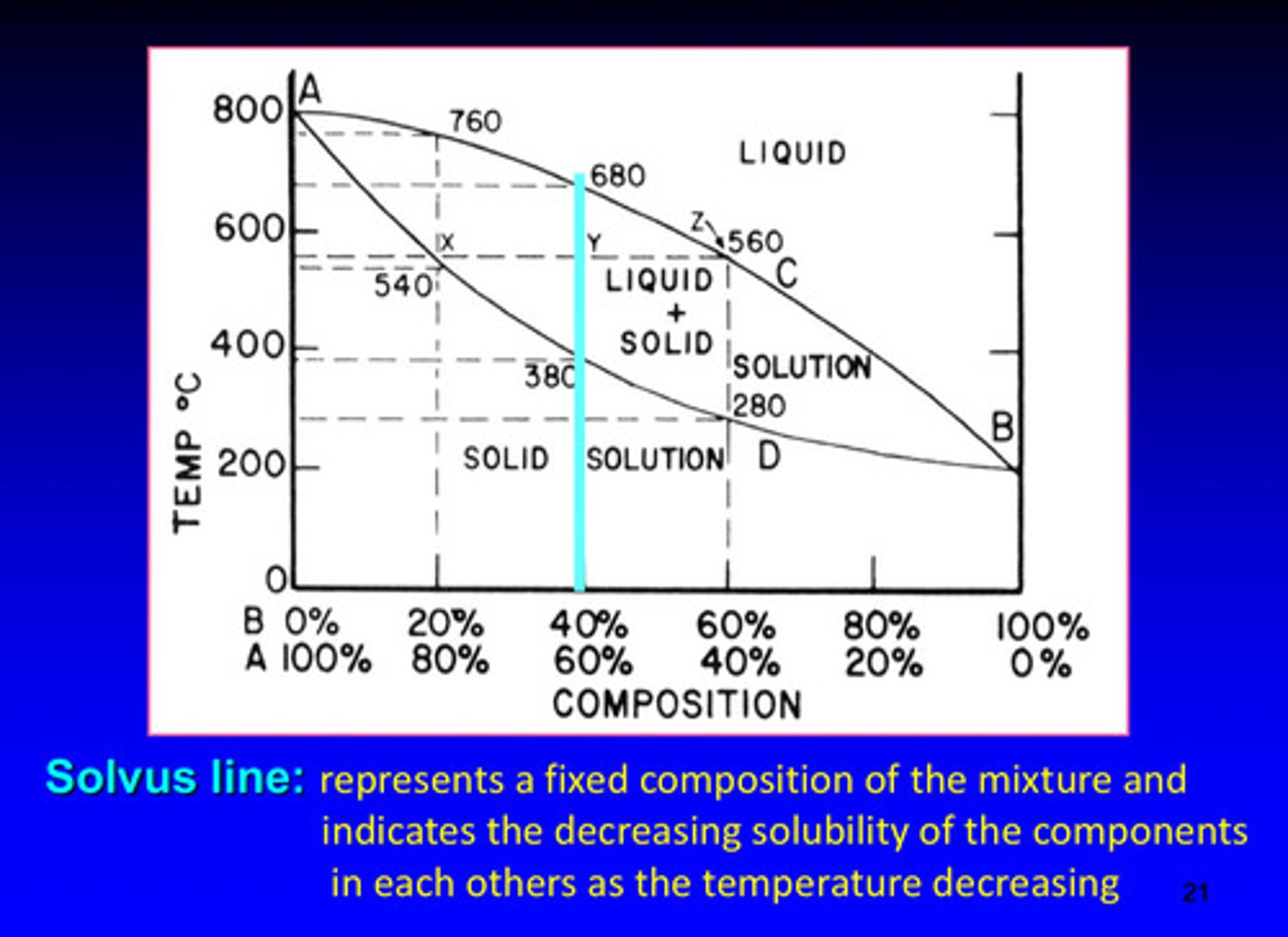

what is the solvus line in a phase diagram

represents a fixed composition of the mixture and indicates the decreasing solubility of the components in each other as the temperature decreases

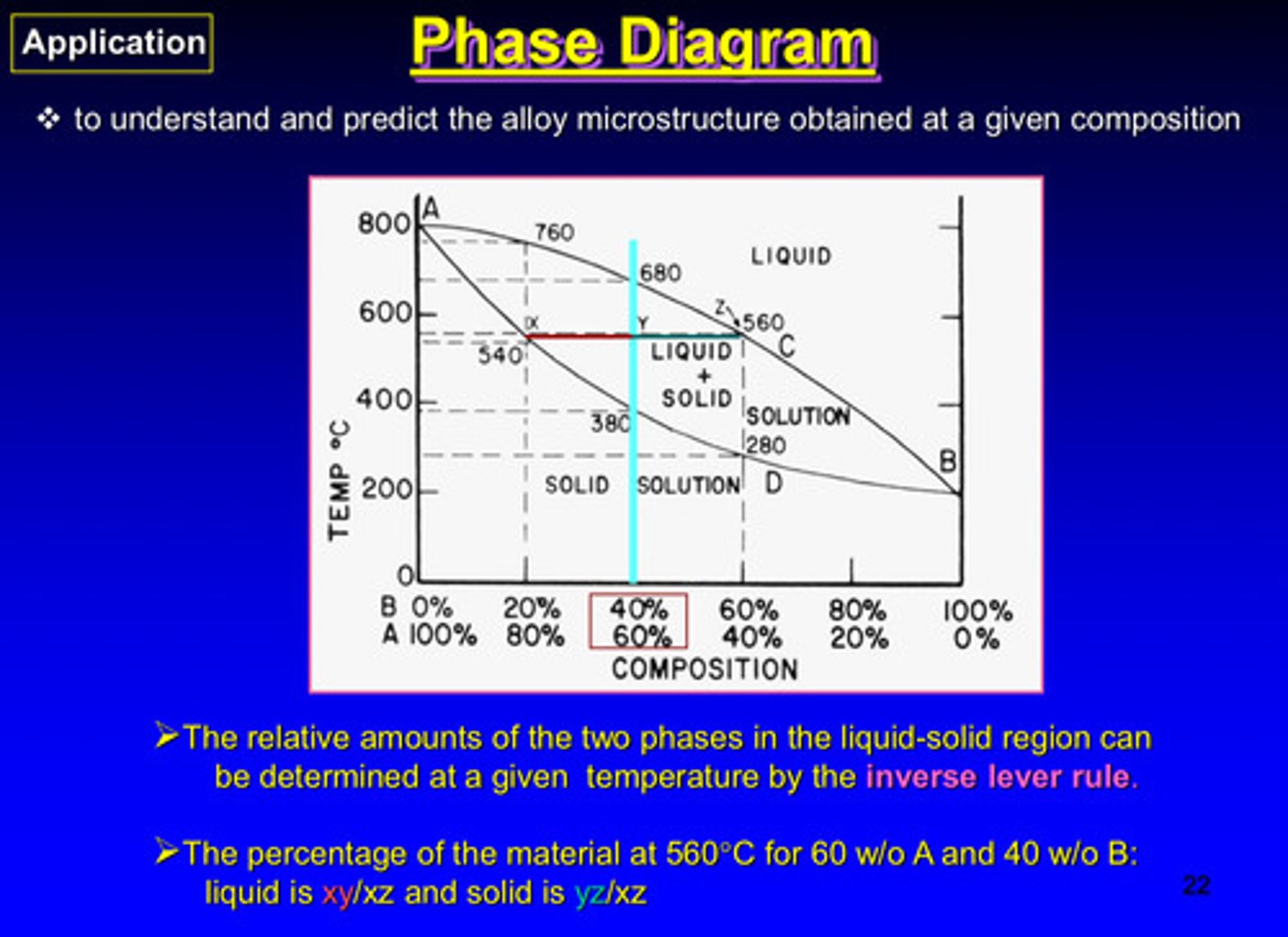

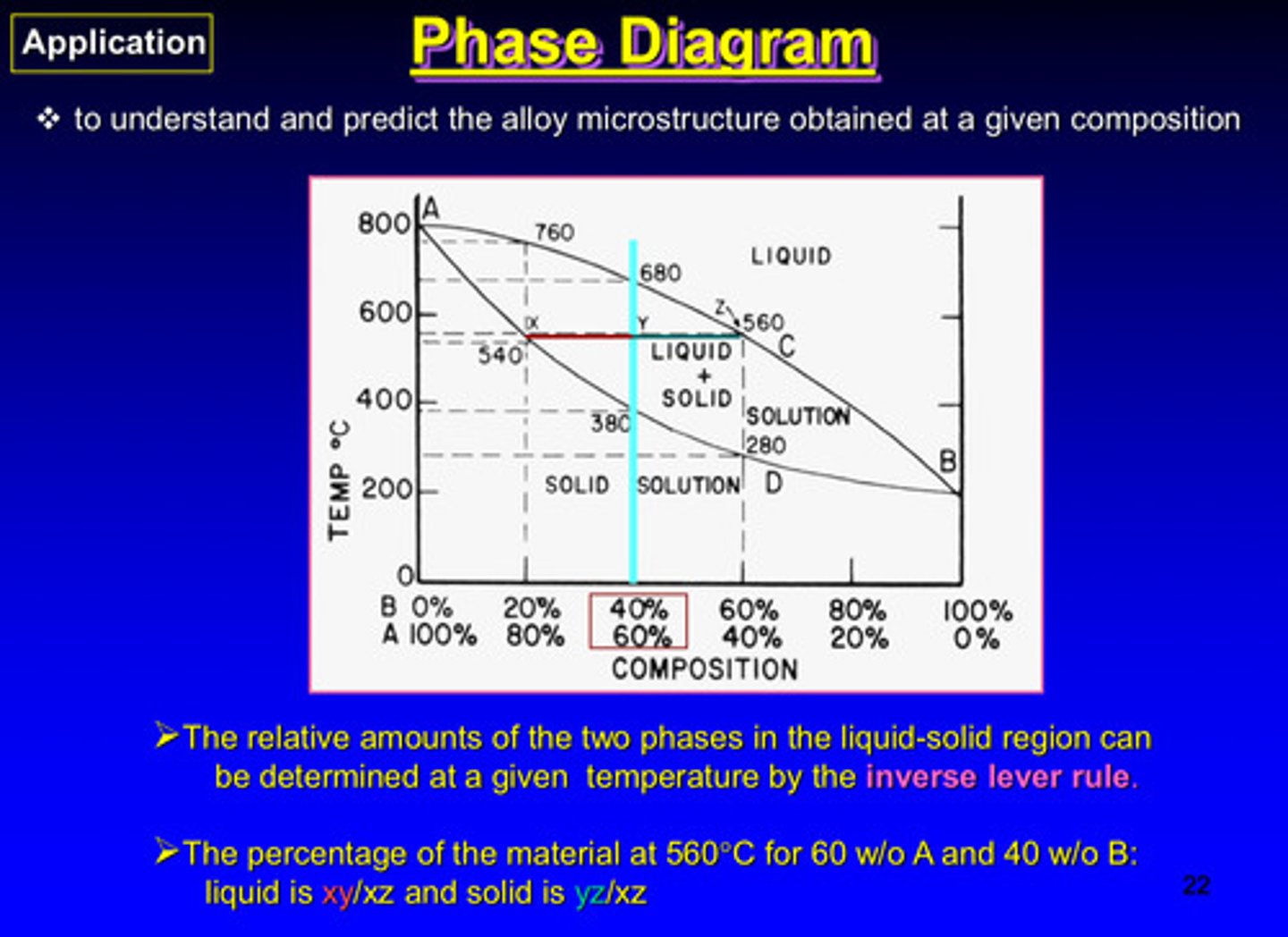

what is the goal of the phase diagram

to understand and predict the alloy microstructure obtained at a given composition

the relative amounts of the two phases in the liquid-solid region can be determined at a given temperature by what rule

the inverse lever rule

the percentage of the material at 560 C for 60% A and 40% B:

