1,2,3 Ceramics

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

Define Ceramics

What type of bonding

Occur as

Chemical mixture of metallic & non-metallic elements, formed at high temperatures

Bonding is a combo of ionic & covalent

Occur as minerals, O, Si and Al, 85% of the earth’s crust

Ceramics Physical, chemical, mechanical and biological properties

Physical: Intermediate density, high melting point, low coefficient of thermal expansion (1-15ppm/C), High modulus (E) / stiffness

Chemical: Low chemical reactivity, low absorption, low solubility

Mechanical: 10x stronger in compression than tension but brittle, low fracture toughness, poor fatigue resistance.

Biological: Relatively inert, excellent biocompatibility, sometimes bioactive

General Advantages & Disadvantages of Ceramics for Biomedical Use

Advantages: chemically inert, bioactive in body, high weight resistance, high modulus (stiffness) and compressive strength, esthetic for dental applications (can be translucent, ZrO2, opaque)

Disadvantages: Brittle, Low tensile strength, Poor fatigue resistance, difficult to fabricate and expensive

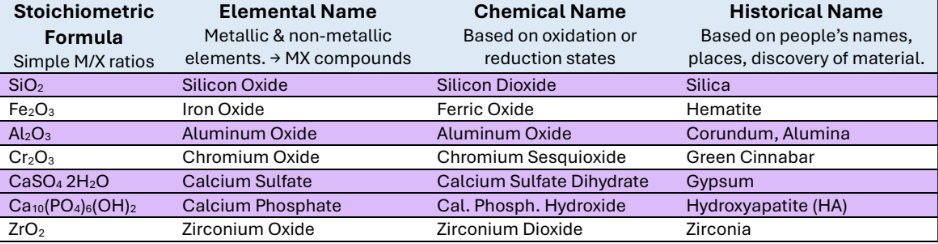

Historical names: Silica, Hematite, Corundum/ Alumina, Green Cinnabar, Gypsum, Hydroxyapatite (HA), Zirconia

Stoichiometric formula

Elemental Name

Chemical Name

Define Glass

Glass is an inorganic product of melting something (fusion) and then cooling it to a rigid state quickly without allowing it to solidify

Amorphous: lacking lattice structure/ crystallinity and possessing only short-range atomic order AKA glassy or vitreous

Define glass-ceramic

A controlled, partial crystallization of glass that yields a semi-crystalline solid → better translucency and machinability than fully crystalline

Partly amorphous: meaning it has some crystals/lattice structure

Ex: porcelain and emax

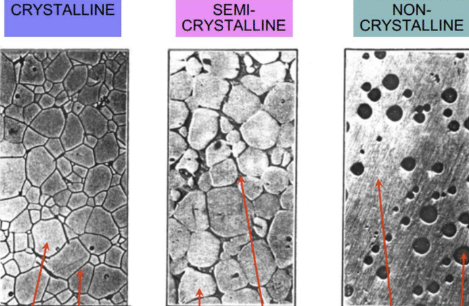

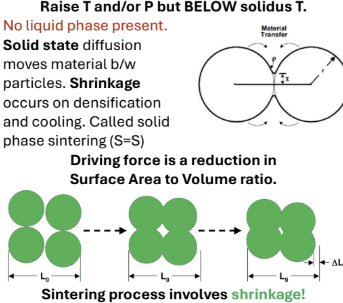

Define Dental Porcelain

Glass ceramic → vitreous (semi-crystalline) + Potassium oxide alumina silica/ K2OAl2O3-SiO2

Derived from the thermal processing of Quartz, Feldspar and Clay

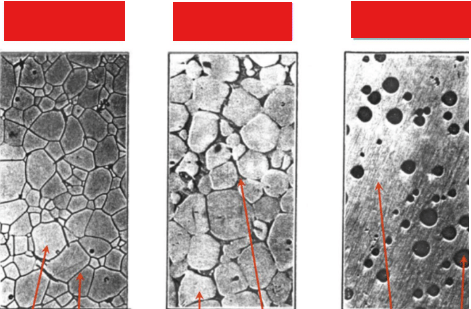

Characteristics that make ceramic crystallization difficult, and label pictures

Thermodynamic considerations: heat maximizes packing efficiency and coordination number

Kinetic considerations: affects symmetry, requires heat and time

Mechanisms of Crystallization: Nucleation and growth is slower due to large critical radius size and complicated symmetry

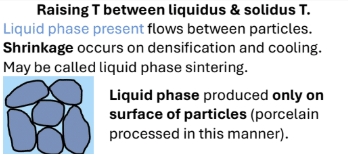

Densification

The process of forming a coherent solid from particles by melting, vitrification or sintering

Melting: cant be done to ceramics with high melting temps

Vitrification: temperature between liquid and solid temp that causes the melted liquid portion flows around the unmelted portions and fills gap, thus strengthening the material

Sintering: temperature lowered below solidus temp, which causes shrinkage and decreases SA to Volume ratio (increases density)

Solid state diffusion

Ex: zirconia

How does porosity affect strength in a ceramic?

