CSUF MGMT 430 Final

1/63

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

64 Terms

lot size

the quantity that a stage of a supply chain either produces or purchases at a time

cycle inventory

the average inventory in a supply chain due to either production or purchases in lot sizes that are larger than those demanded by the customer

Q

quantity in a lot or batch size

D

demand per unit time

C or p

material cost

S

fixed ordering cost

H = hC

holding cost

fixed ordering cost

includes all costs that do not vary with the size of the order but are incurred each time an order is placed

holding cost

the cost of carrying one unit in inventory for a specified period of time

true

primary role of cycle inventory is to allow different stages to purchase products in lot sizes that minimize the total sum of material, ordering, and holding costs

price

average price paid per unit purchased is a key cost in the lot-sizing decision

CD

annual material cost

economic order quantity

lot sizing for a single product

annual demand of the product

D

fixed cost incurred per order

S

cost per unit

C

holding cost per year as a fraction of product cost

h

true

aggregating replenishment across products, retailers, or suppliers in a single order allows for a reduction in lot size for individual products

lot size based discount

discounts based on quantity ordered in a single lot

volume based discount

discount is based on total quantity purchased over a given period

forward buying

the purchase of any raw materials, supplies, components, or other items in advance of current requirements

safety inventory

carried to satisfy demand that exceeds the amount forecasted, as well as a contingency to potential disruptions in the supply line

true

raising the level of safety inventory increases product availability and inventory holding costs

true

safety inventory is determined by the uncertainty of both demand and supply and the desired level of product availability

continuous review

inventory is continuously tracked, order for a lot size Q is placed when the inventory declines to the reorder point (rop)

periodic review

inventory status is checked at regular periodic intervals, order is placed to raise the inventory level to a specified threshold

true

periodic review replenishment policies require more safety inventory than continuous review policies for the same lead time and level of product availability

postponement

delay product differentiation or customization until closer to the time the product is sold

reorder point

specifies the level to which the inventory balance of an item must fall before an order to replenish stock is initiated

commonality

different components are replaced by common components or same components are used for multiple products

modes of transportation

1. air

2. package carriers

3. truck (LTL or FTL)

4. rail

5. water

6. pipeline

7. intermodal

package carriers

small packages up to 150 lbs., door to door service, expensive

truck

significant fraction of goods moved, low fixed cost

rail

moves commodities over large distances, high fixed costs

water

very large loads at a low cost, slow

pipeline

primarily used for fuels, for large and stable flows, high fixed cost

intermodal

more than one mode of transportation for a shipment, has grown with increased use of containers

transportation infrastructure

governments take full responsibility or play a significant role in building and managing infrastructure

true

without a monopoly, deregulation and market forces help create an effective industry structure

