Polymerization & Dental Polymers

1/128

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

129 Terms

polymers are used extensively in dentistry and an understanding and review of the basic nature of polymers will aid in what?

aid in proper selection and use of polymeric dental materials

which 4 aspects of dentistry utilizes polymers frequently

prosthodontics: denture bases and teeth, custom trays, impression materials, etc

operative dentistry: dentin bonding agents, cavity filling materials, cements, etc

orthodontics: brackets, bracket bonding resins, elastics, etc

endodontic: root canal sealants, gutta-percha points, rubber dams, etc

other equipment: mixing bowls and spatulas, mouth guards, etc

what is a monomer

simplest repeating chemical structural unit from which the polymer is composed ("mer unit")

what is a polymer

consists of large, organic molecules built up by repetition of smaller and simpler chemical units

what is a copolymer

polymers prepared from a mixture of 2 different monomers

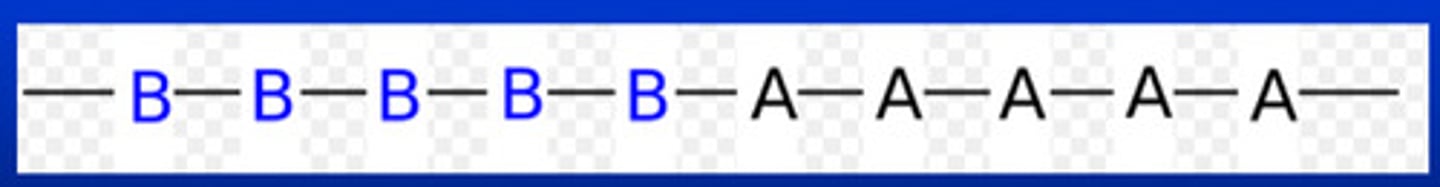

what is a block copolymer

mer units are arranged in a way that a large number of a mer type are connected to a large number of ANOTHER mer type

what is a stereospecific polymer

polymers in which mer units have a specific spatial arrangement with respect to adjacent units such as many natural and synthetic rubbers

polymer chains are often connected together to form what 3 spatial structures?

a nonlinear, branched, OR cross linked polymer

crosslinking forms what kinds of bonds between the polymer chains and this dramatically increases what?

forms chemical bonds between the chains; increases molecular weight

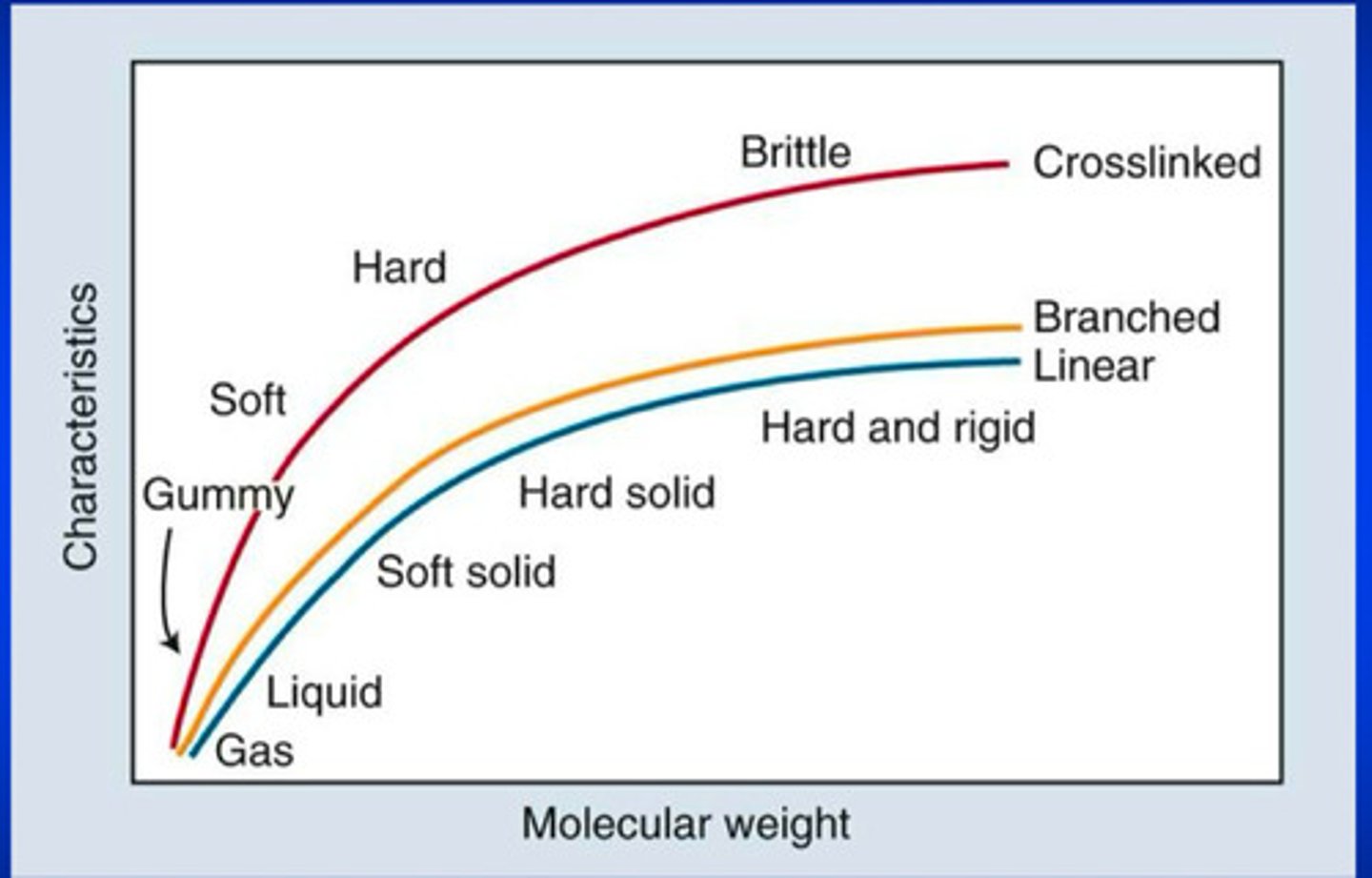

physical and mechanical properties vary with what 2 qualities for a given polymer system

vary with composition and extent of crosslinking for a given polymer system

the 3-D network of crosslinked polymers increases what 2 things to solvents

increases rigidity and resistance

the longer the polymer chain, the greater ?

the greater the number of entanglements

the greater the number of entanglements in a polymer chain, the more difficult it is to what?

to distort the polymeric material

so what 3 properties increase with increasing chain length (as it is more difficult to distort the polymeric material with greater number of entanglements)

rigidity, strength, and melting temperature

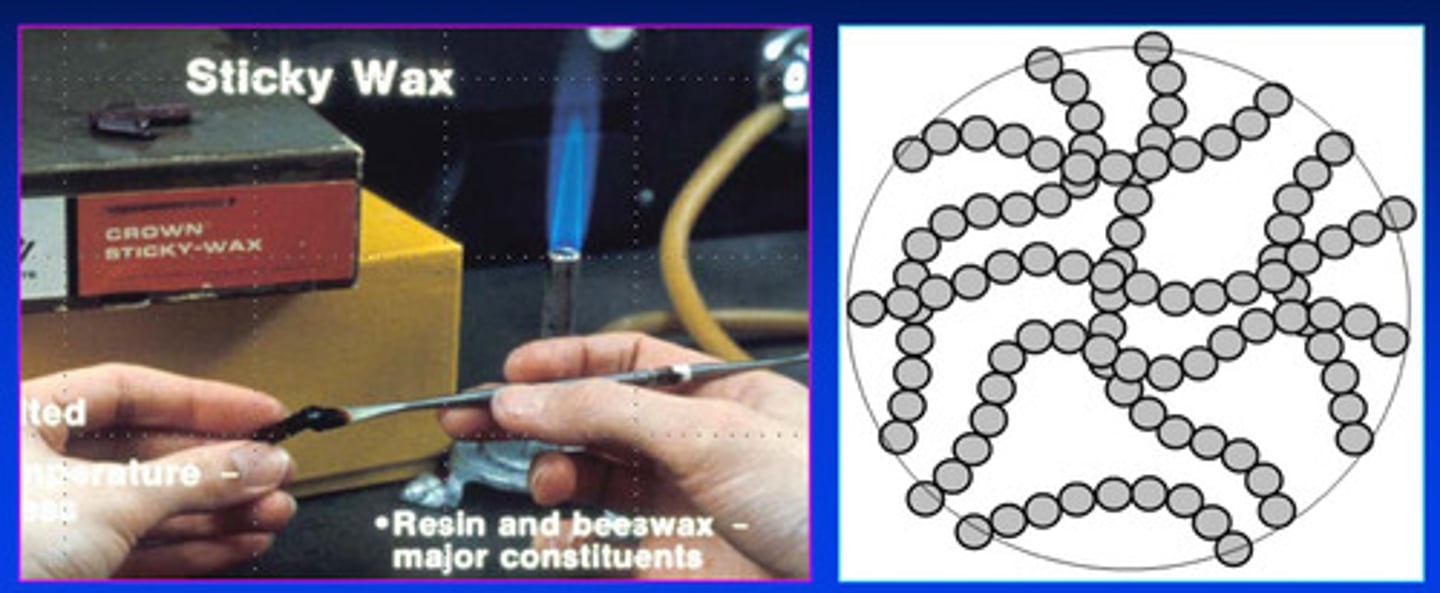

what are thermoplastic polymers made of

made of linear and/or branched chains

thermoplastic polymers ______ when heating above the glass transition temperature

soften

what is the glass transition temperature

the temperature at which molecular motion begins to force the chains apart

once the thermoplastic polymers soften after being heated above the glass transition, the materials (such as dental waxes) can then be shaped and molded; and upon cooling, it will ?

will harden REVERSIBLY in this form

upon reheating, thermoplastic polymers will soften again and can be reshaped; why is this setting reaction reversible?

due to the relatively weak bonds among the molecular chains

thermoPLASTIC polymers therefore undergo a ________ change

physical

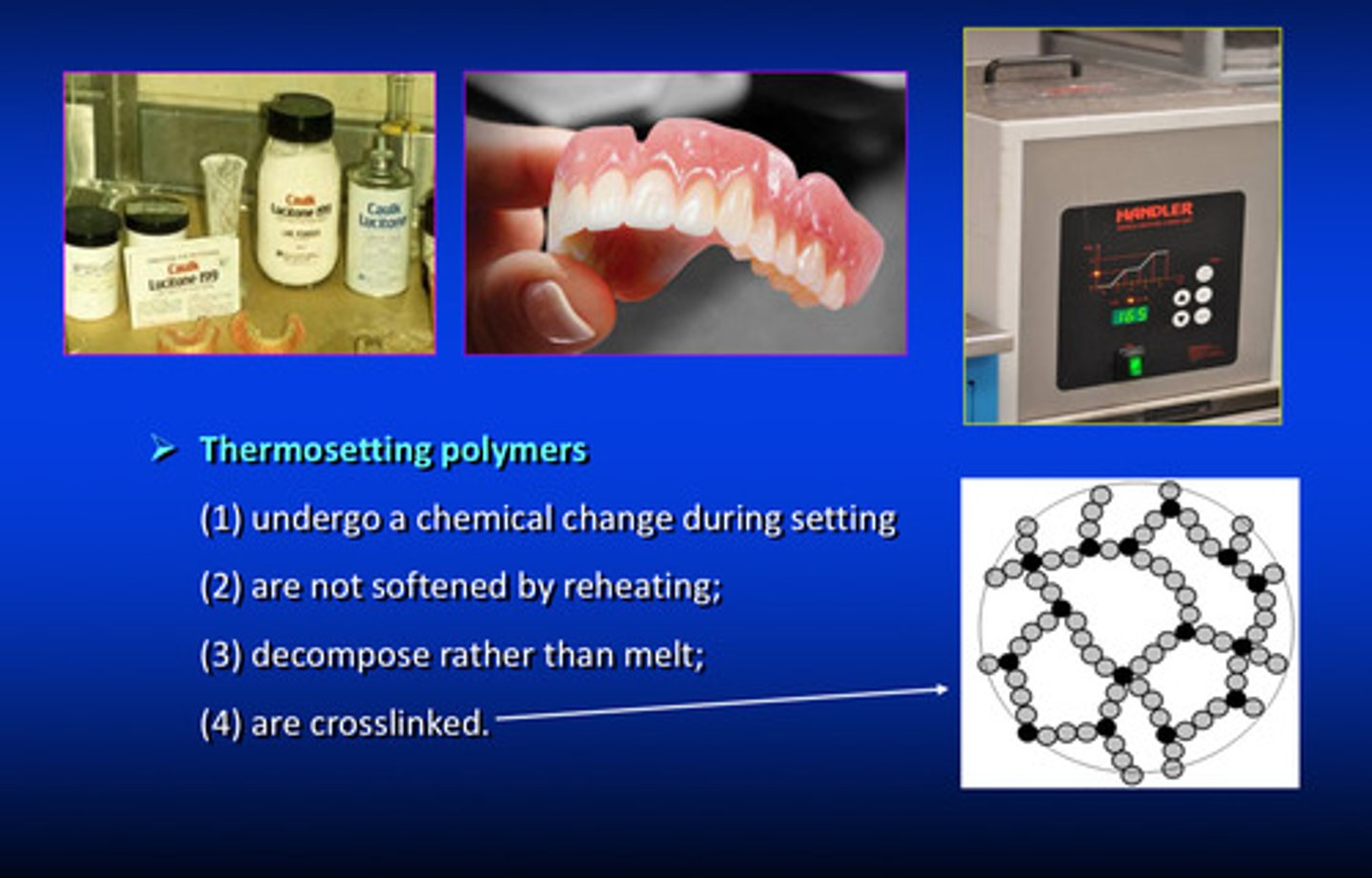

what are the 4 characteristics of thermoSETTING polymers

1) undergo a chemical change during setting

2) are not softened by reheating

3) decompose rather than melt

4) are cross linked

the "mers" of the polymers are joined through what kinds of bonds?

