Wk 2 Cement Mortar and Concrete

1/35

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

36 Terms

What concrete comprised of?

cement

water

aggregates

optional admixtures

What do admixtures do?

they tailor workability, setting and durability (adjusts properties) - usually in liquid or powder form

What are the good qualities of concrete?

mouldability

rapid early gain (quick gain in strength after being placed)

versatility

high long term compressive capacity

What is mortar?

a mix of cement water and sand (with no course aggregate)

What is the use of cement?/ what is cement?

a powder substance used for bonding parts to form a single whole

What are the two types of cement?

Hydraulic cement - consists of inorganic, non-metalic compounds that react with water to set

Portland cement - a type of hydraulic cement that contains Calcium Oxide and silicon dioxide

What are aggregates?

the materials mixed with cement and water to provide bulk and modify the physical properties of the concrete

What type of reaction occurs between cement and water?

hydration

starts of by remaining plastic until it sets and begins to gain strength (hardening)

What is gel porosity?

degree of hydration that governs strength stiffness and permeability

What is essential for continued hydration and densification?

adequate moisture and time

What is fine aggregate and its use?

e.g. sand

improves cohesion

workability

finish

What is the use of coarse aggregate?

provides bulk

reduces shrinkage

What is grading?

the distribution of particles of aggregates amongst various sizes - usually expressed in terms of cumulative percentages of larger or smaller than each other

What is proper grading?

The way we use different sized aggregates in combination to minimise voids and reduces the demand for paste (cement and water mix)

How are aggregates graded?

Using a tower of sieves with successively reducing sizes

aggregate placed inside and vibrated for a specific period

aggregates in each sieve are then weighed

weights are used to provide a profile of the distribution of different particle sizes

can create the aggregate grading curve

What are the properties aggregates should have?

hard

strong

chemically inert

non-porous

durable

good adhesion

good shape (sharp vs rounded)

recycled materials can be used as aggregates

What happens when w/c is so low that it is below critical?

too little water can lead to

incomplete hydration

harsh mixes

poor consolidation (not properly mixed - nonuniform)

What happens when w/c ratio is too high?

increases porosity

reduces strength

What will low w/c cause in general?

increased strength

increased durability

but it still needs to have sufficient water for workability

examples of admixtures and their uses?

air-entrainers (freeze thaw protection)

plasticizers - reduce water demand (makes it more flexible)

accelerators/retarders - speed up or slow down the setting process

What is workability?

the ability to place concrete without segregation of its components

influenced by w/c, aggregates, admixtures

poor workability causes voids, weak bonds to the reinforcements

workable concrete defined as suitable for placing and compacting under site conditions

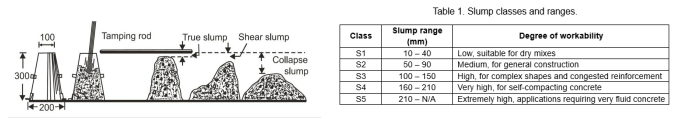

What is the slump test?

fresh concrete placed in a mould (trapezium shaped)

in 3 layers

when each layer is added, the concrete is compacted using a tamping rod 25 times (penetrating the layers below without touching the bottom layer)

the mould is lifted and the concrete settles

the way it settles will measure the consistency (used as quality control)

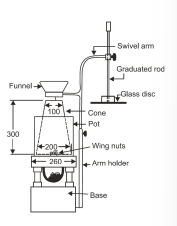

What is the vebe test?

Measures time required for a concrete volume, shaped as a conical frustum, to spread into a cylindrical form under vibration. After the cone is lifted, vibration causes the concrete to spread, and a stopwatch records the time until it fully contacts the glass disc

time known as the vebe degree (VB) measured in seconds

time indicates consistency of concrete

Hand mixing vs machine mixing

Mixing: the combining of the materials to form a uniform and workable mass, ensuring uniform coating of aggregate with paste

Hand mixing

suitable for small scale works

requires thorough mixing

poor mixing can cause segregation and weak zones/inconsistent properties

Machine mixing

used in most construction projects

more efficient and ensures better uniformity

What must we do with transport to ensure that the mixed materials don’t segregate?

transport promptly (can use a pump, bucket, wheelbarrow)

minimise delays

maintain temperature

avoid contamination

What must we do with placing to avoid segregation of materials?

place as close to the final position as possible to ensure bonding and compaction

place in layers

avoid drops of more than 1.5 meters - avoids cold joints (a visible seam that forms when fresh concrete is poured onto hardened concrete due to a delay between pours caused by mixing times)

Purpose of compaction

remove entrapped air

to make the concrete more dense and strong/durable

What happens if the concrete is insufficiently compact?

voids

honey combing

poor bonding to the reinforcement

higher permeability

less strong

air becomes trapped - significantly reduces strength

Methods of compaction?

Manual - rodding tamping or light hammering

Mechanical - interal vibrators, table vibrators, surface vibrators

What can over vibration cause?

bleeding

segregation

ensure the correct vibration frequency, amplitude and time

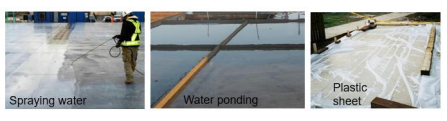

What is curing?

the maintenance of optimal conditions of temperature (greater than 10 degrees celsius) and humidity to promote the hydration of cement

It plays an important role on strength development and durability of concrete

Methods : water curing (sprinkling/ponding), membrane curing compounds, plastic sheeting and steam curing (precast)

Proper curing reduces permeability, cracking and enhances long-term strength

Strength development of concrete?

most of the strength is developed in the first 3 days (40-50%)

increases to 60-70% after a week

curing beyond 28 days will increase strength and durability

What is durability?

ability to resist environmental/service actions (chlorides, sulfates, freeze– thaw, carbonation) over service life.

How can we achieve durability?

low permeability - low w/c, good compaction, good curing

account for exposure environment (de-icing salts, marine, industrial)

quality control, placing and curing

What can cause durability issues in concrete?

reinforcement corrosion (the steel around it deteriorating/rusting)

freeze thaw damage (we can minimise by air entraining the mixes)

sulfate attack (reduce permeability)

carbonation

alkali-silica reaction

What are the desirable properties of hardened concrete?

strength

water tightness (low permeability)

durability

resistance to cracking

abrasion resistance