Water Supply Week 14

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

29 Terms

sedimentation type determination

determines how particle settling velocity may be computed

Type I Sedimentation

particles settle discretely and do not flocculate (without interaction)

settle with a constant velocity

e.g., sand, grit

normal, “dropping” down, no interaction

Type II Sedimentation (flocculant settling)

particles flocculate while settling

size and velocity varying ➔ typically settling velocity increases with flocculation

e.g., particles formed during alum or iron coagulation, trickling filtration

reality, flocculation

Type III Sedimentation (zone settling)

settling of high concentration particles (i.e., > 1000 mgsolids/L)

particles settling as a mass

with a distinct clear zone and sludge zone

e.g., lime softening sedimentation, activated sludge sedimentation, sludge thickeners

very dense presence of solids

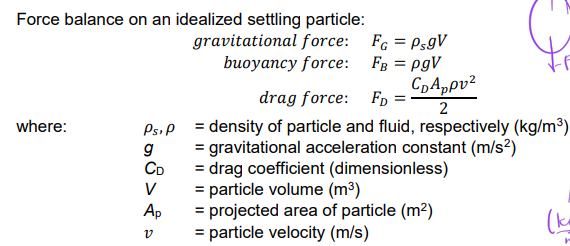

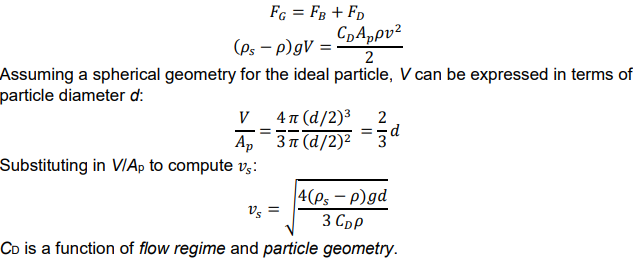

Particle Settling Velocity 𝒗s

dissolved or suspended matters (inorganics, organics) + algae

spectrophotometric measurements against standard solution

terminal particle settling velocity

At force equilibrium, the gravitational force is balanced by the sum of the buoyancy force and the drag force, so 𝑣 → vs

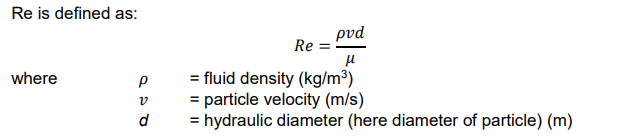

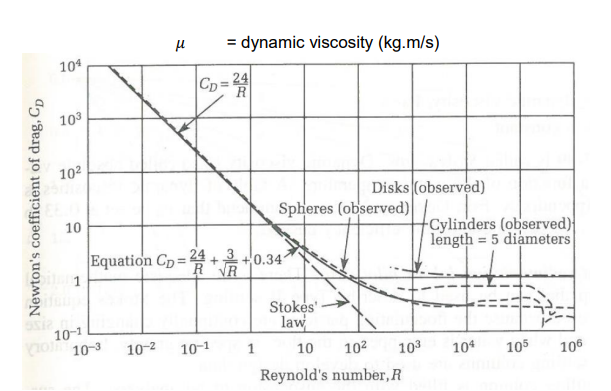

Reynolds’ number, Re

dimensionless number that evaluate a fluid’s inertial force to its viscous force

CD vs Re

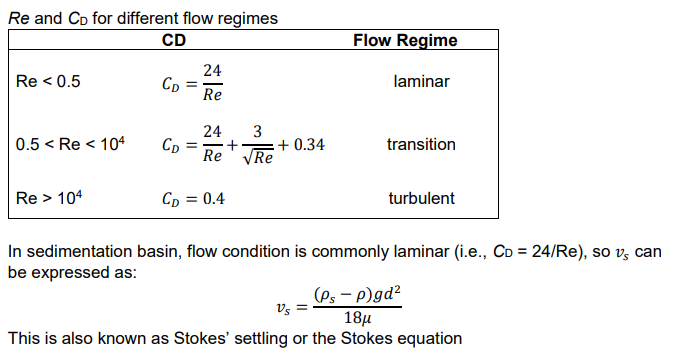

Non-Idealities in Settling: short circuiting of flow

(plug flow unrealistic)