covalent C-C bonds

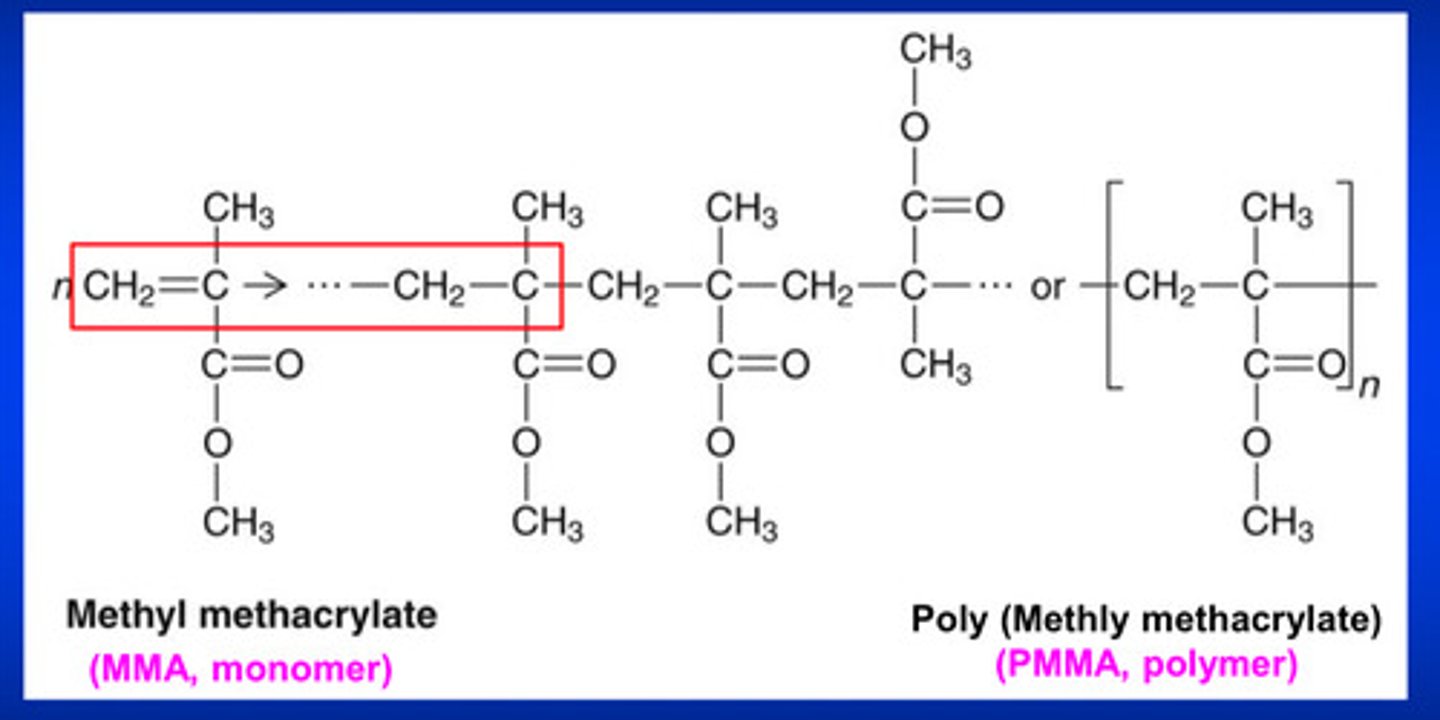

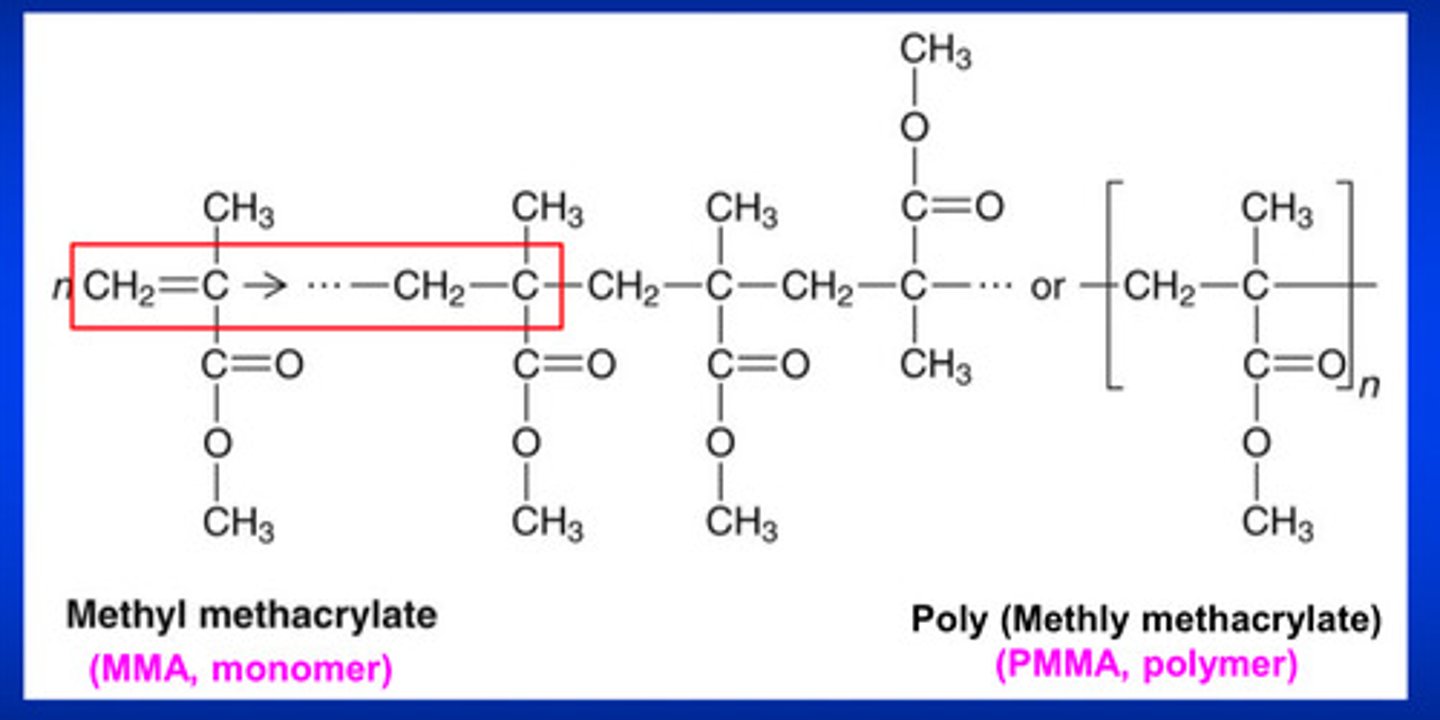

typically, during the polymerization process, C=C double bonds are converted to _____ _______ bonds and a "mer" is attached to one of the carbon atoms that was part of the C=C double bond

C-C single bonds

monomers may be joined together by means of either _______ or _________ reactions

addition or condensation

how does addition polymerization work

monomers are activated one at a time and added together in sequence to form a growing chain

what are examples of important additional polymerization reactions

free-radical and ring-opening reactions

how does condensation polymerization work

the components are di-functional and all are or become reactive simultaneously

the condensation polymerization reaction sometimes produces what kind of by-product?

a low molecular weight by product

what is condensation polymerization also known as

step growth polymerization

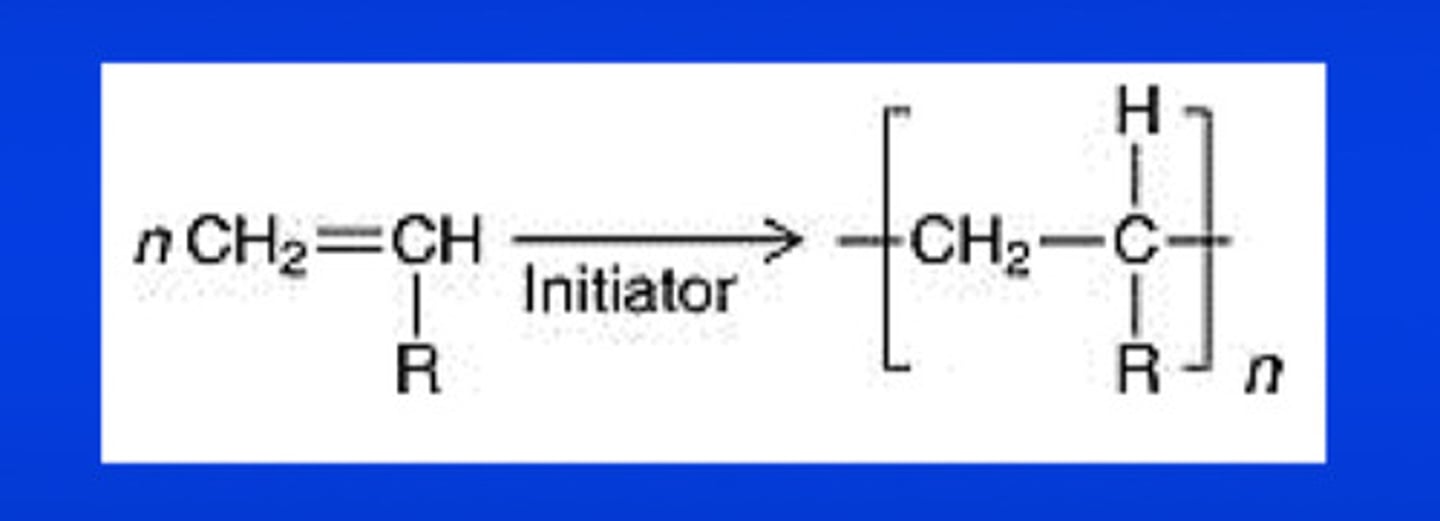

free-radical polymerization (a kind of addition polymer rxn) usually occurs with ____________ molecules containing ________ bonds

unsaturated molecules containing double bonds; in the equation, R represents any organic group, chlorine, or hydrogen

what are the 3 stages of the free-radical polymer rxn

initiation, propagation, and termination stages

the free-radical polymer rxn may be accelerated by what 3 things

chemical agents, heat, and visible light

in free-radical polymer rxn, is a byproduct obtained?

NO

free radical polymerization reactions can be inhibited by the presence of what

presence of any material or impurities in the monomer that will react with a free radical

when a free-radical polymerization rxn is inhibited, what may become decreased and what may become increased

decrease in the rate of initiation OR increase in the rate of termination

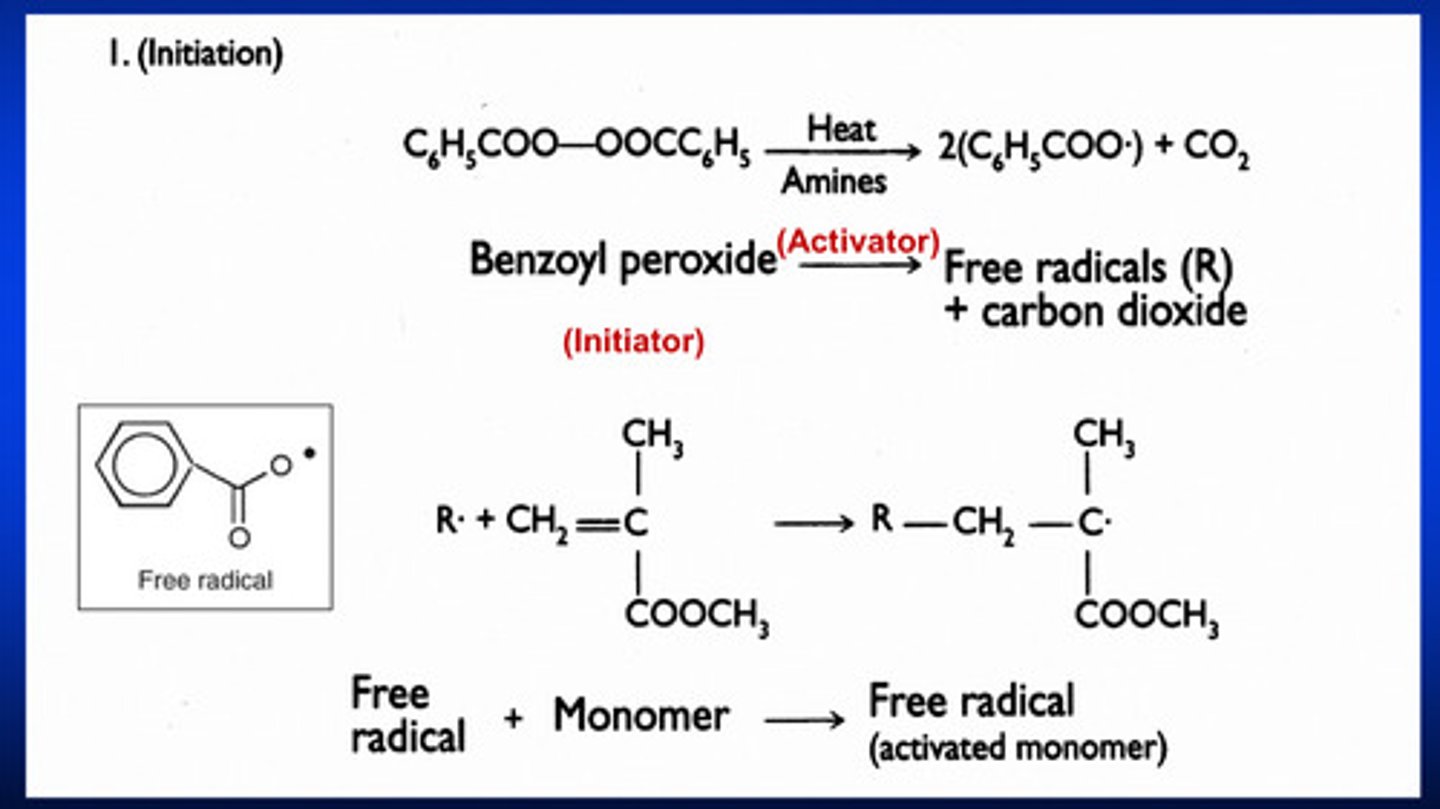

initiation stage of free-radical polymerization rxn

1) free radical bombards unsaturated double bond

2) activate the monomer which will start a chain reaction —> next stage of propagation

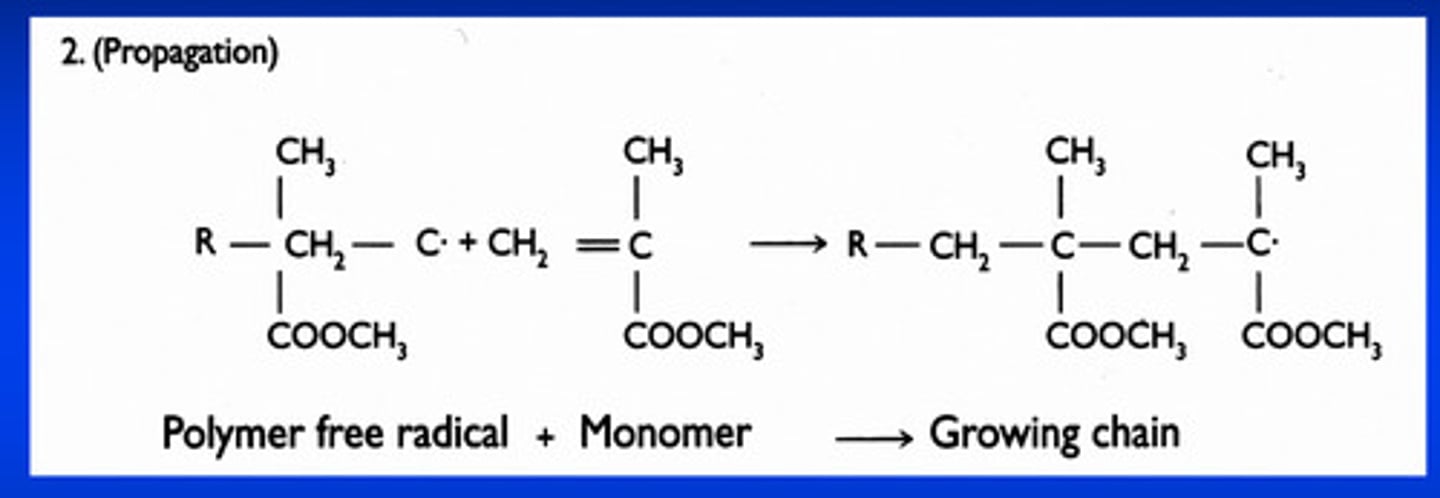

propagation stage of free-radical polymerization rxn

1) as the activated monomer with an unpaired electron approaches the other methyl methacrylate molecule, one of the electrons in the double bonds is attracted to the free radical to form an electron pair AND a covalent bond between the free radical and the monomer molecule