Ceramics can lose 70% strength at 10% porosity

Can be the result of incomplete sintering

Volumetric defects such as voids, pores, etc are key to mechanical behavior

Relationship between thermal expansion, melting point, and modulus

High melting point, low thermal conductivity, low CTE (1-15ppm)

High Modulus (E) → very stiff

Melting point and Modulus are usually proportionate

Most ceramics are anisotropic, meaning properties depend on crystallinity and temperature (measurement direction)

Chemical reactivity of most ceramics

Very limited reactivity, relatively inert and resistant to all acids except HF

HF is a weak acid but F- is super reactive

Not subject to corrosion

Fluoride treatments can etch dental ceramics like porcelain

Dental porcelain basic composition and uses

ALL are glass-ceramics and composed of Silica (SiO2), Alumina (Al2O3) and Potassium Oxide (K2O)

Used for veneers, posterior/anterior crowns, bridges, FPDs

Explain the CTE mismatch in PFM (porcelain-fused-metal)

CTE for Metal is slightly higher (so it contracts) than porcelain (1-15) so upon cooling after heating, the metal places porcelain on compression

Metal wants to shrink but cant because porcelain is bonded on top

Porcelain is stronger 10x in compression than tension so pre-loading it makes it harder for cracks to open

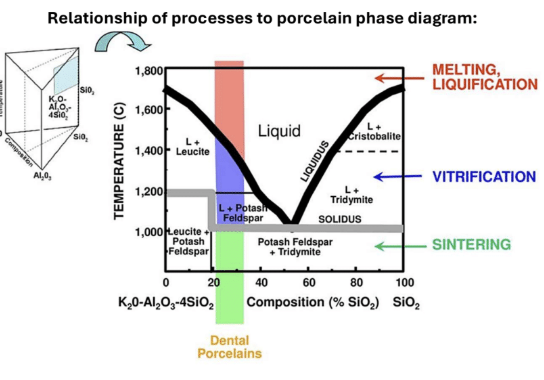

Feldspathic porcelain

Traditional porcelain, 15-20% Volume of leucine crystals, glassy matrix

Only used for veneering, not monolithic

Leucite-Reinforced Porcelain

+ ex.

35-45% Leucite crystals by volume, makes it 50% tougher (resistance to defect propagation) than Feldspathic

Ex. IPS Empress, good for veneering and improved strength

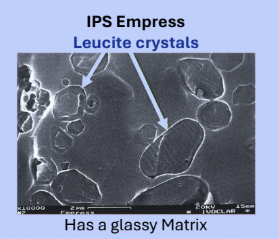

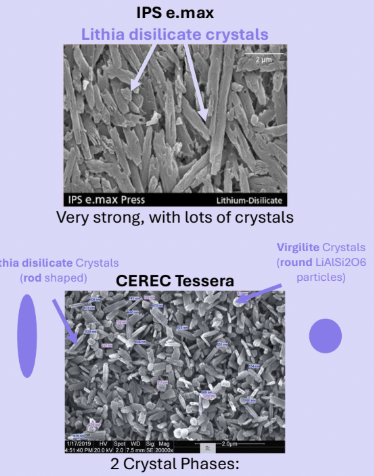

Lithium disilicate (ceramic material)

+ ex.

Glass ceramic; has 70% Lithium disilicate (Li2Si2O5) which are rod shaped crystals that block crack propagation

Balance between esthetics due to glassy matrix and durability

Used monolithically or veneered

Ex. IPS, Emax

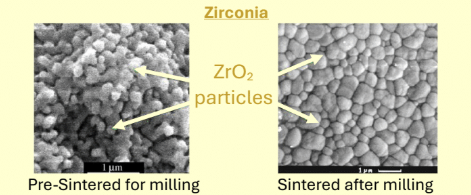

Partially Stabilized Zirconia (PSZ)

Explain its phase transformation

Explain fabrication

Dentistry uses

Explain Monolithic Zirconia

Explain High Translucency Zirconia

Stable form of zirconia with the highest fracture resistance of all ceramics because they are durable and fatigue resistant

Phase transformation: from tetragonal to monoclinic associated with 4-5% volumetric expansion

Fabrication thru sintering, gets 25-30% shrinkage

Used for everything; crowns, bridges, implants, abutments

Very tough but ofc no as tough as metals, and do not produce significant wear on opposing natural teeth

Monolithic zirconia: the entire crown is zirconia. eliminates problem where veneering porcelain layer would fracture

Disadvantage is that it has very limited optical properties, they are also hard to adjust due to complete crystallinity after sintering

Most popular in the US

High Translucency zirconia: mix of cubed (transparent) and tetragonal zirconia; improved esthetics but decreased fracture strength

Must me 0.5mm or less, no sharp angles

CAD/CAM advantages and disadvantages

Advantages: speed, reproducibility, elimination of physical impressions, improvement of dimensional accuracy, warns if prep is under-reduced → Best for high volume bc of cost

Disadvantages: expensive, must have high volume

Zirconia milling caveat with CAD/CAM

When milling zirconia, there is partial sintering of the block previously and then there is fully sintering so CAD design must compensate for shrinkage

What contributes to clinical failures with ceramics?

Material limits, poor design (sharp angles, thin, etc.), adjustment with handpiece (introduction of flaws)