Oral Solid Dosage Forms

1/100

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

101 Terms

What is a tablet?

A solid dosage form

It comprises the API and excipients, all compressed into a single unit

All components are solids

What is a capsule

A solid dosage form

It comprises an API and excipients loaded into a shell, which may be hard or soft

The contents of the capsule may be solid or liquid

2 different types of capsules

Hard-shell capsules:

Comprise two pieces, a body and a cap

Made of e.g. starch or hydroxypropylmethylcelluose

May have solid or liquid contents

Soft shell capsules:

Consist of a single-piece shell, typically made of gelatin

The contents are liquid

Why do we use solid dosage forms?

Convenient and accurate dose

Increased drug stability

Simple and easy administration

Altered drug release rates - IR or MR

Mass production

Advantage of solid dosage forms in the context of doses

Can make a wide range of doses and a wide range of drug release profiles

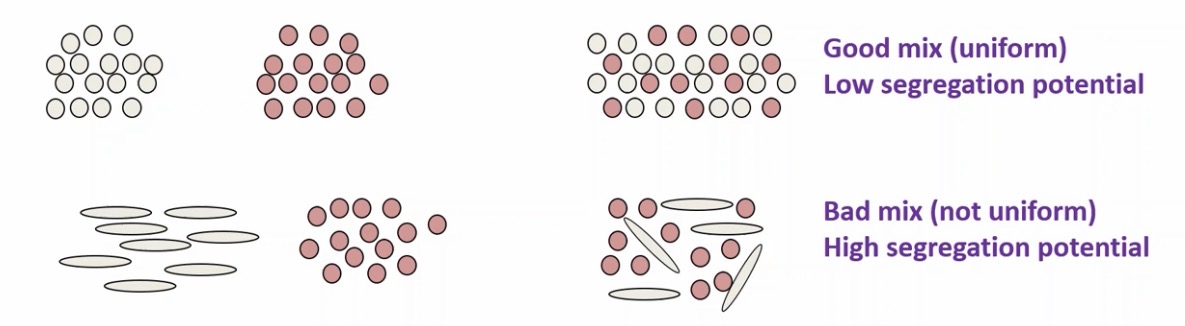

2 problems with making tablets and capsules

Powder formulation

Segregation

Problems with tablets and capsules

Powder Flow

Most APIs are crystalline materials

This means the particles are irregular shaped

This means they usually have poor flow properties

So there is a lot of powder flow when making both tablets and capsules

Problems with tablets and capsules

Segregation

Have to prevent segregation of different powders ie. Excipients and APIs

To avoid this, particles must be the same size and shape

Problems with tablets and capsules

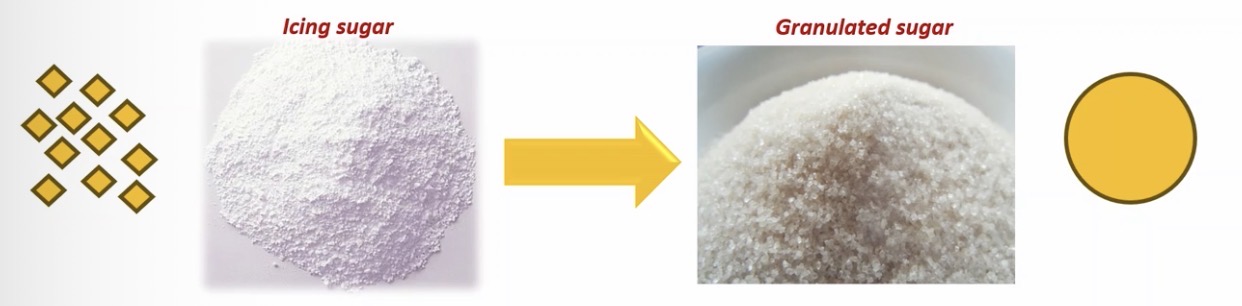

How can we solve the problems of powder flow and segregation?

Granulation

Particles of varying shape and size are gathered into larger, uniform and permanent aggregates

In which the original particles can still be identified

Problems with tablets and capsules

Granulation

We seek to make granules which…

Have a narrow particle size distribution and a shape close to spherical

Are easily fluidised and flow well

Are easily compressible, and stable when compressed » for making tablets

Are produced by a robust and reproducible process, with a clear end-point

Problems with tablets and capsules

Granulation

Benefits of granulation

To improve flow properties of the material.

To prevent segregation of the constituents in a powder mix (content uniformity).