2) the remaining unpaired electron makes the new molecule a free radical

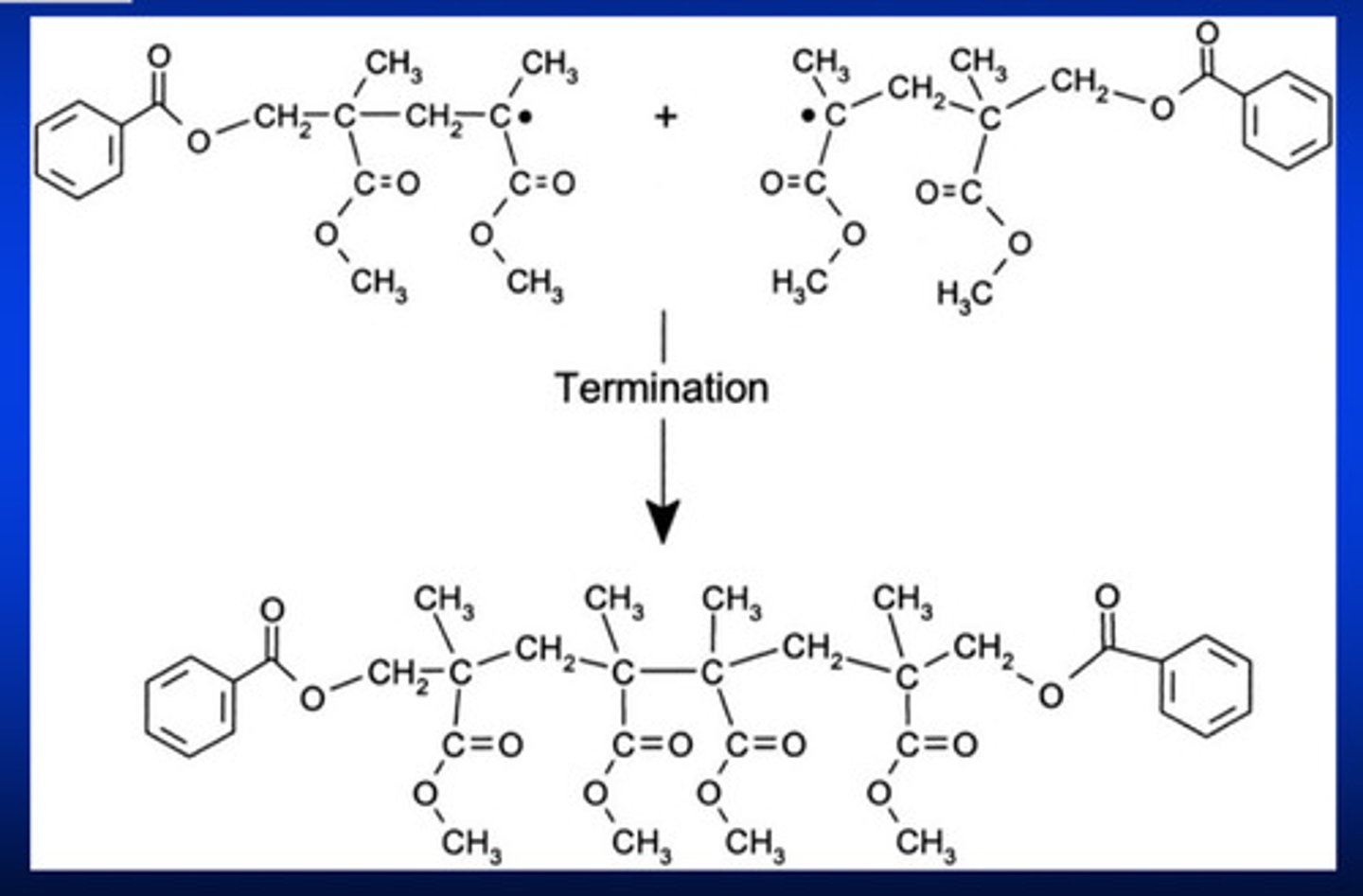

termination stage of free-radical polymerization rxn

occurs when two free radical interacts and form a covalent bond

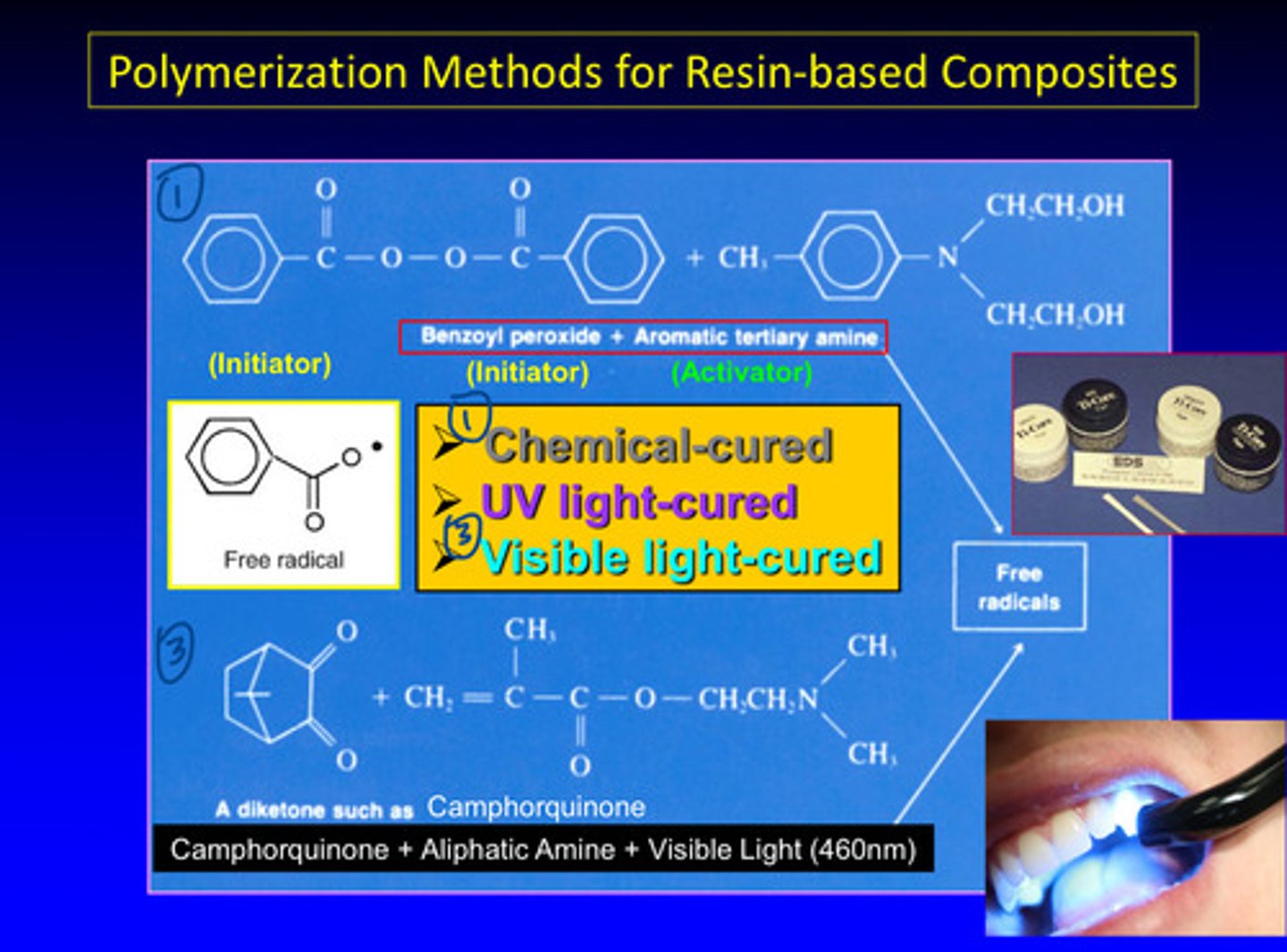

what are 3 polymerization methods for resin-based composites

1) chemical cured: use a chemical to activate or form the free radical; benzoyl peroxide as initiator and aromatic tertiary anime as activator and to produce a free radical —> will go through the 3 stages

2) UV light cured

3) visible light cured: use photons from visible spectrum to activate the aliphatic amine (activator) and camphorquinone acts as initiator to produce a free radical; especially blue light at 460 nm

decreasing the rate of initiation _______ the polymerization reaction

retards

increasing the rate of termination decreases what 2 things

decreases the degree of polymerization or the molecular weight of the final polymer

what 3 materials will inhibit or retard the polymerization?

hydroquinone, eugenol, or large amounts of oxygen

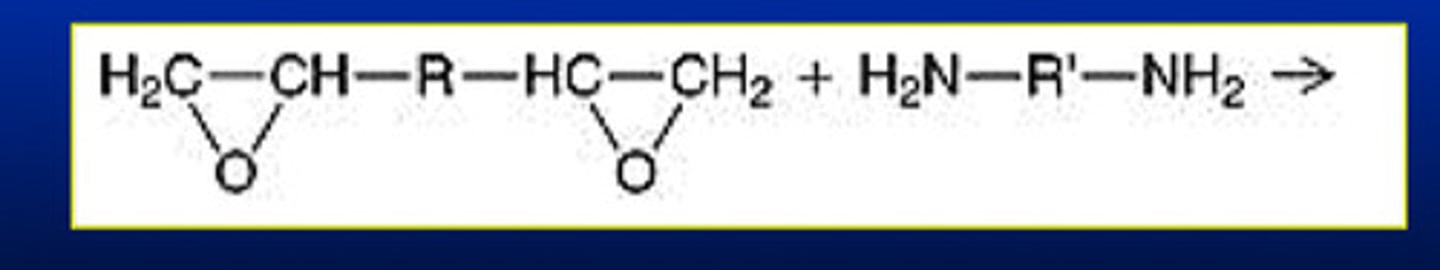

what is ring-opening polymerization (type of add poly rxn)

involves monomers with one or more three-atom end-group rings, which open and then join with other broken rings to form single bonds (similar to the way the C=C bonds open and link up to form C-C bonds)

condensation reactions result in

what are the 2 types of three-atom ring monomers that have found significant usage in dentistry

1) imines: with 2 carbons and a nitrogen

2) epoxies: with 2 carbons and an oxygen (example shown)

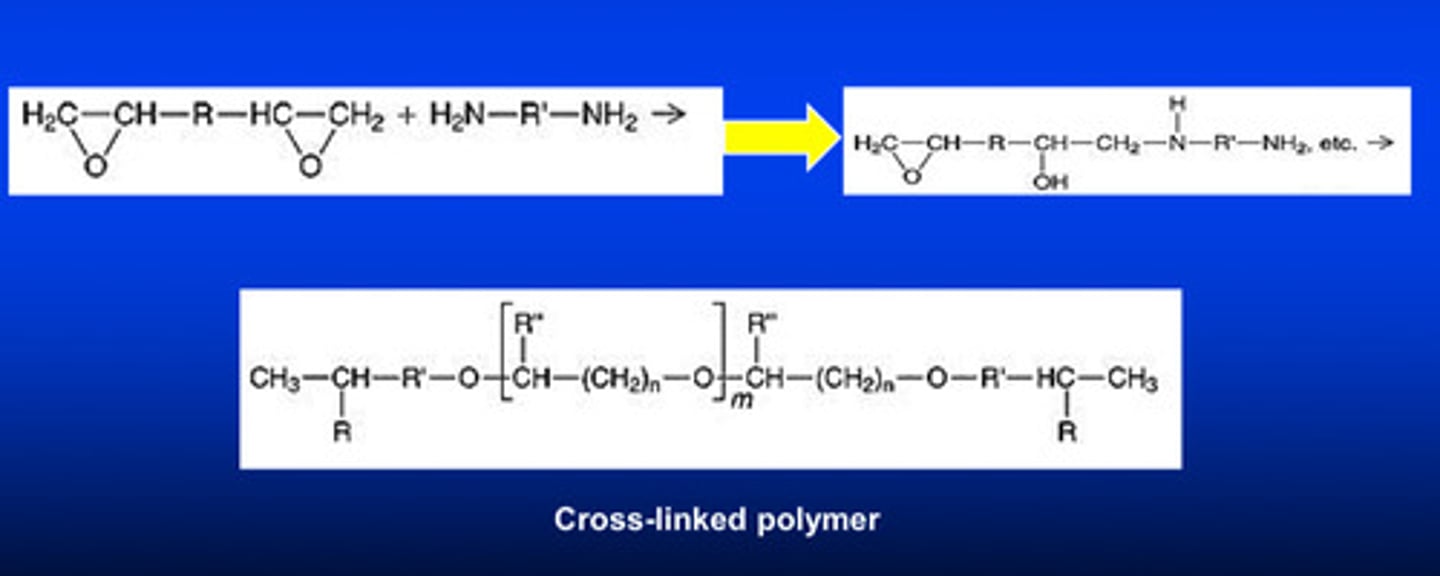

what are the 2 reactants for the epoxy system in a ring-opening polymerization reaction and what do they form

di-functional epoxide oligomer AND di-functional amine; form a cation

condensation reactions also result in polymerization plus the production of what kinds of by products?

production of low molecular weight by products such as water and lead sulfide

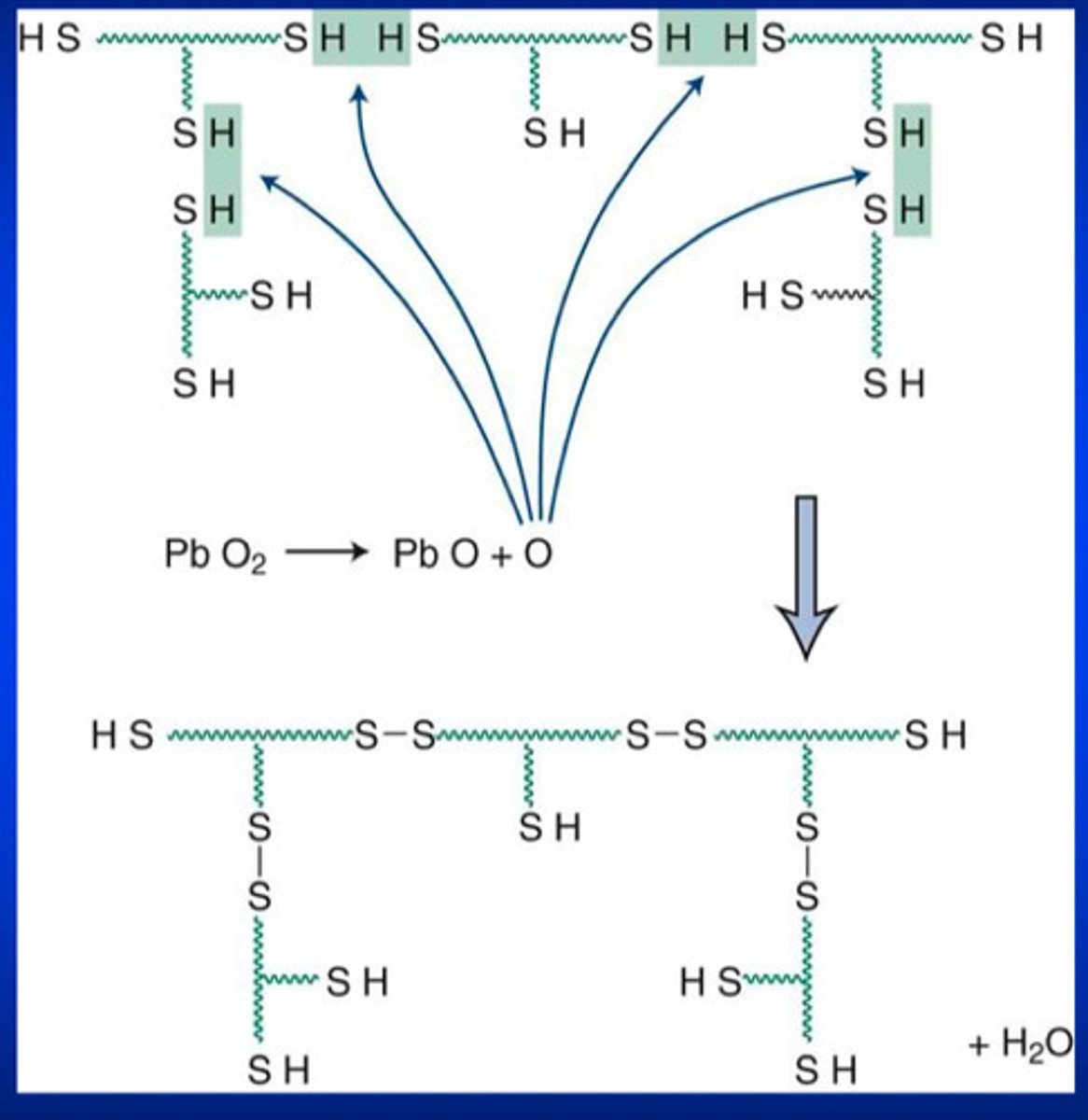

what kinds of rubbers are formed by a condensation reaction

polysulfide rubbers

describe how the condensation polymerization reaction works in 2 steps

1) SH groups interact with oxygen released from lead dioxide

2) completion of the condensation reaction results in water as a by product (so when the water evaporates, there is a porosity left inside the polymer material)

what is the most general kind of condensation reaction that forms polysulfide rubbers

reaction between low molecular weight polysulfide polymers that have mercaptan (-SH) groups AND lead dioxide (catalyst)

