SOM1 - Pharmaceutical suspensions

1/34

Earn XP

Description and Tags

Lecture 41-42

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

35 Terms

Dispersion of the solid phase creates a large interface (in a solid-liquid interface)

See diagram showing aggregation of particles to create a large interface to decrease surface tension, as the SA is the smallest in a single large particle

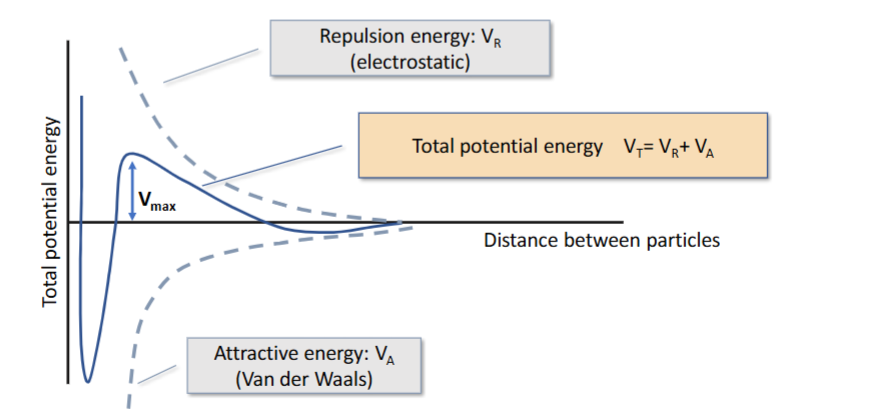

DLVO theory

Solid line in middle of graph is sum of repulsive and attractive energy

Below X axis means: overall attractive forces, primary minimum is caked solution, forces too strong to be undone by shaking, secondary minimum is flocculated , coalescence can be undone by shaking due to weak attractive forces

Above X axis means: Slightly above means particles stay suspended and don’t coalesce (stable suspension)

Uses of pharmaceutical suspensions

Pharmaceutical suspension can be used to:

Administer insoluble drugs

Minimise drug degradation (if it degrades in water)

Mask a bad taste

Alter absorption profile

Cater to special populations (children who can’t swallow pills, for example)

Advantages of suspensions

Easy dosage adjustment (just drink less/more)

Easy to administer, good adherence

Good bioavailability (in theory)

Nearly directly to absorption (doesn’t need to dissolve capsule shell, only needs to dissolve in body fluid)

Disadvantages of suspensions

Can be bulky to carry, due to extra liquid

May need refrigeration

Properties of the ideal suspension

Homogenous during dosing

Easy to resuspend just by shaking

Has an adequate viscosity

Characterised by a small particle size and narrow distribution

Because narrow distribution is equal dosage, and small size means faster dissolution in vivo

Why are suspensions prone to instability

Fine suspended particles

Small particles = high SA, and high instability as a result, as the system tries minimise the energy in the system

High surface energy

Thermodynamic instability

A high amount of free energy in a system will destabilise it.

Self-aggregation-settling-resuspension

Controlling these components allows the suspension to be resuspended with shaking

We can control sedimentation rate to achieve stability

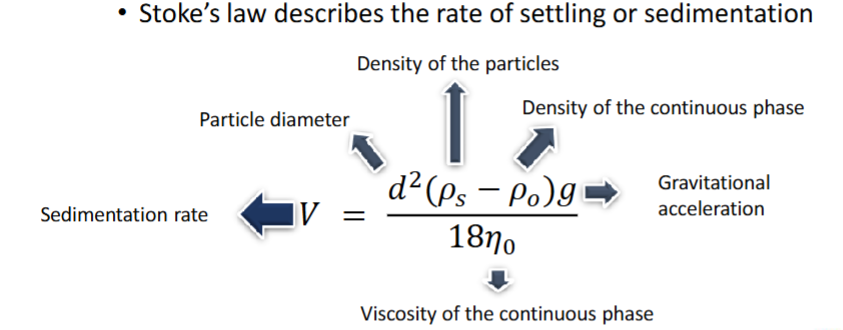

What is settling + recite Stoke’s law

Downward movement of solid particles under the effect of gravity

Viscosity decreases settling, as viscosity prevent motion in the system

What effect does Stoke’s law apply to, and 5 requirements for it to be valid

Stoke’s law applies to settling

Only valid when:

Concentration of dispersed phase is <2% solids

This concentration is considered dilute

Dilute concentration means settling is not hindered, and so can occur freely, without turbulence

Dispersed phase is composed of spherical particles

Particle size distribution is narrow

Solvent is polar

Suspended particles are not subjected to Brownian motion

Brownian motion is the random movement of small particles, so the particles must be bigger than colloidal particles to not be affected

How can we prevent or reduce settling

Viscosity, particle diameter and density of dispersed/continuous phase are the factors we can change

Settling: Viscosity

Viscosity can be changed with suspending agents or viscosity enhancer

Downsides of excess viscosity

Oral

Can be hard to measure with a spoon or swallow

Injection

Can be painful

Topical

Can be gunky and hard to spread

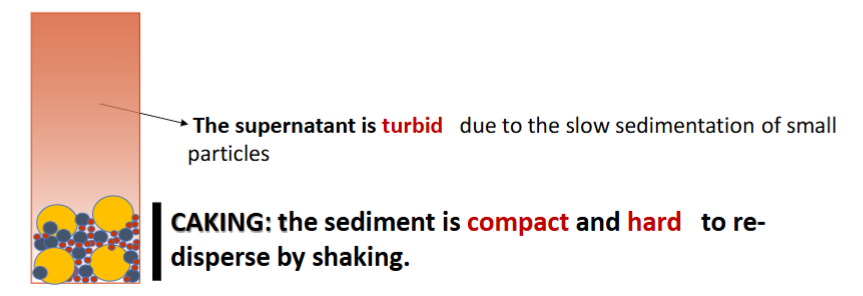

What is the term used when the suspension aggregates at the primary minimum (DVLO)

Caking

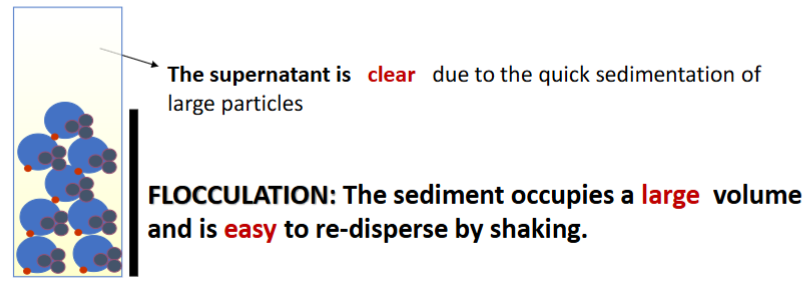

What is the term used when the suspension aggregates at the secondary minimum (DVLO)

Flocculation

What implications does a high energy barrier have

Stable suspension, as the particles have high repulsive forces when closer together after the secondary minimum, so caking is very unlikely, as the particles need to overcome the energy barrier to get close enough to cake.

Aggregation at primary minimum

Initially, electrostatic forces (zeta forces) keep particles in suspension

Over time, uncontrolled settling occurs, leading to caking (very hard to redisperse by shaking alone)

When enough particles in the solution eventually settle, the pressure from the top of the settling layer allows the particles to break the energy barrier and overcome resistive forces, and a cake is formed

Supernatant = layer of liquid above sedimented layer

Turbid = opaque/cloudy (its turbid because the small particles sediment slower)

Aggregation at secondary minimum

Suspension is modified to reduce repulsive forces (compared to the caking suspension)

allowing it to avoid caking at primary minimum

But it does allow formation of loose aggregates (flocs)

Due to reduced repulsive forces, it also settles much quicker than a caking solution, but can be shaken to redisperse

Increases overall suspension volume, as the flocs stack with large gaps between

Properties of flocs

Weakly bonded aggregates

Quick settling rate due to a large particle size (stoke’s law)

Do not form cakes

Easily resuspended

Formed in the presence of floculating agents

How do electrolytes function as flocculating agents?