a portion of the flow leaves the reactor before the bulk of the flow arrive at the exit

i.e., 𝑡̅ 𝑠𝑐 < 𝑡̅(or reduced effective volume)

induced by density difference or external force

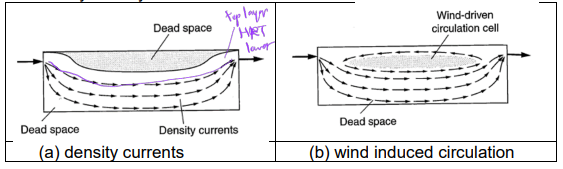

Non-Idealities in Settling: dead zone / space

regions in tank with poor flow condition

originated from reactor geometry (i.e., poor aspect ratio)

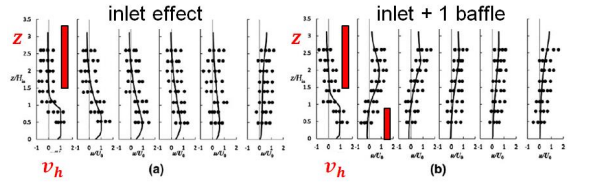

Non-Idealities in Settling: inlet position & baffle

- can alter and complicate velocity profiles

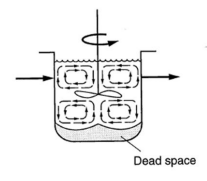

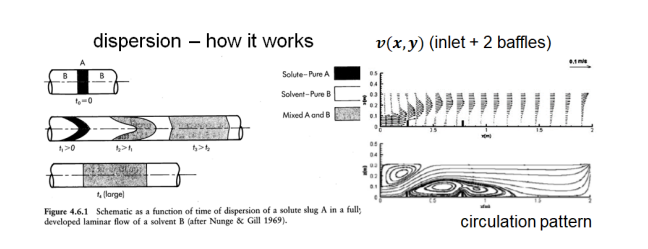

Non-Idealities in Settling: axial dispersion

axial spreading of particles (or chemicals) down concentration gradient

caused by velocity differences, turbulent eddies, and molecular diffusion

disinfection

reduce pathogens / microorganism in water to an acceptable level; not all organisms are destroyed during the process

sterilization

destruction of all organisms

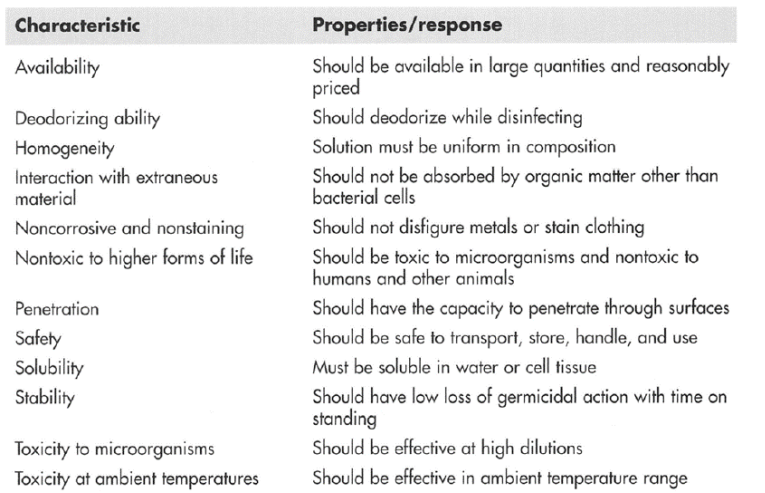

Characteristics of an Ideal Disinfectant

Disinfection Processes

a) Chemical agents

- mostly oxidizing chemicals - chlorine, bromine, iodine

- ozone, phenol and phenolic compounds, alcohols

- soaps, synthetic detergents, hydrogen peroxide

b) physical agents

- heat

- light

- sound wave (i.e., sonication)

c) mechanical means

- pathogens / microbes removed together with particles / colloids

d) radiation

- electromagnetic and acoustic radiation

- radioisotopes (e.g., Cobalt-60, 60Co) emit Gamma rays; used for sterilization because of their penetration power