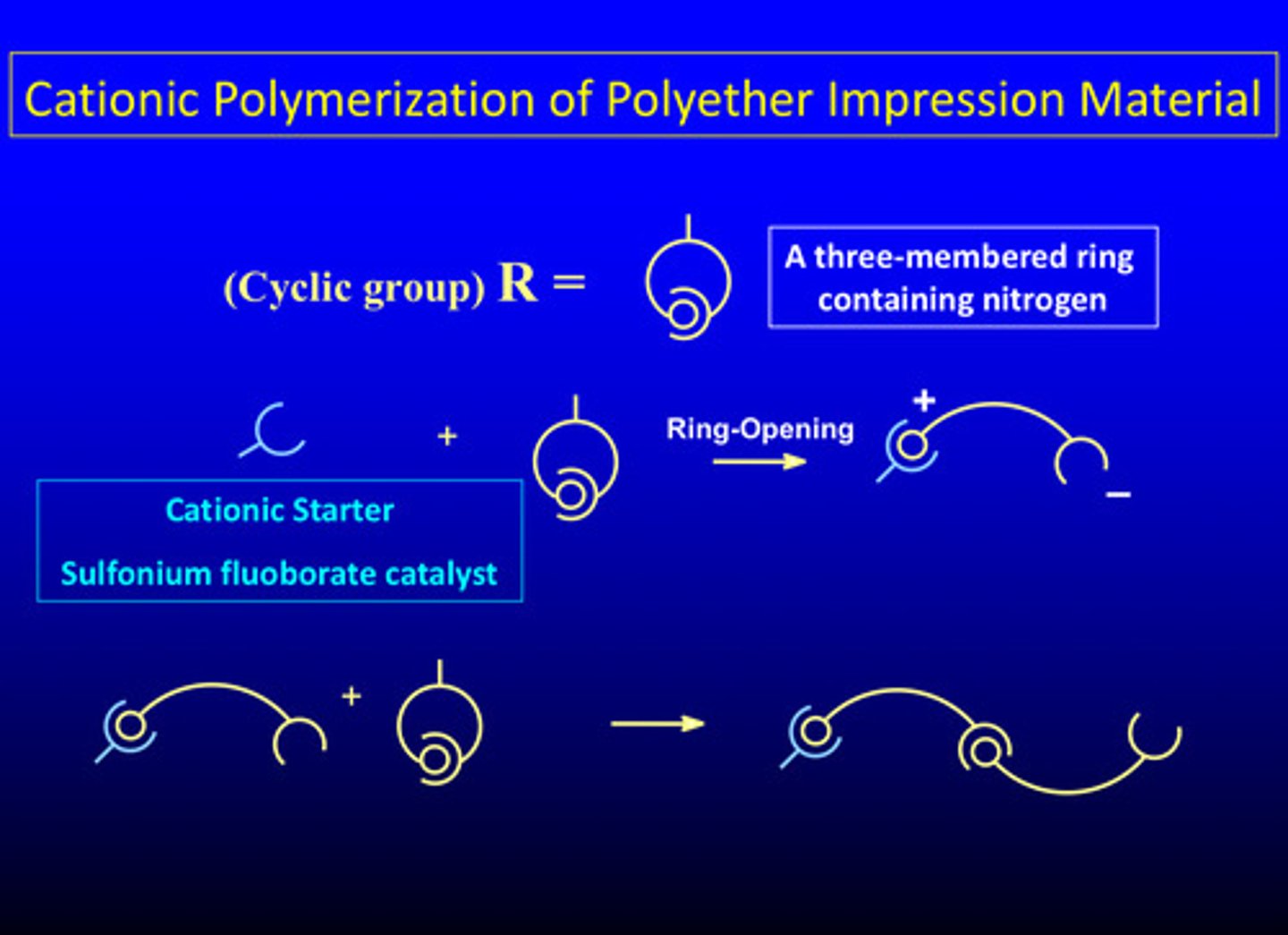

cationic polymerization of polyether impression material (aka ring-opening)

1) cation is formed from the 2 reactants

2) ring opens

3) a chain reaction is formed

4) cross linking network is formed for the final material

in condensation poly rxns, pendant -SH is for _______________ and terminal -SH is for _______ ________________ of the polymer

cross-linking; chain lengthening of the polymer

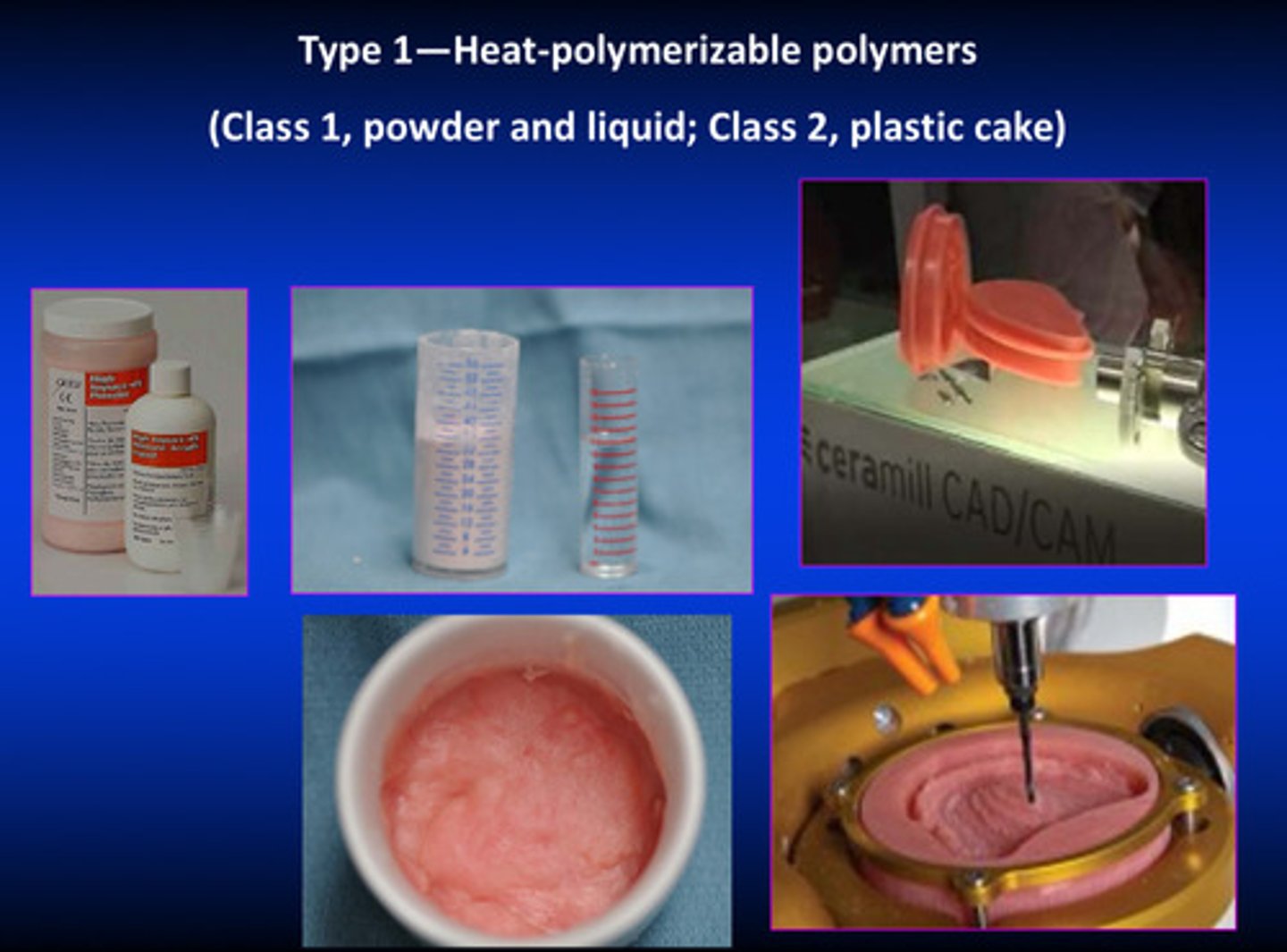

what are type 1 denture base resins

heat-polymerization polymers (vast majority of dentures made today are fabricated from heat-cured polymers (methyl methacrylate) and rubber reinforced polymers (methyl methacrylate)

what are class 1 and class 2 specifications of type 1 denture base resins

class 1: powder and liquid

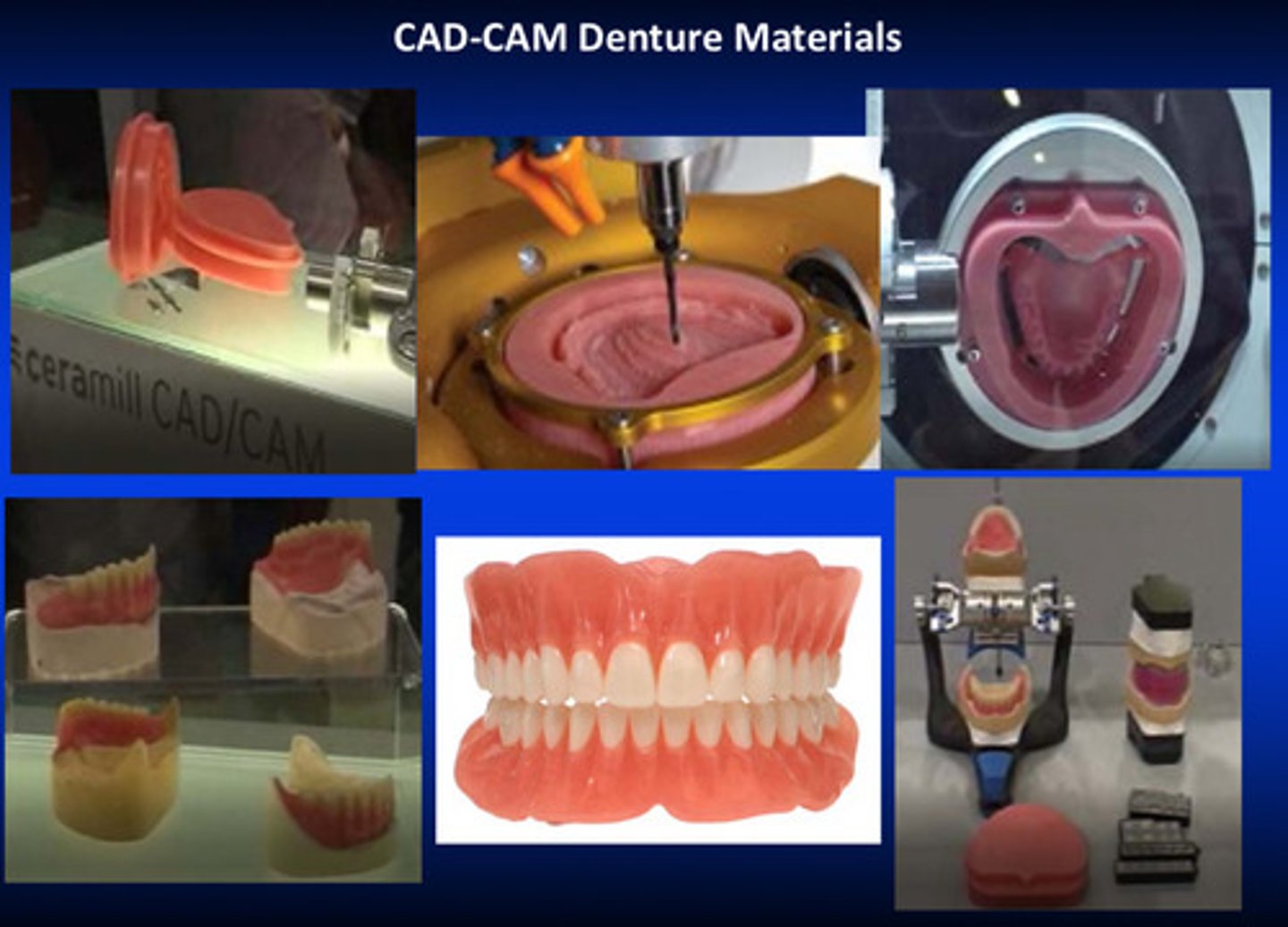

class 2: plastic cake (related to CAD/CAM manufacturing)

