Global Production & Supply Chain Management

1/32

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

33 Terms

3 ways to make your production cheaper and company more efficient

Offshoring = company say not produce europe but china

Outsourcing = give certain activities ask to an other external party to do somthing for us

Lean manufacturing= we are going to do nothing before an order is made to avoid waste (things custumer dont want to pay for )

When will those 3 ways of making production cheaper work ???

Offshoring = company say not produce europe but china

Outsourcing = give certain activities ask to an other external party to do somthing for us

Lean manufacturing= we are going to do nothing before an order is made to avoid waste (things custumer dont want to pay for )

but only work in a predictable environement but you need to have predictable economy

(Offshoring ,Outsourcing ,Lean manufacturing)

only works in a predictable environement but you need to have predictable economy exaple of what happende when economy was not predictabla?

For example hospitals

= use those 3 things no bugger no risk managent so beds and personeel for thebthe prediction when corona came it was i bog problem

What is logistics?=

Every process between in our company between our 4 walls

Make a promess and do it : effective

No loosing money : efficient

To be efficent and effectiv the process between in our company between our 4 walls (logistics management)have to be great but disadvantage you are vurnerable like pandemic )

What is a supply chain?

From production to the custumers home

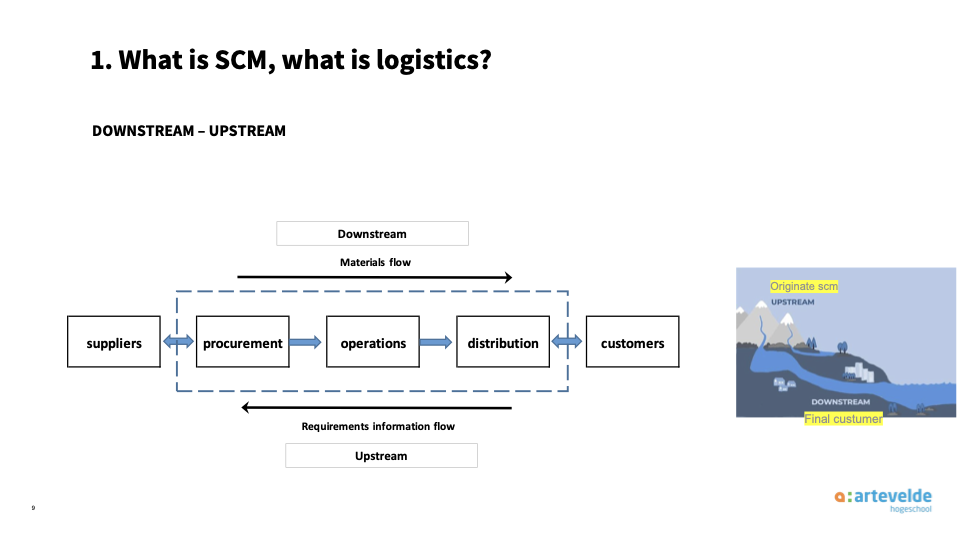

SCM

:DOWNSTREAM – UPSTREAM

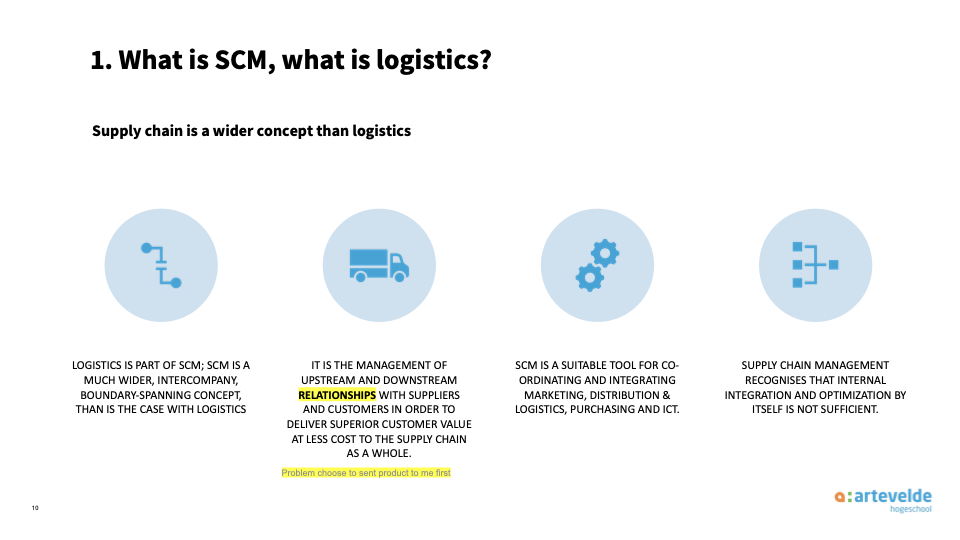

Supply chain is a wider concept than logistics

relationships Problem choose to sent product to me first

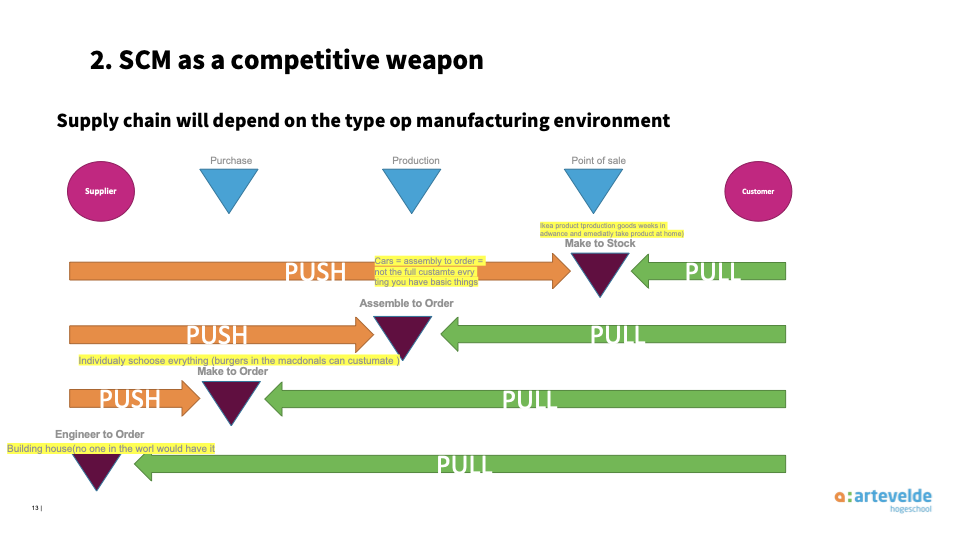

SCM as a competitive weapon

Supply chain will depend on the type op manufacturing environment

give an exemple: Make to Stock (MTS):

Same pizas evryday(produce in advace based on a for cost)

give an exemple: Assemble to Order (ATO)

Hamburgers:not the full custamte evry ting you have basic things

give an exemple: Make to Order (MTO):

give an exemple: Engineer to Order (ETO)

Custumaze bridge (never produce in advace)

Trends 30 years

Offshoring (production china) and outsoucing

Lean production(reducing waste )