To increase bulk density = improves flow

To reduce dust production (hazard)

To improve compression characteristics

To improve* dissolution rate » faster OR slower depending on desired properties

For control of moisture content

Problems with tablets and capsules

Granulation

Components

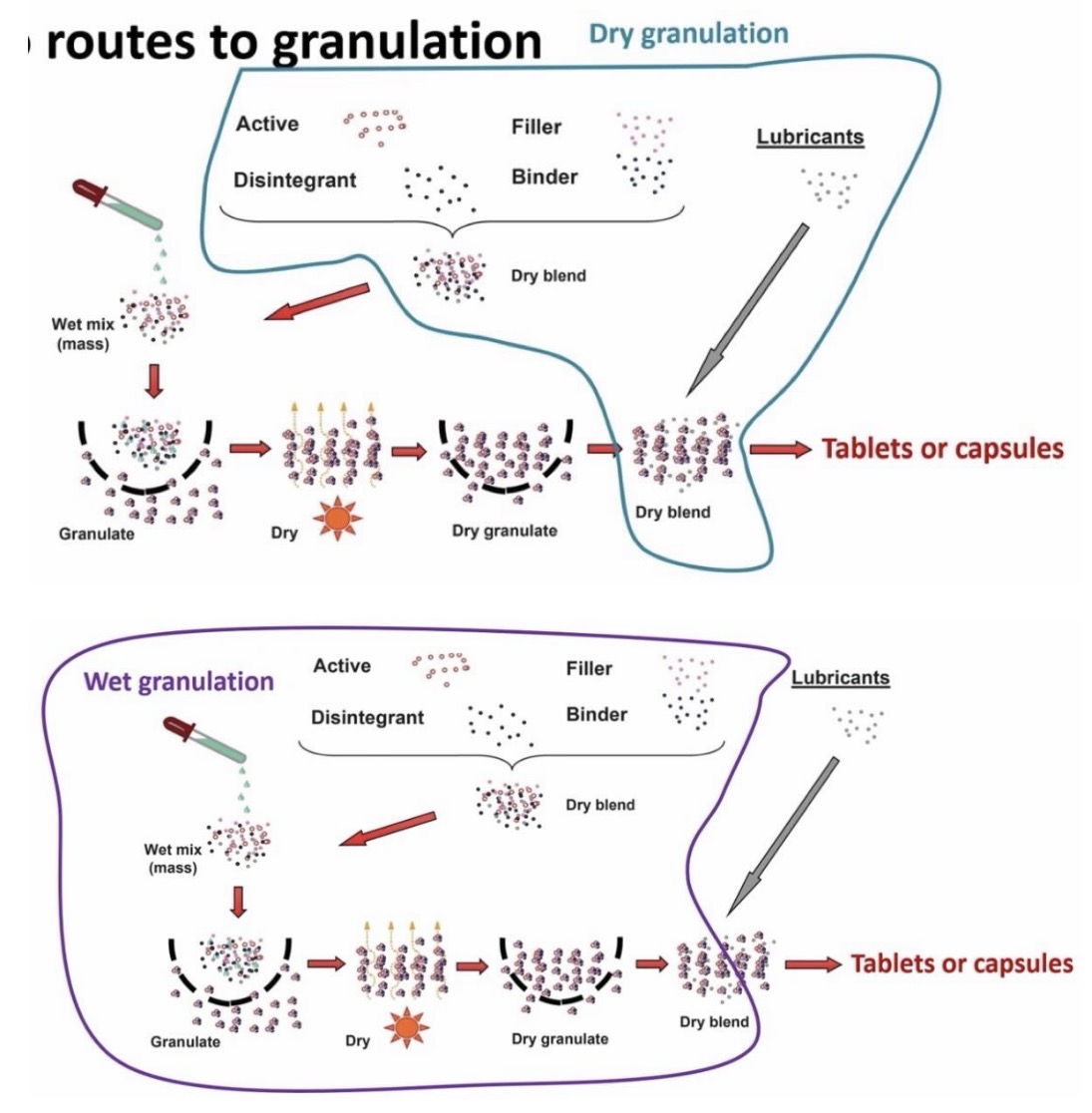

2 routes of granulation

Powders:

API

Filler - provides bulk to the tablet

Binder - sticks together API and excipients

Disintegrant - breaks tablet/capsule up in the body, releasing drug

Dry granulation

Wet granulation

Problems with tablets and capsules

Granulation

Wet vs Dry granulation

Wet:

Commonly used as more likely to produce good granules

If needed, we can do wet granulation in solvents other than water, but water is preferred. We use the minimum amount we can

Dry:

Dry granulation is necessary when the ingredients are sensitive to moisture or heat