what are type 2 denture base resins

auto-polymerizable polymers

what are class 1 and class 2 specifications of type 2 denture base resins

class 1: power and liquid

class 2: powder and liquid pour-type resins

what are type 3 denture base resins

thermoplastic blank or powder

what are type 4 denture base resins

light-activated materials

what are type 5 denture base resins

microwave-cured materials

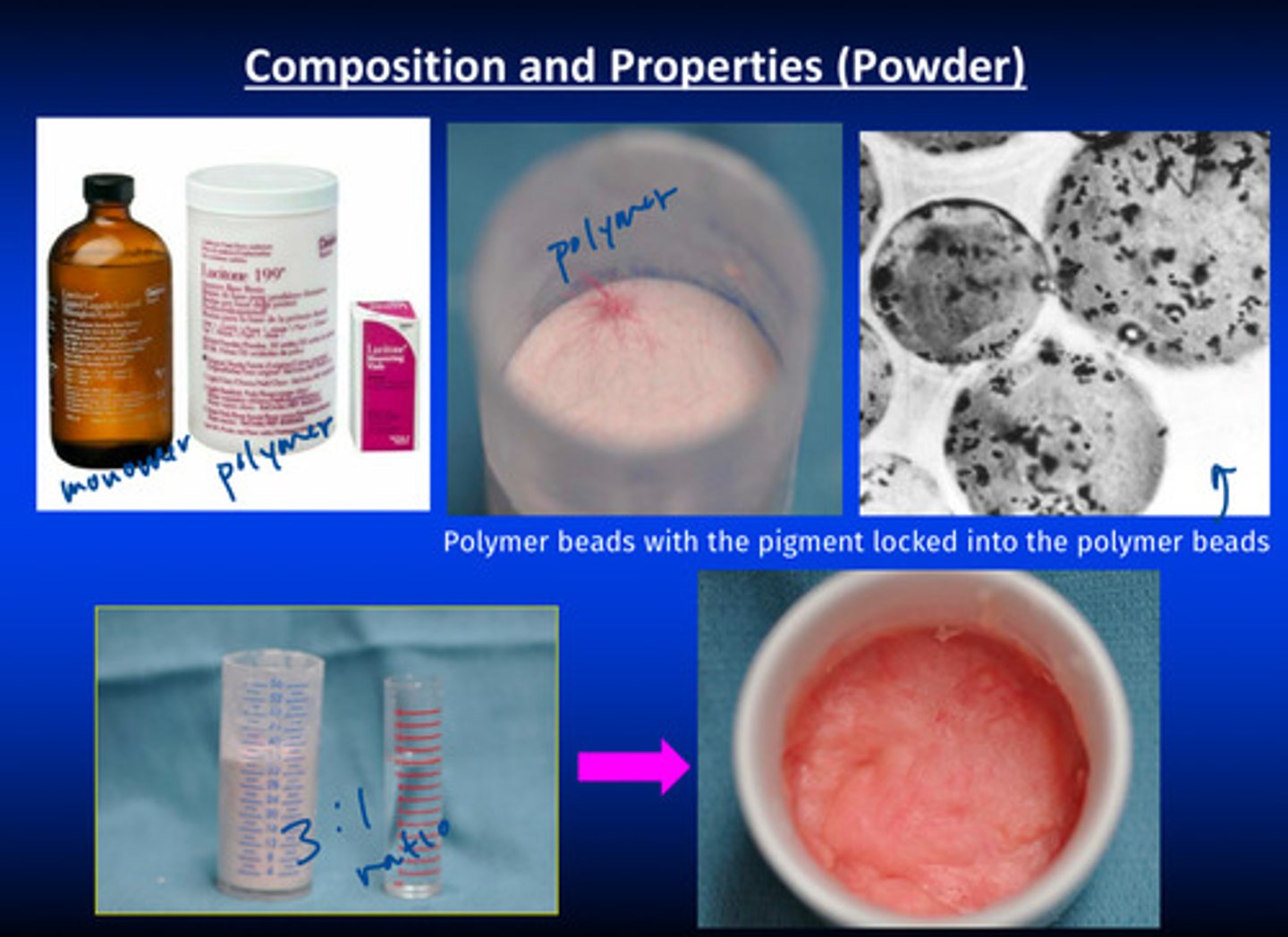

is the powder a polymer or a monomer

polymer

is the liquid a polymer or a monomer

monomer

the powder requires what 2 things

initiator: benzoyl peroxide

plasticizer: dibutyl phthalate to decrease polymerization and strength

the liquid requires what 3 things

inhibitor: hydroquinone necessary to prevent premature polymerization bc monomers are very active molecules (increases shelf life of monomer)

plasticizer: added to produce a softer and more resilient polymer but it may leach out

cross-linking agent: glycol dimethacrylate yields a network structure and provides resistance to crack

powders have pink dyed organic fibers that helps to simulate what

blood vessels in the denture base

mixing the powder with the liquid, what starts

the polymerization reaction

the main ingredient inside the powder and the liquid is the?

plasticizer; we add this in a high enough amount to make the denture have good impact strength

what are the 8 components of the powder

1) polymer beads

2) initiator

3) rubber

4) plasticizer

5) inorganic particles

6) dyed organic fibers

7) pigments

8) opacifiers

powder polymers beads result in what 2 properties

decreased shrinkage and increased strength

powder initiator results in what

initiates polymerization

powder rubber results in what 2 properties and what is the chemical used for it

increased resilience and increased impacts; butadiene-styrene

powder plasticizer results in what property

increased resilience

picture of powder stuff woohoo

powder to liquid is 3:1 ratio

powder inorganic particles result in what 2 properties

increased stiffness, and decreased TEC (thermal expansion coefficient)

powder opacifiers result in what 2 properties

decreased translucence and increased radiopacity (you cannot find denture without opacifier through an x-ray)

what are the 5 components of the liquid

1) monomer

2) inhibitor

3) accelerator

4) plasticizer

5) cross-linking agent

liquid monomer results in what property and what is the chemical

increased strength; MMA

liquid inhibitor results in what property and what is the chemical

increased shelf life; hydroquinone

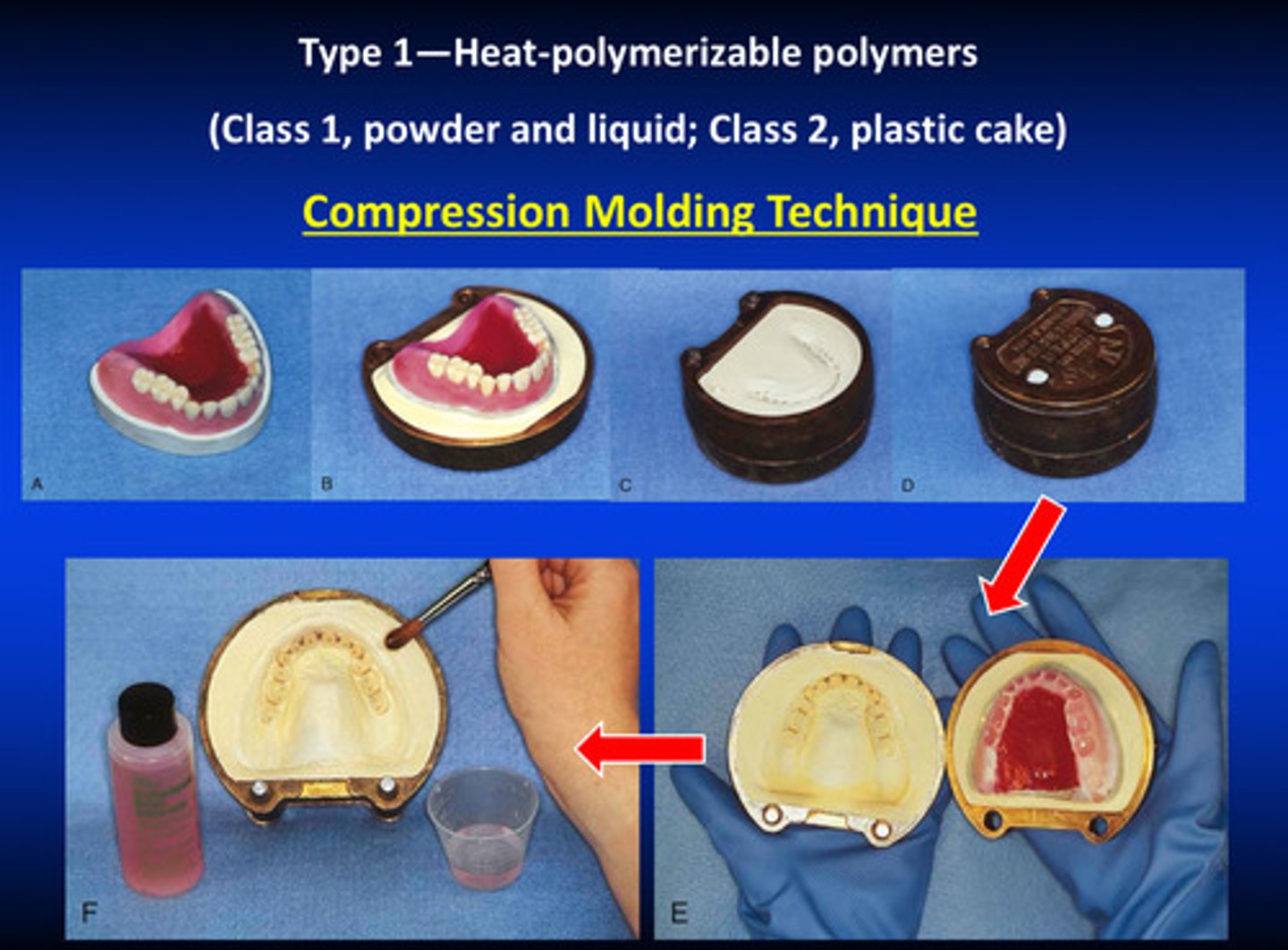

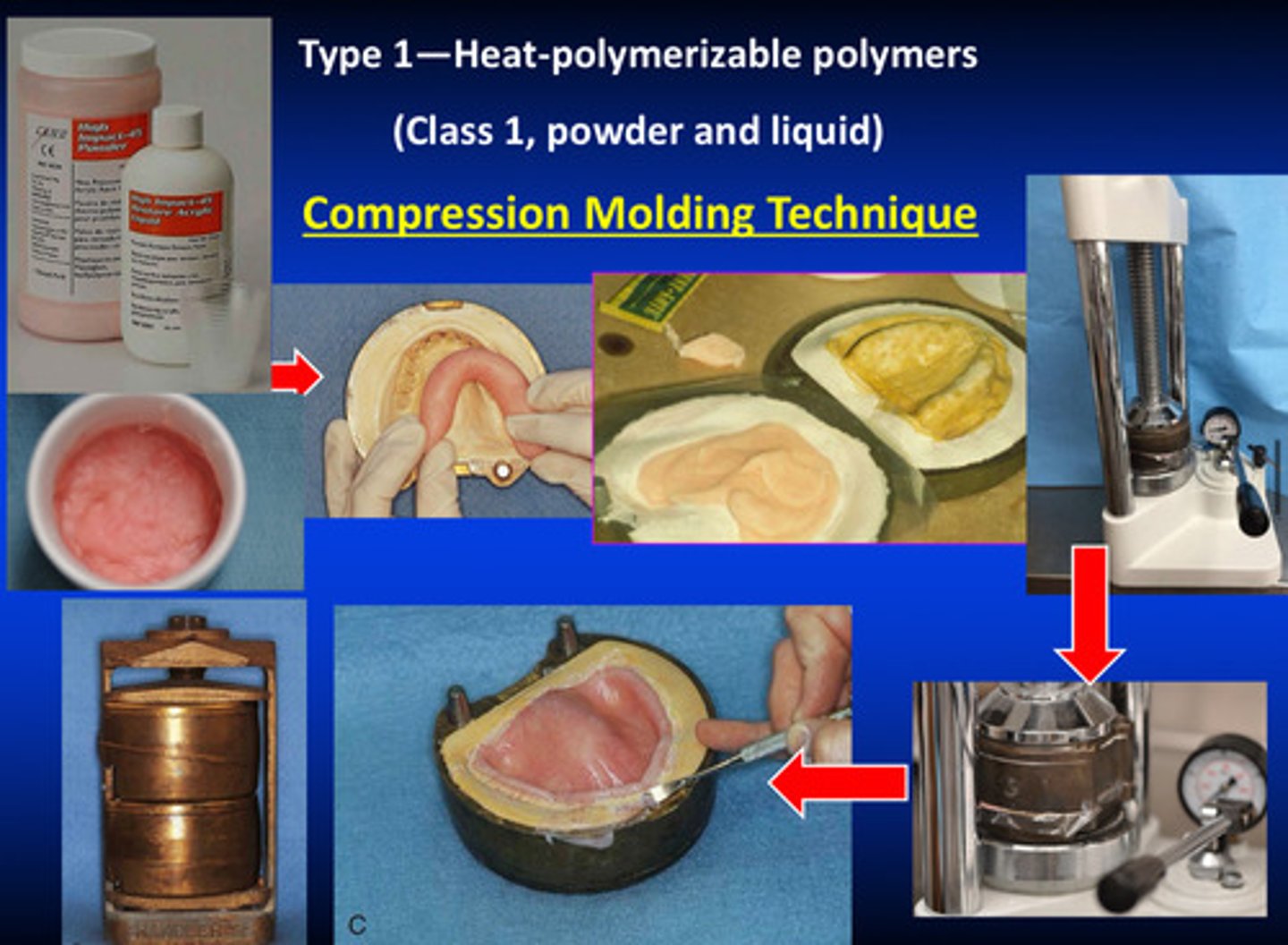

type 1 class 1 compression molding techniques

1) wax up denture base with baseplate wax

2) create teeth and put in correct position

3) embed the denture into plaster

4) we soften the wax; one side of the plaster holds the denture teeth and is detached from the base

5) clean up and add separator

type 1 compression molding techniques

milling technique is used for plastic cake (class 2) instead of compression method; material mixing is used for powder and liquid (class 1)

CAD-CAM denture materials with class 2 type 1 polymers

compression molding techniques continued for class 1 type 1

1) after mixing, the materials go through chemical setting reaction

2) place the materials in the space where the base plate wax was initially

3) compress the materials to fill the cavity but to also make the materials become more solid (eliminates all air left inside the materials)

4) after removing excess material, you use a special frame and flask to put the denture into the curing machine

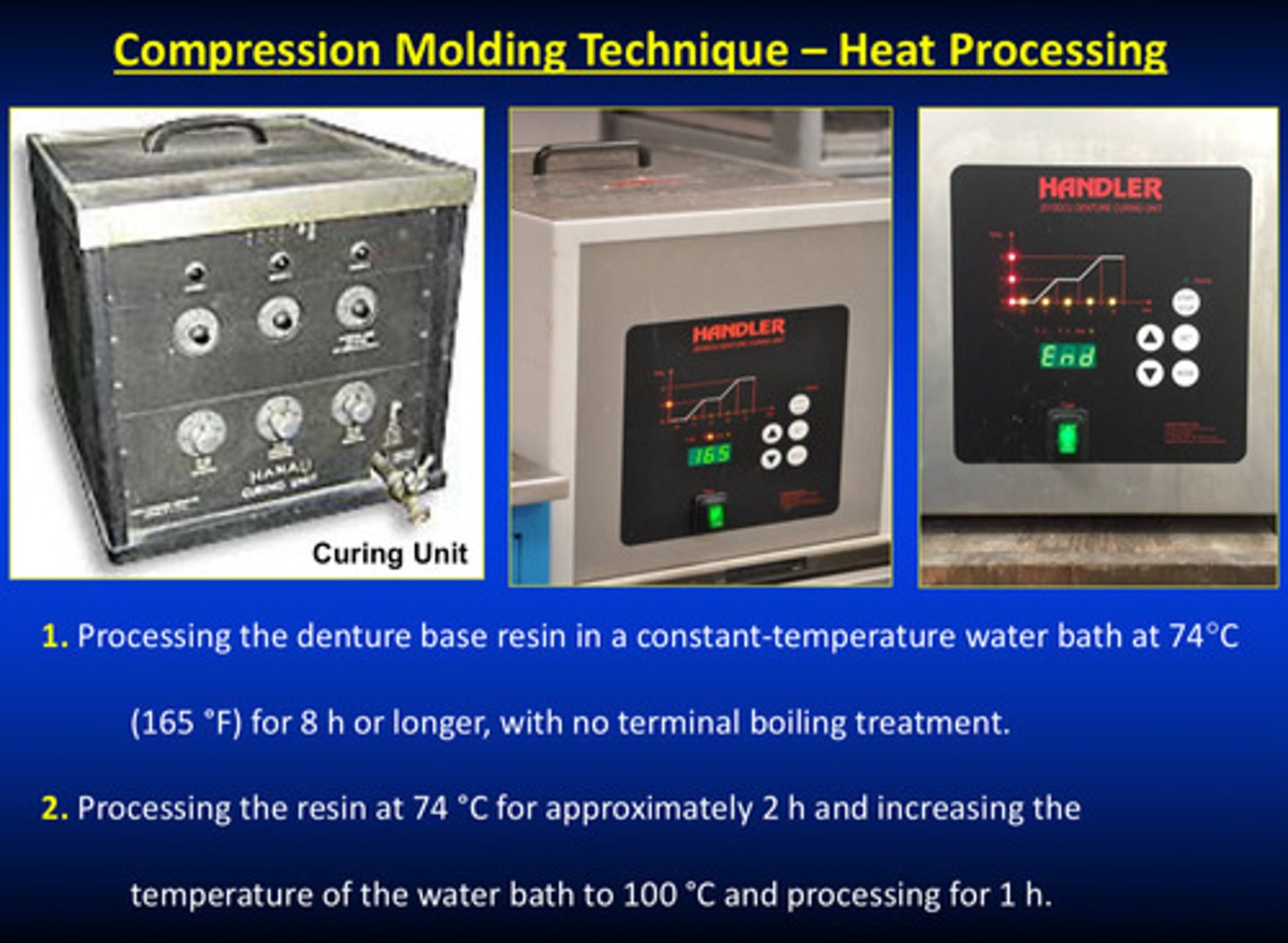

compression molding techniques continued for class 1 type 1; heat processing

1) process the denture base resin in a constant-temp water bath at 74 degrees C for 8 hours or longer with NO terminal boiling treatment (long-term)