liquid is xy/xz and solid is yz/xz

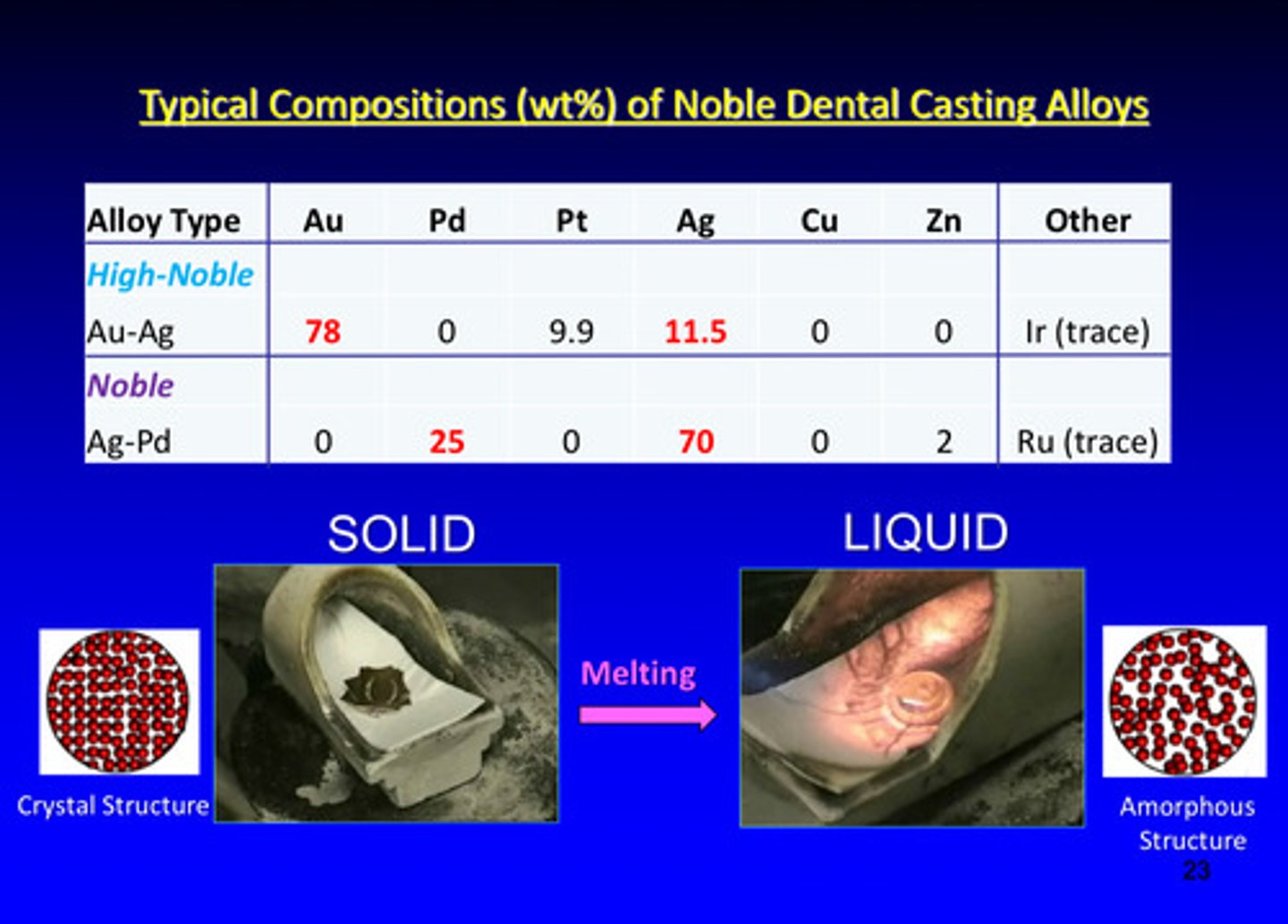

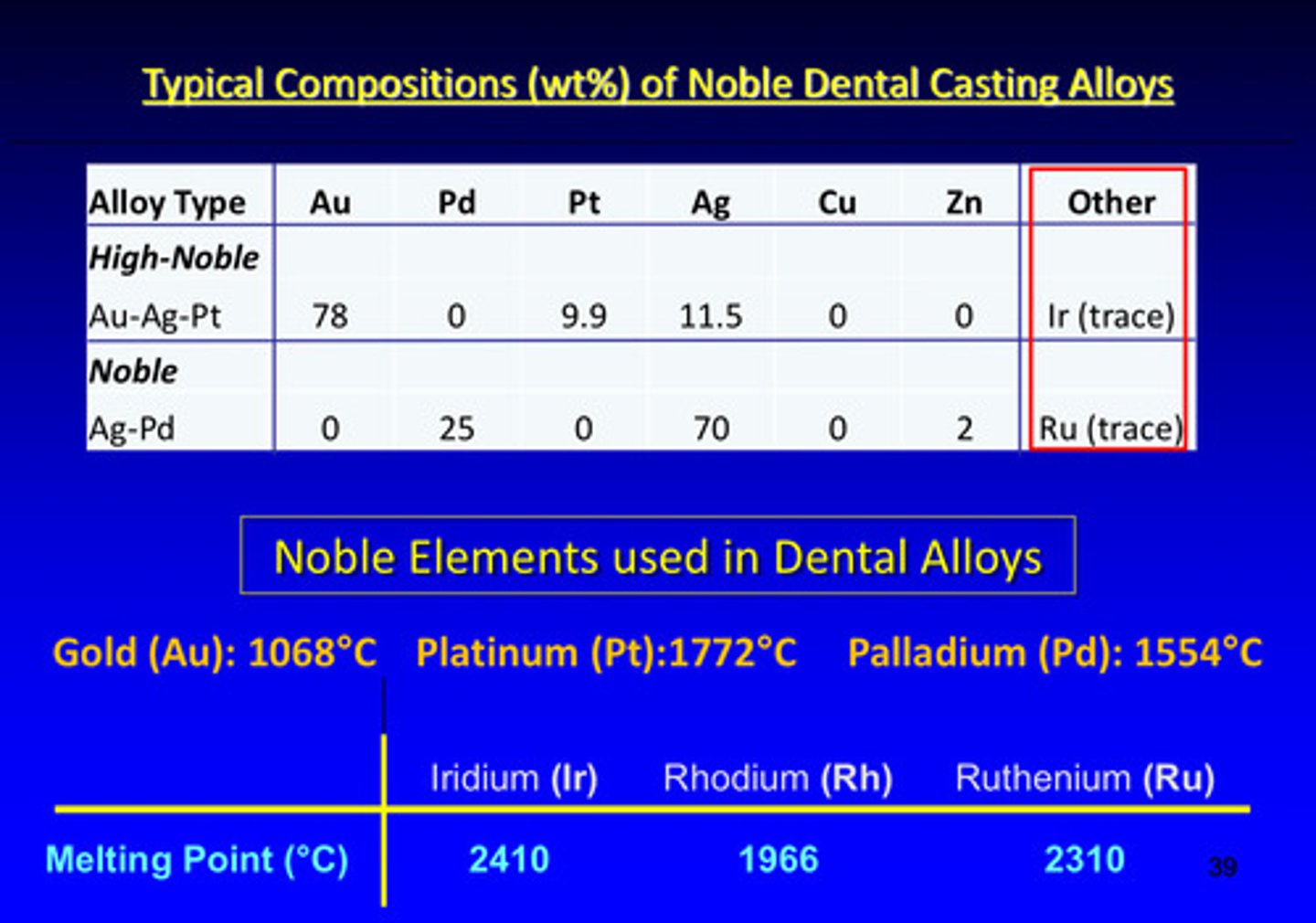

typical compositions (weight %) of noble dental casting alloys

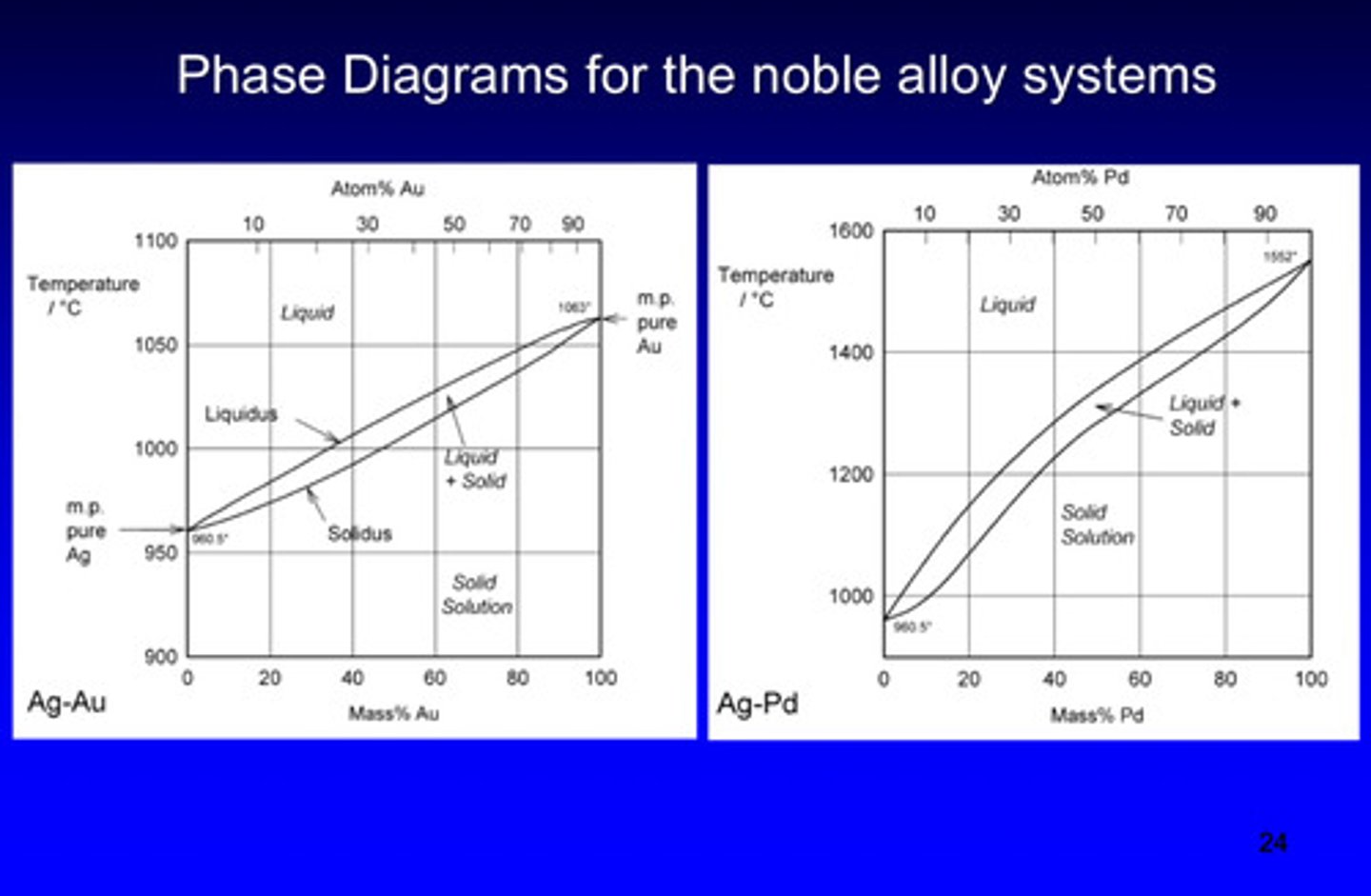

phase diagram for the noble alloy systems

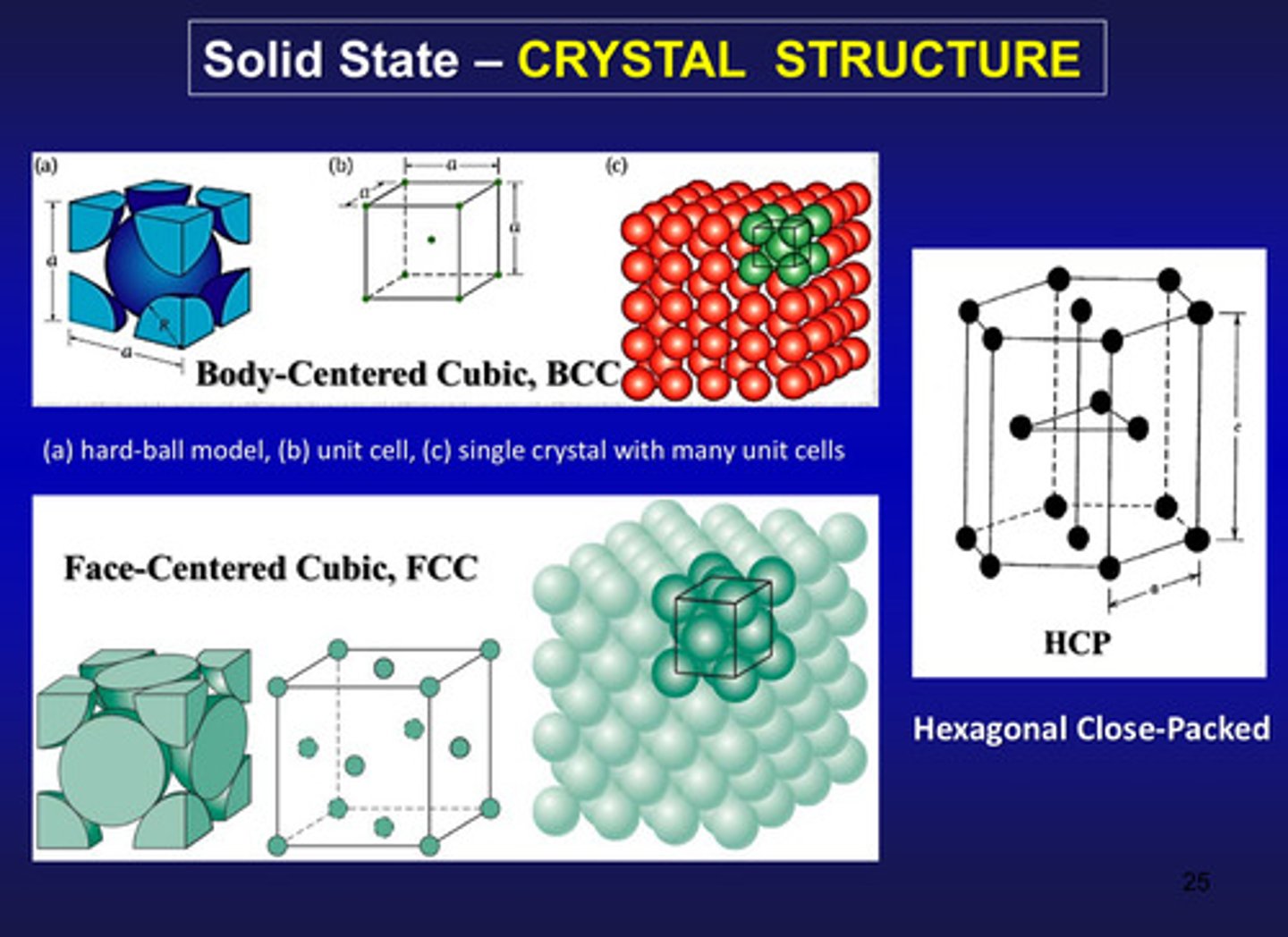

in the solid state, what structure does the system have

crystal (3 types: hard ball model, unit cell, and single crystal with many unit cells)

when a mixture of two or more metals is cooled, one of three possibilities may take place:

1) solid solution

2) compound

3) eutectic alloy

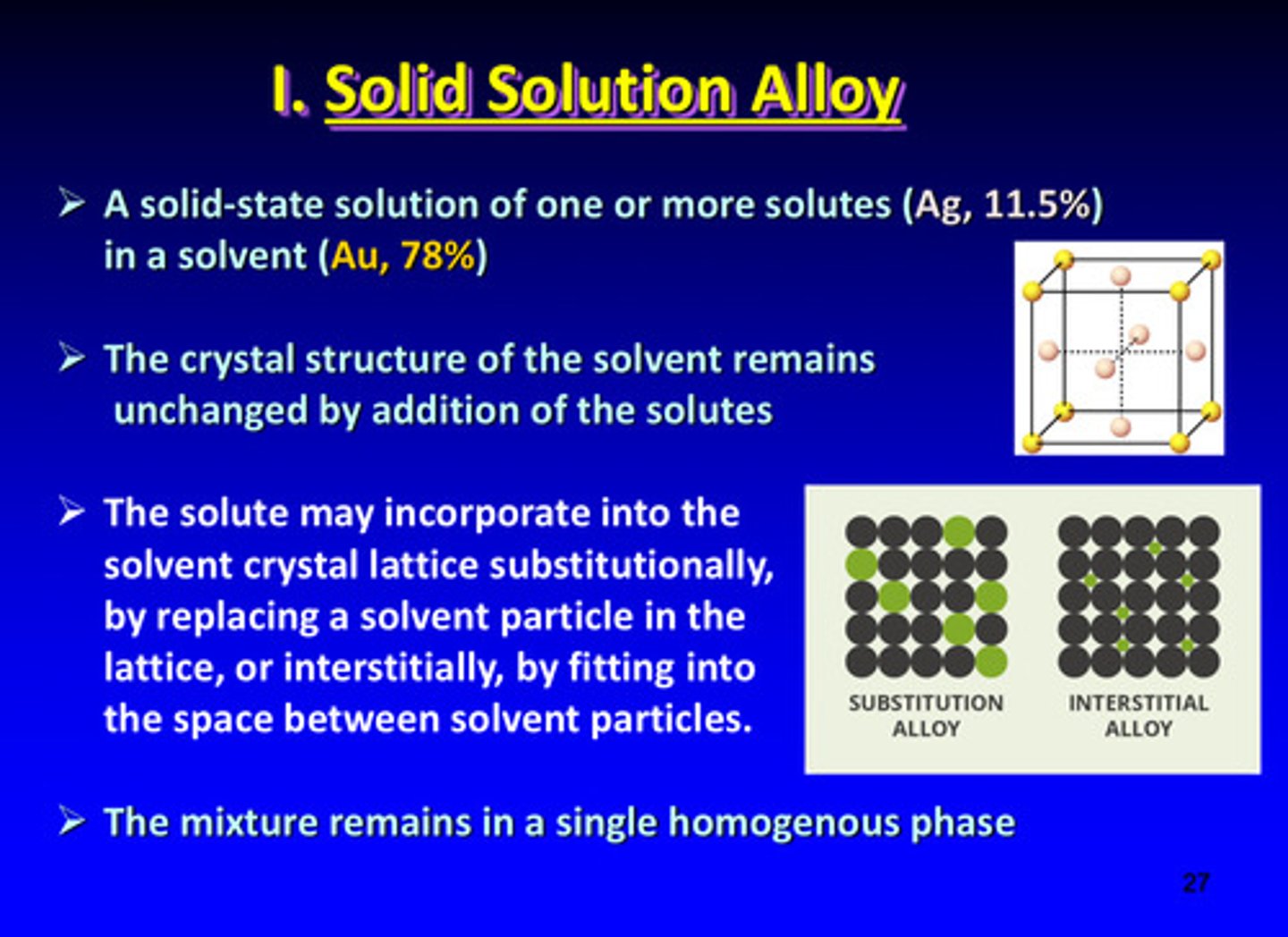

what is a solid solution alloy

a solid-state solution of one or more solutes (Ag, 11.5%) in a solvent (Au, 78%)

the crystal structure of the solvent in a solid solution alloy remains _________ by the addition of the solutes

unchanged

solid solution alloy: the solute may incorporate into the solvent crystal lattice substitutionally or interstitially: how?

by replacing a solvent particle in the lattice OR by fitting into the space between solvent particles

the solid solution alloy mixture remains in a single _____________ phase

homogenous

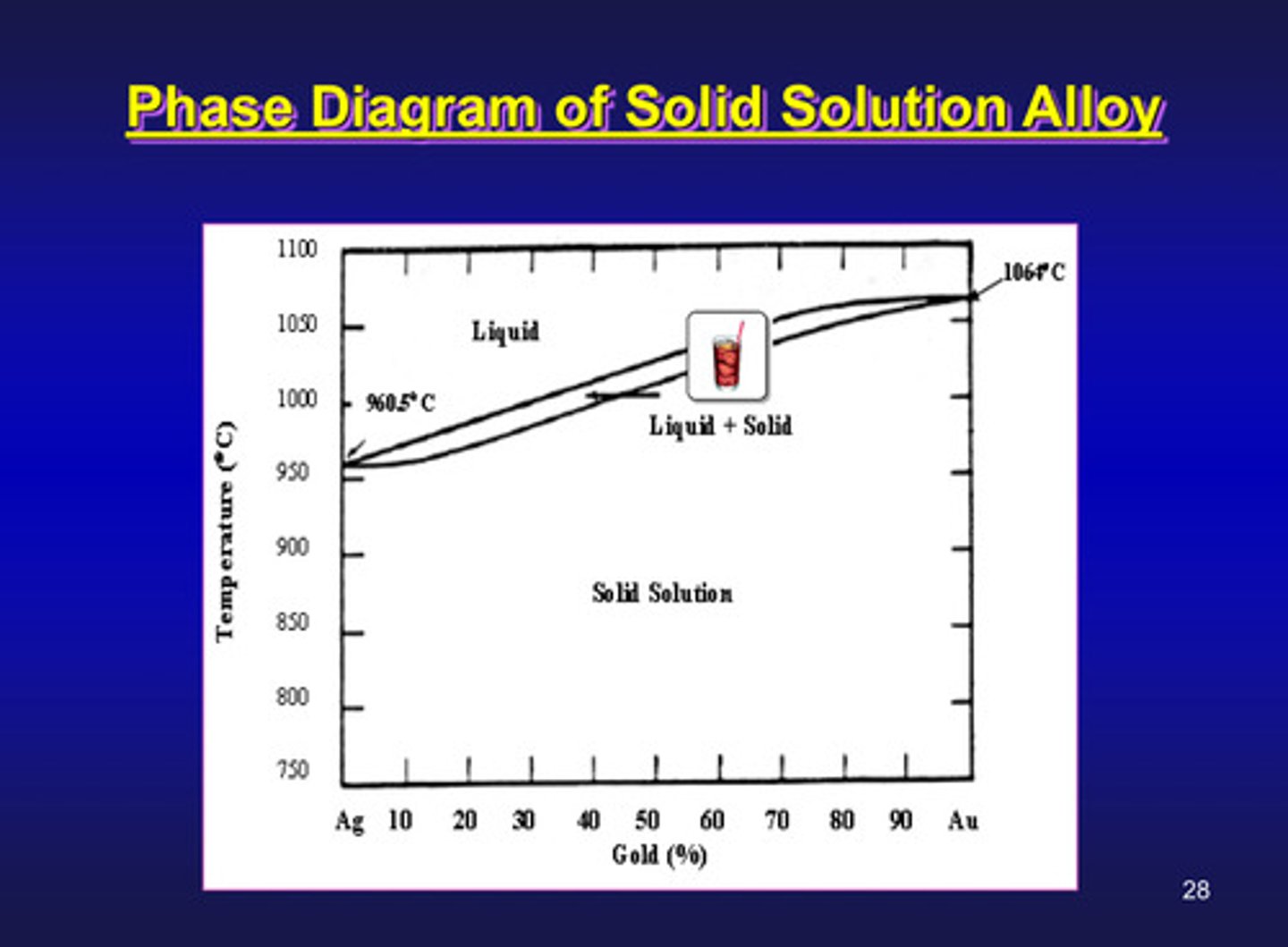

phase diagram of solid solution alloy

solid solution alloys are dictated by hume-rothery rules, what are they?

