Direct Restorative Dentistry 1 Midterm

1/164

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

165 Terms

hydrocolloids

impression material - are mixed with water to form a gel

hydrated materials examples

alginate, agar, gypsum - (mixed with water to make a set structure)

colloid

a substance of large and small particles equally mixed (particles dont settle)

examples of colloids

gels, sols, emulsions

Alginate

irreversible, hydrocolloid impression material - poured immediately

Gelation

transforming a hydrocolloid from a sol to a gel

Sol

the mixture of substances forming a flowing mixture that can thicken up into a gel

Gel

hydrocolloid for impressions that is slightly elastic

Phases of gel formation

sol phase

chemical rxn

transition to gel

gel formation

Thixotropic

substance that isn’t fluid but is spreadable

when water is squeezed out of a gel mould as it dries

Syneresis

imbibition

when one fluid replaces/displaces another in a hydrocolloid (ex saliva replaces water)

Agar

hydrocolloid that sets at 37-50ºC - reversible at high temp - immediate poor required before it cools

Gypsum

Stone that is poured into a hydrocolloid mould forming a cast - expands in air

Cast vs Model

Cast is pt replica, model is perfect anatomy for learning

Hygroscopic setting expansion

when a substance expands due to exposure to moisture or water

Gypsum type 1

plaster or paris (fragile) - for endentulous pt’s - calcium sulfate B-hemihydrated

water/powder ratio 0.75

gypsum type 2

mounting stone to articulate for dentures or for study models - calcium sulfate B-hemihydrate

water/powder ratio 0.5

Gypsum type 3

Dental stone for models or base for cast - calcium sulfate alpha-hemihydrate

water/powder ratio 0.3

gypsum type 4

die stone for detailed cast - microstone - calcium sulfate alpha-hemihydrated

water/powder ratio 0.24

gypsum type 5

die stone - jade stone - calcuim sulfate alpha-hemihydrated modified

water/powder ratio 0.18

Instrument Nomenclature by G.V Black

order - purpose of instrument

suborder - matter of use

class - form of blade

angle - number of angles

driving power - electric or not

contrangle

shank with two or more angles

3 digit numbering on instruments

width-length-angle

4 digit instrument numbering

width - angle of primary edge to long axis - length - angle of blade to long axis

Use for diamond bur

wear through enamel

use for bladed bur

made of tungsten carbide for removing caries in dentin

more blades on a bur = ________ roughness

less

bigger abrasive particles on a bur = ___________ resulted surface roughness

decreased

CAD CAM stands for

Computer Aid Design

Computer Aid Machining

outline form

form of the prep

cavosurface margin

junction between the prep surface and the outside of the tooth

resistance form

the form of the prep that helps the filling resist failure

retention form

convergence or divergence of prep to retain the prep

convenience form

the form of the prep being a good size that makes it easily accessible

dental liners

when prep is close ot pulp it is put down to protect it

dental bases. applied when

if carrie is too deep, place base to get surface back to ideal restoration

cavosurface angle

angle of prep following pulp horns and cusp shape

debridement

process of cleaning/disinfecting the cavity prep

G.V. Black Classifications are for what?

cavity classifications based on location

Class 1 carries

on one surface

class 2 carries

prep covers two surfaces ot the tooth (molar/premolar)

class 3 carries

in between teeth (anterior incisers)

class 4 carries

on an angle of tooth (anterior incisors)

class 5 carries

prep at neck of tooth by gingiva

class 6 prep

cavity at cusp tip (of molar/premolar)