OR

2) process the resin at 74 degrees C for 2 hours and increase the temp of the water bath to 100 degrees C and process for 1 hour (short-term and most common procedure)

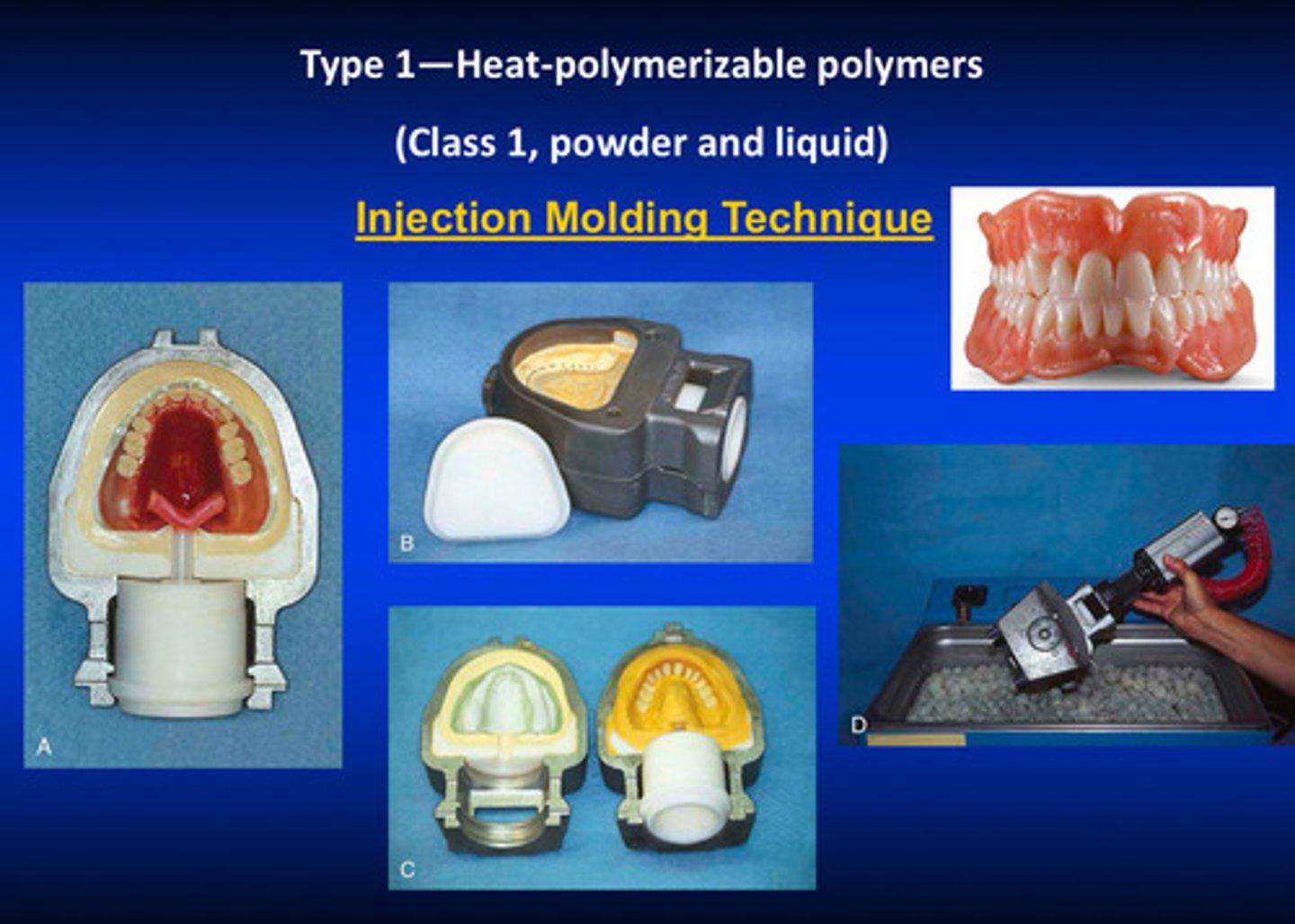

type 1 class 1 injection molding technique

uses injection instead of compression

1) inject flowable resin

2) use a special flask to put the base under pressure under a water bath

3) ^^ starts polymerization reaction

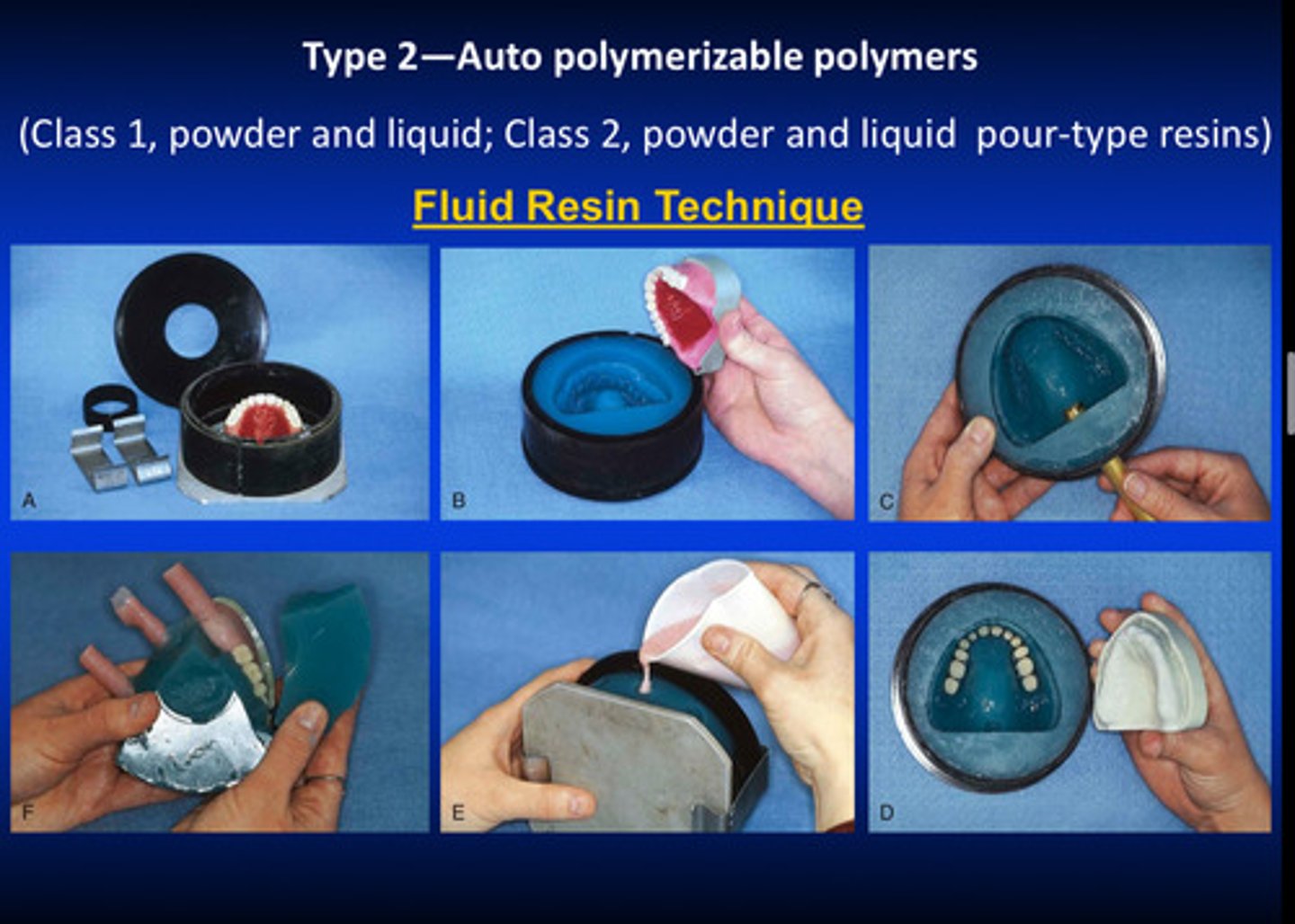

type 2 auto-polymerization polymers, fluid resin technique

used for class 1 (powder and liquid) and class 2 (powder and liquid pour-type resins) for type 2

resin is very flowable and can fill the cavity in between the denture teeth and the cast

liquid plasticizer results in what property

increased resilience

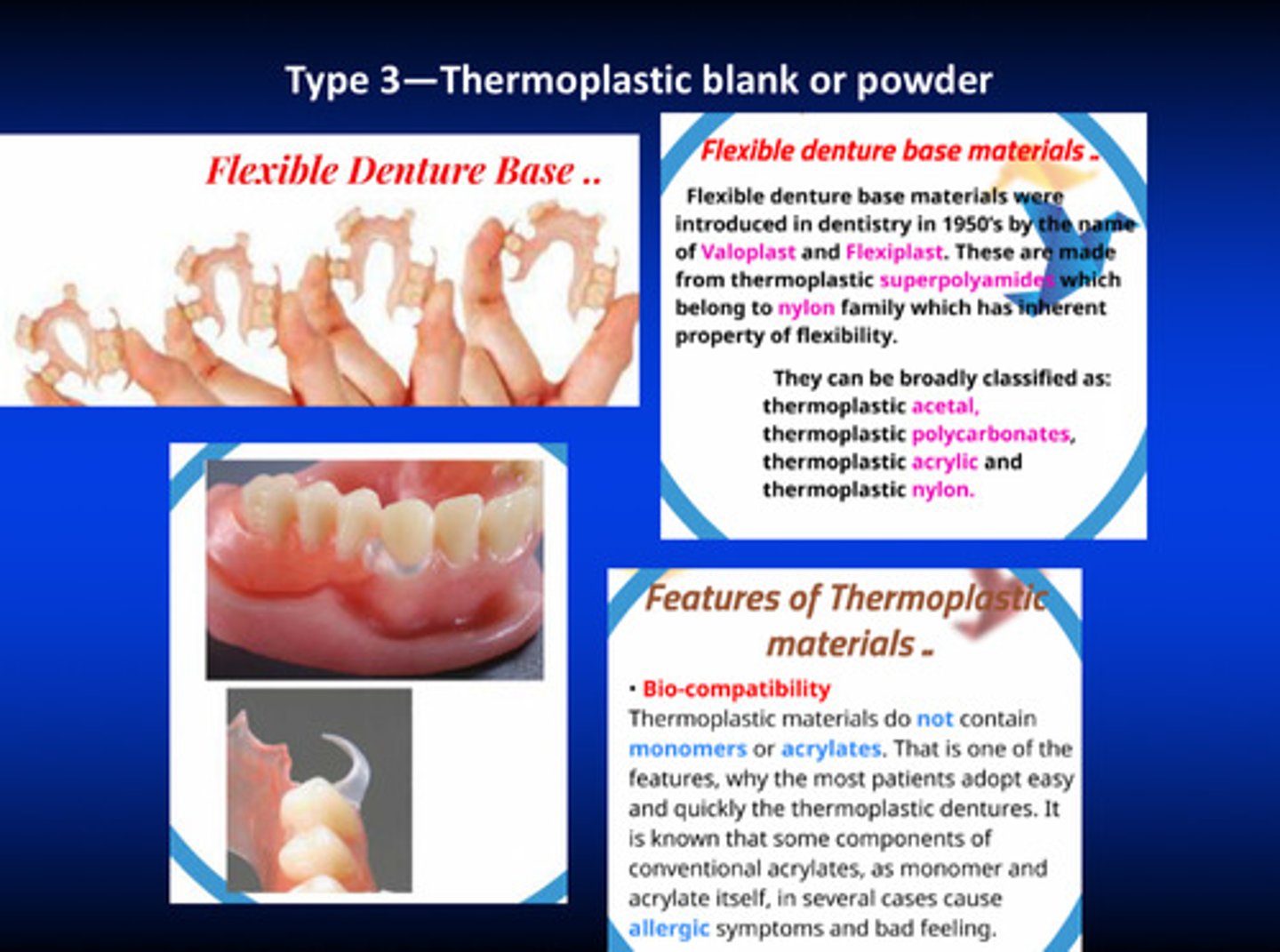

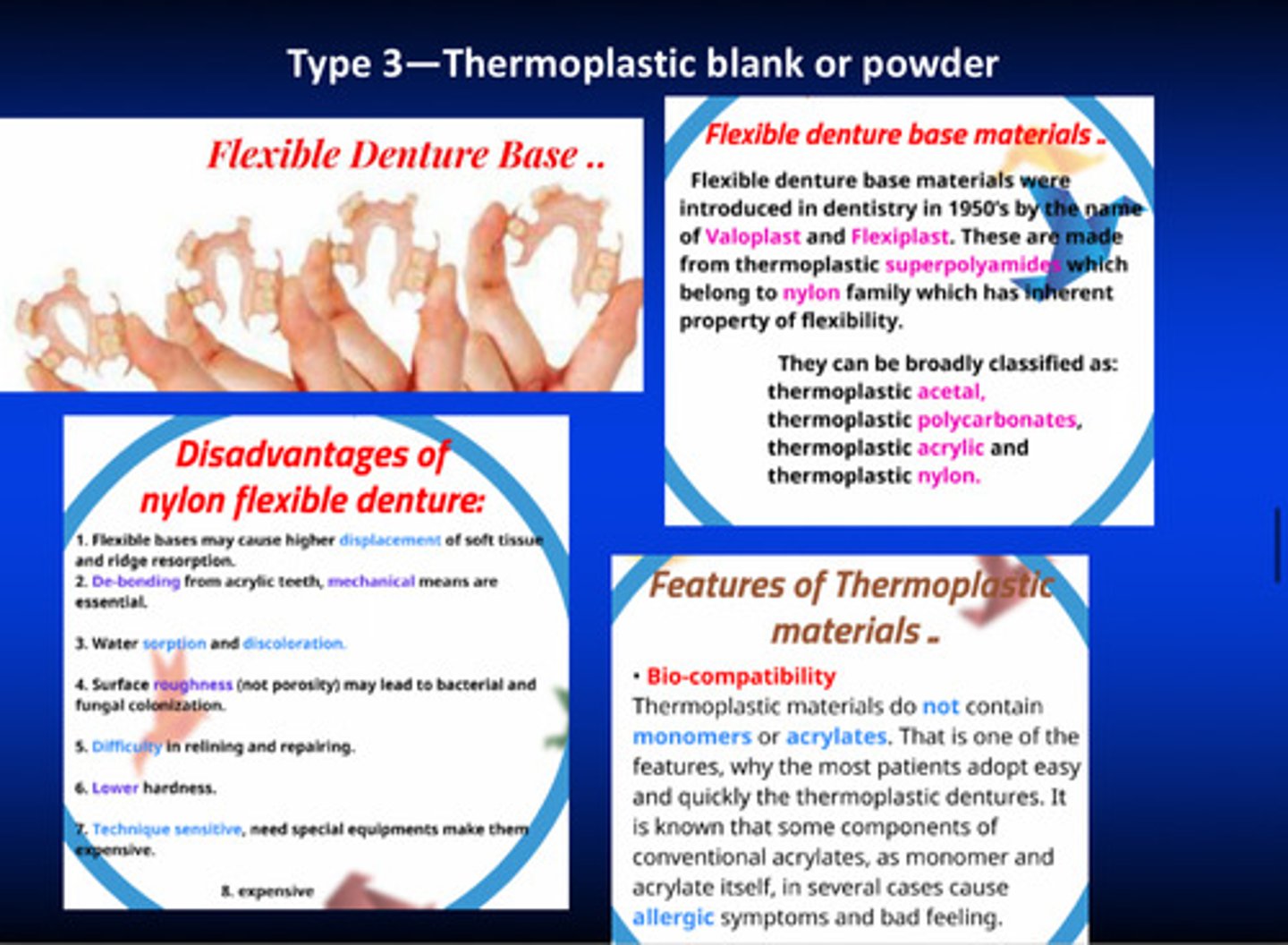

in type 3 (thermoplastic blank or powder), we have ________ denture bases

flexible

why are type 3 flexible denture bases not really taught or used widely

they are completely different from the MMA/PMMA conventional materials: if it is used for esthetics in anterior it is good; but when used for posterior, under the occlusal forces, the denture will move and compress the tissue and push the adjacent teeth —> whole bunch of problems!