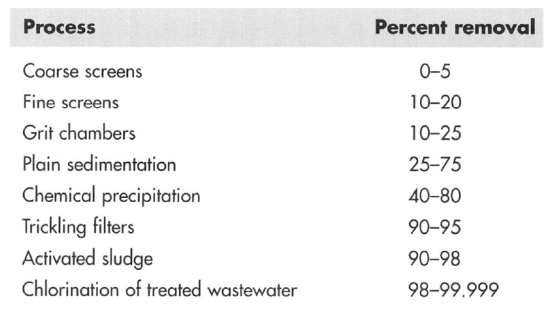

Bacterial Removal / Destruction Efficiency

Mechanisms of Disinfection

1) damage to cell wall

- cell lysis - materials within cell leak out - cell death

2) alteration of cell permeability

- chemicals such as phenolic compounds and detergents can alter permeability of cytoplasmic membrane - selective permeability of the membrane is destroyed - vital nutrients (e.g., N, P) leak out of the cell

3) alteration of colloidal nature of protoplasm

- heat, radiation, strong acids/alkalines can alter colloidal nature of the protoplasm - heat will coagulate cell proteins - acids/bases will denature proteins - proteins cannot function properly

4) alteration of organism DNA or RNA

- UV radiation can cause formation of double bonds in microorganisms as well as rupturing some DNA strands - when UV photons are absorbed by DNA in bacteria and protozoa, DNA and RNA in viruses, covalent dimers can be formed from adjacent thymines in DNA or uracils in RNA - formation of double bonds disrupts the replication process - consequently, the organism can no longer reproduce and is thus inactivated

5) inhibition of enzyme activity

- oxidizing agents (e.g., chlorine) can alter chemical arrangement enzymes and inactivate the enzymes - enzymes cannot perform required functions

Factors Influencing Disinfection Efficiency

1) type of disinfectant

2) contact time

3) concentration of disinfectant

4) temperature

5) type of organism / microbe

6) nature of solution (i.e., dissolved organic matter, suspended particles, chemistry of solution)

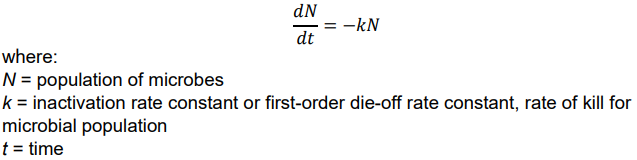

Disinfection Kinetics - Chick’s Law

- when microbe contains a single site vulnerable to a single unit of disinfectant, the rate of die-off follows Chick’s law:

let N0 be initial microbe population (i.e., at t = 0), then

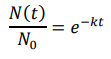

Role of Disinfectant Concentration

Herbert Watson observed inactivation rate related to disinfectant concentration:

Assumptions

1) concentration C is constant with respect to time

2) well-mixed condition for both microbes and disinfectants (i.e., instantaneous well-mixed + homogeneous)

3) no time lag for disinfectant to reach vulnerable sites in microbes

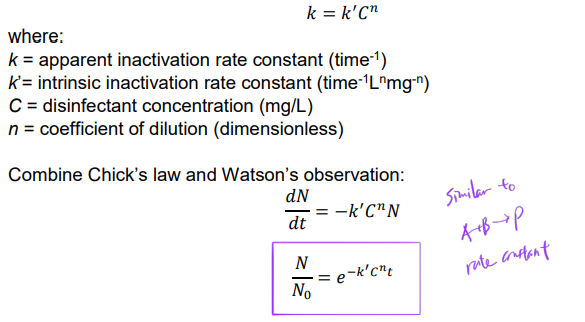

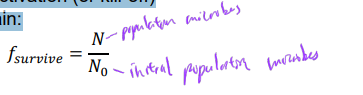

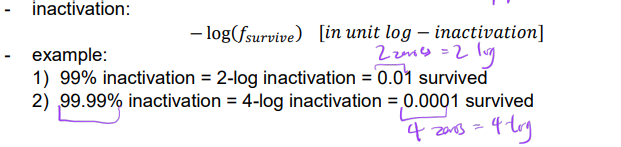

Inactivation

- depicts the extent of microbial inactivation (or kill-off)