Problems with tablets and capsules

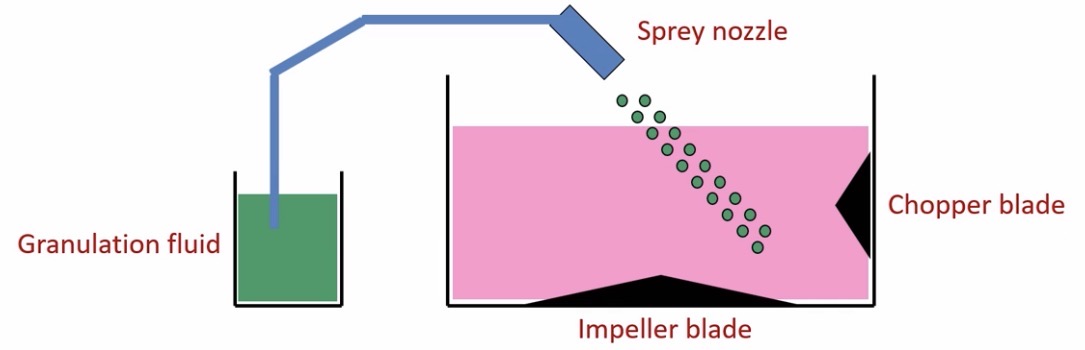

Granulation - Wet

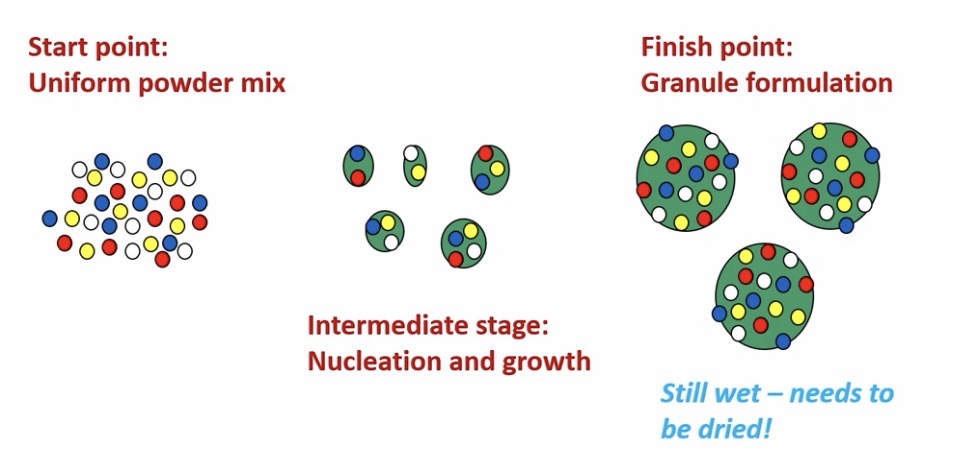

Process

Start with materials that have been ground to the same size

A binder is then added:

Either added to the drug and diluent as a powder mix followed by mixing with water (dry binder)

or as a pre-formed solution (wet binder)

Binders are typically polymers like sucrose, starch, celluloses etc.

Granulating fluid added to make the wet mass

Chopper blade turns to break big lumps up

Problems with tablets and capsules

Granulation - Wet

What does the granulation fluid do?

Sticks particles together in small aggregates

Which then forms bigger granules

Once granules are big enough, they are dried

Problems with tablets and capsules

Granulation - Wet

Properties of dried granules

Porous structure

Solid bridges between particles in the granules

Problems with tablets and capsules

Granulation - Wet

What does it mean if dried granules are more porous?

More porous granules = dissolve faster BUT weaker mechanical strength

Problems with tablets and capsules

Granulation - Wet

How can we control the porosity and bridges between particles in the dried granules?

By controlling:

Amount of binder added

The length of time particles are granulated for

The concentration of the powders in the system

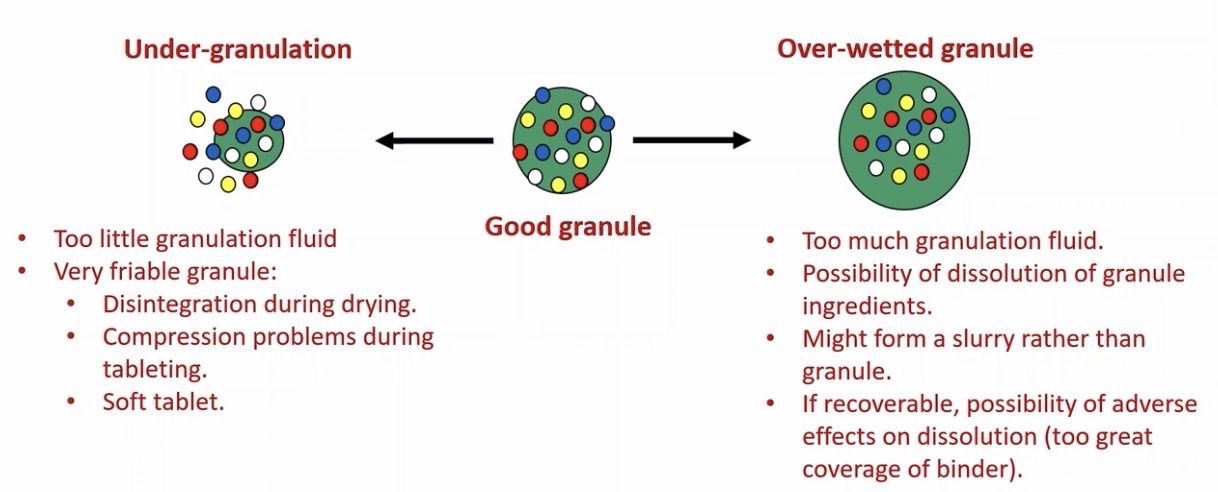

Problems with tablets and capsules

Granulation - Wet

When can wet granulation go bad?