Reduced the repulsion barrier (Vr)

By neutralising the surface charge, repulsive forces are reduced, allowing for flocculation

Anionic agents are used to flocculate cationic particles (e.g. K₂SO₄)

Cationic agents are used to flocculate anionic particles (e.g. AlCl₃, NaCl)

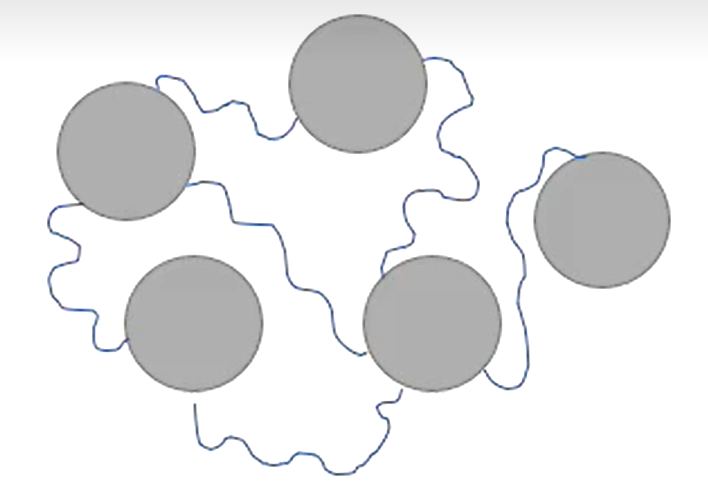

How do polymers function as flocculating agents?

Polymers form a “bridge” between particles and allow them to get closer. Surfactants work in a similar way, and can be ionic or non-ionic. (Loose aggregate-forming agent pictured)