- fraction microbial population remain:

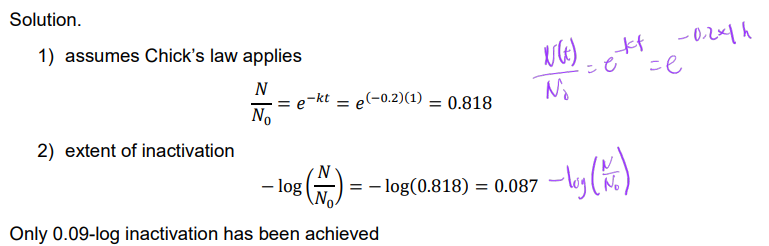

Ex. Determination the extent of inactivation (in log-inactivation) for a water undergoing a disinfection process with a k of 0.2 h-1 for 1 h.

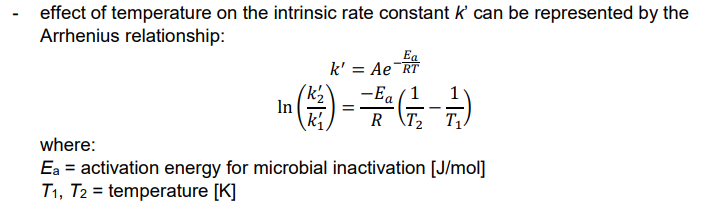

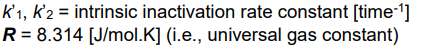

Disinfection Temperature

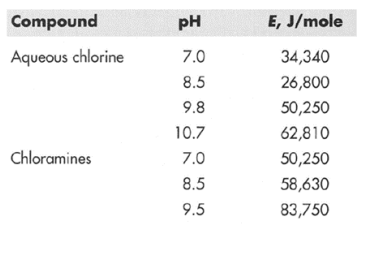

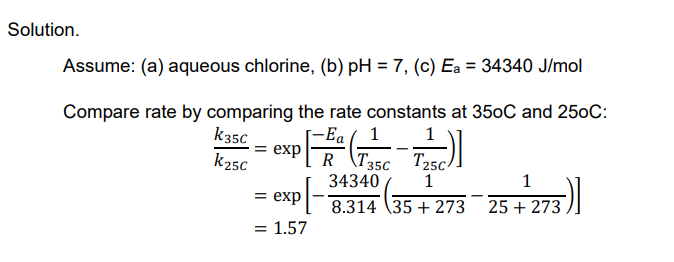

Ex. Compare the inactivation rates of chlorine disinfection at 35oC and 25oC. Assume that the treated water has a pH of 7.0.

