Polymers and Composites

1/95

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

96 Terms

homopolymer vs copolymer

homo jus one type of building unit, co is two or more

Polymers: how are they 3D?

cross-linked between linear molecules to form 3D network

Polymers: may have ___ or __ regions, (i.e a varying % of each)

What determines physical properties?

amorphous or crystalline

Length/side branching/cross-linking

How does an increase in MW or chain length affect the polymer?

Increases rigidity, strength, melting temp

cross linking dramatically changes ___ of a polymer. How does an increase in cross-linking affect?

molecular weight

physical properties:

Increases rigidity and resistance to solvents

Increases glass transition temperature

Softening temperature from glassy solid to more flexible solid

Polymers elastic deformation: chains uncoil but do not slip past each other due to?

How well do they recoil when stress is removed?

crystalline regions, entanglements, cross-links

completely

Permanent deformation in polymer

What does the quantity of slippage depend on?

Polymer chains slide over one another and become relocated within material

Duration of loading

viscoelastic

combo of elastic and plastic strain with recovery of elastic strain that is time dependent

Thermoplastic

polymers that soften by heating and solidify on cooling, glass transition temperature

Poly (methyl methacrylate) and polystyrene are what kinds of plastic

thermoplastic

cross-linked poly(methyl methacrylate) and silicones are waht kind of plastic

thermosettng

thermosetting

polymers that solidify during fabrication but do not soften by heating

solvation properties are dependent on?

MW and crosslinking

Solvation properties;

Longer chains (or higher MW) dissolve ?

Why?

How does cross-linking affect dissolution?

small amount of swelling of dental polymers goes a long ?

what can this affect?

more slowly: due to polymers tend to absorb, swell and soften, then possibly dissolve in solvent

retards dissolution: highly cross linked cannot be dissolved

goes a long way: can affect fit of presthesis, some benefit in dentures as they shrink during processing

polymerization: definition and what are they two kinds?

chemical linking of monomer units to form high MW molecules: condensation and addition

Condensation polymerization, or ___: is what? What does this commonly make?

step growth

difunctional components, all become reactive simultaneously

Produce low MW byproduct (H20 or C-OH)

Impression materials (condensation sillicones, polysulfide)

addition polymerzation

starts from active center, adds monomer sequentially to form a chain

impression material and nylons are formed thru?

condensation polymerization

Addition polymerization can uses ____ polymerization. What are the stages?

free-radical

Induction: activation and induction

Propagation

Chain transfer

Termination

Free radical polymerization: Induction stage

Free radicals generated by activation of radical producing molecules using second chemical, heat, light, etc.

Free radical, (as part of the initiator), looks for something to attack, preferably double bond

Forms a bond with one carbon, leaving the other with excess electron (another free radical)

This initiates polymerization reaction

During free radical polymerization and during the induction phase, what molecule has the free radical initally?

Initiator

____ activates ___ __ initiator for denture base resins

____ activates __ in self cured resins

__ in some composite resins

Heat activates benzoyl peroxide

Chemical (tertiary amine) activates benzoyl peroxide

Light-activation

Free radical polymerization: Propogation phase?

Free radical reacts with another double bond, bonds to it, creates another free radical, and so on

Free radical polymerization: chain transfer

Active free radical of growing chain is transferred to another molecule (another monomer or inactivated polymer chain) and a new free radical for further growth is created

How does free radical polyermization end in the termination phase?

Additional typers of termination rxns may occur also, especially in ?

Coupling/Annihilation: free radical meets anther free radical

branched and cross linked polymers

PMMA: poly(Methyl methacrylate) is used for what? What can alter its properities?

denture bases

Pigmenting, composition, and processing variations

what is gutta percha used for?

What is it classified as?

fills space after root canal

natural polymer/plastic

Rubber

What is a rubber? Different kinds?

polymer of isoprene: may have different structural arrangements depending on where CH3 and H groups are (geometric isomer)

cis-isoprene: natural rubber

trans-isoprene: gutta percha

-(NH)-(C=O)-O-O structural unit:?

what used for?

polyurethane: orthodontic ligatures and modules or chains

polycarbonate is used for? What is it often reinforced with?

some plastic orthodontic brackets

ceramic fillers or glass fibers

Polyether is used for?

impression material

Polysulfide is used for?

impression material

Polyvinlyl siloxane is used for?