Problems with tablets and capsules

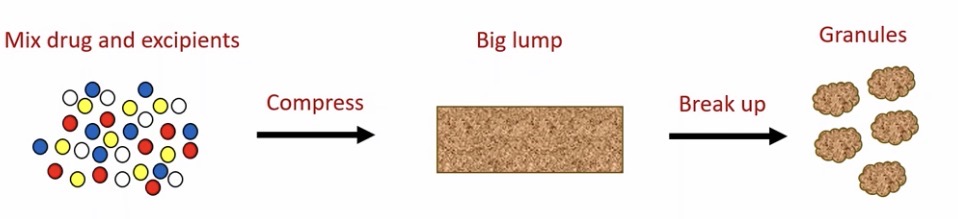

Granulation - Dry

Process

Mix drug and excipients

Lubricant is added » helps powder flow through tablet machinery effectively

Compressed to form a big lump

Lump is broken up into granules

Problems with tablets and capsules

Granulation - Dry

Why is this process not very good?

Granules produced are not very regular and much less spherical = poor flow properties

Problems with tablets and capsules

Granulation

Pros and cons of wet granulation

Pros:

Increases granule strength

Can be used with a wide range of API concentrations

Useful for APIs with poor flow properties

Uniform distribution of drug and different colours

Prevents segregation

Produces tablet that are hard, non-friable and easy to coat

Cons:

Many stages

Long process times

Expensive equipment

Potentially hazardous dust

Requires solvents » bad for water soluble drugs

Drug is heated » bad for drugs which are not heat stable

Migration of soluble components to granule surface

Problems with tablets and capsules

Granulation

Pros and cons of dry granulation

Pros:

Less equipment so cheaper

No expensive drying process

No binders

No heat or liquid » good for sensitive APIs

Cons:

Multiple steps

Produces irregular granules so poor powder flow

Poor colour distribution

Hazardous dust production

Final tablets are softer than those from wet granulation and harder to coat

2 routes of making a tablet

Powder —> Granules —> Tablets (via granulation, then compression)

Powder —> Tablets (via direct compression)

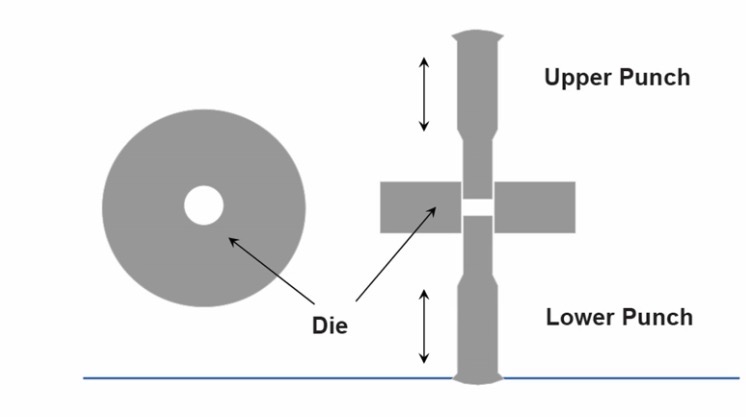

Making Tablets

How do you make a tablet?

Take a powder and squash it:

Die is filled with powder

Lower punch is moved up and down to control how much powder fills the die

Pressure is applied from upper punch and lower punch to squash all powders together to form a single unit

Making Tablets

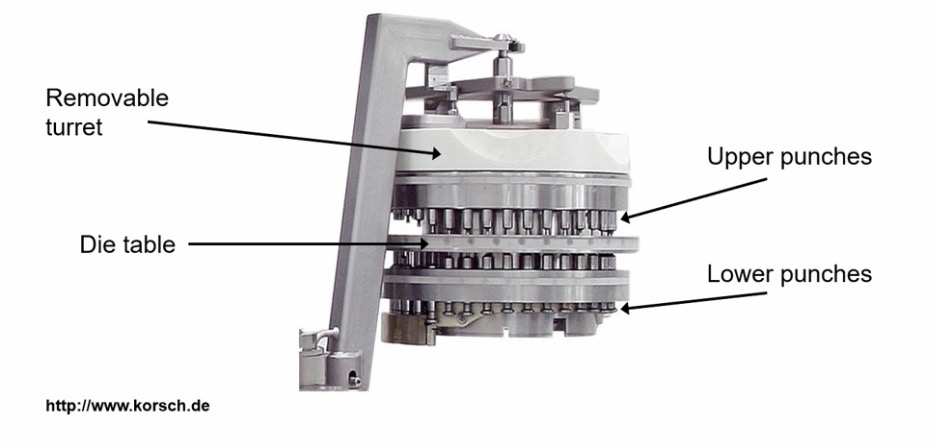

What machine is used to make tablets in large-scale manufacturing?