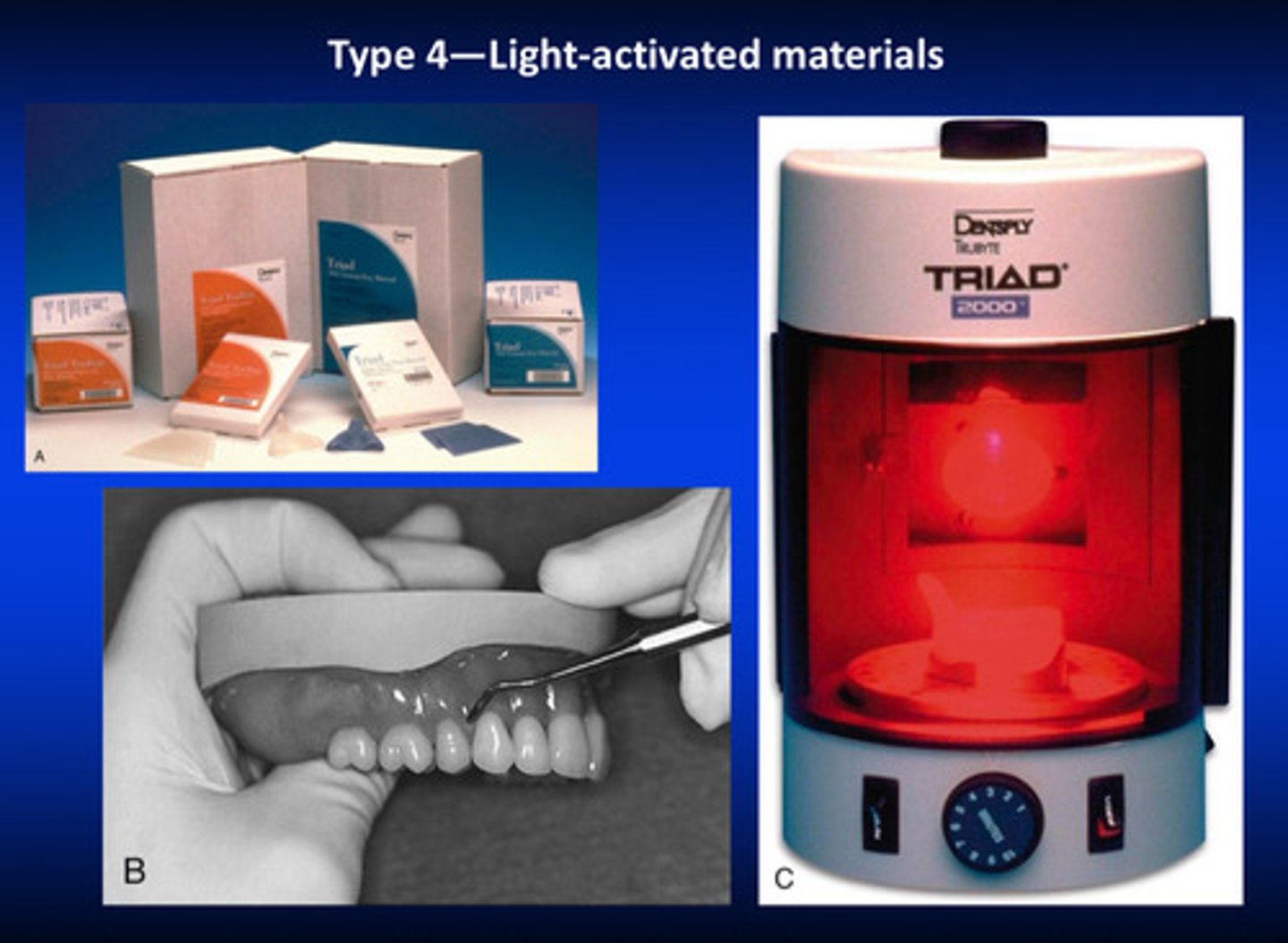

type 4 (light activated materials) use what kind of technique

use the relevant materials like wax, beautify it, add teeth, and put into special curing unit for a couple of minutes and the final denture is ready

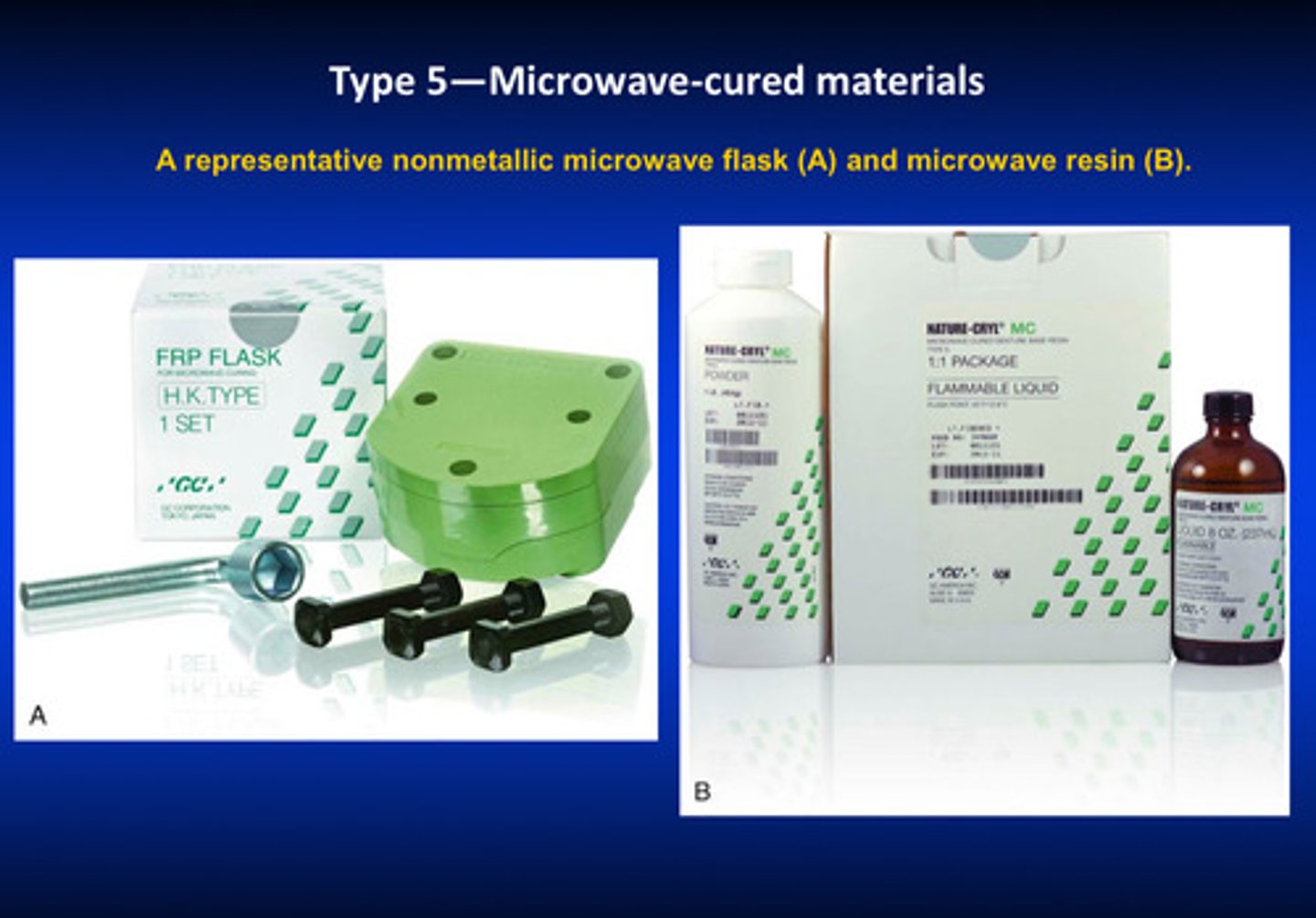

type 5 (microwave cured materials) use what kind of technique

use a representative NONmetallic microwave flask (A) and microwave resin (B) —> use fiber reinforced polymer as a flask bc metal will cause boom boom explosion

liquid cross-linking agent results in what 2 properties

increased stiffness and increased strength

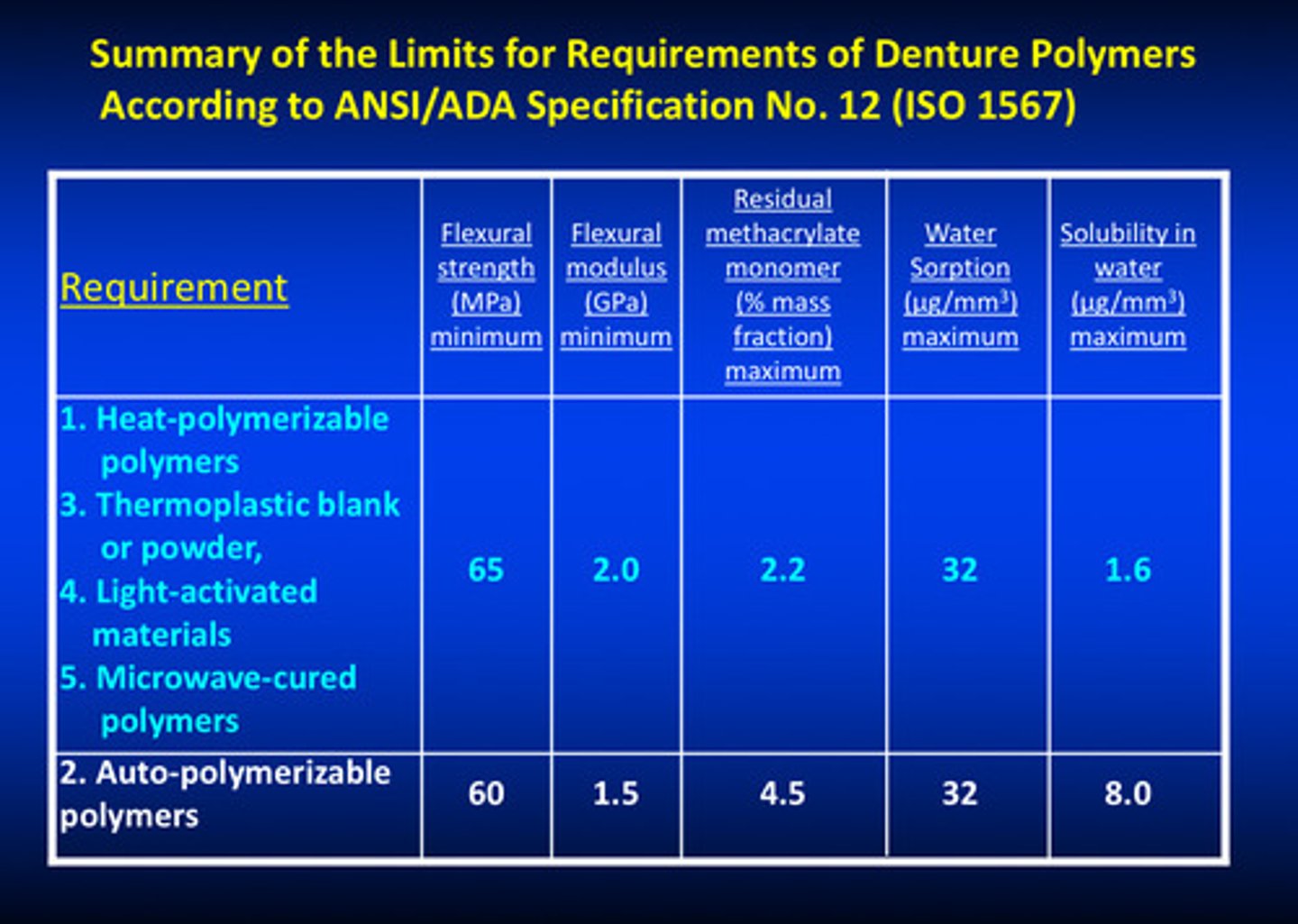

summary of the limits for requirements of denture polymers

types 1, 3, 4, and 5 have same limits; type 2 have lower limits because it uses mixing of powder and liquid and completion of the rxn on the bench instead of under pressure or using heat processing —> may have more voids, flaws, porosities, etc

what are 7 disadvantages of PMMA

1) allergies to MMA monomer

2) high porosity (microorganisms can colonize in the porosities)