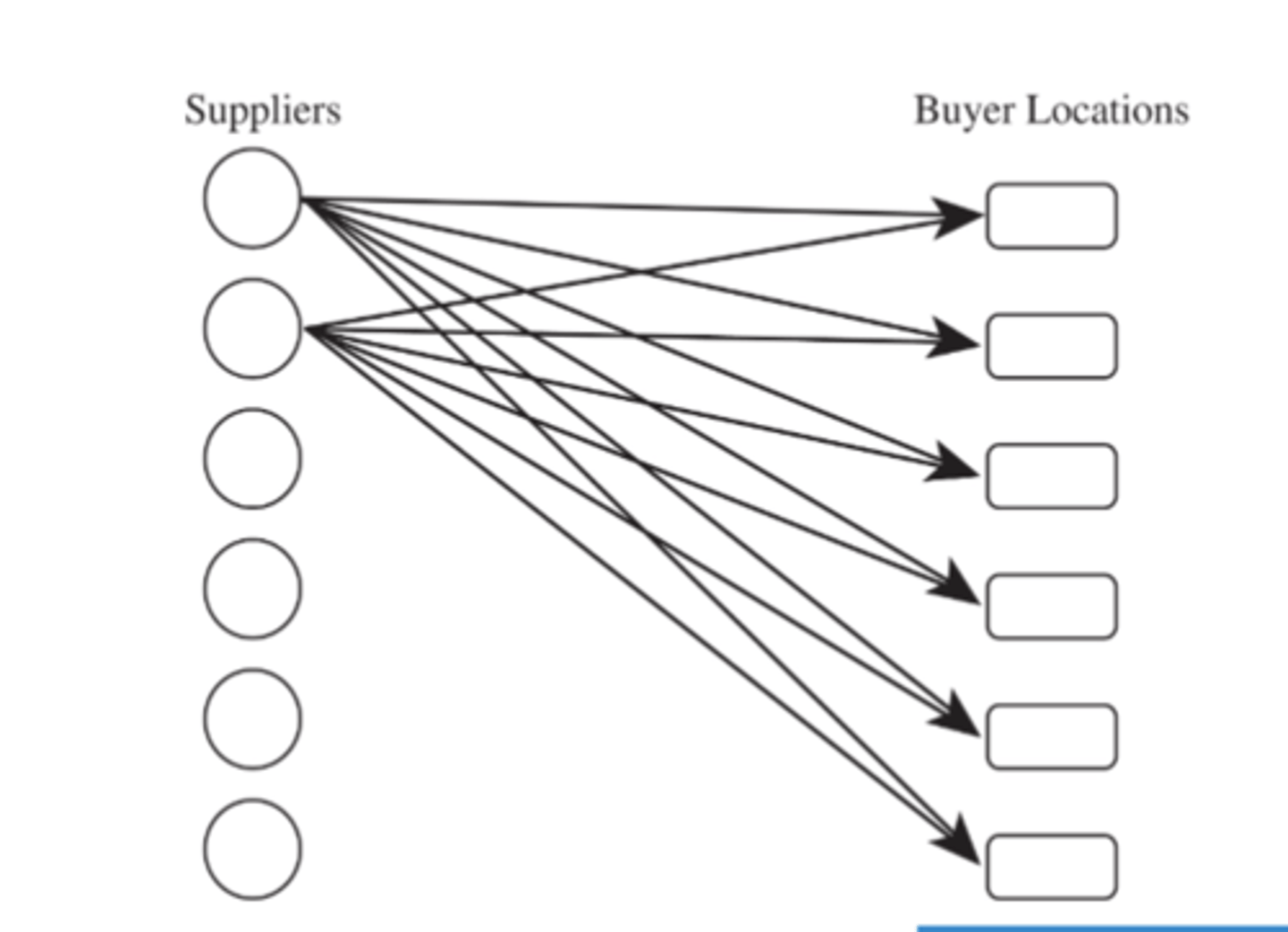

direct shipment network to single destination

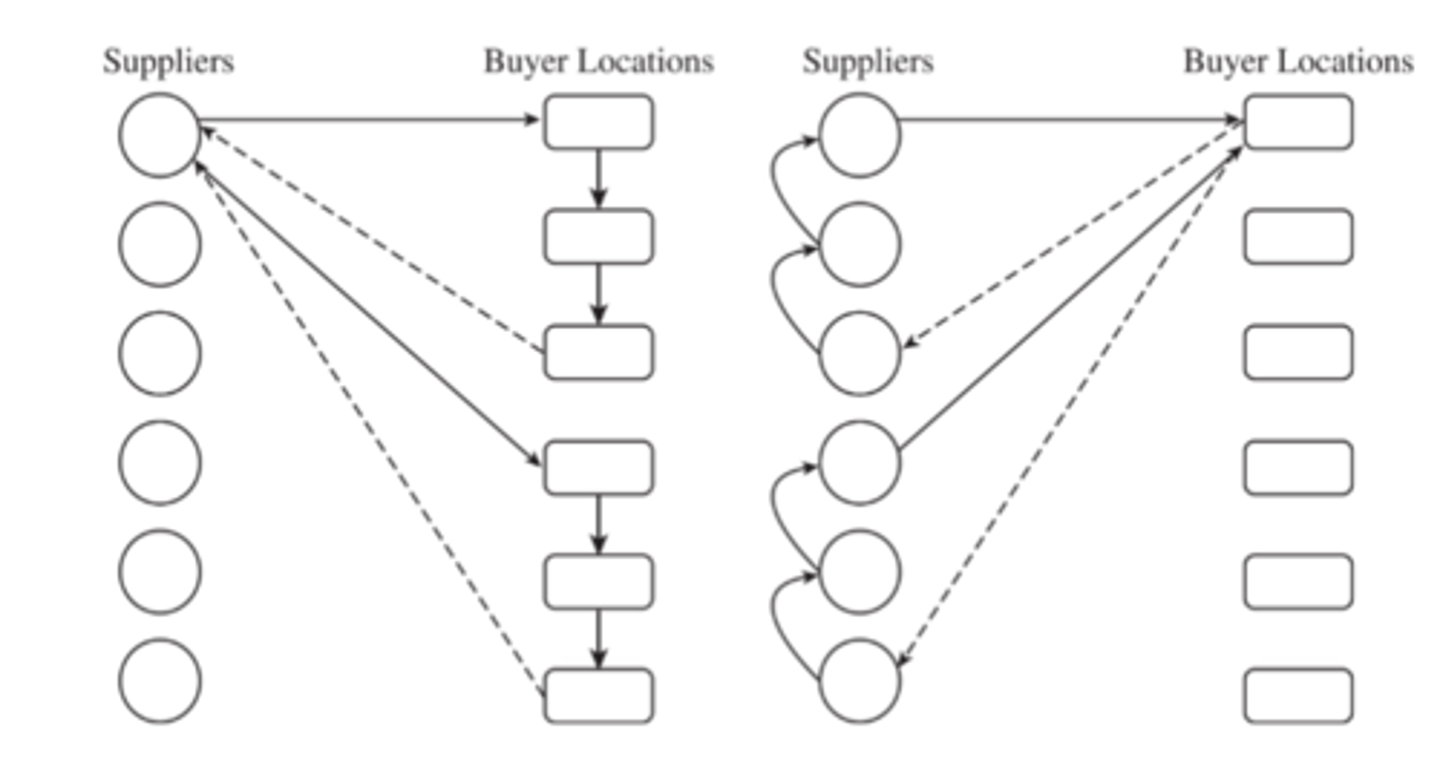

direct shipping with milk runs