Impression material

composite definition

Dental composites?

mixture of two different classes of material

Mixture of polymer (resin) and ceramic (glass particles known as “fillers”)

the material of choice for direct esthetic anterior restorations?

Resin compsosite

What are the major components of the resin composite?

Matrix, filler, coupling agent

What is the matrix in the composite components?

What are the 3 common dimethacrylate matrices? (or can be blended)

plastic resin material that forms a continuous phase and binds the filer particles

BIS-GMA (propane), UDMA: urethane dimethacrylate, TEGDMA: triethylene glycol dimethacrylate

TEDGMA, HIDDMA (hexanediol dimethacrylate), DDDMA (dodecanediol dimethacrylate), PCDMA (polycarbonate dimethacryate): are all what?

These are sometimes called ___ bc they …

For example, TEDMA added varies with intended purpose: restorative resins are __wt% BIS-GMA, _%wt TEGDMA, while resin luting agents (which may need to flow better) may be a ? mixture

low viscosity monomers (matrix)

dilutents, lower viscosity of monomer system (compared to all BIS-GMA)

75%, 25%, 50-50

EBPADMA is?

newer dimetharcylaet: low water sorption substitute for BIS-GMA

Filler in a composite component is ?

What the the typical volume % or weight % of a composite?

reinforcing particles and/or fibers that are dispersed in the matrix

30-70% vol, 50-85% of weight

silica, borosillicate glass, lithium aluminum silicate, barium aluminum silicate, strontium or zinc glass are all examples of ?

Filler

Compared to the matrix itself, adding filler:

Flexure (2)?

Coefficient of thermal expansion?

Hardness?

Polymerization shrinkage?

Thermal conductivity?

increases flexure and compressive strength

Increases flexure and compressive modulus

reduces coefficient of thermal expansion

Increases hardness

Reduces polymerization shrinkage

Increases thermal conductivity (but not problematically so)

coupling agent does what?

When/How?

Most common:?

What would happen w out it?

bonds filler to matrix

surface of filler is treated with coupling agent before mixing with matrix

silanes

lack of bonding between filler and matrix, leading to decreases fracture resistance, fatigue resistance, and wear resistance

what is that?

typical silane: organic silicon compounds used as coupling agent

Composite additional components:

initiators, activators, accelerators?

Inhibitors?

Pigments?

Opacifiers?