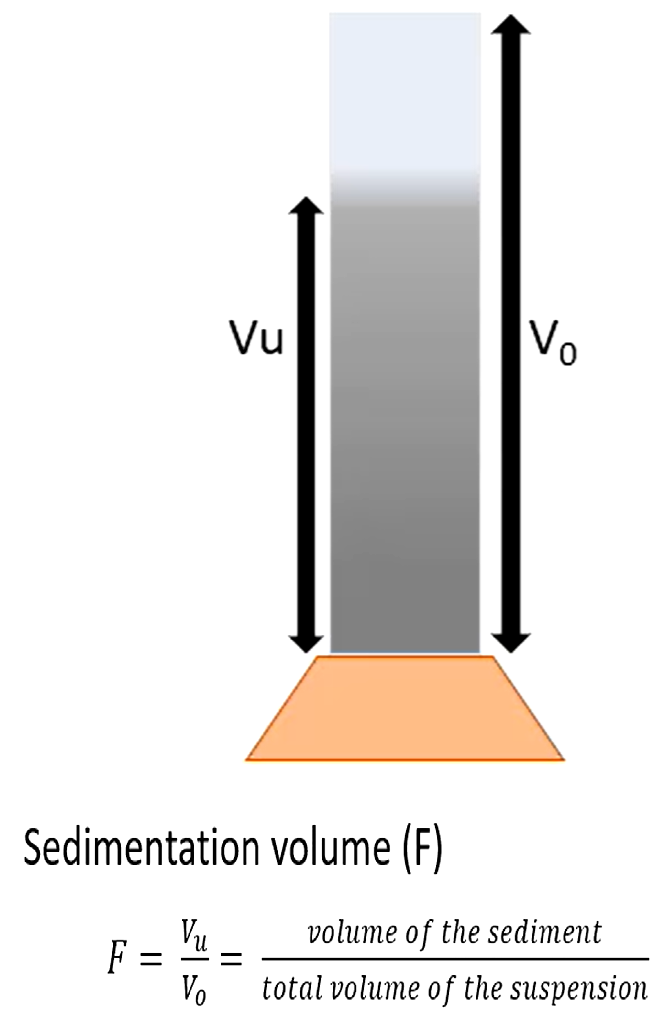

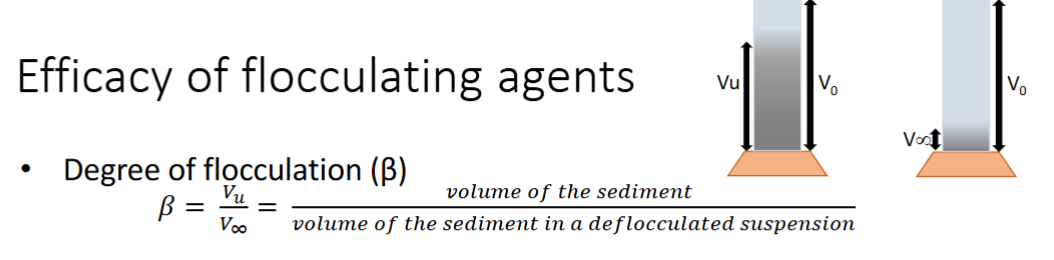

Efficacy of flocculating agents - calculating sedimentation volume

F will be higher on a flocculated suspension

Calculated by letting suspension sit for a moment with flocculating agent in a measuring cylinder, and then measuring sedimentation and total suspension volume.

Efficacy of flocculating agents - calculating degree of flocculation

β will be higher in a flocculated suspension

β indicates how good an agent is at flocculating a suspension (its basically a ratio between unaffected suspension and suspension with agent)

A functional flocculating agent will have a value higher than 1 (a value of 1 means it doesn’t do anything at all)

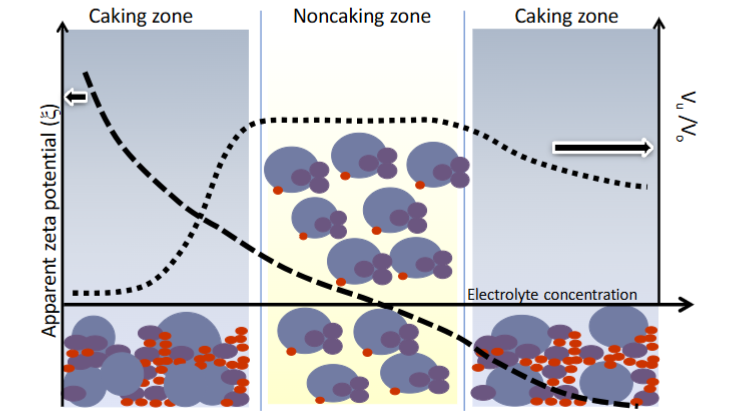

Controlled flocculation - describe what happens at positive, negative and neutral zeta potential

When zeta potential is too highly negative or positive, the particles repel each other, and don’t aggregate, until they sediment, at which point a cake is formed as they are rammed close together

At a weak/neutral zeta potential, the particles can aggregate gently with weak bonds and form flocs, so can be broken apart easily with shaking and don’t cake

What is zeta potential

Effetively the “net surface charge” between the surface, slipping and stern layers. Measured at the slipping plane