Reorganisation of distrubution network

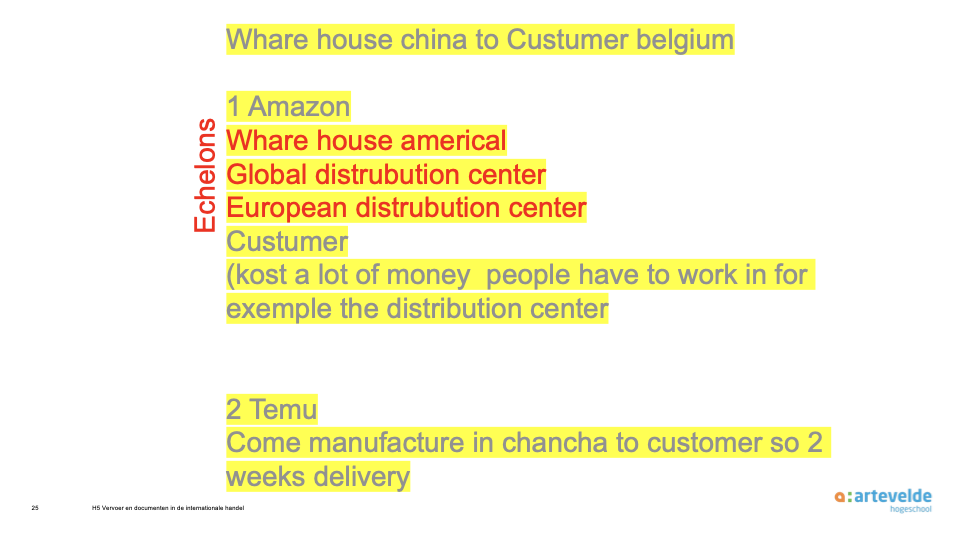

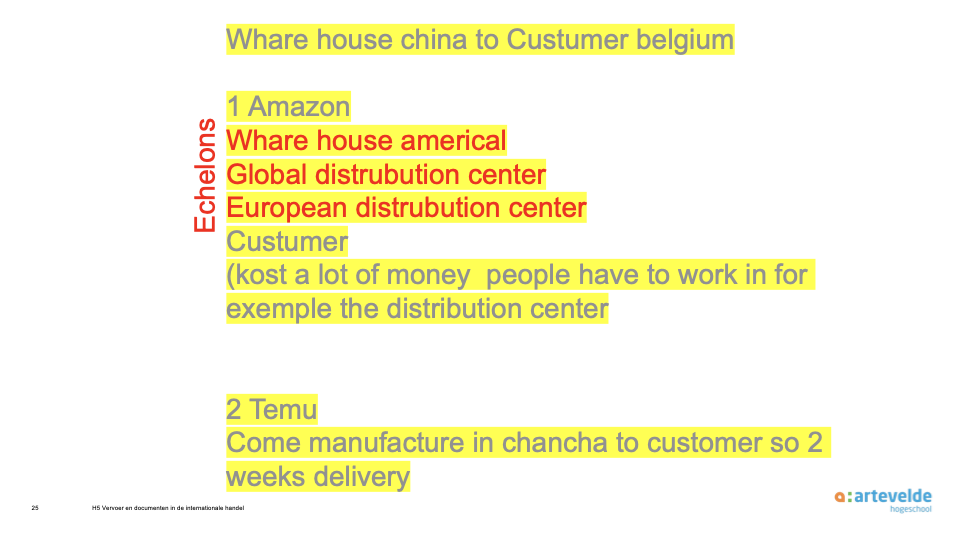

Logistics Network Optimisation/Optimization

= Amazon

Whare house americal

Global distrubution center

European distrubution center

Custumer

(kost a lot of money people have to work in for exemple the distribution center

Logistics Network Optimisation/Optimization

= Temu

Come manufacture in china to customer so 2 weeks delivery

Bring all chinise goods to Main hub (main whare house) then to Main hub in EU to save cost