Multi-station press

Making Tablets

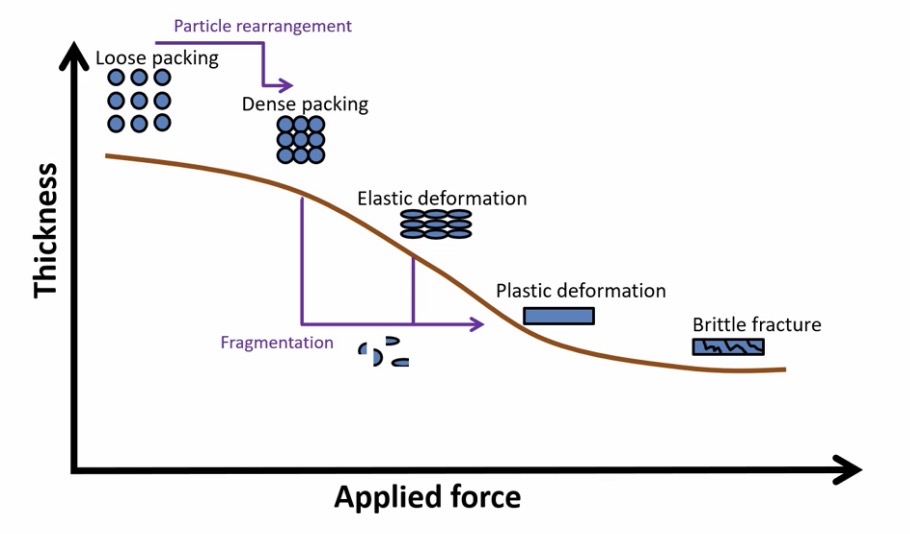

Stages of powder compaction

As pressure is applied:

Loose packing

Dense packing - air removed, particles pushed close together

Elastic deformation - shape of particles changes, reverses when pressure is removed

Plastic deformation - permanent change in shape, tablet is formed

However, if too much pressure is applied:

Brittle fracture - tablet breaks into pieces

By which forces are tablets held together?

Non-covalent adhesive forces between particles - Van der Waals forces

2 types of compression characteristics of the drug/granules

Brittle fracture on compression

Particles break on compression

This creates a larger surface area for adhesion

Plastic deformation on compression

Shape of particles changes permanently on compression

Does not increase surface area

» we need to have a balance of these in our tablet

Why do we need both brittle fracture and plastic deformation in our tablet?

Brittle fracture leads to more inter-particulate bonding = produces stronger tablets

BUT the tablets are harder to remove from the die, and there may be problems with distintegration and drug release in the body

Plastic deformation gives less inter-particulate bonding = produces weaker tablets

BUT the tablets are easier to remove from the die, and have fewer dissolution problems

We want a balance between brittle fracture and plastic deformation to get optimum tablets

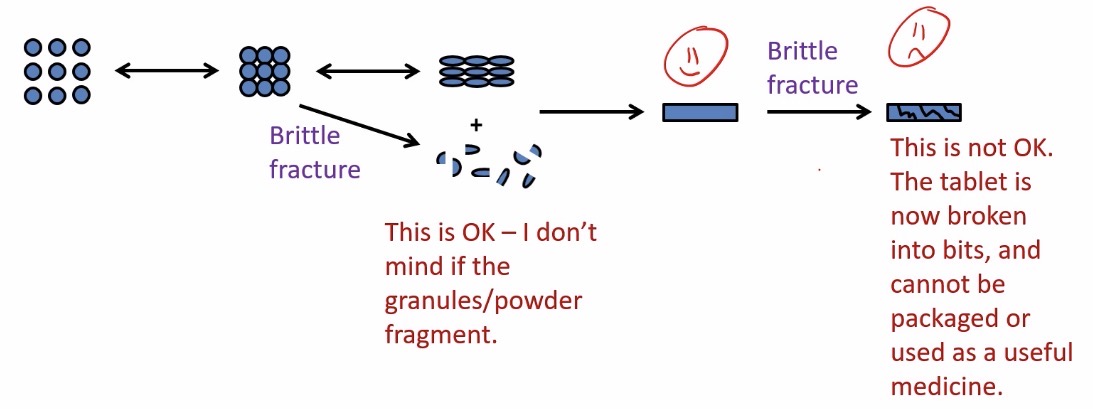

Both the tablets and granules/powder can undergo brittle fracture. Explain what this means

When pressure is applied, before a tablet is formed, some of the powder/granules might fragment » this is completely okay for the tablet formulation

However, once the tablet is formed, if more pressure is applied the tablet will break up » not okay as cannot be packaged or used

Criteria of the powder and tablets for successful tablet formulation

The powder must:

Flow well - to give a consistent tablet weight.

Not segregate - to give a consistent dosage per tablet

Be compressible - to form robust tablets.

Be lubricated - to avoid sticking in the tableting machine.