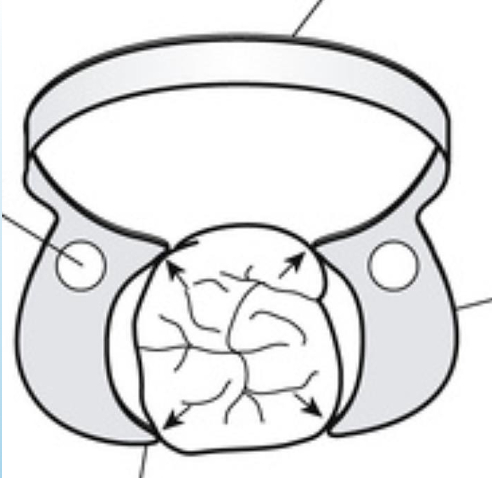

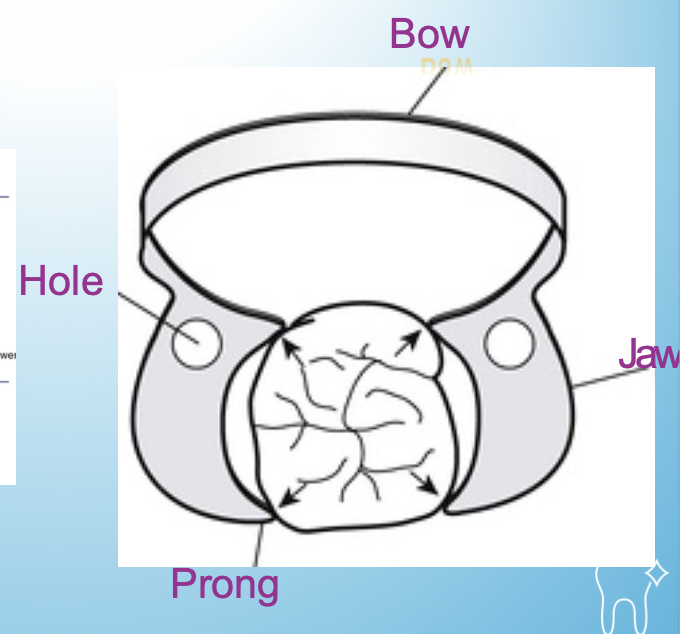

Name with lines

septa

rubber dam material that goes between teeth

light cure dental dam

barrier that is squeezed on gingival like to create a dry field

indirect restoration

done by lab and dentist

tensile stress

the stress of pulling/stretching the material

shear stress

grinding stress, sliding force

flexural stress

bending/tension/compression force (bridge or prosthetic)

strain

deformation (elongate or shorten) due to applied force

fatigue of structure

progressive damage due to repeat stress

Surface Energy

Extra energy at a solid’s surface makes it want to bond with other substances.

Surface tension

Cohesive force at a liquid’s surface resists spreading.

Wetting

How well a liquid can spread determined by the contract angle

<90 = good wetting - also, surface energy > surface tension

TheraCal

Light-cure resin - liner or pulp capping

Mineral Trioxide Aggregate

Material for pulp capping that releases calcium

Biodentine

Dentin substitute that helps regenerate dentin

Glass Ionomer Cement

self-adhesive, releases fluoride, lower strength

Compomers

polyacid resin, fluoride release, low stress areas

Giomer

with pre-reacted class ionomer, sustained fluoride release

Dental Sealants

Applied to pit and fissure to prevent carries

non-carious cervical lesions

Loss of hard dental tissue near CEJ (groove)

Abfraction

Tooth structure loss from flexural forces causing denting on front of tooth

Abrasion

Mechanical wear of tooth structure from external objects

Erosion

Chemical loss of tooth structure from acids not involving bacteria

Etiology

the study of the cause of a disease

White spots in enamel

start of carries, can be remineralized

Desensitizer (Gluma)

seals dentin close to pulp (like a liner)

Amalgamation

the process of mixing the liquid mercury with the powder metal alloys

Amalgam thermal expansion

higher than human enamel which can cause fractures if heated too muc (material expands but enamel doesn’t)

How to protect the pulp from the thermal conductivity of amalgam?

Cements or liners

Types of powder configurations with amalgam

lathe-cut

spherical

admixed

Lathe-Cut amalgam configuration

irregularly shaped amalgam that resists condensation of material but requires more mercury - stronger because of resistance to condenastion

Spherical Amalgam configuration

regular spherical shaped amalgam with reduced surface area - requires less mercury for reaction

it is harder to condense because of the spherical shape, meaning the filling is weaker

Admixed amalgam configuration

both spherical and lathe-cut (cylindar) amalgam particles - middle of the two types, resistant to condensation and requires middle amount of mercury

Tritration

mixing of mercury and alloy to make amalgam (microstructures)

Gamma phase of amalgam formation

Unreacted silver and tin phase - present before and after tritration

gamma 1 phase of amalgam formation

silver and mercury together (like a glue) - strongest phase - matrix phase

gamma 2 phase of amalgam formation

phase that we don’t really want - tin and mercury together - we want to minimize by condensing and removing mercury - weakest and least stable

Copper as an alloy in amalgam

Strengthens silver-tin alloy (brittle and difficult to blend) and reduces corrosion and gamma 2 phase

zinc and an alloy in amalgam

more brittle instead of deforming - can lead to delayed expansion if contaminated with water or saliva (fractures)

preparing an amalgam restoration

2mm deep into dentin

creep of amalgam

strain of deformation produced by stress over time when the patient uses the tooth with the amalgam filling (slow but permenant)

Examples of inelastic materials

plaster of paris, impression compound

plaster of paris is used for what

for edentulous patients

synersis

loses water as it dries.

imbibition

The process where certain impression materials, particularly hydrocolloids like alginate, absorb water from saliva and outside things and swell

mounting stone

what is gypsum type 1 used for

dental stone used for models

gypsum 3

the time from start mixing until setting rxn of impression material stops

Setting time

the time from start of gelation until the material becomes solid

working time

what are the three numbers on a handpiece

width of blade to 1/10 mm - length of blade in mm - angle of blade to long axis

what are the four numbers on a handpiece

width of blade to 1/10 mm - length of blade in mm - angle of blade to long axis - the second angle of the blade

bevel

the angle that one surface/line makes w/ another when not at right angles

flutes

ridges in carbide bur

G.V. Black Principals of cavity design

outline form

prep depth - 1.5 to 2 mm

prep width - ¼ to 1/3 intercuspal dimensions

line angles

mesial and distal walls diverge

buccal and lingual walls

convergecavosurface margin