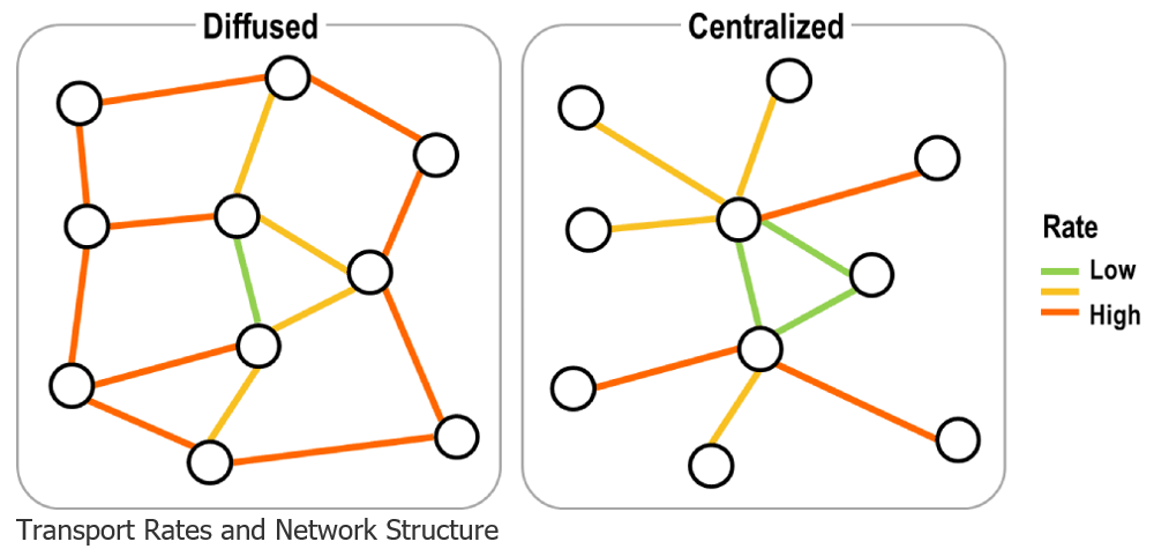

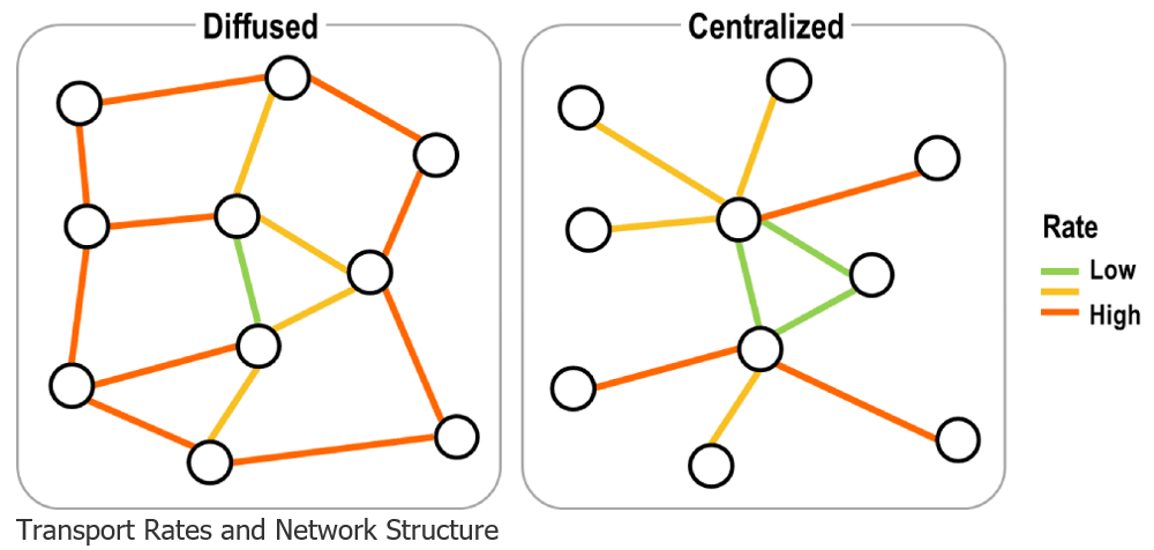

Is Amazon’s supply and distribution network is centralized or decentralized?

Amazon’s supply and distribution network is diffused, meaning it uses multiple, widely spread-out locations around the world to handle the storage and delivery of goods.

Is Temu’s supply and distribution network is centralized or decentralized?

Temu’s supply and distribution network is centralized, as it relies on a central manufacturing and shipping hub (China) to handle most of its logistics, without having many local warehouses in other countries.