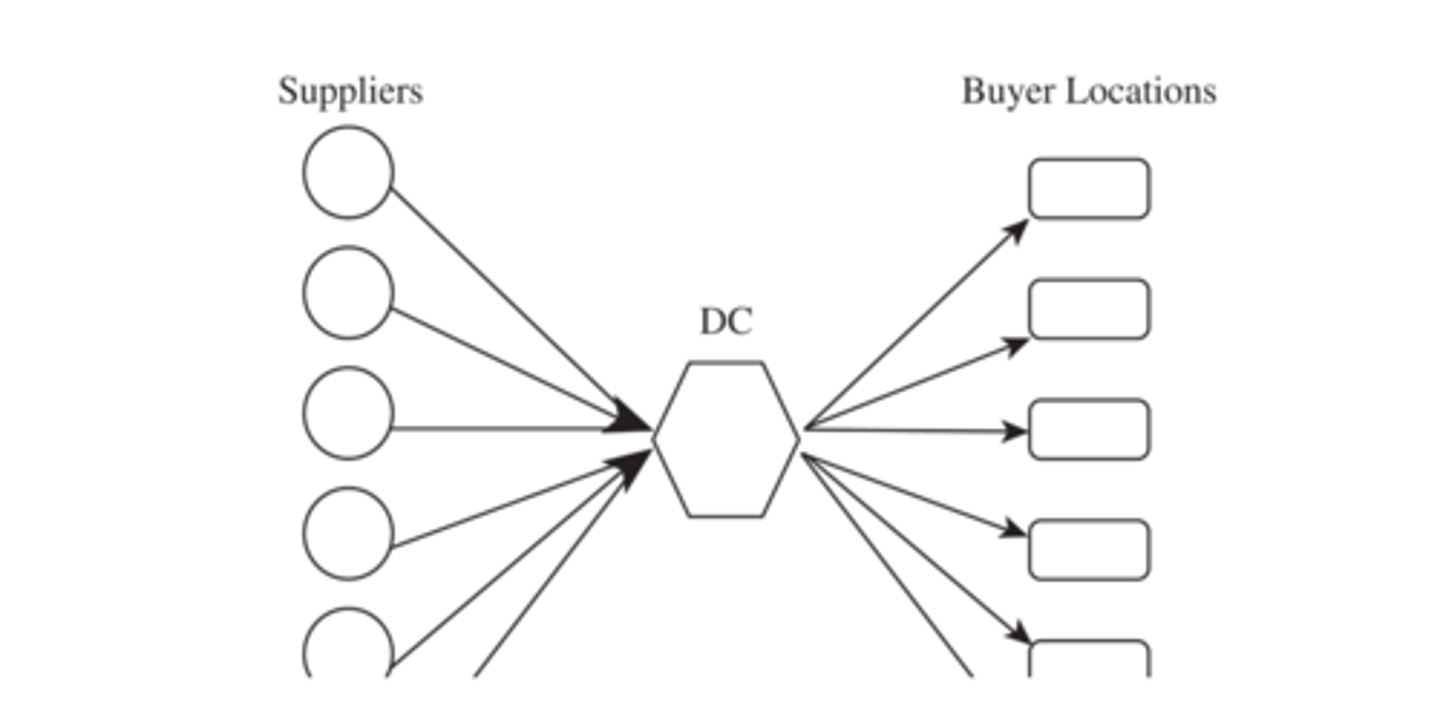

all shipments via intermediate distribution center with storage

all shipments via intermediate transit point with storage

suppliers send their shipments to a central distribution center which are stored until needed by buyers and shipped to each buyer location