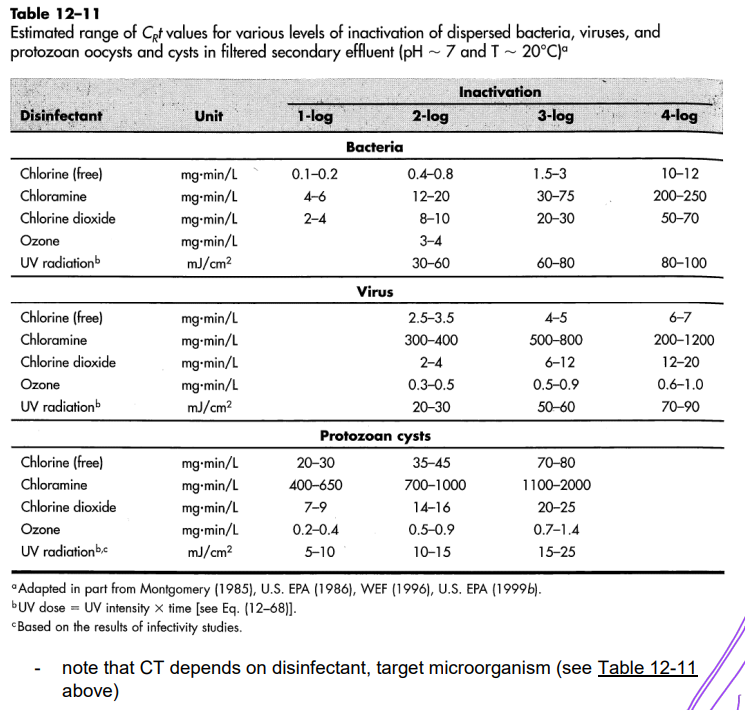

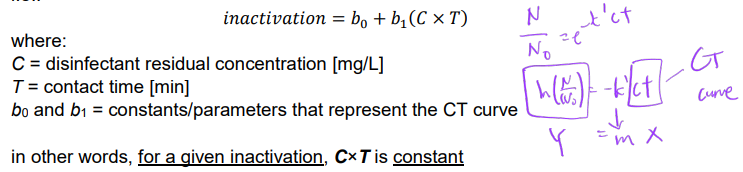

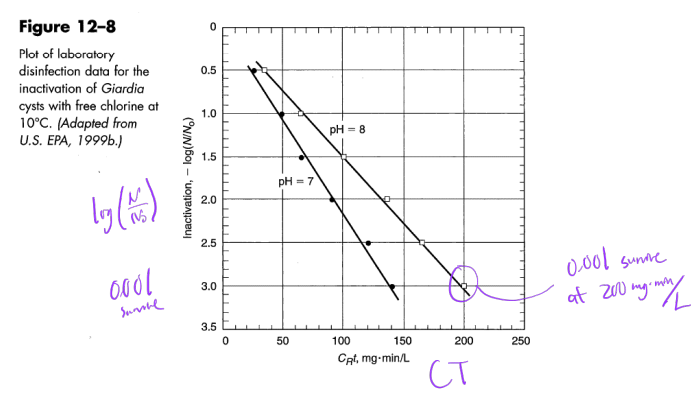

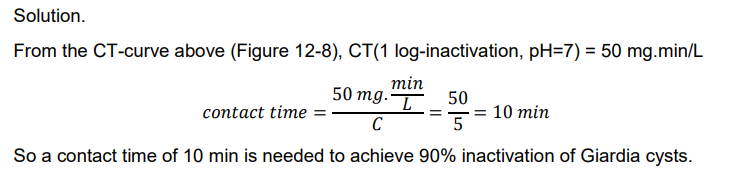

C-T Curve

can achieve extent of inactivation by controlling 1) concentration of disinfectant residual and 2 contact time

Ex. Determine the contact time needed to achieve a 1 log-inactivation of Giardia cysts using 5 mg/L free chlorine at 10oC and pH 7

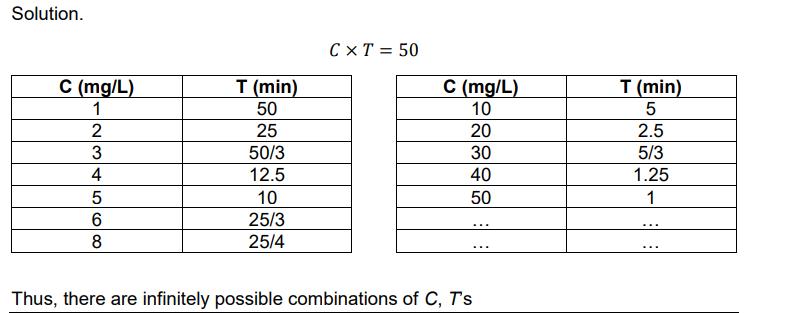

Ex. What are the combinations of C and T for a CT value of 50 mg.min/L?

Estimated range of CRt values