a set of basic rules that describe the conditions under which an element could dissolve in a metal, forming a solid solution, if the solute and solvent have 4 particular characteristics

what are the 4 characteristics of the hume-rothery rules

1) atom radius: differed by <15%

2) valence: similar valency

3) chemical affinity: similar electro negativity

4) crystal structure: must match between solvent and solute

summary of solid solution alloys

1) when 2 metals are completely miscible in the liquid state and they remain completely mixed on solidification

2) they form a single-phase system

3) system is NOT mechanically separable

4) ordered solutions indicate higher hardness and strengths in properties

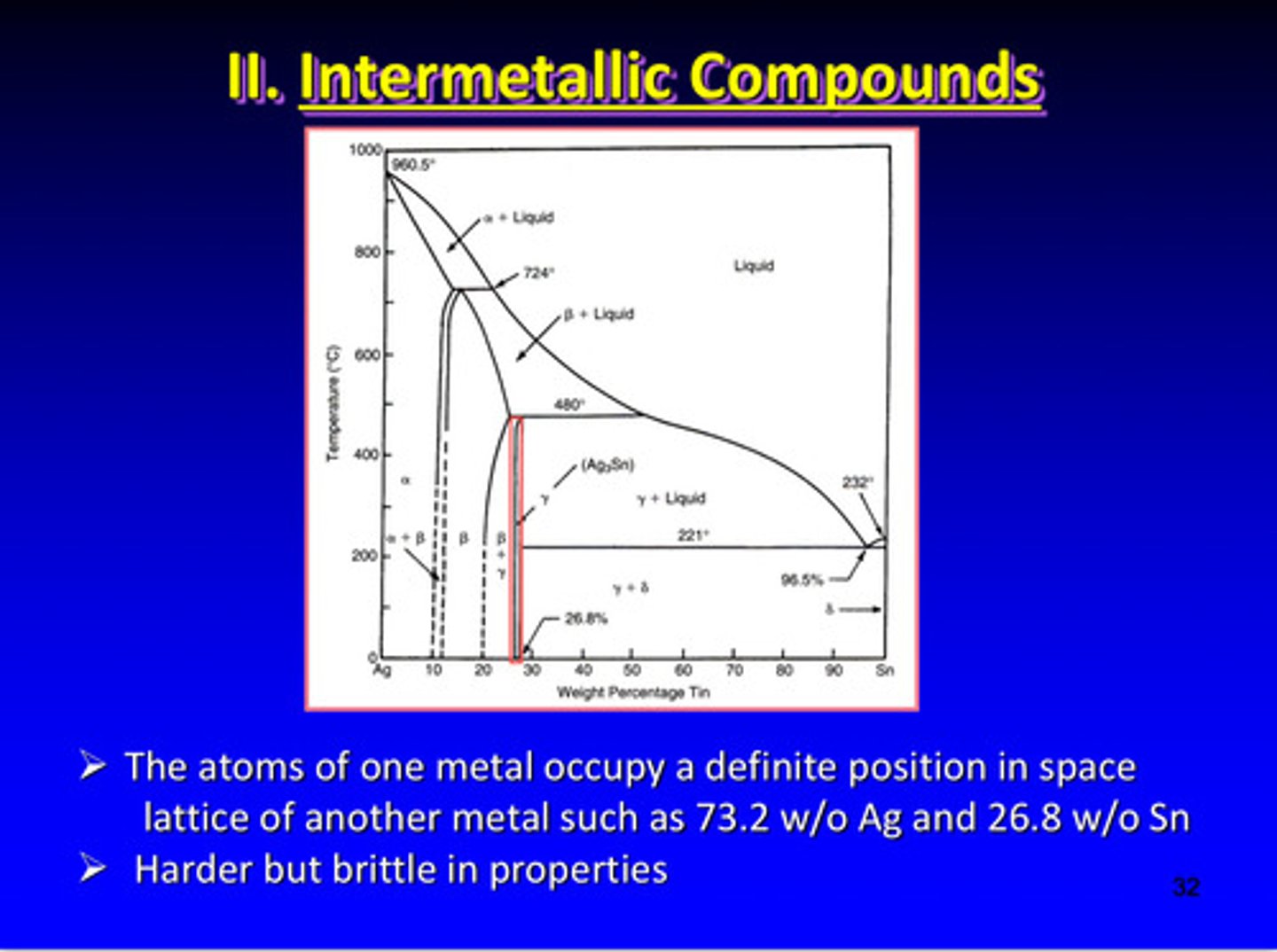

what are intermetallic compounds

2 metals are completely miscible in the liquid state and have a tendency to form unique chemical compounds on solidifying

intermetallic compounds are solid-state phase involving a more ________ structure and often a well-defined, fixed _____________

ordered; stoichiometry

in an intermetallic compound, the atoms of one metal occupy a ___________ position in the lattice space of another metal such as 73.2% Ag and 26.8% Sn

definite

intermetallic compounds are harder but _______ in properties

brittle

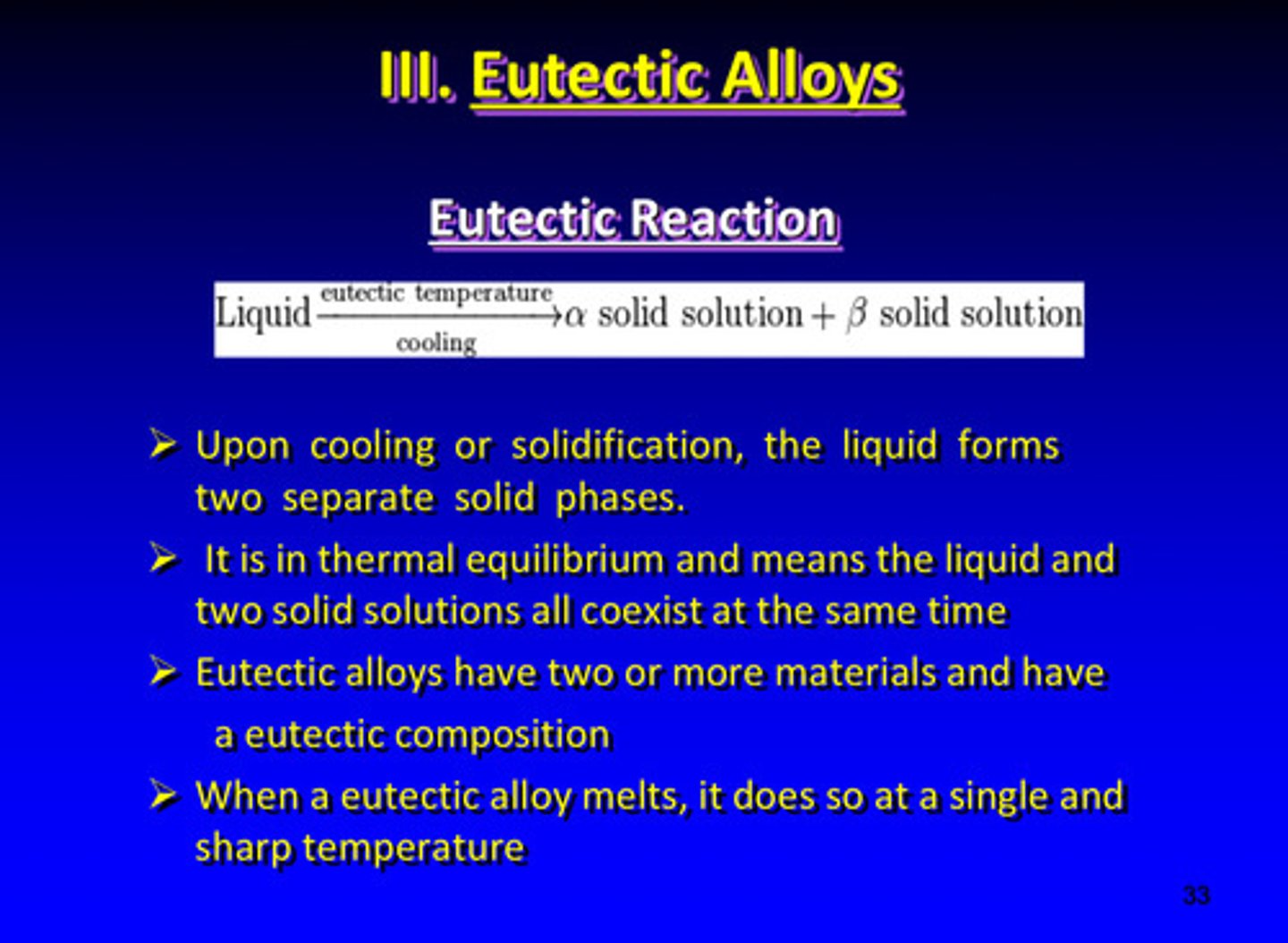

what are eutectic alloys

upon cooling or solidification, the liquid forms 2 separate solid phases

eutectic alloys are in _______ equilibrium and this means that the liquid and 2 solid solutions all ______ at the same time

coexist

eutectic alloys have _______ materials and have a eutectic composition

2+

when a eutectic alloy metals, it does so at a ______ and ______ temperature

single and sharp

eutectic reaction image

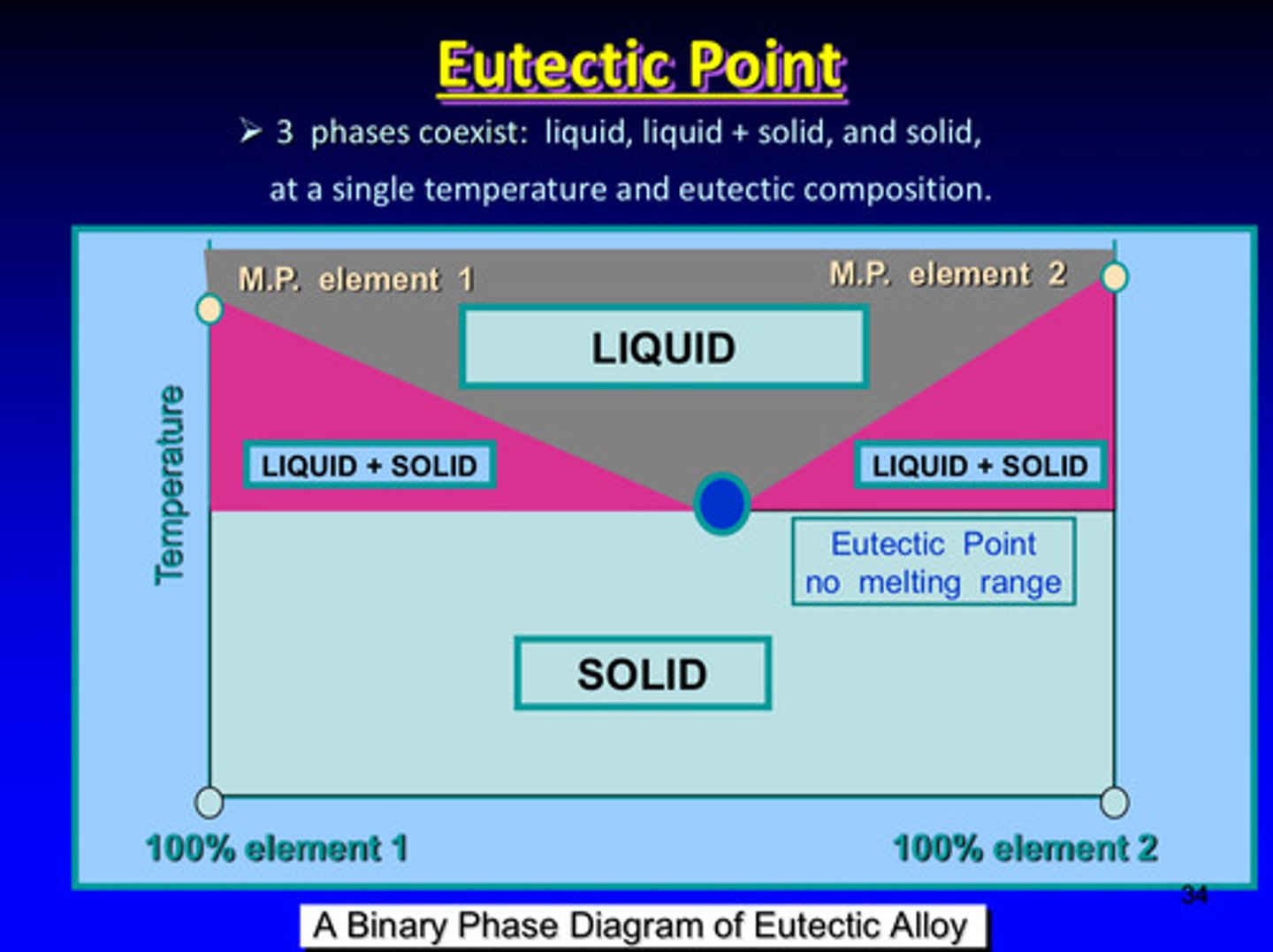

what is the eutectic point

the point in which all 3 phases coexist: liquid, liquid + solid, and solid —> all at a single temperature and eutectic composition

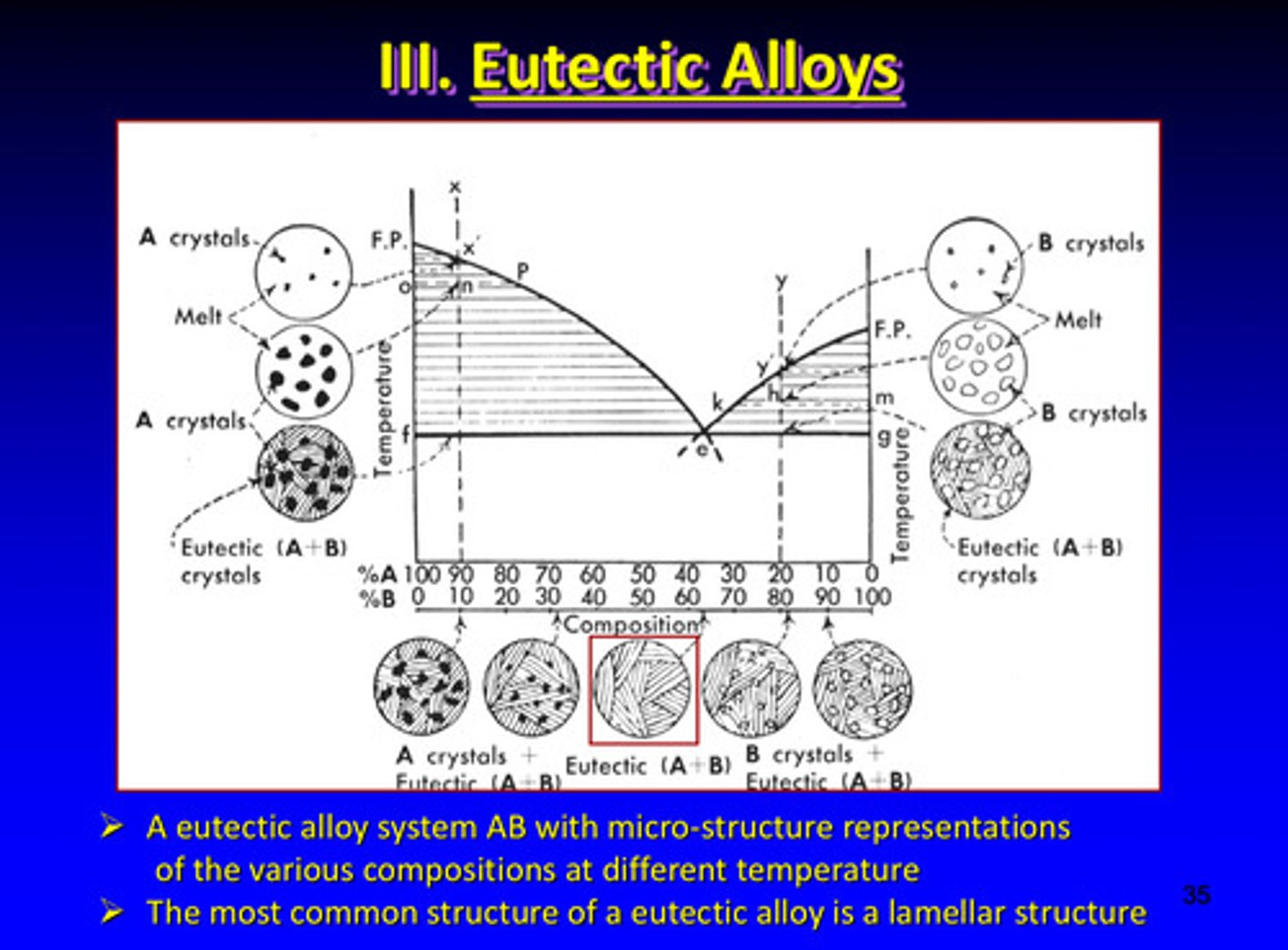

a eutectic alloy system AB with micro-structure representations of the various compositions at different temperatures

the most common structure of a eutectic alloy is a ?