And the tablets must:

Disintegrate - i.e. break up to release the drug.

Release the drug - determined by dissolution testing.

Be fit for purpose - tablets that the patient can handle!

What powder criteria does granulation allow us to achieve and why (summary)

Allows the powder to:

Flow well » forms spherical particles

Not segregate » api and excipients stuck together

Be compressible » right balance of brittle fracture and plastic deformation

How can tablets be made without granulation?

Direct compression

Making Tablets

Direct Compression

Direct compression is used if the drug is of low dosage and will flow well

We add a compression aid - a bulking agent with good flow and compression properties

Examples of compression aids include:

Microcrystalline cellulose (Avicel®) = plastic deformation excipient

Dicalcium phosphate (Emcompress®) = brittle fracture excipient

Spray dried lactose = brittle fracture excipient

Making Tablets

Direct Compression

Pros and Cons

Advantages:

Two step process » blend and compress

Improved stability

No heat

No water

Disadvantages:

Require specialist (spray-dried) excipients = expansive

Poor flow/compression properties

Use of flow aid.

Segregation (uniformity of dosage form)

Size and density of API and excipients may be different = segregation

What is a film coat?

Thin outer layer that covers a tablet core

Film coatings are usually either:

Sugar

Polymer

Why do we film coat?

As a physical barrier:

To protect the drug (moisture, light, O2 etc)

To protect the user (some drugs are very potent)

For identification:

Patients/HCPs can quickly identify a tablet based on colour

Taste-masking

To improve handling - if tablet is friable (easily broken)

To modify the rate of drug release

Example of very potent drugs that are film coated to prevent patient overdosing on these drugs e..g by licking fingers

Finasteride

Chlorambucil

What is an enteric film coat?

Where a film coat is designed to delay or modify drug release (usually by a polymer)

If we did not want a certain drug to dissolve in the stomach acid, what would we make the film coating out of?

A polymer with pH-dependent solubility

If a tablet is ‘gastro-resistant’…

This means it has an enteric coating

What should you tell patients when giving tablets which are enteric-coated?

Do not break tablet in half

Do not crush tablet

Do not put tablet in juice etc (acidic = causes drug to be released early)

How can you tell whether a film coating of a tablet is made of sugar or polymers?

Sugar film coating are thicker than polymers

Sugar Film Coating

Properties

E.g. like M&Ms

Thick coat (0.5-2mm) that covers imperfections

Gives a shiny finish

Masks bitter taste

Not used to control drug release » sugar dissolves quickly at any pH

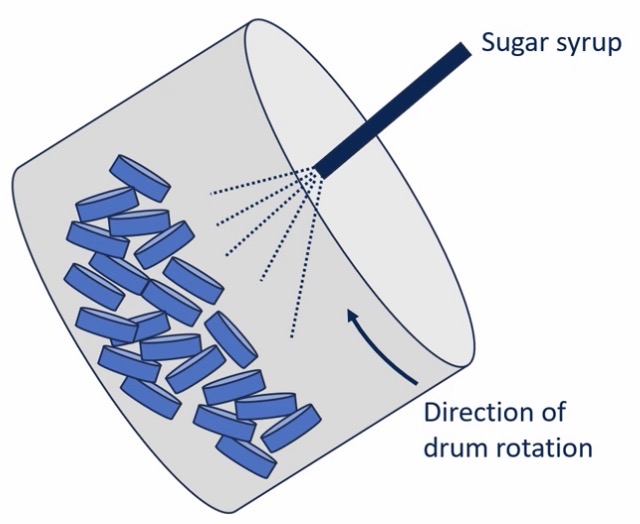

Sugar Film Coating

How is it made?

Tablet cores are placed in a rotating drum

Sugar syrup is sprayed into the drum

Usually multiple layers of sugar coating:

Seal

Sub-coat(s)

Smoothing coats)

Colour coat

Polishing coat

Printing coat (optional)

Polymer Film Coating

Properties

Thin coat (20-200 um) that does not cover imperfections

Gives a matte finish

Masks bitter taster

Can control drug release » polymer has pH dependent solubility

Polymer Film Coating

Basic film coat

No pH-dependent dissolution

Typically comprises:

HPMC » forms a high strength film

HPC » gives good flexibility

Titanium dioxide » makes the film opaque

Dye

» all dissolved in water

Polymer Film Coating

Enteric film coat

Designed to be insoluble at low pH

Typically comprises:

Polymer - Cellulose acetate phthalate (Aquateric) OR Polymethacrylates (Eudragit)

Plasticiser (like triacetin or PEG) » goes between polymer chains and makes the film more flexible