Initiators: help begin polymerization process

Inhibitors: Prevent accidental/spontaneous polymerization

Pigments: Inorganic oxides

Opacifiers: Alter translucency

Titanium dioxide, aluminum oxide

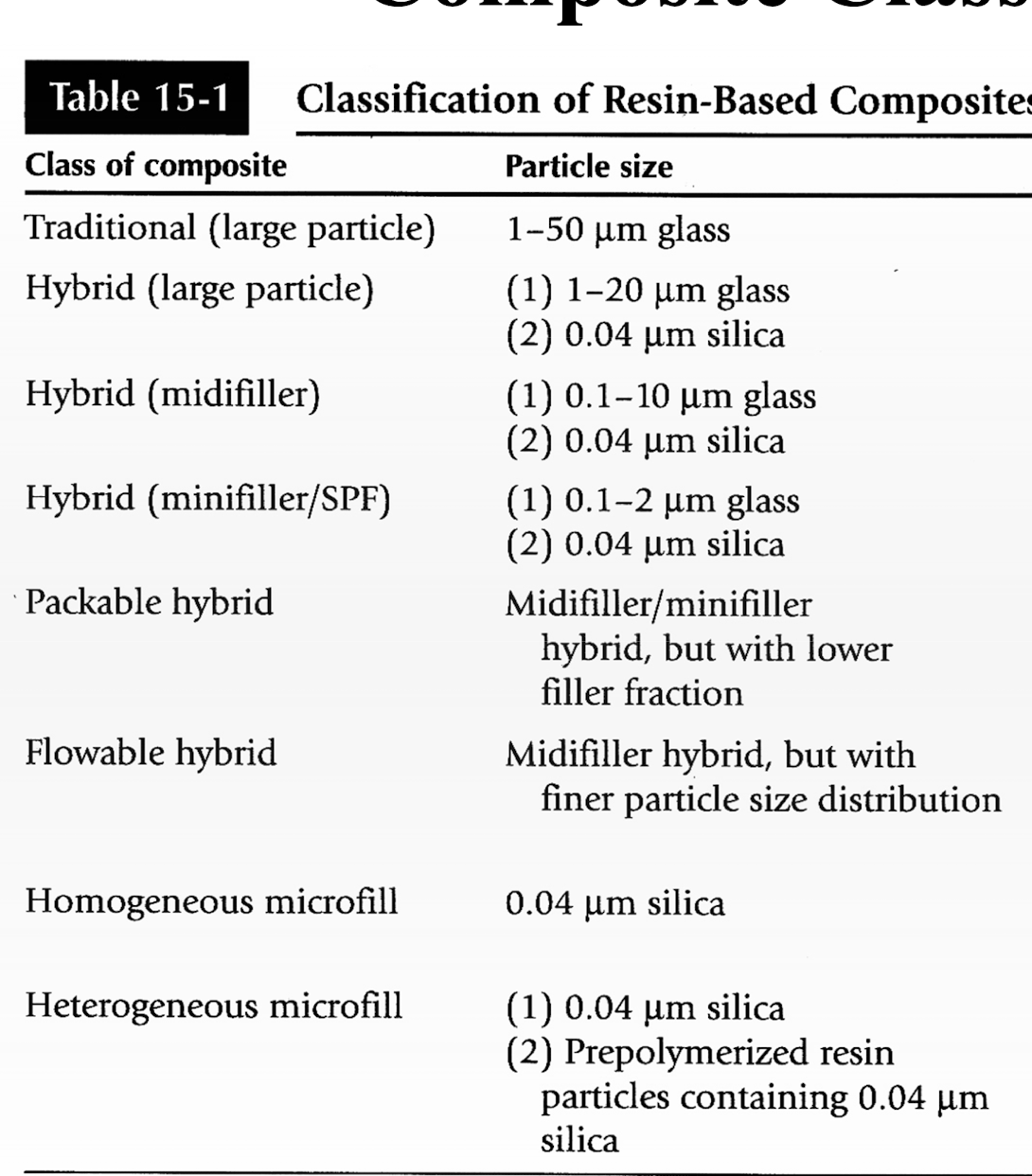

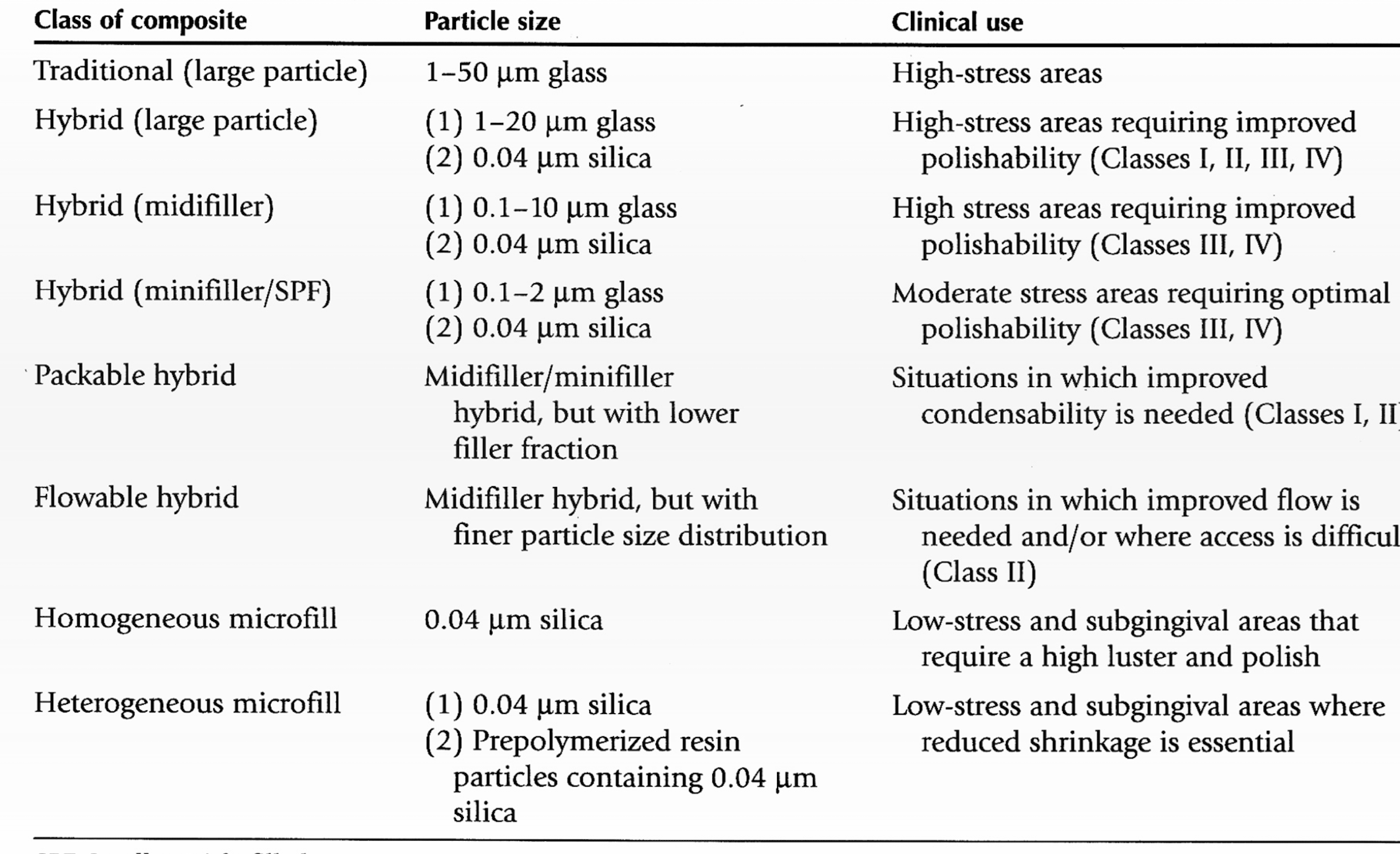

what are the different classifcations of composite? Which is arbitrary?

activation mode, usage, filler characteristics: arbitrary

Activation Mode: Composite Classification:

What are the different modes?

Light cured, chemically cured (AKA cold cured, self cured), dual cured

Composite classification: activation mode:

LIGHT CURED: what does it contain and what are the pros/cons

Contains photosensitive initiator (CQ, camphorquinone)

Pro: latitude in placement and time

cons: depth of cure → have to do it in increments

Composite classification: Chemically cured, or self cured, or cold cured:

What are the components? What is the pro/cons?

Base: contains activator (amine)

Catalyst: peroxide initiator

pro: proper mixing → uniform curing

con: limited working time, mixing porosity

Composite Classification: by usage

Anterior: superior surface texture and esthetic qualities

Posterior: higher resistance to wear and fracture

Universal: compromises between the two

Composite classification: filler characteristics

Based on? What are the types

particle size and distribution

All % are of filler!

Traditional:

60-70% vol

70-80% wt

10-100 um (biggest)

Hybrid

60-65% vol

75-90% wt

.01-0.1 and 1-50 um particle size

Microfilled

20-59% vol

35-67% wt

.01-0.1 um

Small

0.1-1 um

hybrid types of filler characteristics:

Generally contain: ?

What is the aim?