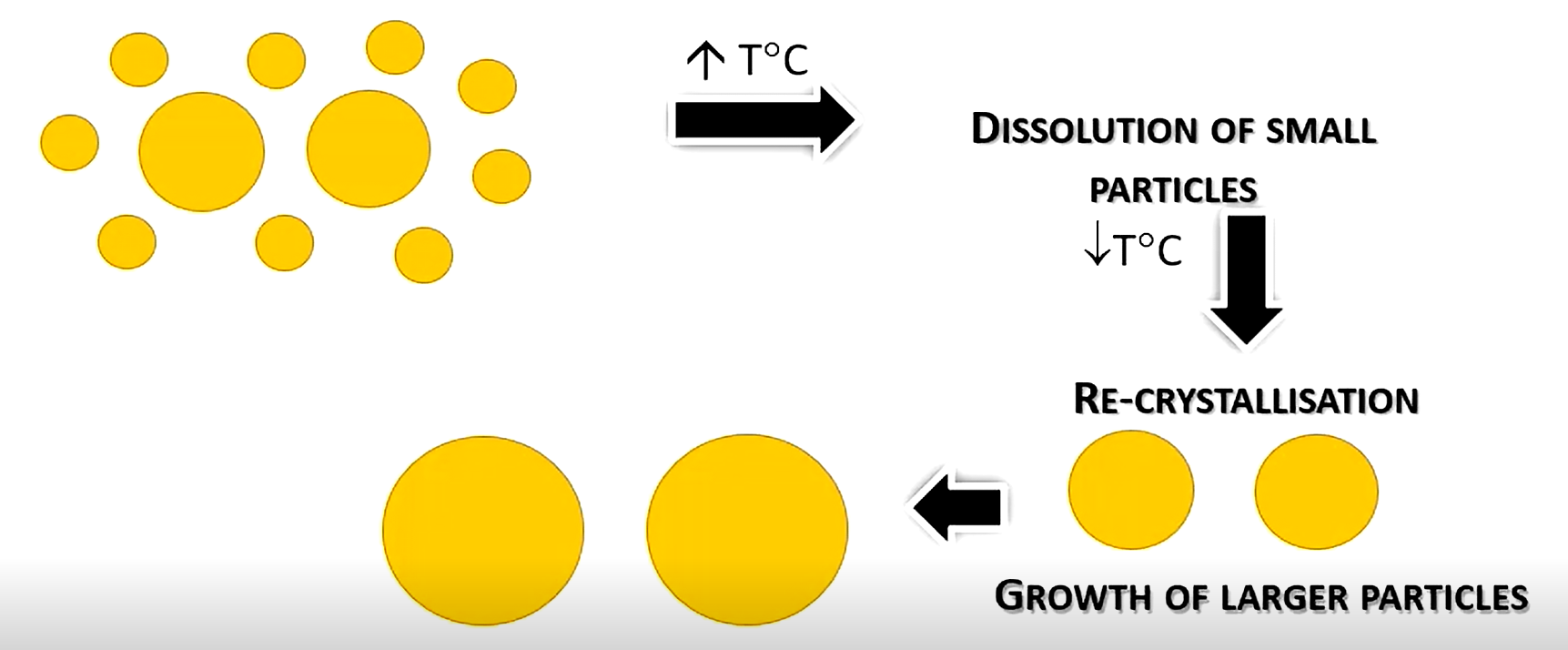

What is Ostwald ripening?

When temperature fluctuations cause small particles to dissolve, and recrystallise onto larger particles.

Larger particles affect dispersed phase size, and therefore sedimentation rate, which could cause caking or grittiness

Why can surfactants worsen Ostwald ripening?

It can make smaller particles more soluble than larger particles, so more small particles dissolve quicker at more minor temperature changes.

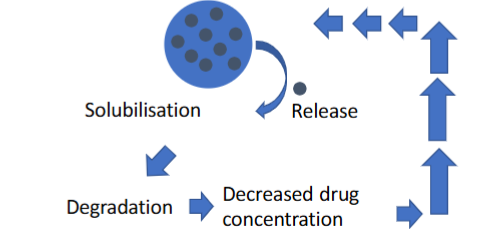

How do suspension solubility affect stability

Only the dissolved part of the suspension is prone to degradation, so the more soluble a suspension is, the more prone to degradation it is.

Often displays Zero-order degradation kinetics

Extemporaneous (unprepared) compounding

Take into account

Source of drug powder

(capsule, tablet, need to think about excipients)

Powder size

Reduce particle size (mortar and pestle usually)

Physio-chemical properties of dispersed phase

Determines

What excipients are required

How easily suspension is to prepare

Physical stability of preparation (in part)

Importance of particle size and size distribution

Affects:

Sedimentation

Stoke’s law

Ostwald ripening

Differences in solubility between small and large particles exaggerates ripening

Taste

perceived for particles >10mcm

Grittiness

Can be an irritant, perceived for particles >5mcm

Syringeability

size >25 mcm can be painful/too big to fit through needle tip

How do surfactants act as wetting agents

Surfactants bridge the gap between dispersed and dispersing phase, decreasing contact angle and interfacial tension.

How do low concentration hygroscopic solvents act as wetting agents + 2 examples

Coat the dispersed phase , decreasing contact angle

Glycerin, propylene glycol, ethanol

How do hydrophilic colloids act as wetting agents , and give 2 examples

Coat the dispersed particles in colloids, which increases affinity and decreases contact angle

Have no effect of interfacial tension, unlike surfactants

examples: bentonite, gums, cellulose derivatives and alginate

(most of these are also thickeners)

3 Concerns about surfactants as a wetting agent

Make sure it is anionic or non-ionic as cationic surfactants can be toxic

Bitter taste

Increase affinity for air, can cause foaming

Can exacerbate Ostwald ripening

What is a suspending agent?

