Food management systems

1/16

Earn XP

Description and Tags

this lecture sucked and I talked to Torrey about it and she gave me permission to make flashcards like this

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

17 Terms

What is HACCP?

a system which identifies, evaluates, and controls hazards which are significant for food safety

What does HACCP stand for?

hazard, analysis, critical, point

What is the food chain?

the food chain consists of the entire sequence of stages and operations involved in the creation and consumption of food products

this includes every step from initial production to final consumption

it includes the production, processing, distribution, storage, and handling of all food and food ingredients

What are biological hazards?

includes food poisoning bacteria because they can survive inadequate cooking; multiply to harmful levels given the right conditions and spread from raw foods to ready-to-eat foods

What are chemical hazards?

includes drug residues, cleaning chemical contamination, non food-grade equipment causing contamination

What are physical hazards?

foreign bodies- metal, glass, hair, flies

What are operational pre-requisites?

the measures that provide the basic environmental and operating conditions in a food operation that are necessary to produce safe and wholesome food

What are examples of food production pre-requisites?

maintenance program

cleaning program

water quality

pest control

staff training program

personal health and hygiene

temp controls and calibration

suppliers and raw materials

waste management

wrapping and packing

transport hygiene

traceability and recall

document controls

What are the 7 principles of HACCP?

conduct a hazard analysis

determine the critical control points

establish critical limits

establish a monitoring system

establish a corrective action system

establish verification system

establish documents concerning all procedures and records

What is hazard analysis and what is important to include when making one?

hazard analysis is when you evaluate your processes and identify where hazards can be introduced

schematic and systemic presentation of the sequence and interactions of steps

include addition of ingredients

consider feedback loops

validate the diagram once complete and modify as necessary

Now try to create a flow diagram for milk production.

Or skip this because who cares

equipment set up →

raw milk transfer →

pasteurisation →

chill to 2 degrees C →

bottle or transfer to milk station →

storage/refrigeration

What is the critical control point step?

step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level

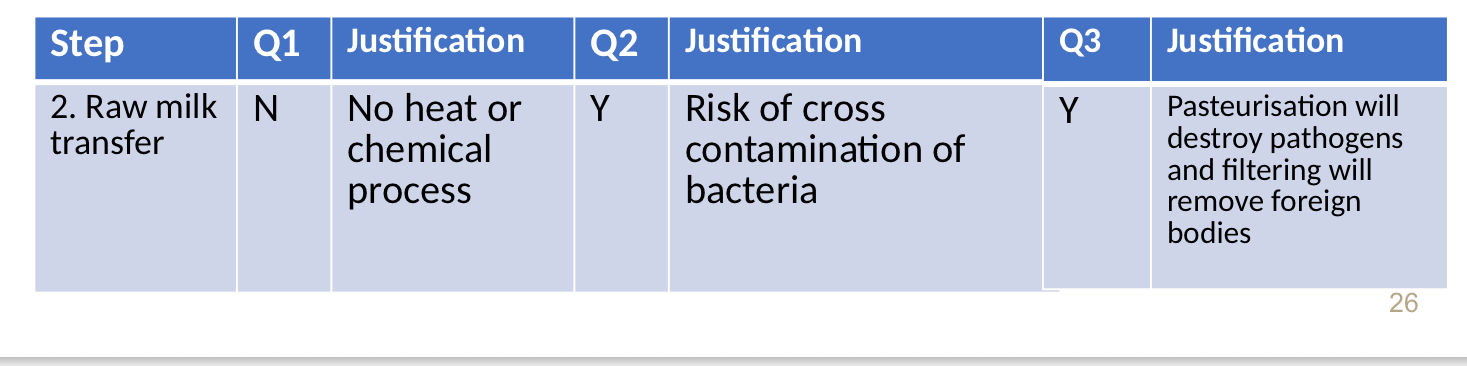

What are the questions you ask yourself in a ccp decision tree?

Q1: does the process step reduce contamination to an acceptable level? if yes this is a CCP. if no, go to Q2

Q2: could the product become contamination in excess of acceptable levels or increase to unacceptable levels? if no this step is not a CCP. if yes go to Q3

Q3: will a subsequent process step reduce contamination to an acceptable level? if yes this step is not a CCP, if no this step is a CCP

What are critical limits?

the maximum or minimum limit of a CCP to prevent, eliminate, control a hazard

must have a scientific basis

measurable/observable

must meet minimum legal requirements

What is the monitoring step?

conduction a planned sequence of observations or measurements to assess whether the control measures are operating as intended

carried out during operations

What are steps you can take if CCP is not under control?

quarantine product since last good check

re-establish control

investigate the reason for failure and upgrade systems accordingly

What goes into establishing a verification system?

validation: obtaining evidence that the control measures managed by the HACCP plan are effective

verification: confirming through the provision of objective evidence that the specified requirements have been fulfilled