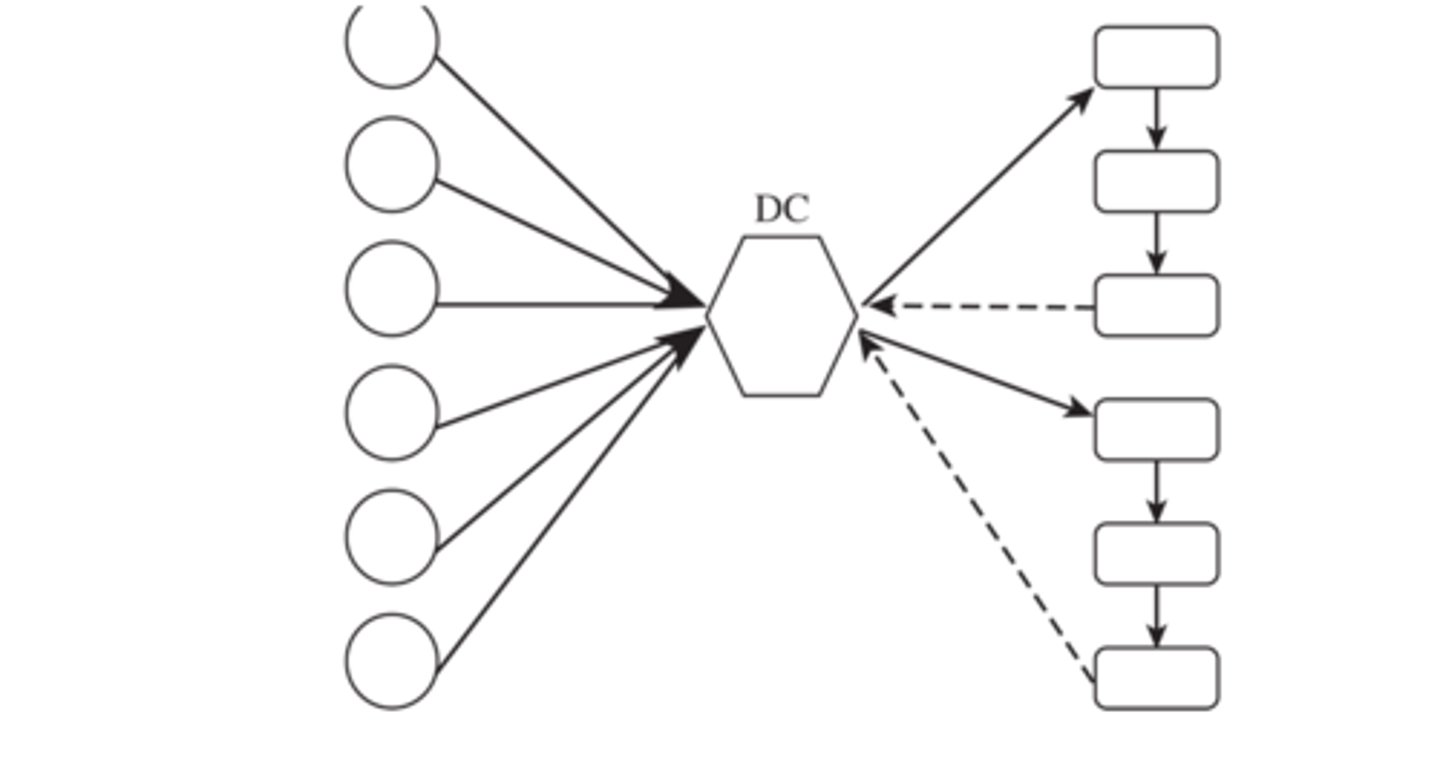

all shipments via intermediate transit point with cross docking

suppliers send their shipments to an intermediate transit point which are then cross docked and sent to buyer locations without storing them

shipping via dc using milk runs

temporal aggregation

combining orders across time

procurement

companies acquire raw materials, components, products, services, or other resources from suppliers to execute their operations

sourcing

entire set of business processes required to purchase goods and services (who/where from)

outsourcing

supply chain function being performed by a third party (product or services)

free on board

indicates when the ownership of goods transfers from buyer to seller

offshoring

the relocation of business processes and services to a lower-cost foreign location

onshoring

relocation of business processes or production to a lower-cost location inside the same country as the business.

buyback

the buyer will purchase a certain quantity of goods, and the supplier will guarantee the repurchase of any unsold goods at an agreed-upon price

revenue sharing

a retailer pays a supplier a wholesale price for each unit purchased plus a percentage of the revenue the retailer generates

quantity flexibility

allows the buyer in a supply chain to postpone some of his purchases to a later date and at a favorable price after an improved forecast of the customer demand becomes available

quantity discount

economic incentive to encourage organizations to purchase goods in large quantities

erp

enterprise resource planning

enterprise resource planning

software that helps automate, streamline, and enhance essential business processes (collects financials, operations, and activities in one place)

tragedy of the commons

individuals with access to a shared resource act in their own interest and ultimately deplete the resource

facilities

offer the best opportunity to simultaneously improve the environmental and financial performances through innovation

cap and trade

a method for managing pollution in which a limit is placed on emissions and businesses or countries can buy and sell emissions allowances

carbon tax

a charge placed on greenhouse gas pollution mainly from burning fossil fuels

corporate social responsibility

a business model by which companies make a concerted effort to operate in ways that enhance rather than degrade society and the environment

true

reducing landfill waste use improves overall living conditions for animals, plants, and people alike by reducing the release of greenhouse gases