lamellar structure

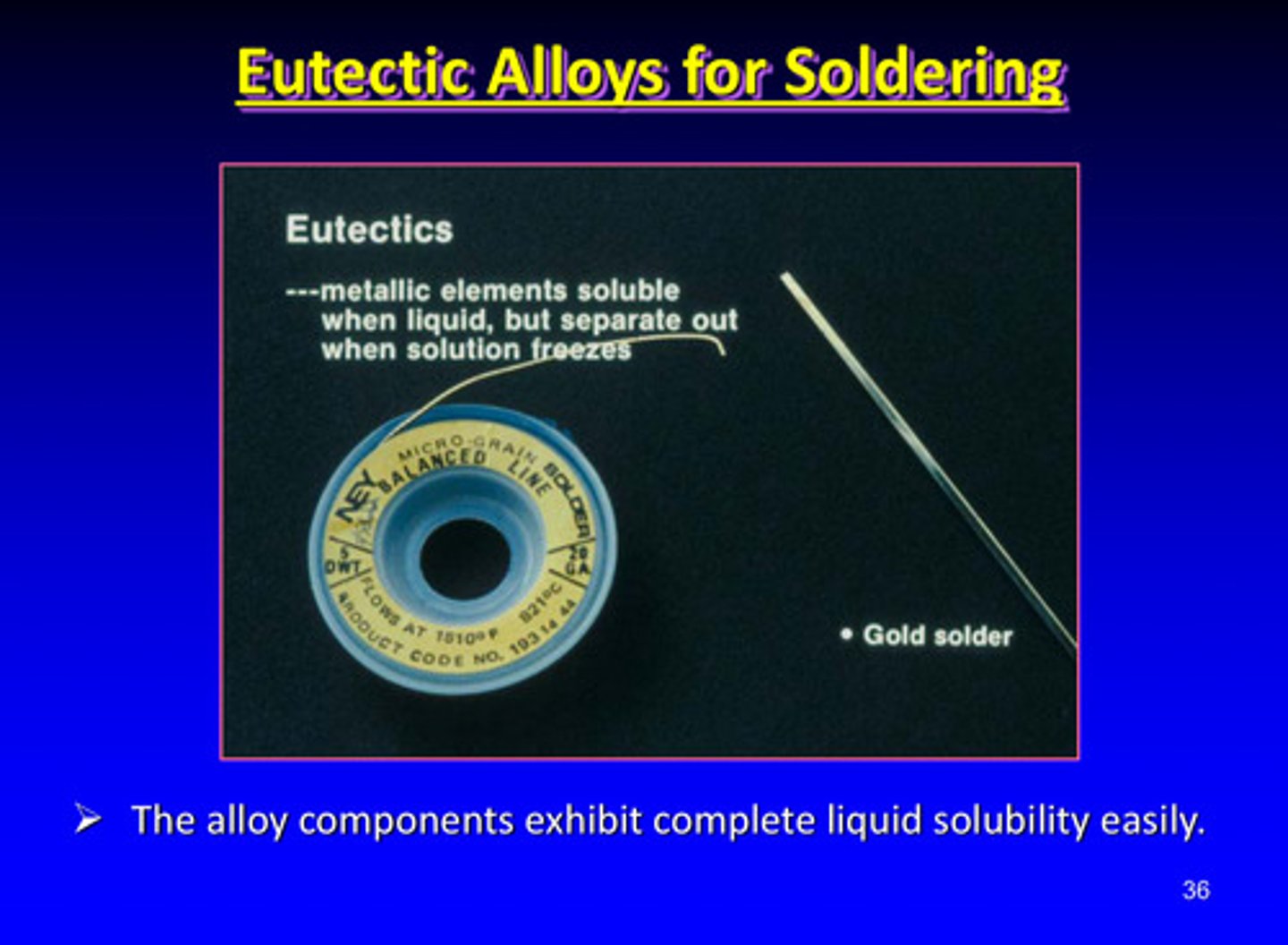

the alloy components of eutectic alloys exhibit what easily

complete liquid solubility

eutectic alloys may be used in what kind of procedure

soldering

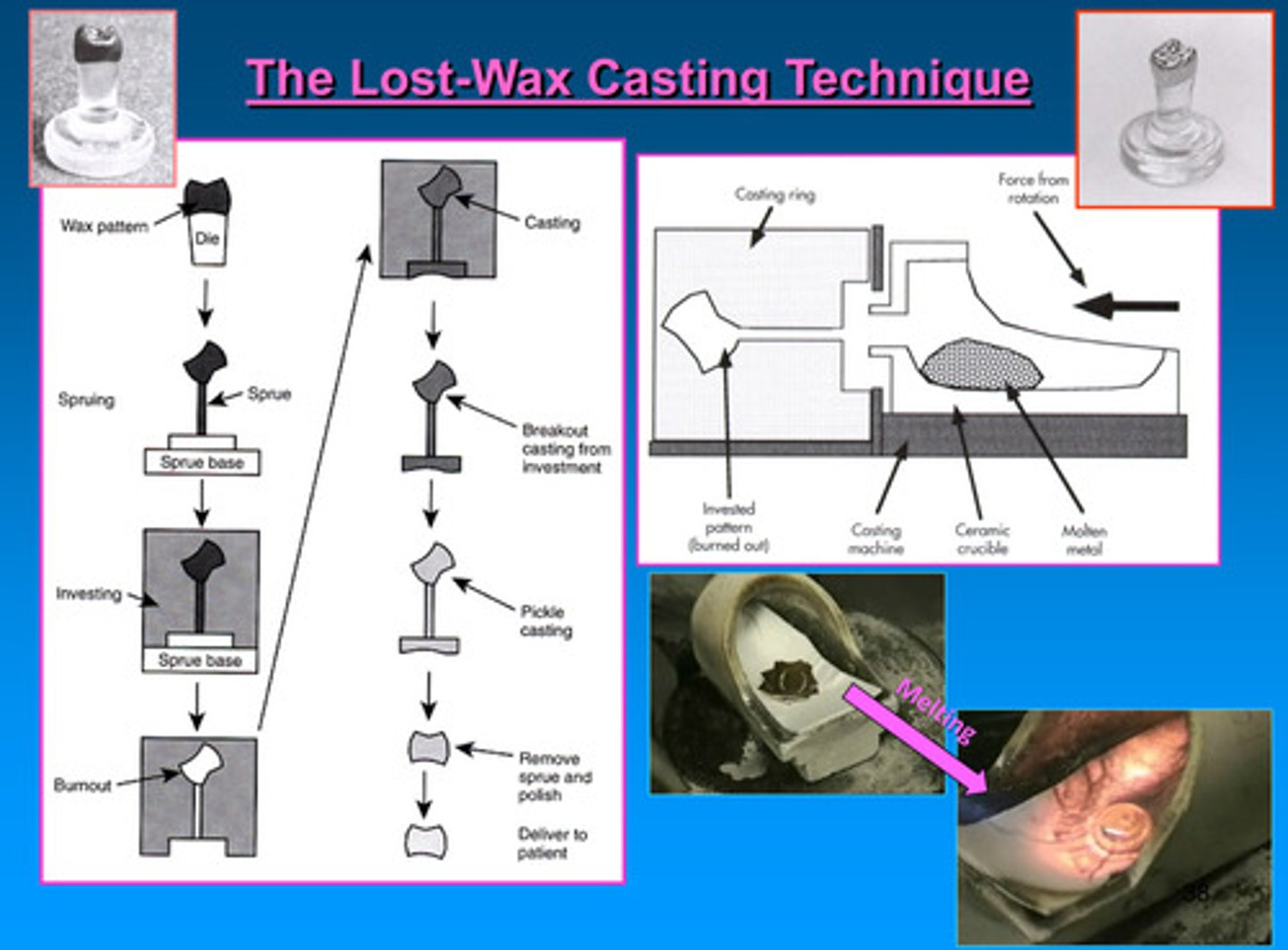

lost wax casting technique image

what are the 3 noble elements used in dental alloys

gold (Au), platinum (Pt), palladium (Pd)

image of structures of metals and alloys in metallic solidification

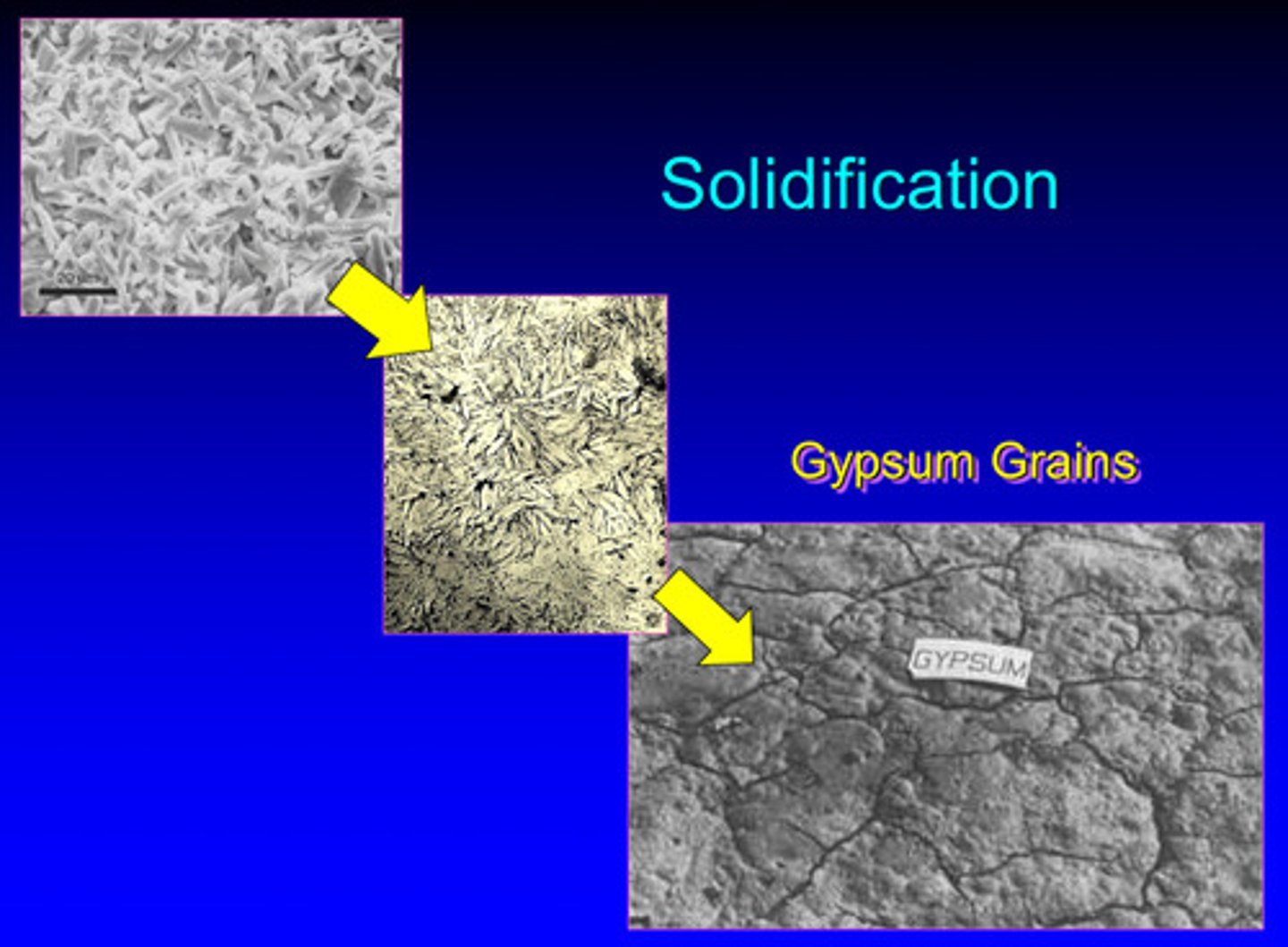

solidifcation image of gypsum grains

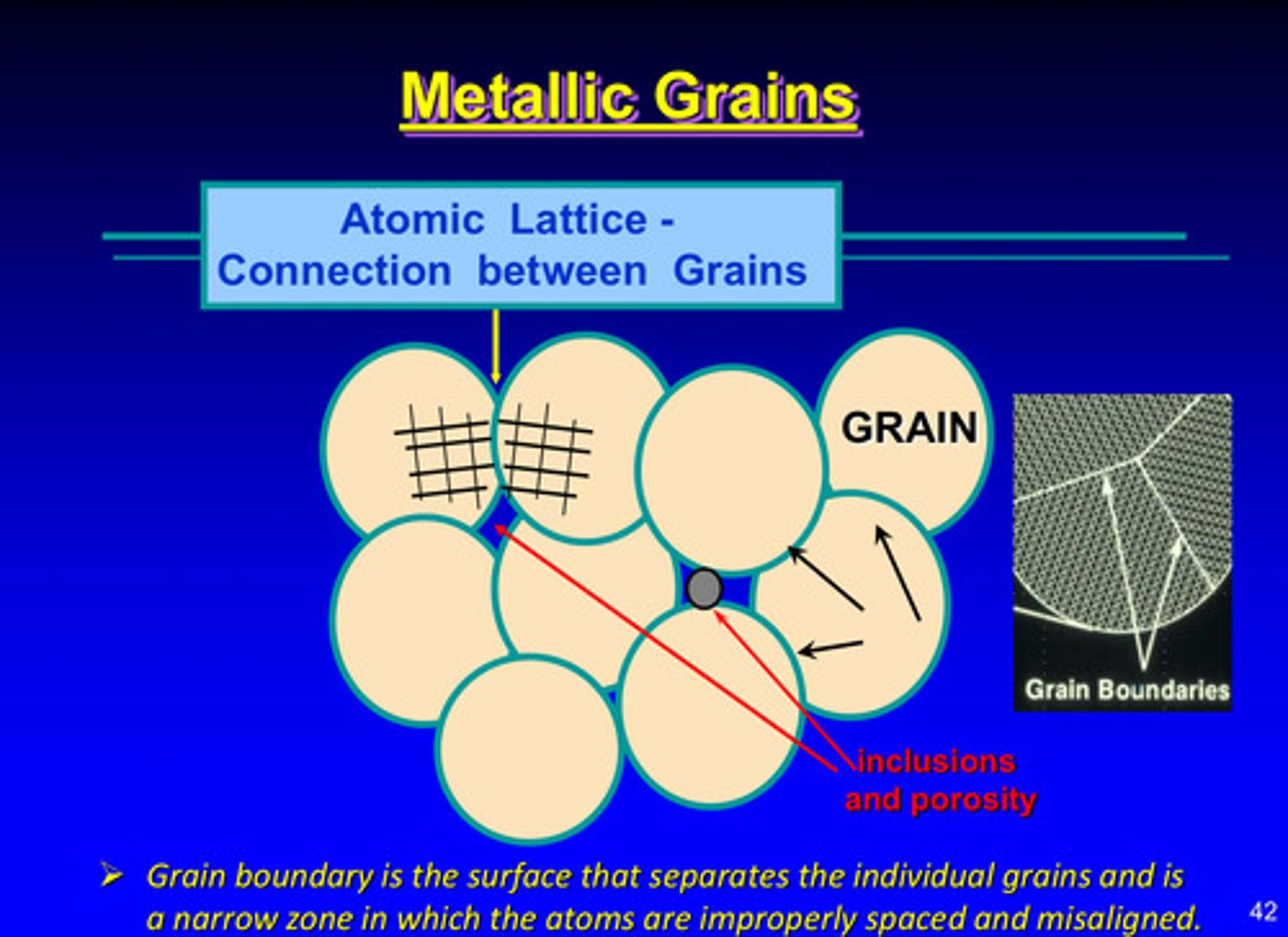

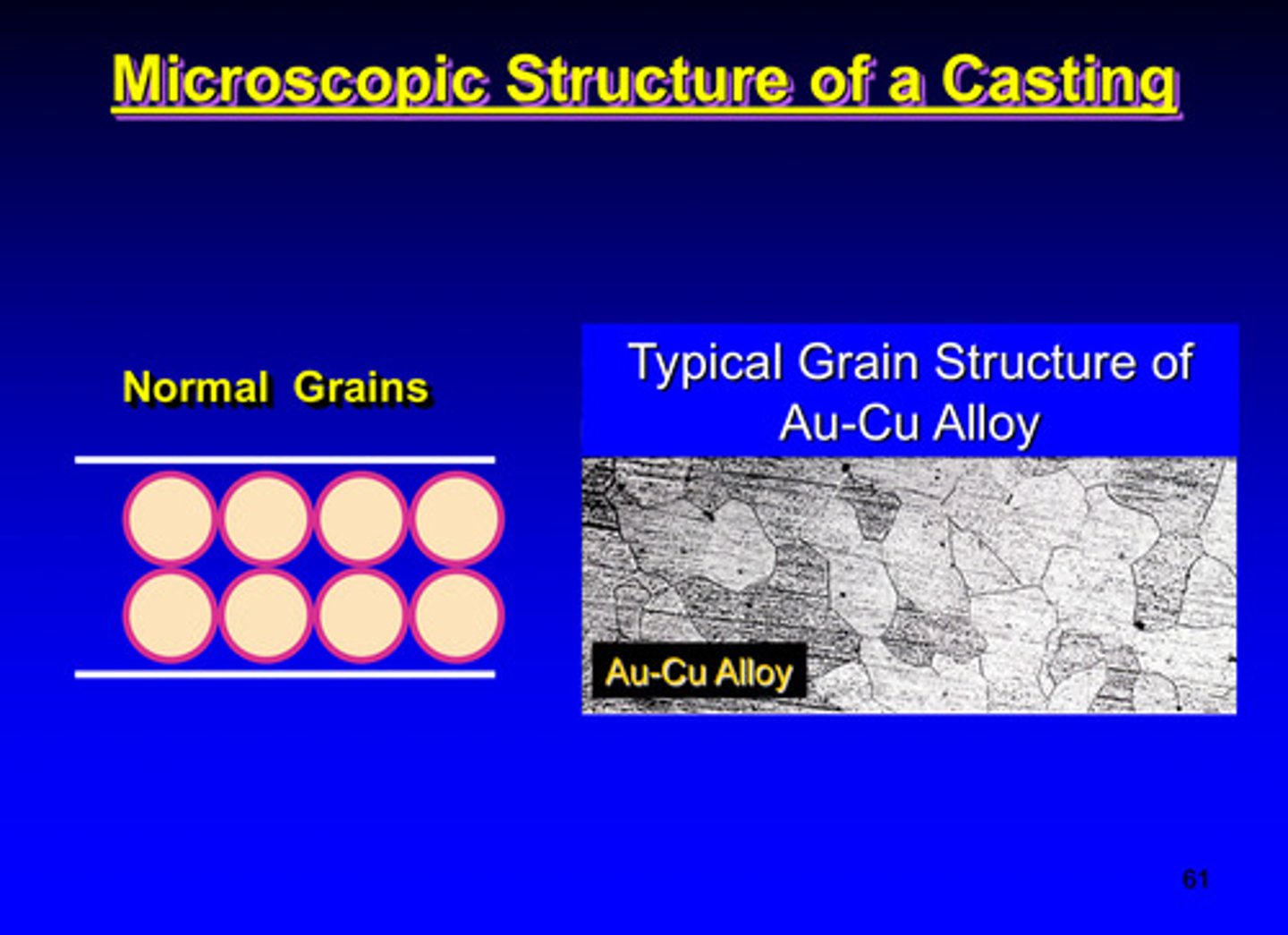

the atomic lattice is made by connections between ?