Microfill: 0.04 um

Second particle size: (large 1-20 um, mid: 0.1-10 um, small: 0.1 - 2 um

obtain smoothness of microfilled with higher mechanical properties of larger particle components

Hybrid variation: Packable vs. flowable

Packable

Higher filler % (48-67% vol, 65-81% wt)

Possibly fibers or textured filler surfaces

Used where condensability is needed

Flowable

lower filler % (30-55% vol, 40-60% wt)

Lower viscosity: but higher shrinkage, water sorption, and thermal expansion

Used where improved flow is needed or difficult to access

Match: Macrofill, microfill, hybrid, minifill/microhybrid, midfill

Better esthetically and polishable, but relatively weak

compromise, adequate strength but still esthetic

Strong but difficult to polish and keep smooth surface

Universals

Microfill

Hybrid

Macrofill

Minifill/microhybrid, Midifill

In general, mechanical properties of composite resin are related to?

How affect?

Filler content

More filler content:

Increased strength

Increased stiffness

Increased fracture toughness

increase contraction stress

less shrinkage

less absorption of water

Oxygen Inhibition Layer?

Signifcance?

In incured composite resin, atmospheric oxygen diffuses into resin. Oxygen inhibits polymerization by oxidizing free radicals into more stable peroxides with lower reactivity towards monomers

After light-curing, resin-rich, oxygen-inhibited layer is formed at the uppermost surface layer, approx 4-40 um thick

If small restorations arent finished, oxygen inhibition layer may be more susceptible to surface staining

Conflicting studies on if is important in the integrity of the incremental layers

Polymerization is seldom entirely complete in?

Degree of conversion?

Typical values? Does not imply?

What can leach out? Why is this an important consideration

Primarily in addition polymerization

% of C=C bonds converted to single bonds

50-70%, does not imply that 30-50% is not converted, as they can be incorporated into monomer, just not reacted

Residual monomer: potential allergen

Dental polymers ___ during curing monomer

shrink

Polymerization shrinkage:

What %?

What does this affect?

the greater amount of polymer present, the greater the potential for shrinkage upon polymerization

2-5% dependent on the class

bond of the composite to tooth, can lead to leakage and secondary caries

Contraction stress:

Greater contraction stress with?

In general?

greater degree of conversion

greater the filler content, the greater the contraction stress (even tho less shrinkage)

C factor

cavity configuration factor

ratio of bonded to unbonded surface of the composite

complex, but in general high C factors → high stress (more bonded surfaces, less unbonded surfaces, = higher stress)

Why care about contraction stress (6)

debonding, marginal staining, microleakage, secondary caries, enamel micro-cracks, post-operative sensitivity

Methods to lower contraction stress: formulation (not able to be controlled by clinician): 4

Larger monomers

non-bonded fillers

Adding inhibitors to slow curing

Different monomer systems

Clinical Factors to lower contraction stress

liners: use of GI, RMGI, or flowable composites

act as stress absorbers

Limiting constrains and curing in increments

Not just for depth reasons, maximizing free surfaces enhances stress relief by allowing more flow

Horizontal, vertical, oblique increments

Clinical factos to lower contraction stress: light cure protocols

What are the 3 kinds and whats the concept behind it?

Ramp: ramp irridance from low value to high value over 10 s

Step: irradiate at low intensity for 10 s then higher value

Pulse: short dose of low intensity, wait several mins, high intensity

Concept: Slow initial polymerization rxn, allowing more time for composite flow prior to gelation → reduces stress

Bisco, reflexions XLS dentin, Premise from Kerr, Kalore from GC america are what?

Low shrink composites

Do low shrink composites reduce shrinkage stress? What does it depend on?

most part: no

some lower cuspal deflection with Filtek LS and Kalore, but shrinkage stress still present.

Depends upon when shrinkage occurs (post gelation) and material properties like elastic modulus

Composite resin properties: Thermal properties

Coefficient of thermal expansion:

Composite > enamel > dentin

Affects margin => effects on bond integrity

Composite Resin properties: Water sorption and solubility

Dental composites ?

Some components of composites ? what does this affect? What kind of issues?

Absorb water: decreases with increased volume % of filler

Typical values: 0.3 - 2 mg/cm²

Some components of composites stablize

Typical 0.01-0.06 mg/cm²

Inadequately polymerized resin and/or silicon may leach out

Affects color stability and wear resistance

Residual monomer bicompatibility issuse

Composite wear forms

Abrasion

Generally 3 body (involving food/other particles)

More uniform loss of substance

Attrition

2 body, more localized

In high stress occlusal areas

Marginal Ditching

At restoration/tooth interface

Composite Wear: Corrosive wear?