Amazon final delivry is expensive (European distrubution center= antwerp to Custumer house’

what did belgium serchers try???

Solutions

Box delhaise to get your package

(wharehouse per city (post. Nl and b-post all-in one whare house not good for them not willing schare inf)

not honna happen because thzy dont wanna share their information with each other

How does the order quantity Q influence the total annual cost?

= Small order quantity

Smaller quantities (new materials evry days or every hours

Reduce amount safety stocks

=result in higher ordering costs and can lead to stockouts.

Work good in predictable environement

How does the order quantity Q influence the total annual cost?

= Large order quantity

lead to high holding costs( wharehouse cost), but reduce ordering costs.

what is the diferance between

=Ordering cost & Holding cost

Ordering cost =money you spend every time you buy a product from the order until we get the product in our hands (transport )= a lot of order is cheaper

Holding cost=money you spend to store the lemons at your stand until you use them.

what does it cost me to have a product in my wharehoude(loan) how more goods order at the same time how biggger more cost

(Inventory)

what is the EOQ(Economical order quantity (kruispunt)

+

How does the order quantity Q influence the total annual cost?

You have a company

If you buy too less products, you'll have to go to the suppliers often, and that costs a lot in ordering.

=Ordering cost

But if you buy too many prodcuts, you'll spend a lot of money just storing them, even if you don’t use them all.=Holding cost

The EOQ is like finding the perfect number of lemons to buy so that you don’t spend too much on ordering or storing. It’s the sweet spot where both costs are the lowest.

what is the Big trent that helps you bring down holding cost

Capacity Management

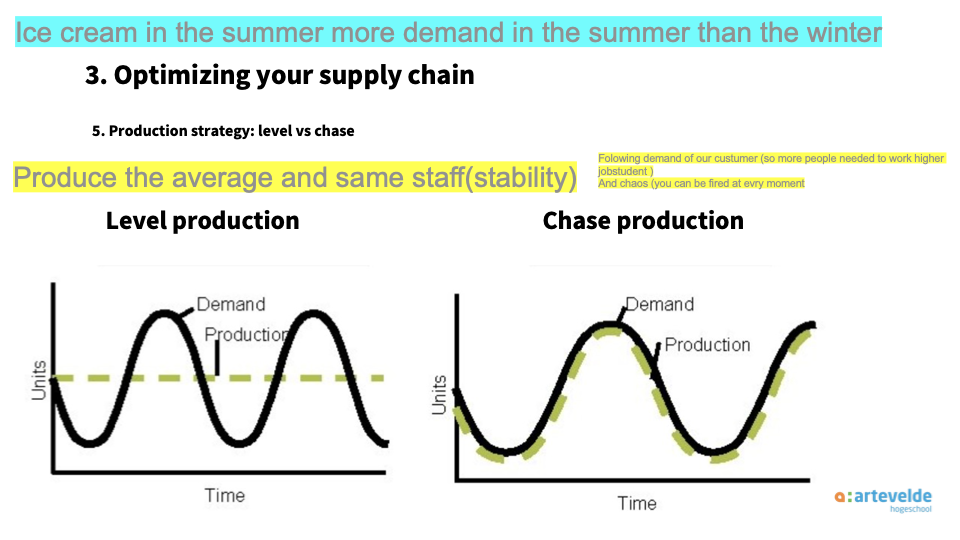

in the Capacity Management there are 2 Production strategy

+

Explain them (image)

Level production & Chase production

Advantages : Level production

Stable, constant production

Predictability

Less money needed for hiring/firing people

Disadvantages : Level production

Buildup of material during the low season

Advantages : Chase production

Less money stuck in inventory

Quicker reaction to sudden changes in demand

disadvantages : Chase production

Constant pressure on production and the people working there

Outsourcing

Focus small part of the supply chain we will do that we will become the best in that part of the supply chain and the rest of the supply chain to other comany its cheaper and they will become expert iun it

Reasons for outsourcing

Advantages and Disadvantages of Outsourcing