grains

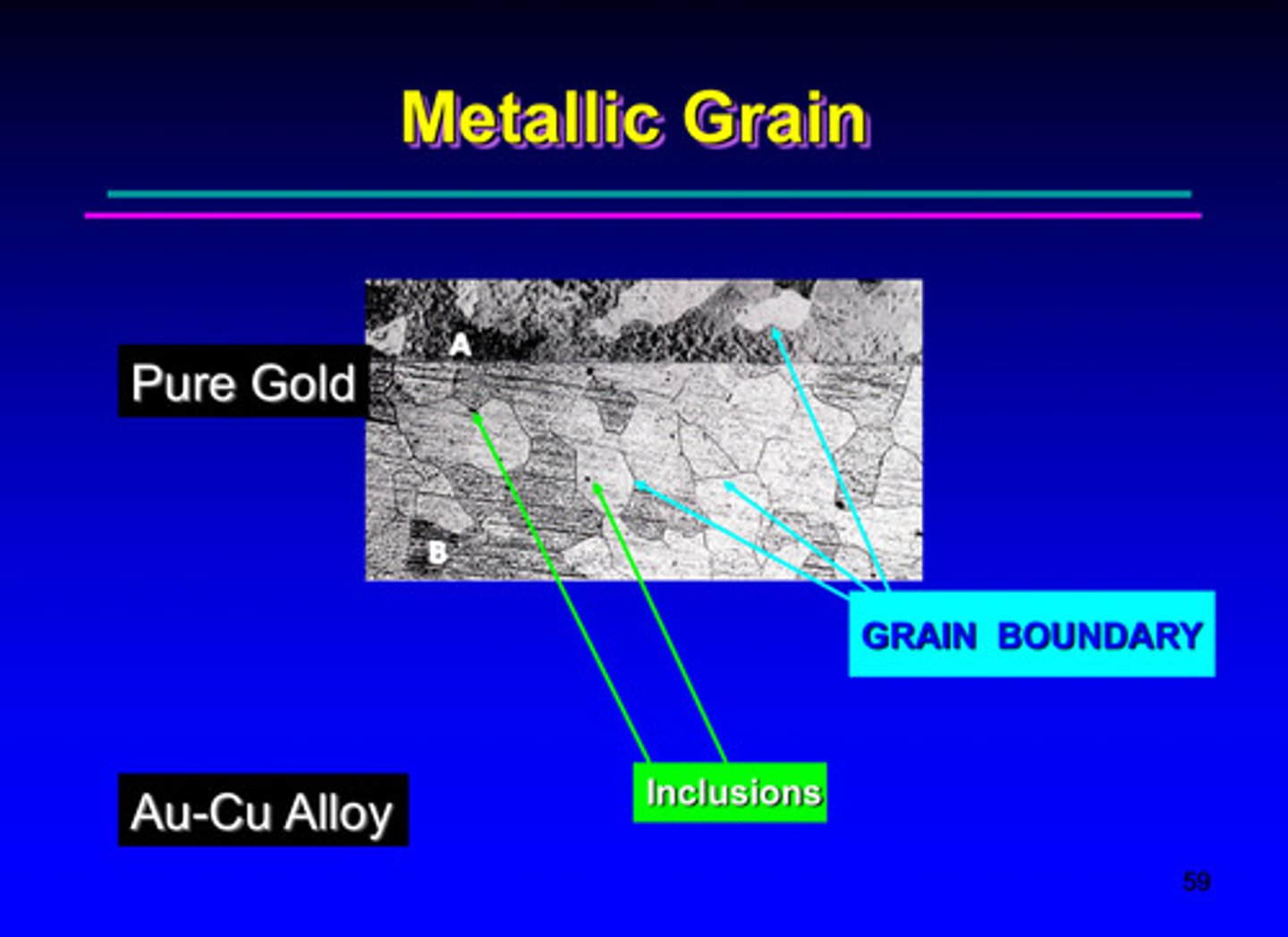

what are grain boundaries

the surface that separates the individual grains and is a narrow zone in which the atoms are improperly spaced and misaligned

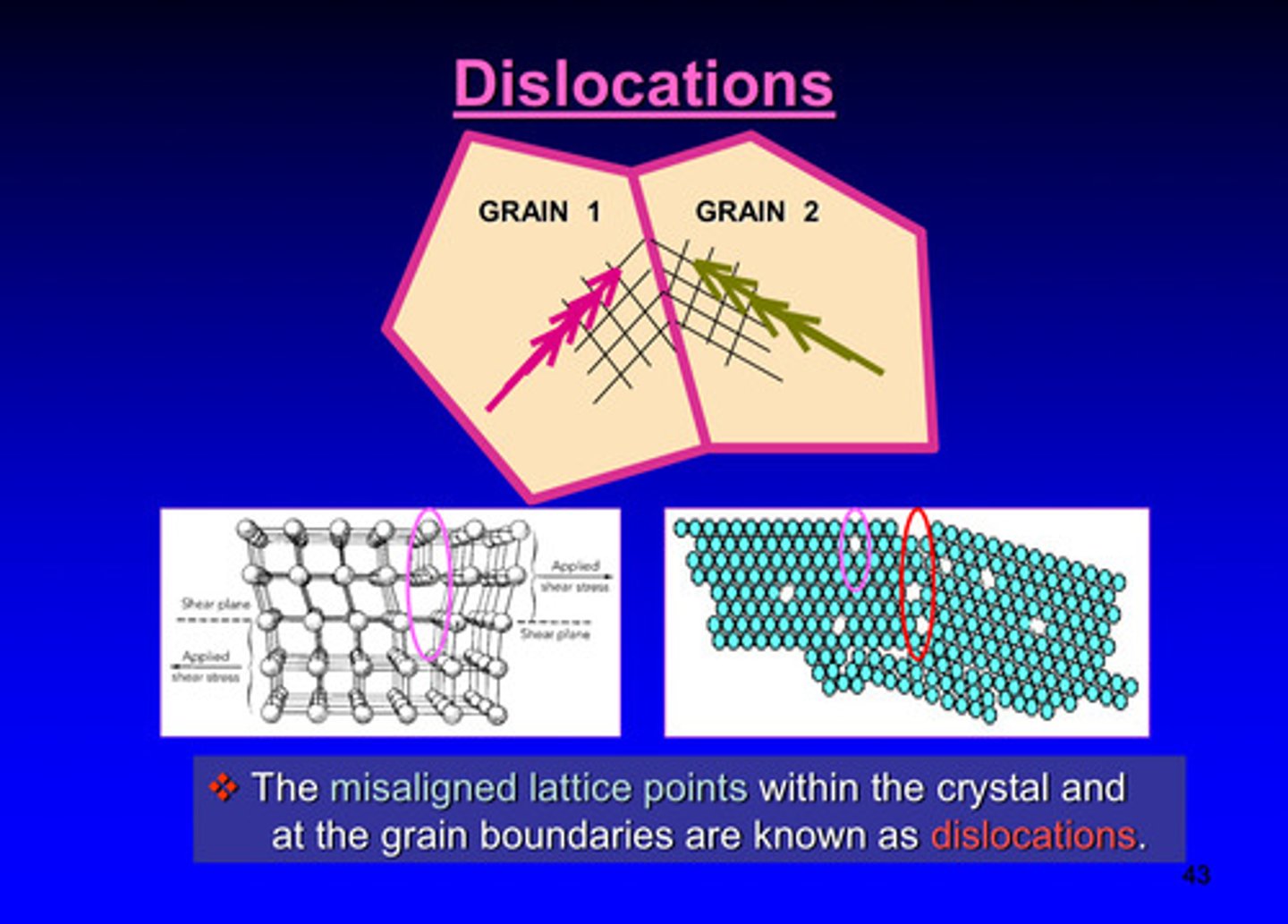

what are dislocations

the misaligned lattice points within the crystal and at the grain boundaries

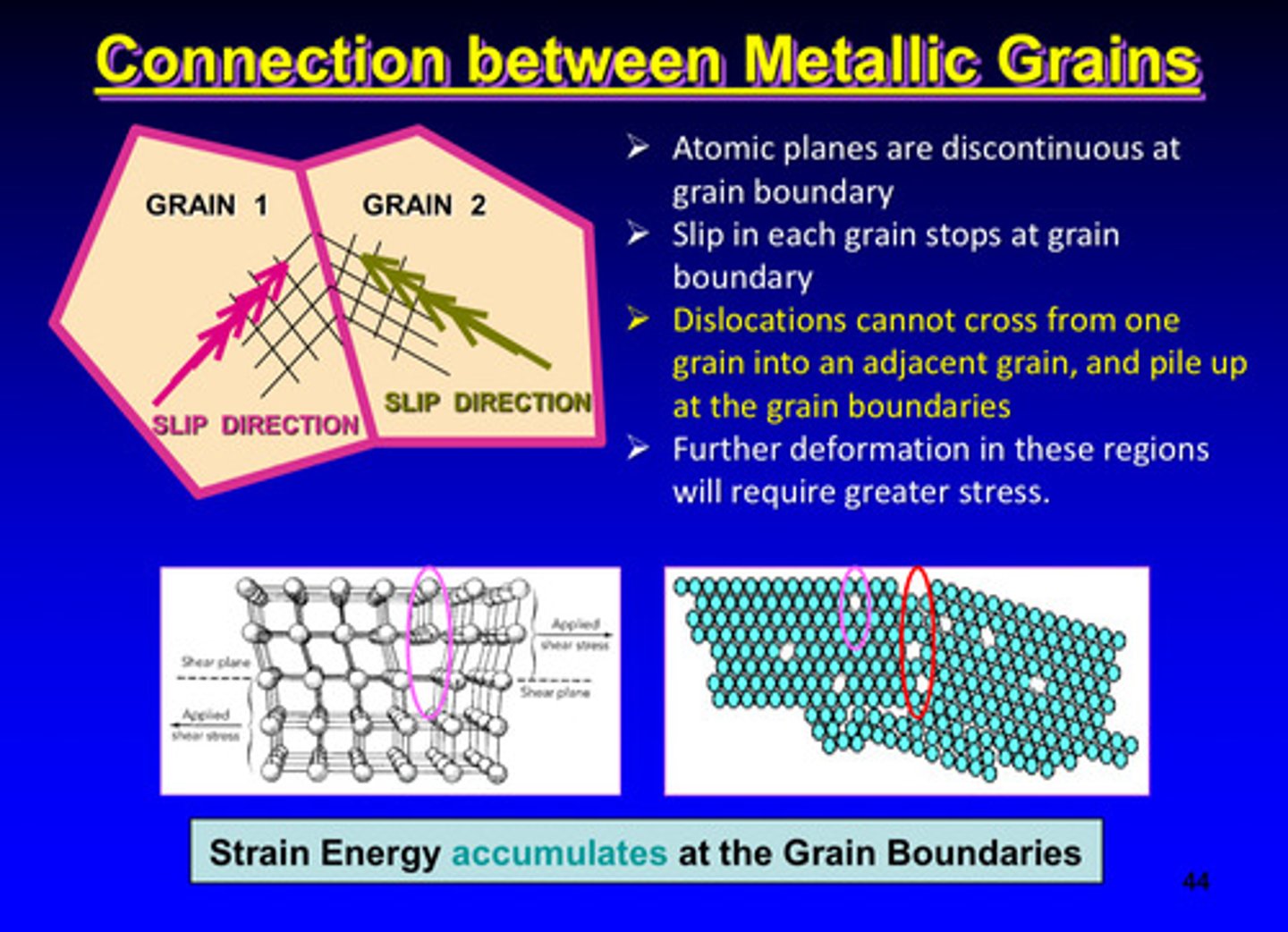

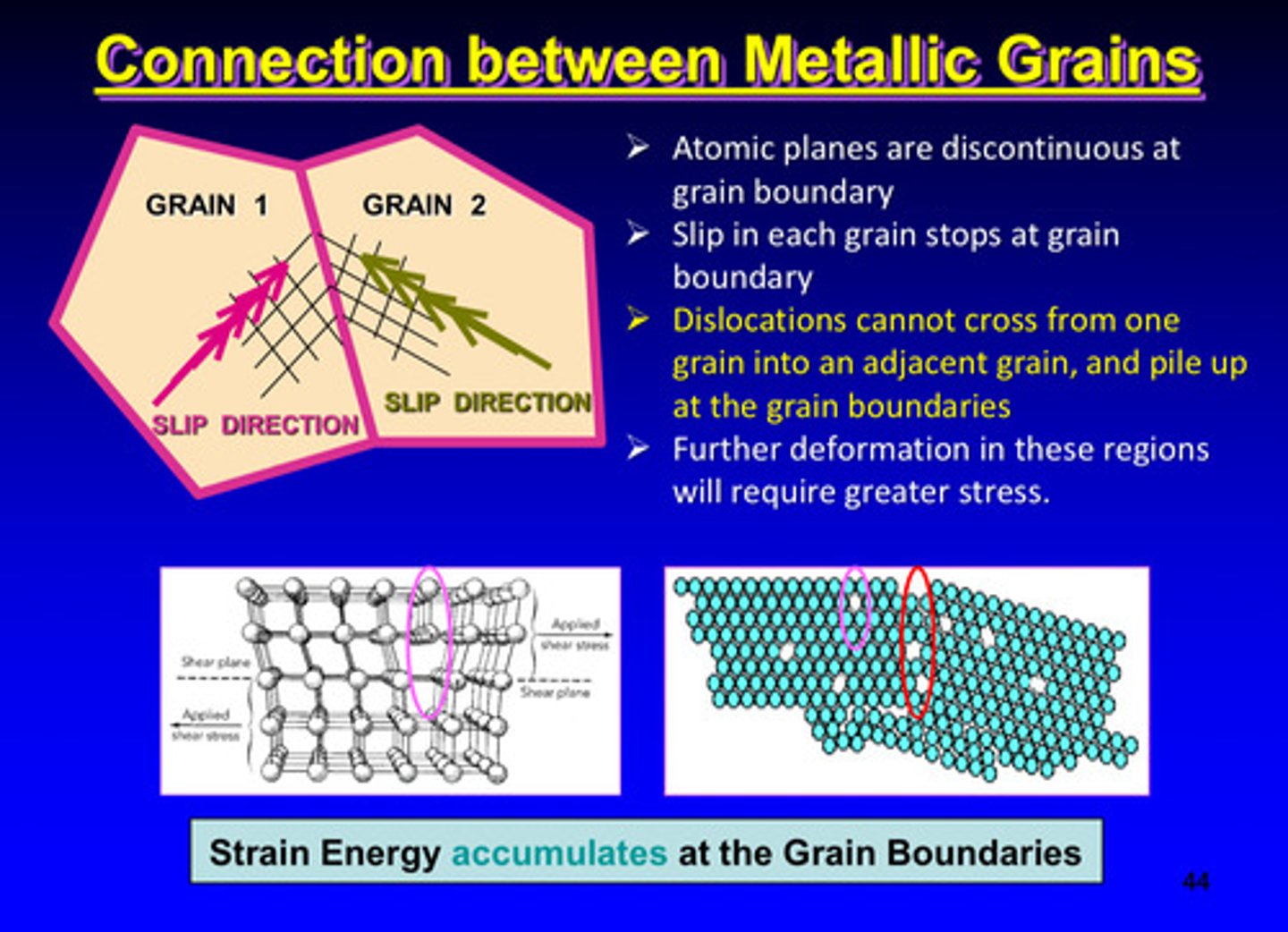

atomic plans are _________ at grain boundaries

discontinuous

slip in each grain stops where

at grain boundaries

dislocations cannot cross from one grain into another adjacent grain, so they ?