3) dimensional changes and polymerization shrinkage

4) difficult to insert in undercut areas

5) hard: causes frictional irritation of mucosa

6) brittle, frequent fracture occurs

7) visibility to metal clasps

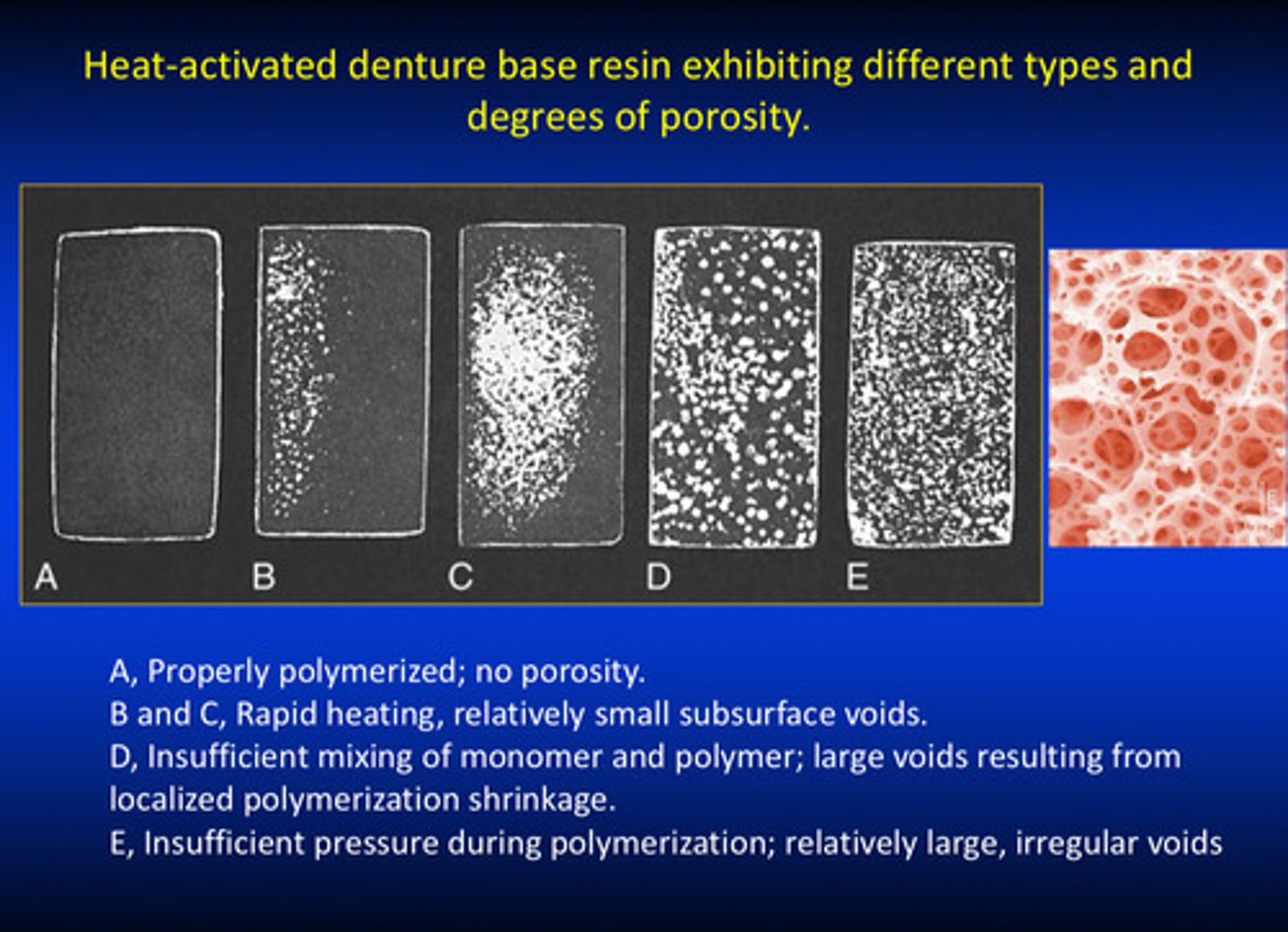

examples of heat activated denture bases resins (type 1) exhibiting different types and degrees of porosity

porosities usually caused by insufficient techniques such as mixing or insufficient pressure

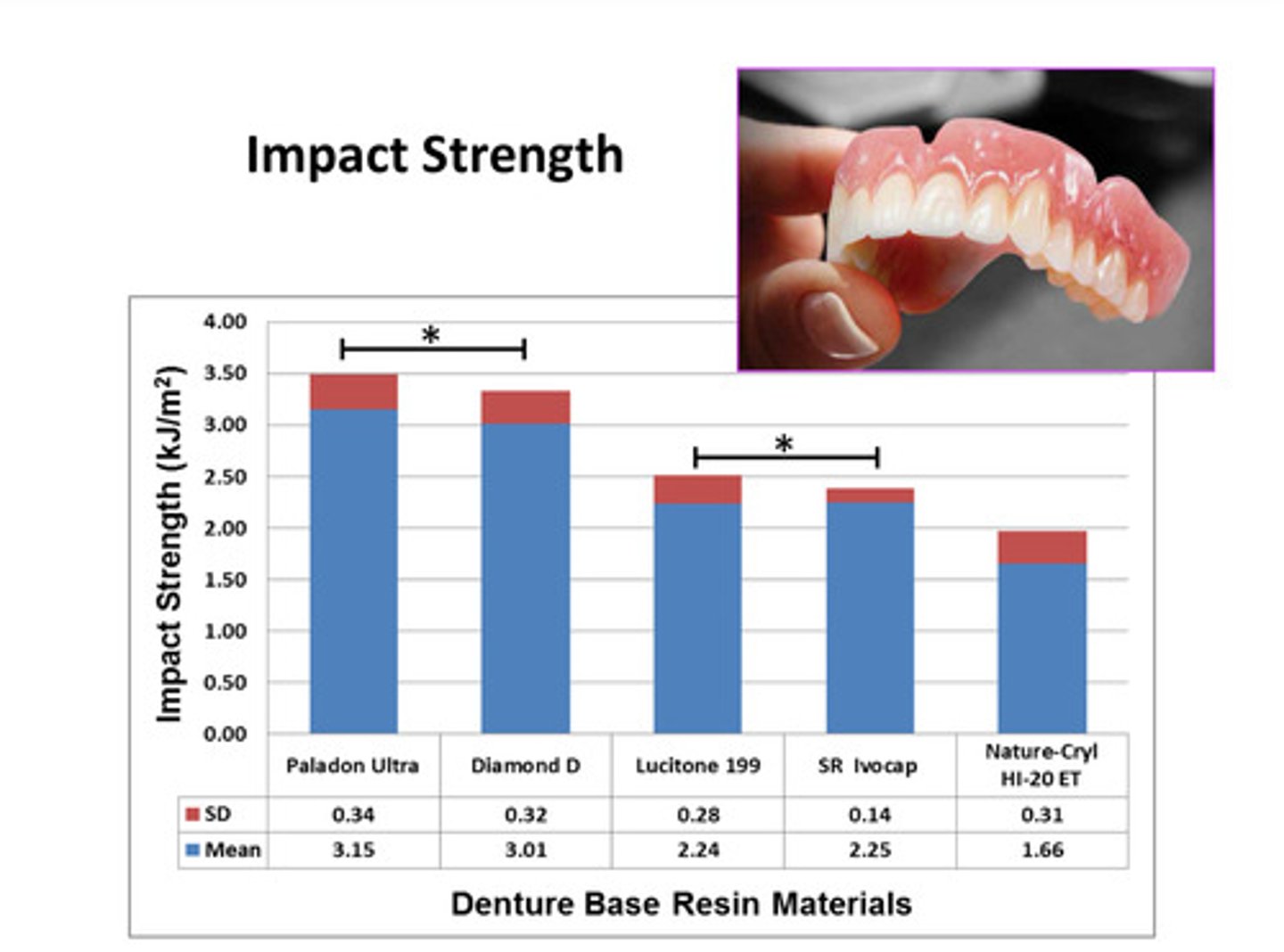

examples of impact strength for various denture base resin materials

different materials may have different impact strengths; impact strength is one of the most imp mechanical properties of denture base materials

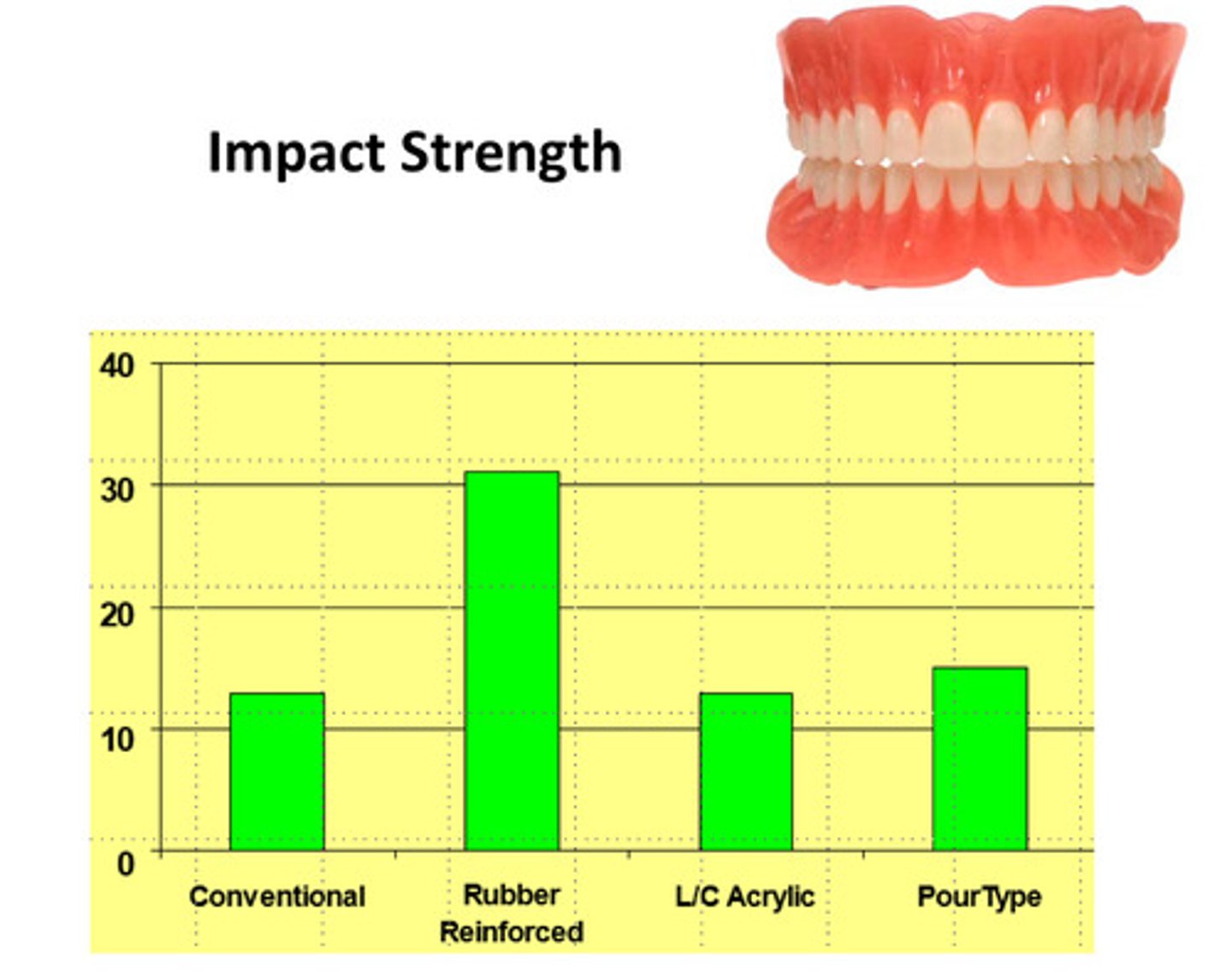

examples of impact strength of denture materials with rubber reinforcement

any rubber reinforcement increases impact strength much more than other materials

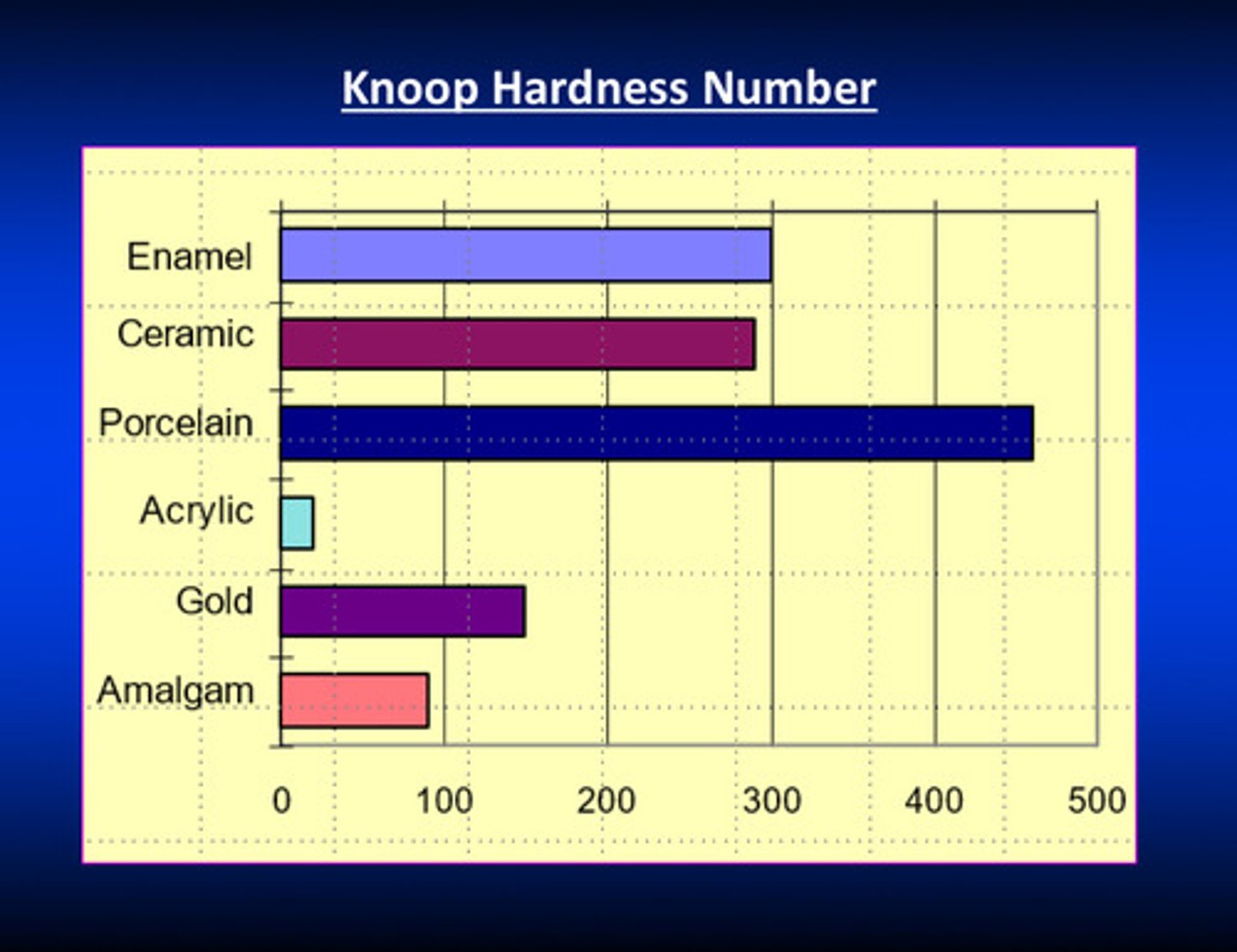

knoop hardness number examples

porcelain has the highest hardness number (recall hardness is resistance to scratching or indentation); denture brushes under water are recommended to clean acrylic dentures due to low hardness AND you must leave acrylic denture out of your mouth while sleeping

"auto" in auto-polymerization polymers (type 2) means what

chemical

what are the 12 requirements for a clinically acceptable denture base material

1) strength and durability

2) satisfactory thermal properties

3) processing accuracy and dimensional stability

4) chemical stability (for both unprocessed and processed material)

5) insolubility in and low sorption of oral fluids

6) absence of taste and odor

7) biocompatible

8) natural appearance

9) color stability

10) adhesion to plastics, metals, and porcelain

11) ease of fabrication and repair

12) moderate cost

the density of methyl methacrylate monomer is only 0.945 g/cm^3 compared to 1.16 to 1.18 for polymer methyl methacrylate, as a result what happens as the monomers polymerize

a volumetric decrease of almost 20% occurs in some dental polymers

as the volumetric decrease occurs, either the mass ______ or internal stresses ______

mass shrinks OR internal stresses accumulate