Where issue and how?

Wear coupled with chemical attack

Issue especially in posterior restorations

Hydrolytic breakdown of resin

Breakdown of resin/filler interface

erosion of the surface from acids

How to mimic optimal, tooth like esthetics?

Layering technique

there may be a small shift in color with?

polyermization of resin composites

Amount depends on brand and shade: confirmation of shade with polymerized material

important to cure in increments why?

prevent uncured resin, limit stress

shade selection before or after rubber dam placement

before: dehydrated teeth elevate values

What are the four catergories of instruments of finishing and polishing

Coated abrasive disks and strips

Cutting carbide, diamond, and stones

Rubberized abrasives

Loose particular abrasives in the form of pastes and powders

Smooth highly polished surface has what effect?

What is the surface roughness threshold for plaque rentention?

Increases longevity

reduces plaque accumulation → less probability of gingival irritation or surface staining

0.2 um

Finishing vs Polishing

Finishing: gross contouring of restoration to obtain desired contour

Polishing: provides smoothness and reduction of finishing scratches

What is the main failure of composite resin?

0-5 years: primarily by restoration failure, then secondary caries

6-17 years: secondary caries

Bulk-fill compsite resin: what are the approaches

Placed in larger depth increments

Place in 1 layer

Most are a bottom bulk-fill layer and then capped with 2 mm increment of traditional composite

Bulk fill composite resin properties compared to traditional

tend to be more translucent: more light transmission → greater depth of cure, some have depth of cure > 4 mm

Tend to be less filled than traditional composite

Inferior mechanical properties: thats why capped for better strength and wear resistance

Indirect composite resin

Made in dental lab

Some are indicated for inlays, onlays, jacket crowns, veneers, crown and bridge

Cured with light-curing machine/box

CAD/CAM

composite resin blocks for milling

Indicated for inlays, onlays, veneers, and crowns

Bonded to tooth

Direct composite resin and MUSOD

TPH spectra (sim lab): universal compsoite: nanohybrid and microfiller compents

Surefil SDR flow (limited use in clinic): less filled and less strong but greater depth of cure

4 types of light-curing

Quartz-tungsten halogen

LED

Plasma arc (PAC)

Argon Laser

Differ in construction, light wavelength range generated, light intensity, cost, durability

____ have broad wavelength distributions

__ have more distinct and narrower wavelength distributions depending on chips

Quartz-tungsten-halogen and PAC LCUs

LEDs

Most compsostie resins (>90%) contain __ as a photoinitator and _ as activator (which)

CQ (camphoquinone),, amine (DMAEMA)

Photoinitators will have certain __ for excitation/absorption

The spectral emission from light curing unit should overlap the ?

wavelength

absorption spectrum of photoinitator in composite

Total energy of the irradation or radiant exposure = ?

Exposure reciprocity law?

What does it influence? How much is needed?

Irradiance * irradation time

Influences degree of conversion and mechanical properties: 4000-16000 mW*sec/cm²

Law: Comparable material properties will result as long as the same radiant exposure is obtained (studies disagree)

Irradiance variability: Should tip be moved around?

Light exiting curing units is not necessarily uniform

No: but if using circular motions, increase curing time so that overall time is greater at single point

Light attenuation

Light intensity decreases with?

During light curing, it may be difficult to have light tip directly adjacent to tooth

Cavity/prep may increase distance from light tip to material

Decreases with distance

Depth of cure:

Light penetration is ___ as it passes through material

Lower depths? Darker shades?

Attenuated

Lower depths do not feel same light intensity: cure in 2 mm or less increments

Darker shades attenuate light to greater extent

angle of light curing units

Light tip as close as possible (w out touching) and parallel to surface

45 degree angle significantly reduces energy delivery

High levels of blue light?

Greatest damage at?

immediate irreversible, chronic exposure accelerated retinal aging and degeneration

440 nm

Does composite resin sufficiently bond to tooth structure?

NO: bonding and bonding agents