they pile up at the grain boundaries

further deformation in grain boundaries will require greater ________

stress

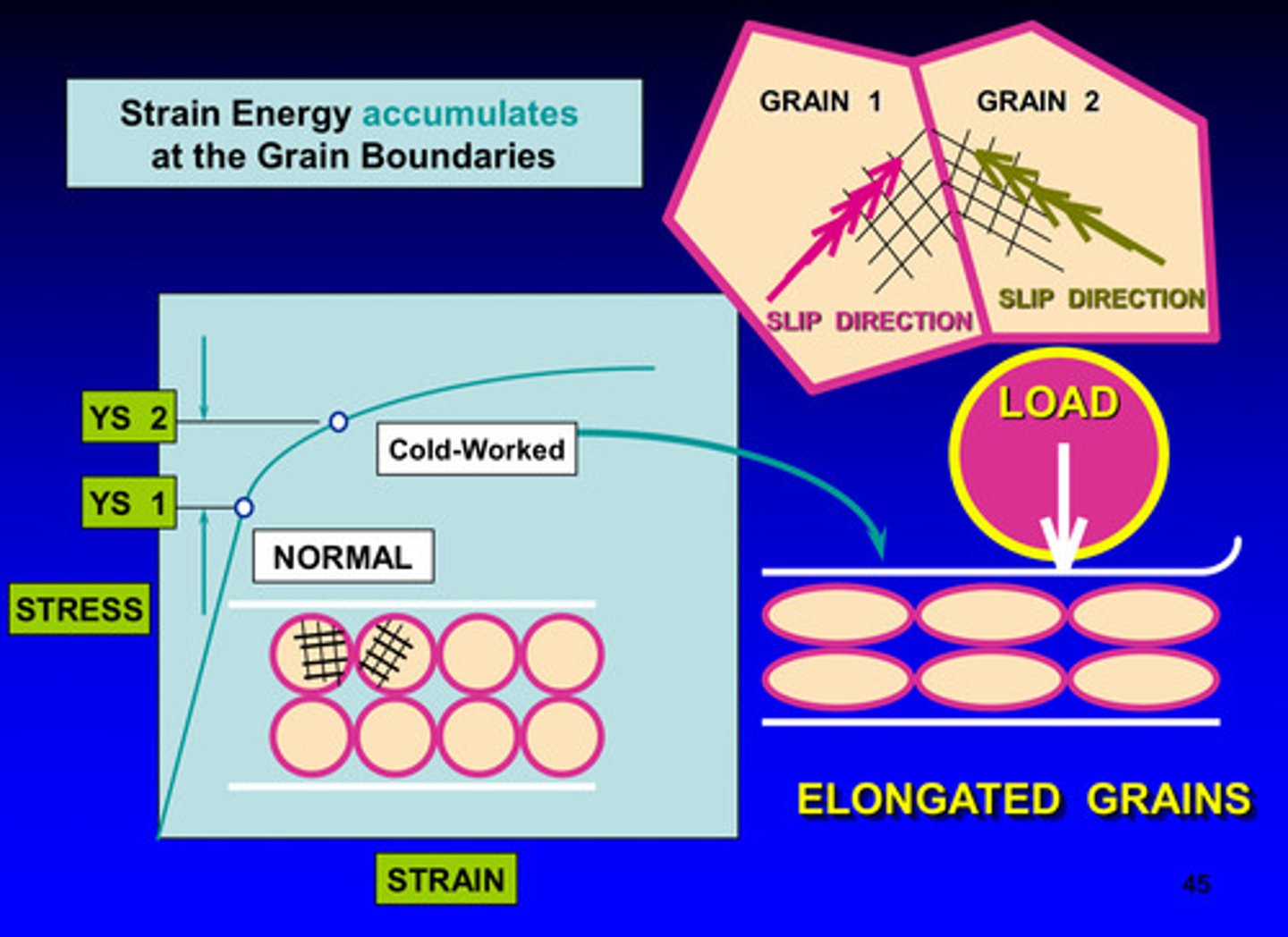

what kind of energy accumulates at the grain boundaries

strain energy

example of strain energy accumulating at grain boundaries

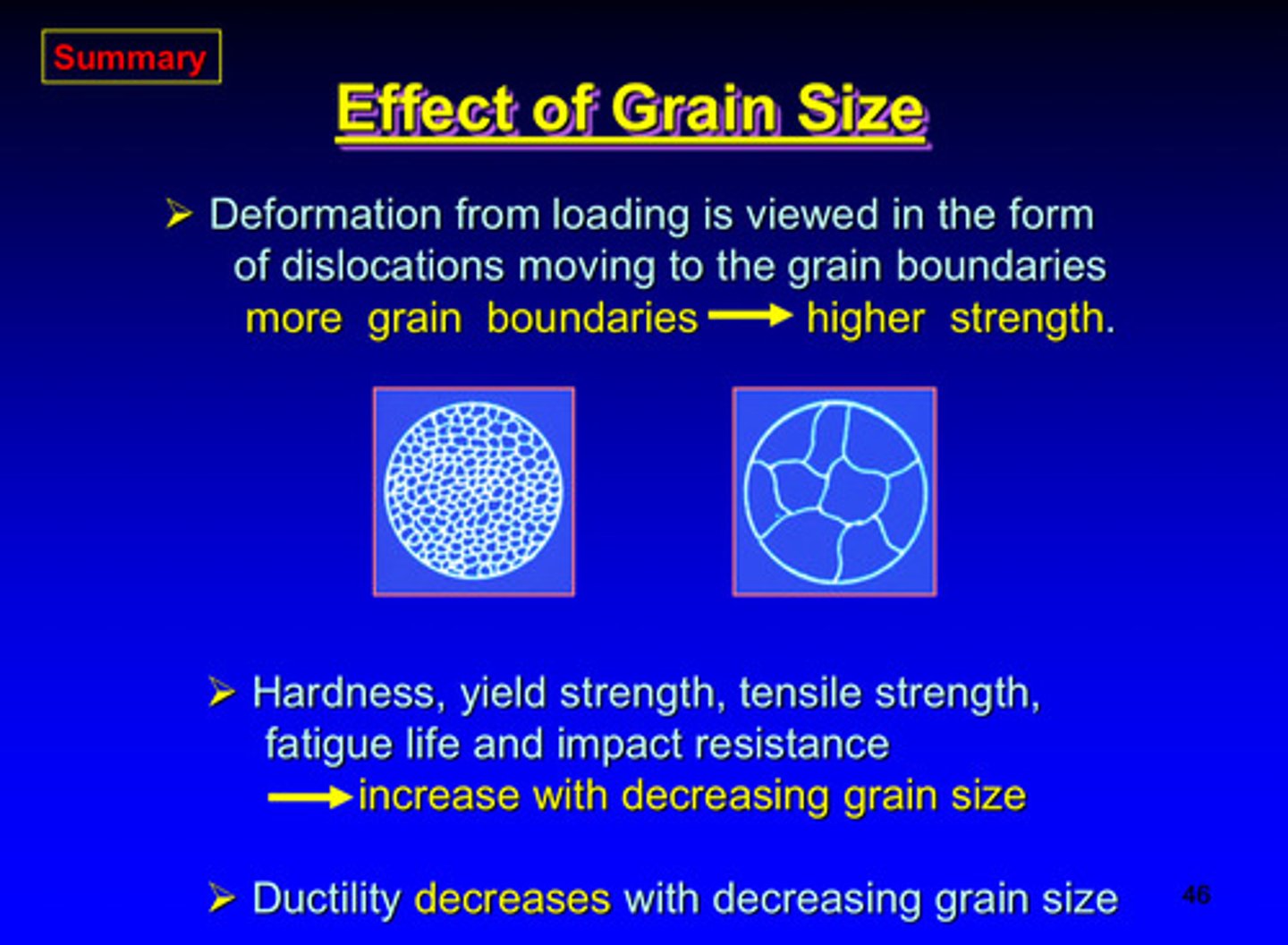

deformation from loading is viewed in the form of what

form of dislocations moving to the grain boundaries (more grain boundaries = higher strength)