Thickener, increases viscosity in a suspension, usually to decrease sedimentation rate

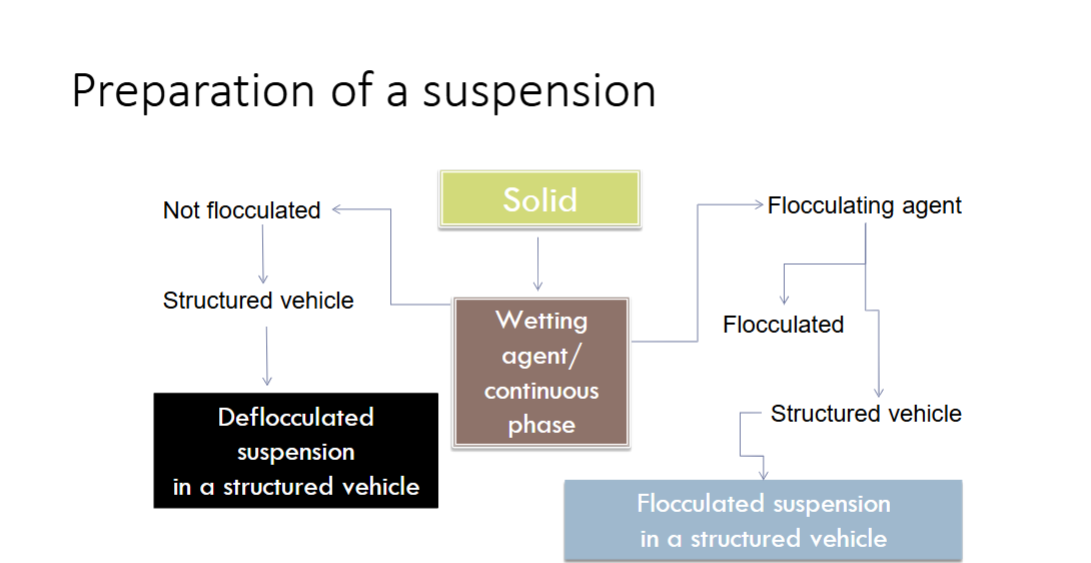

Preparation of a suspension flowchart

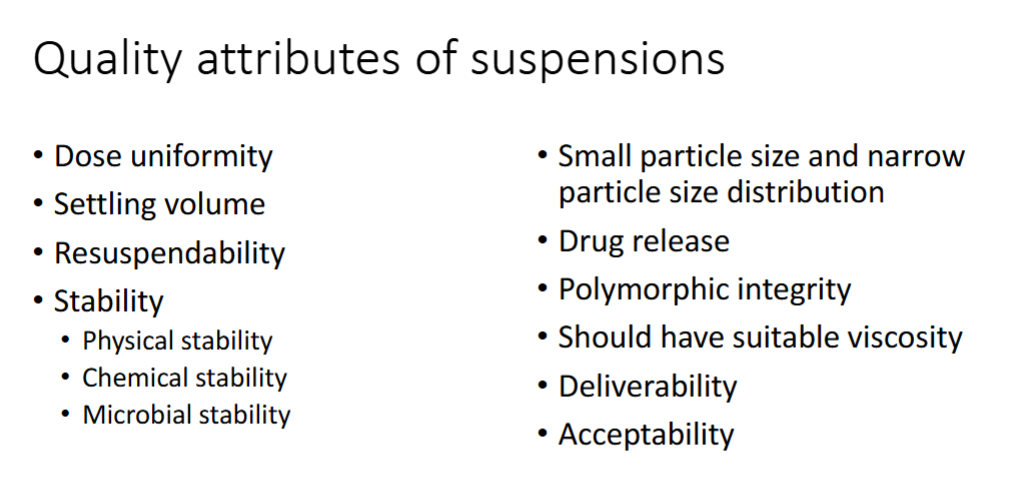

Quality attributes of suspensions