what 5 characteristics increase with decreasing grain size

1) hardness

2) yield strength

3) tensile strength

4) fatigue life

5) impact resistance

what characteristics decreases with decreasing grain size

ductility

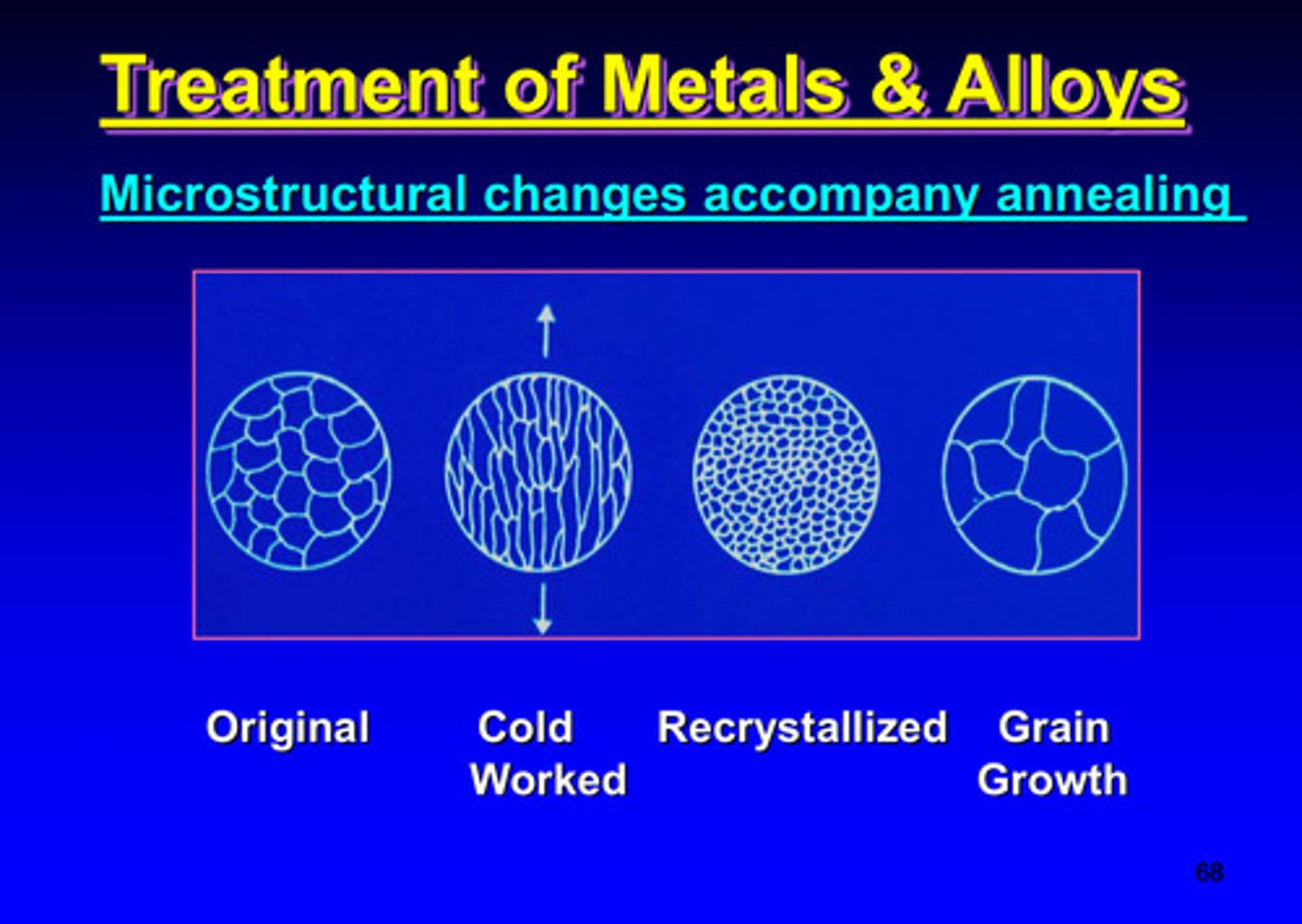

treatments of metals and alloys

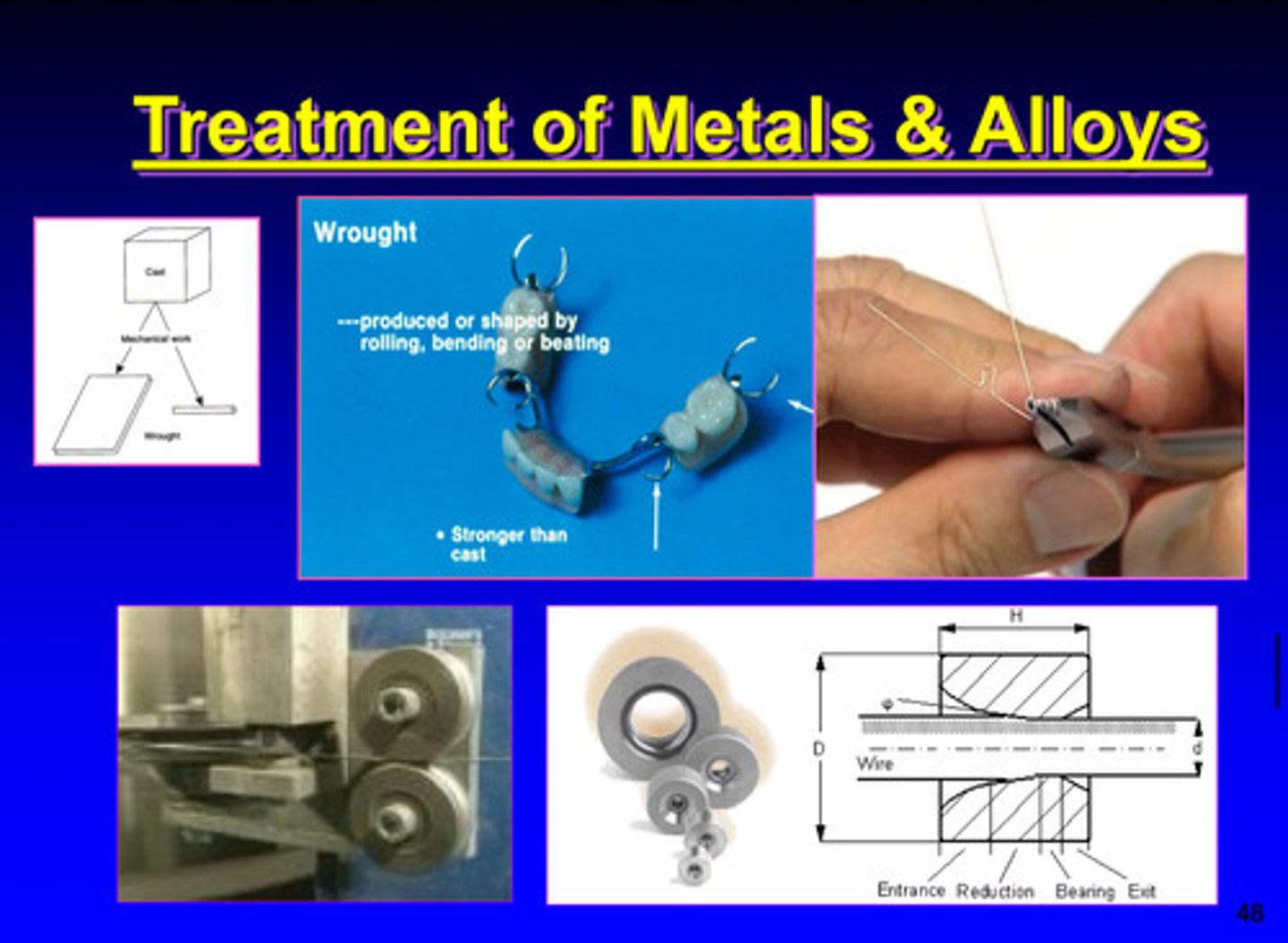

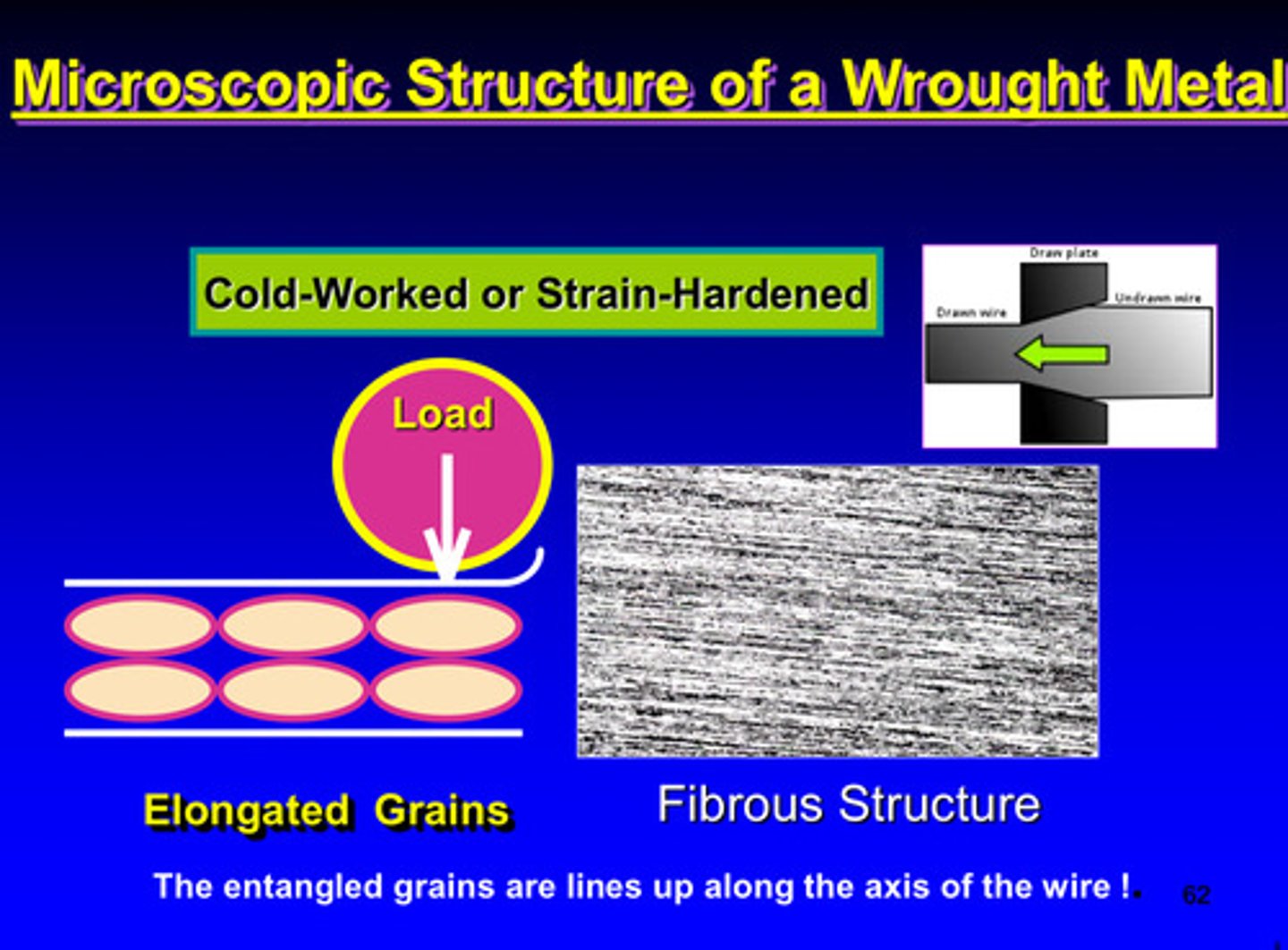

mechanical wrought treatment of metals and alloys

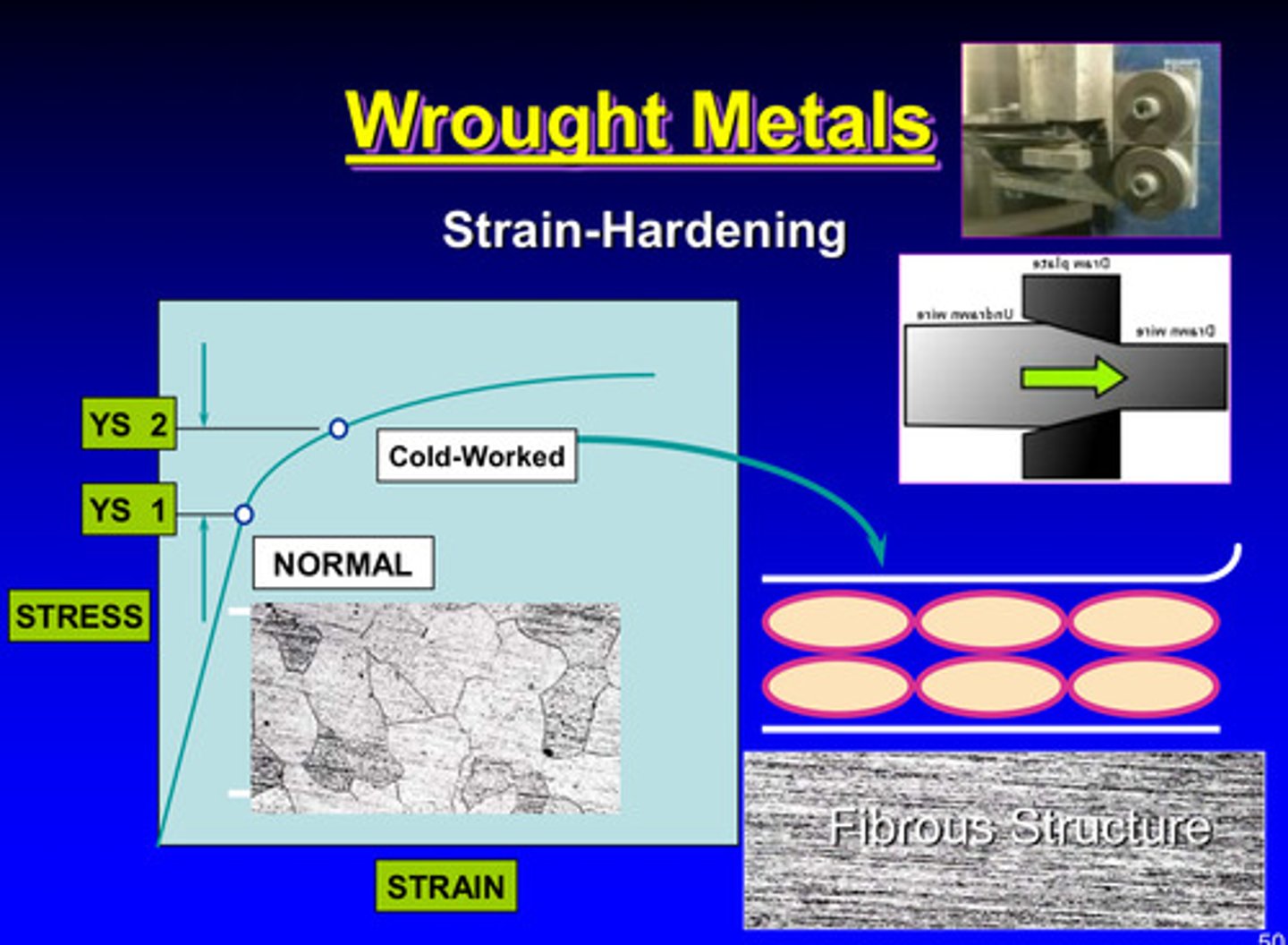

wrought metals image

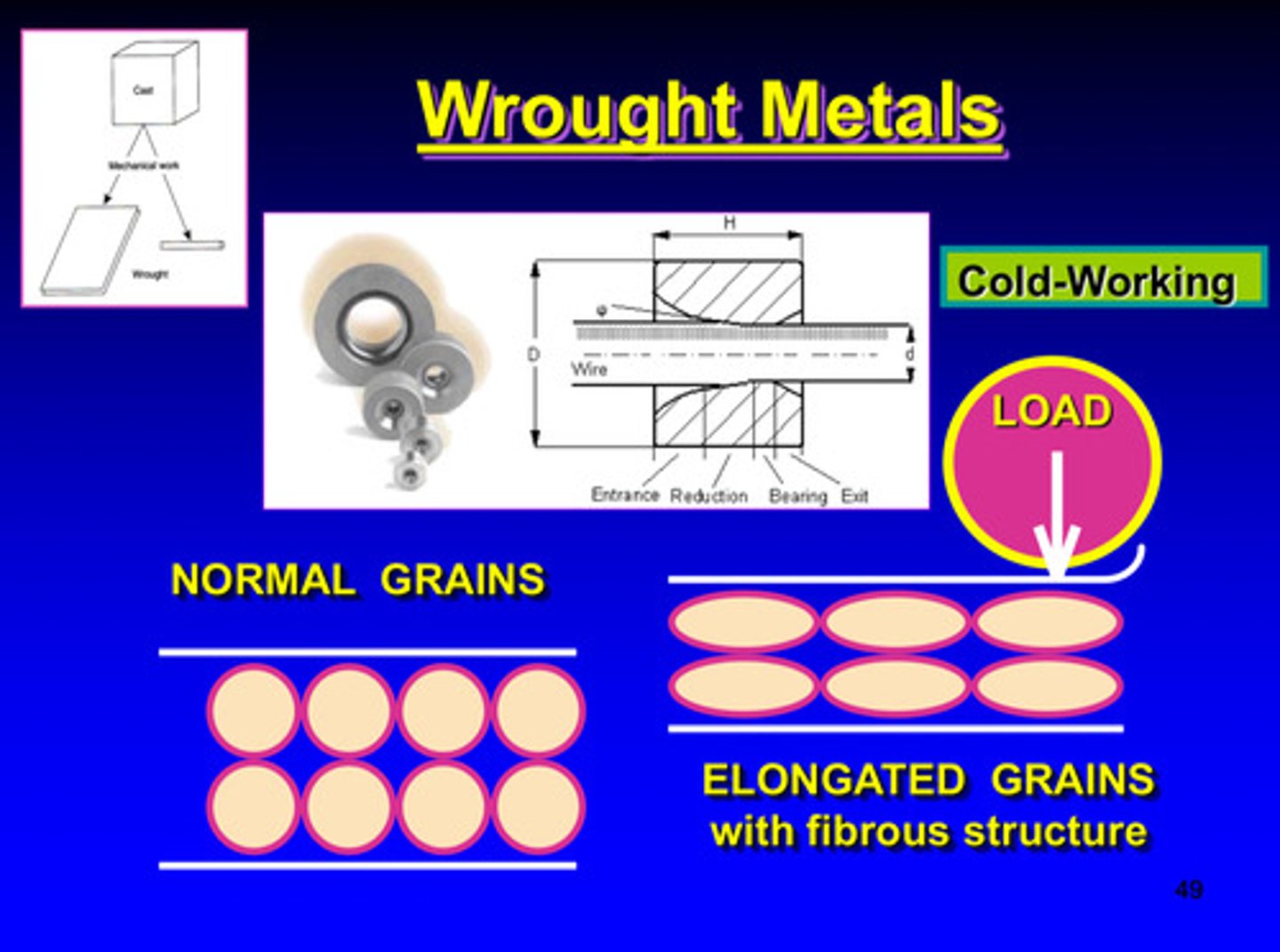

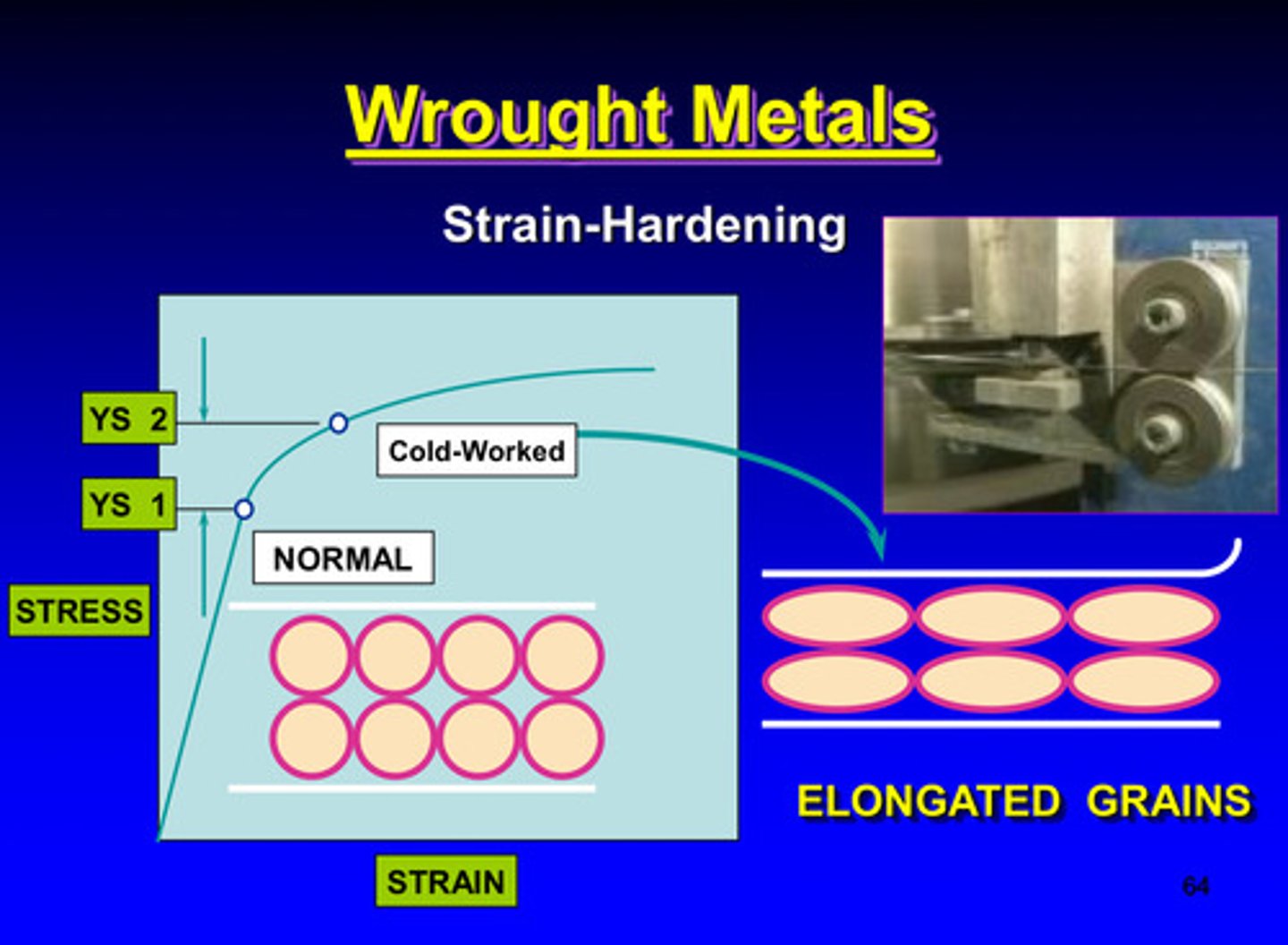

wrought metals and strain-hardening

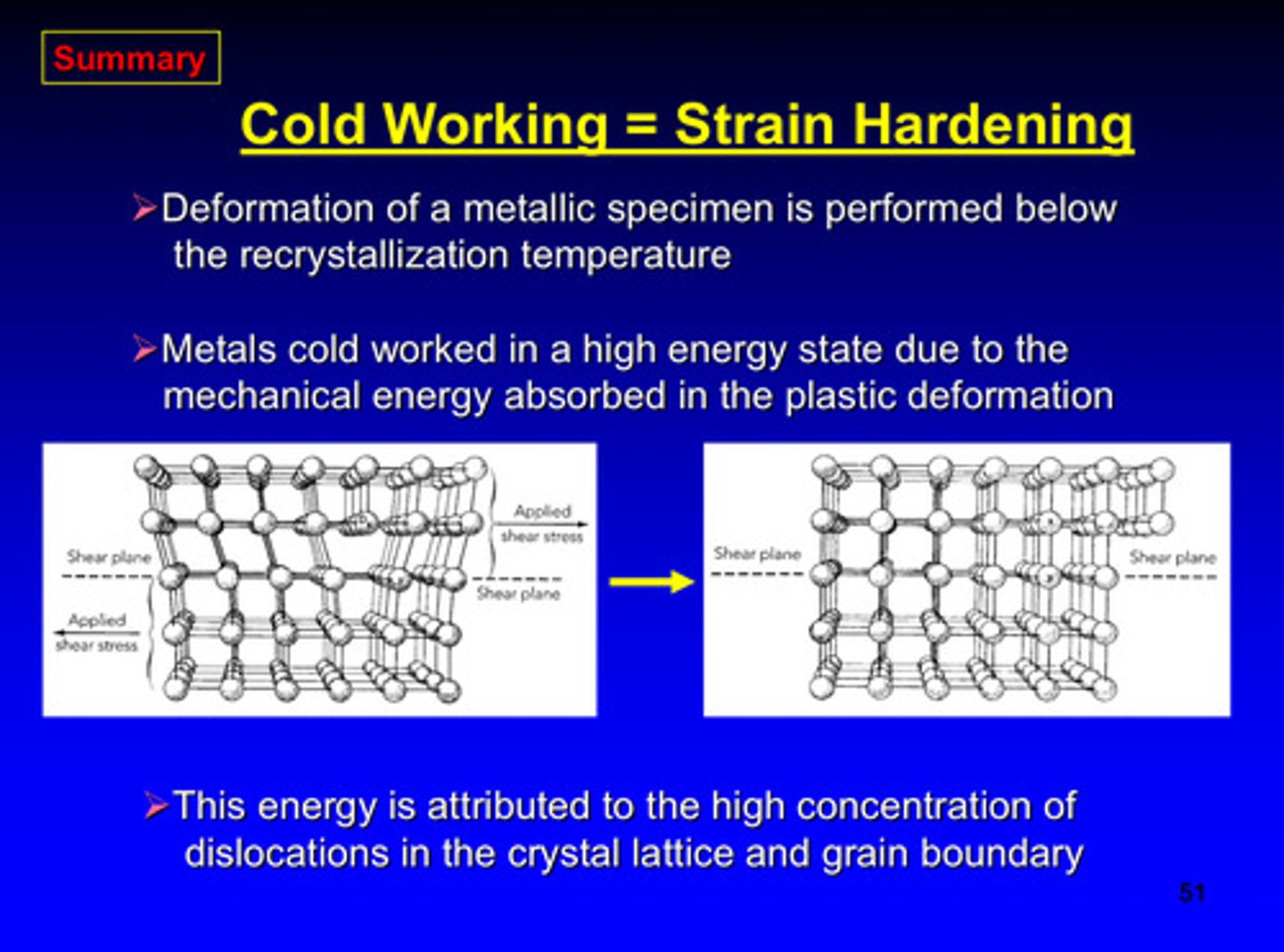

deformation of a metallic specimen is performing below what temperature

the recrystallization temperature

metals are cold worked in a high energy state due to what

the mechanical energy is absorbed in the plastic deformation

the mechanical energy absorbed in plastic deformation is attributed to the _____ concentration of dislocations in the crystal lattice and grain boundary

high

cold working = ?

strain hardening

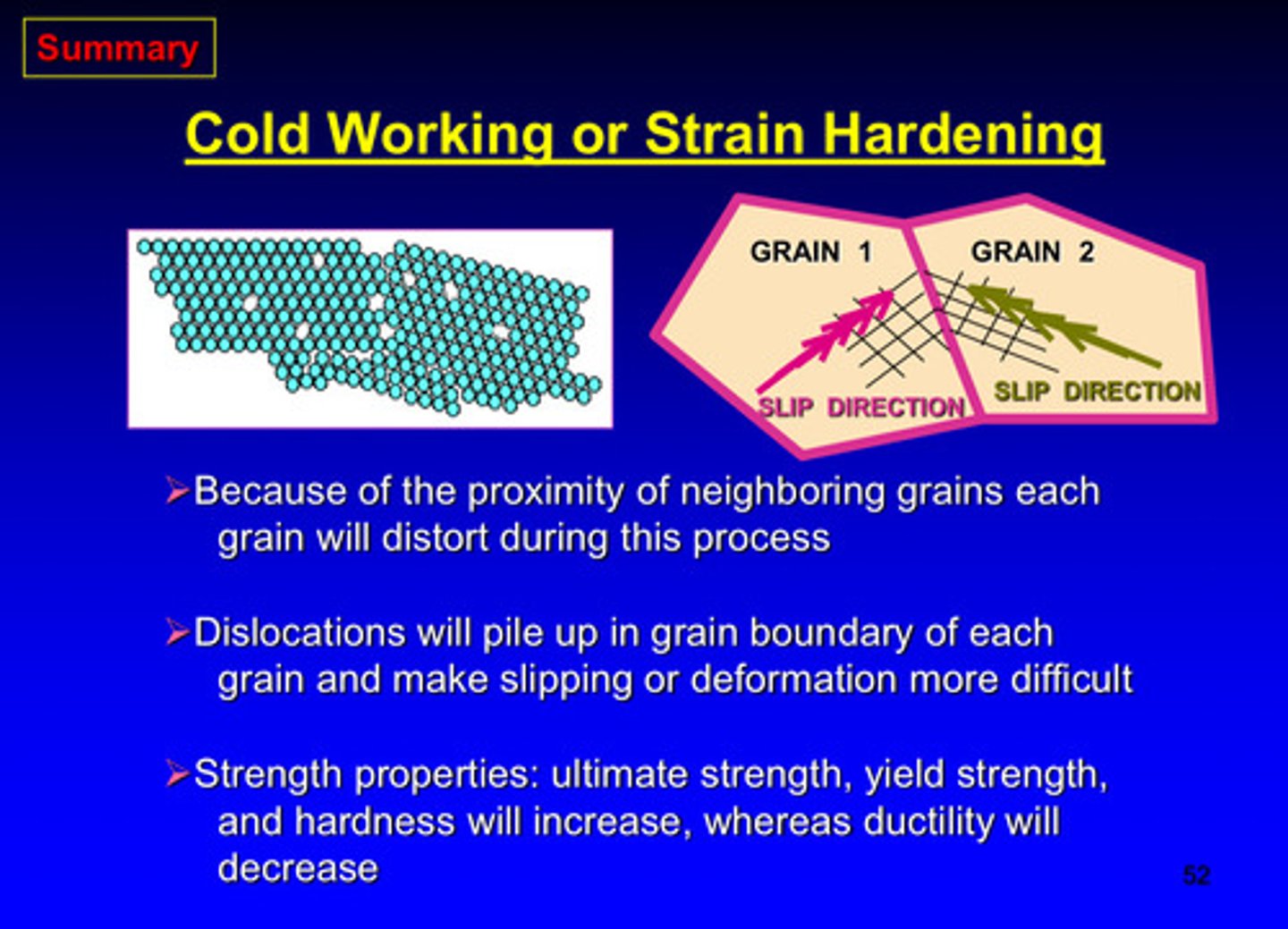

in cold working, because of the proximity of neighboring grains each grain will _______ during this process

distort

dislocations will pile up in grain boundary of each grain and makes ________ or _________ more difficult

slipping or deformation

what properties will increase and which property will decrease in cold working

ultimate strength, yield strength, and hardness will increase & ductility will decrease

milling treatment of metals and alloys (mechanical)

casting treatment of metals and alloys (thermal)

annealing treatment of metals and alloys (thermal)

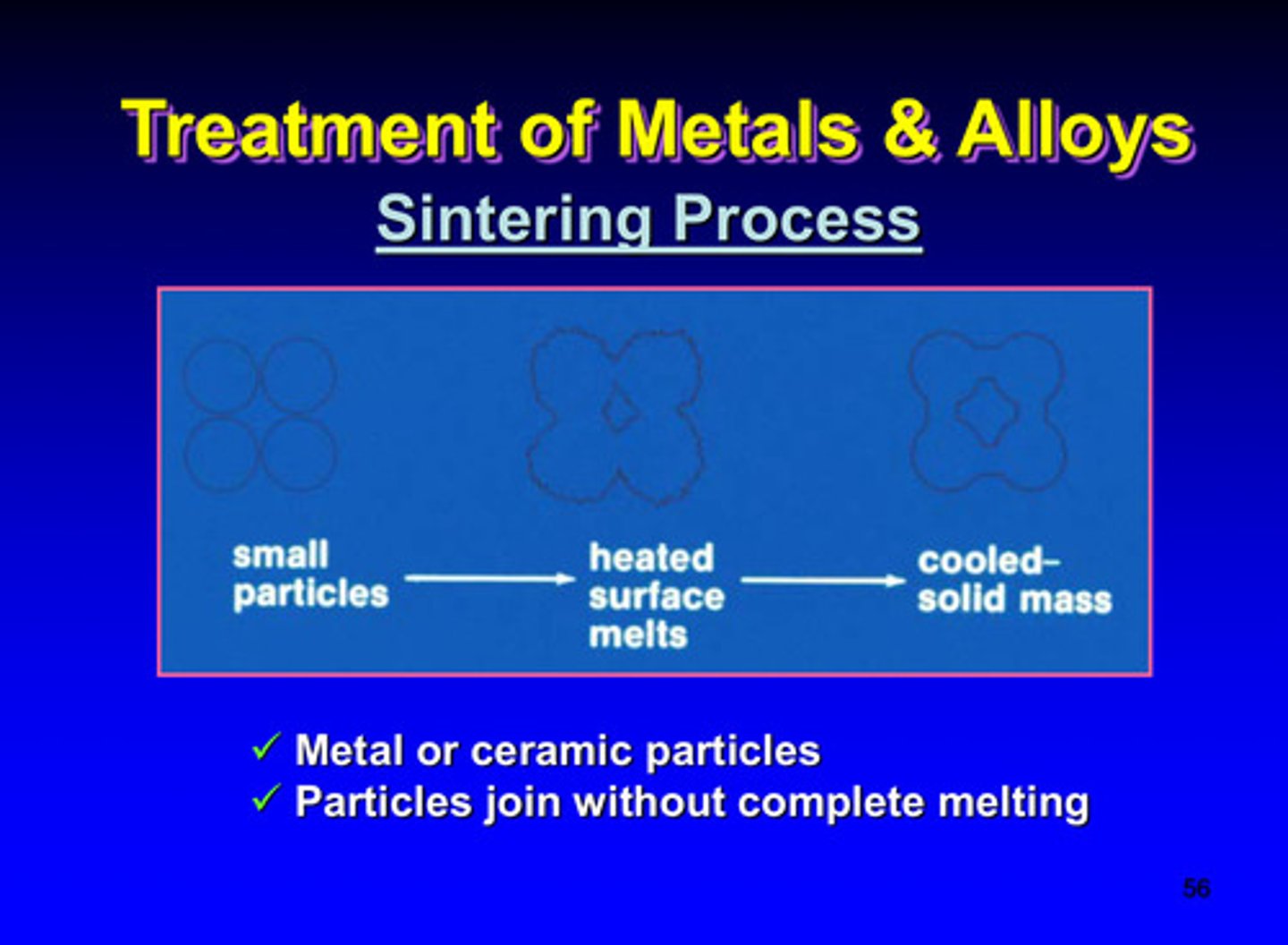

sintering process of metals and alloys (thermal)

uses metal or ceramic particles; particles join without complete melting

quenching process of metals and alloys (thermal)

cooled rapidly in order to freeze the microstructure; to gain the described strength and hardness

pickled and etched treatment of metals and alloys (chemical)

both treated with acid

pickled: to remove contaminating substances

etched: brings out grains and boundaries

metallic grain image of pure gold

microscopic structure of a casted metal

microscopic structure of a wrought metal

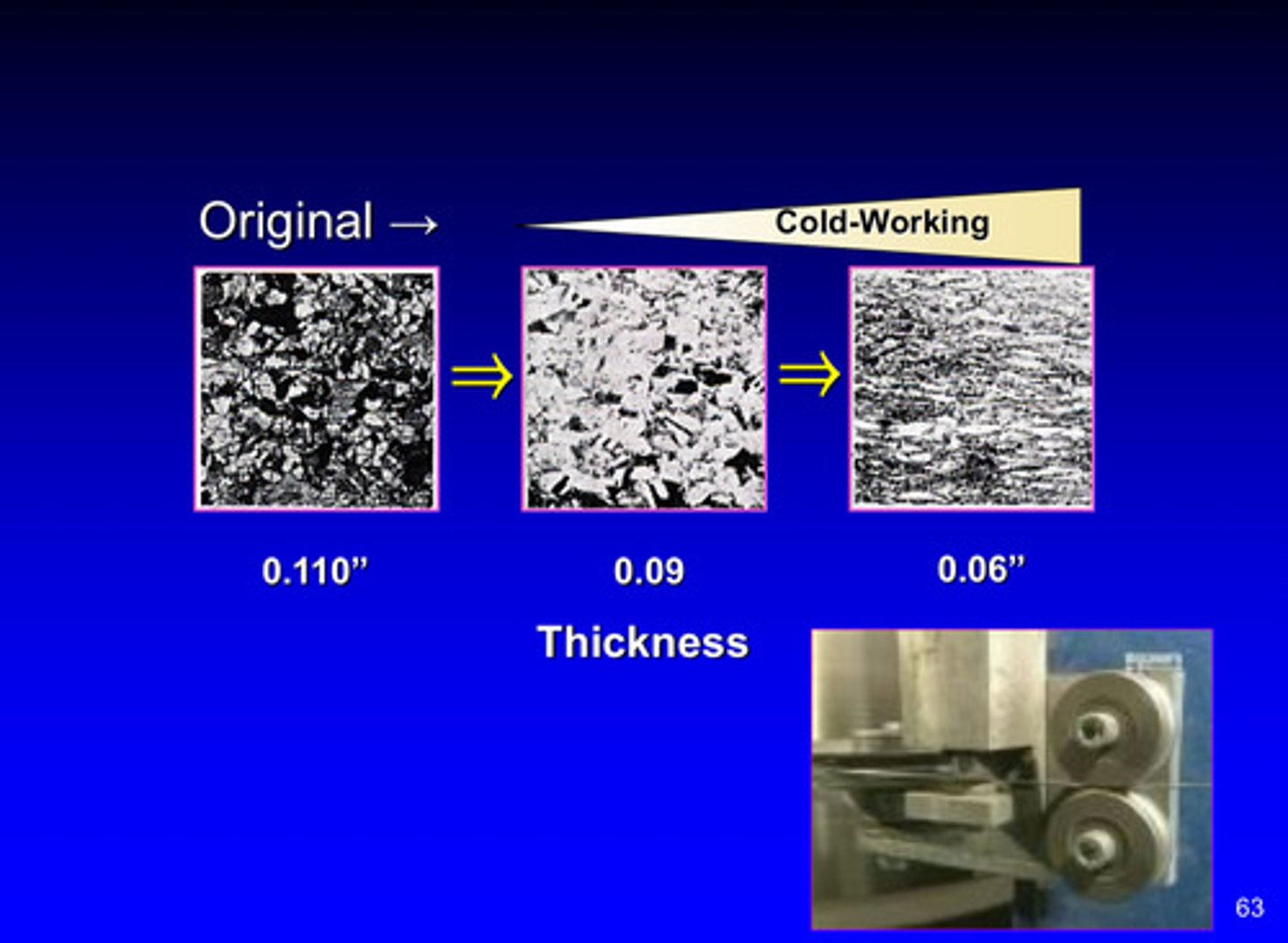

change in thickness during cold working

strain hardening of wrought metals

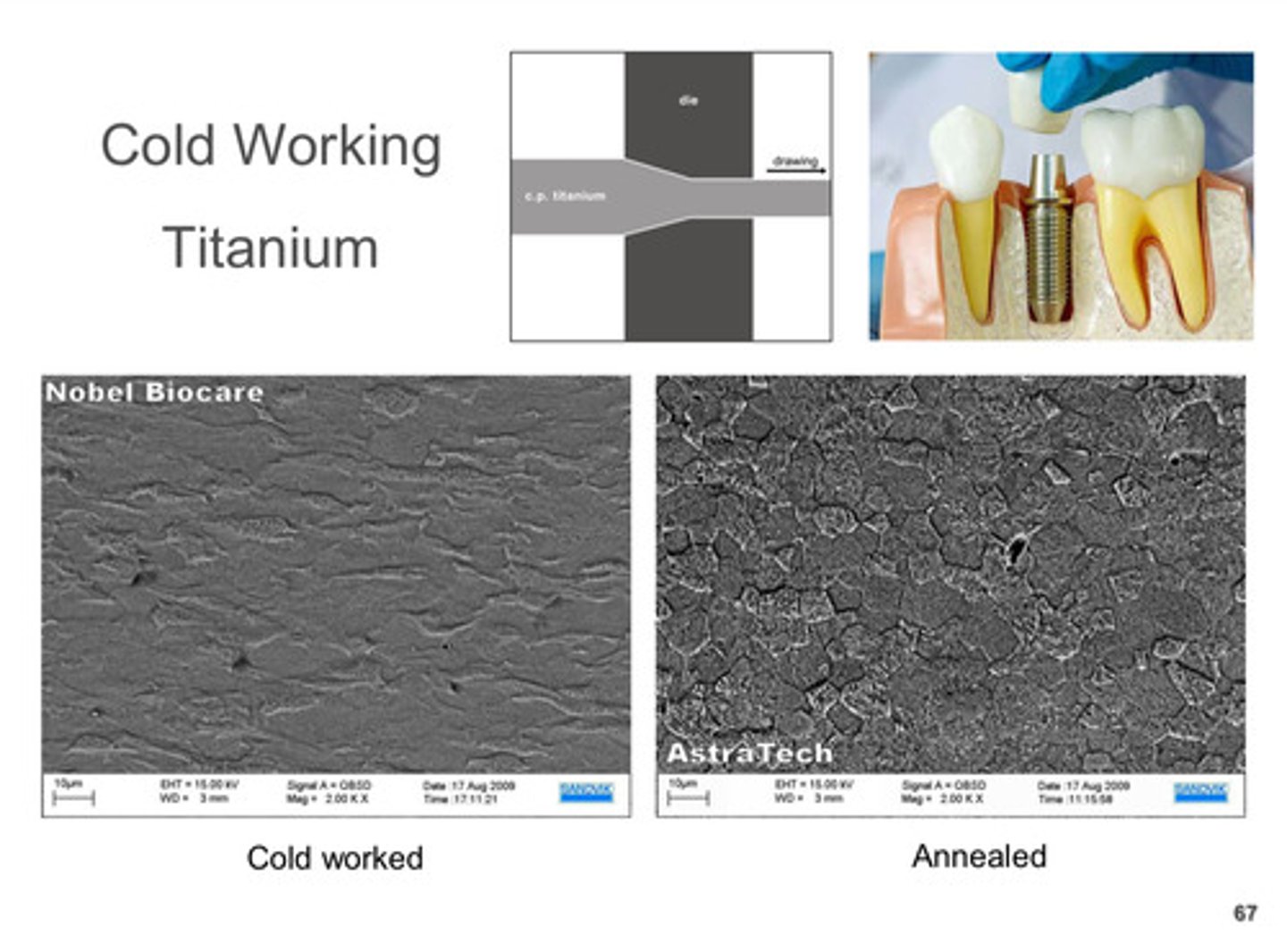

what is annealing

controlled heating or cooling to remove or prevent stresses

annealing is similar to that of __________ heat-treatment

softening

what is the goal of annealing

to form new stress-free crystals in a work-hardened metal through a controlled heat-treatment process

cold working of titanium vs annealing of titanium

_____________ changes accompany annealing

microstructural