» Polymers are insoluble in water at certain pHs, so dissolved in ethanol

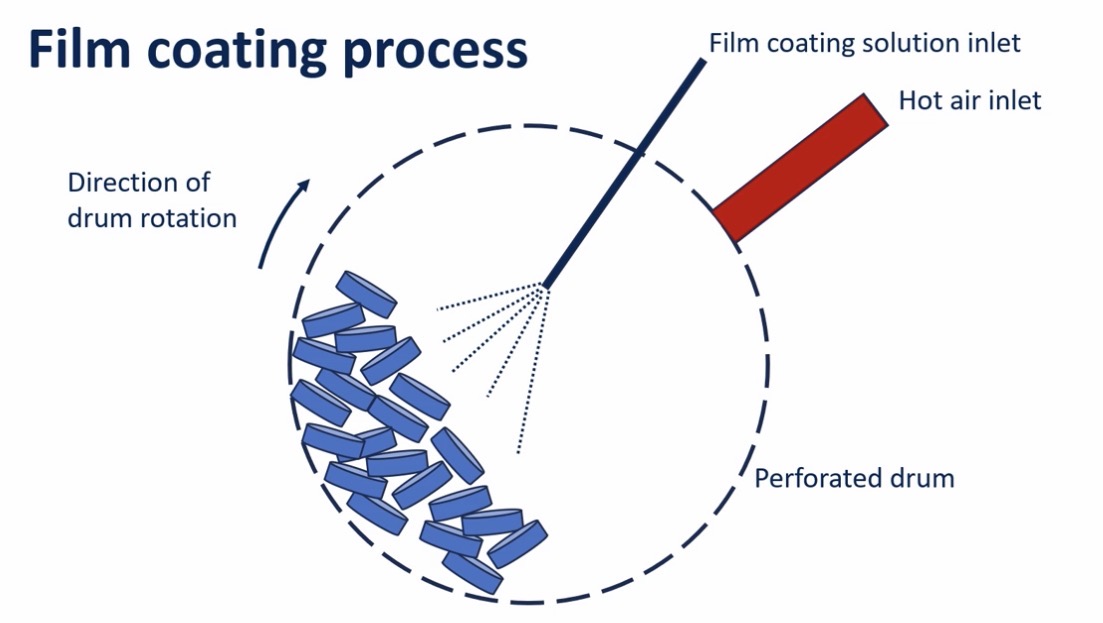

Polymer Film Coating

How is it made?

Tablet cores are placed in a porous/perforated rotating drum

Hot air enters to evaporate the ethanol

Holes in the drum to let ethanol evaporate

Why is a porous drum used in polymer coating but not sugar coating?

In polymer coating, solvent used is ethanol

Pores allow ethanol to evaporate

What is drying?

The removal of water (or another solvent) to form a solid

What samples can be dried?

Wet solid

Suspension

Solution

Are materials ever completely dry?

No

Water may still be on the surface or within cells

Water is important for materials for maintaining their structure

Why do we dry materials?

To improve physical properties e.g. powder flow, compressibility » dry powders will flow better than wet powders (less clumping)

To improve stability by reducing:

Hydrolysis

Polymorph conversion

Growth of microorganisms

Reducing efflorescence » fat crystallising out of a material

Why do we not completely dry materials?

Some water content is needed for good compression

4 methods of drying

Tray-drying

Fluidised-bed drying

Spray-drying

Freeze-drying

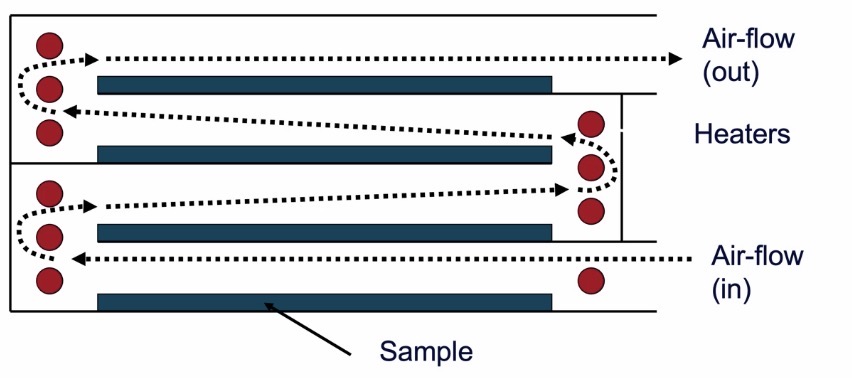

Tray Drying

Method

Advantages

Disadvantages

Sample (wet powder) is spread thinly on a tray in a convective oven

Hot, turbulent air is then passed over the sample

Advantages:

Cheap and easy to use

Disadvantages:

Can take up to 24h to dry

Limited sample mass (a few kg)

Low surface area of solid

Fluidised-bed Drying

Method

Advantages

Disadvantages

Hot, turbulent air passed in from below the powder bed

If air flow is high enough, particles aerosolise and become fluidised

Filter bag prevents powder particles from leaving the top of the dryer, and has small holes to allow the air out

Advantages:

Very rapid drying (ca. 30 mins)

Energy efficient

Can handle large masses (ca 100s kg)

Can smooth particles

Disadvantages:

Risk of dust explosion

Spray Drying

Method

Advantages

For drying solutions / suspensions

Hot air and solution/suspension passed through a nozzle at the same time

Sample becomes an aerosol

Aerosol droplets dried in a vortex of hot air

As the droplets dry = become denser = falls to the bottom of the spray dryer

Advantages:

Very rapid drying (1-2s for each droplet to dry)

Energy efficient

Can run continuously

Produces spherical particles

Often makes material amorphous = dissolve fast

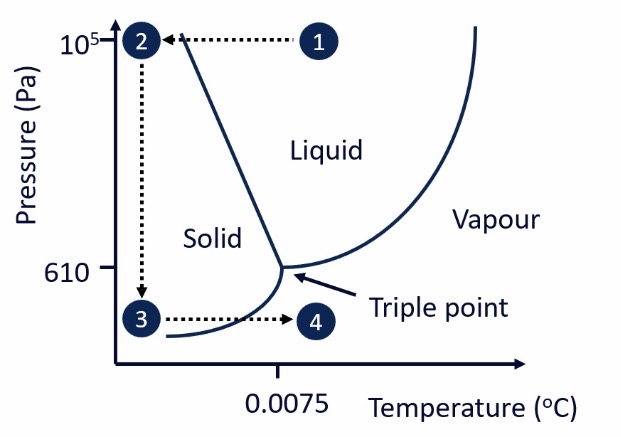

Freeze Drying

Method

Advantages

Disadvantages

Based on the fact that water has a triple point - where solid, liquid and gas intersect

Water is able to go straight from a solid to a gas = sublimation

Solution/suspension inserted into freeze dryer at atmospheric pressure (105 Pa) and room temperature » point 1 on the diagram

Under these conditions, water is a liquid

The sample is frozen » reduce temperature, keep pressure the same » point 1 to point 2

A vacuum is initiated, causing pressure to drop below 610Pa » point 2 to point 3

Increase temperature back to room temperature » point 3 to point 4

Frozen water sublimes and becomes a gas, which is removed

Advantages:

No rise in temperature, so good for heat sensitive samples

Makes highly porous, amorphous material = very fast dissolution

Disadvantages:

Expensive to operate

Small samples (usually in glass vials)

Which is the only drying method where temperature is not increased above room temperature?

Freeze drying

Which solvent, other than water, has a triple point and can be freeze dried

T-butanol

Diluents

What are diluents?

Bulking agents

Added to increase bulk and make the tablet a practical size for compression

Diluents used in direct compression need to have similar particle size to the drug, and good compressibility

With insoluble drugs, need to add hydrophilic diluents

The diluents must have good compatibility with the drug

Diluents

Examples

Lactose monohydrate

Microcrystalline cellulose

Dicalcium phosphate dihydrate

Pregelatinised starch

Mannitol

Calcium sultate

Corn starch

Disintegrants

What are disintegrants?

Facilitate the break up of tablets into individual granules/particles upon contact with water

Mechanisms of action

Wicking - capillary forces promoting rapid water uptake

Swelling

Release of gases upon contact with water

Melting at body temperature

Enzymatic destruction of binder

Disintegrants

Examples

Normal disintegrants

Starches (corn, pre-gelatinised)

Alginates

Super disintegrants

Cross-linked carboxymethylcellulose 2-6% (Ac-di-sol)

Sodium starch glycolate 2-8% (Explotab)

Crospovidone 2 - 6% (Kollidon CL or Polyplasdone)

Disintegrants

When do you use a normal or super disintegrant?

Low solubility = use super disintegrant to speed up disintegration and drug dissolution

Strong granule = use superdisintegrant to speed up disintegration

Disintegrants

When do we add a disintegrant?

Option 1: Add all disintegrant prior to granulation

Option 2 (Preferred/Most common): Split addition

2/3 added prior to granulation

1/3 added to the dry granules before compression

Examples of common excipients used in tablet formulation

Microcrystalline Cellulose (MCC) - 90 microns:

• Excellent compactability and flow

• Limited disintegration properties

Starch 1500

• Adds bulk to the tablets

• Good compactability, flow and lubricity

• Disintegration property

Lubricants

Purpose of lubricants

Examples

Reduces friction between powder and tableting tools

E.g.

Mg stearate / Ca stearate

Polyethylene glycol

Lubricants

When is the lubricants added

Whether tablets are made by:

Direct compression, or

Wet/dry granulation

The lubrication step is essentially the same:

Lubricant is added at the final blending stage, just before compression

Lubricants

Advantages

Reduce friction between powder/granules and dies and punches

Prevent material from sticking to equipment

Ensure smooth tablet ejection

Low shear mixing → avoids excessive coating

Minimum effective amount → typically 0.25–1%

Short mixing time → limits negative effects

Lubricants

What happens if there is too much lubrication?

Particles become over-coated

Results in:

Soft tablets (reduced hardness)

Poor dissolution (water cannot penetrate easily)

This happens because lubricants repel water and weaken particle bonding

Lubricants

What happens if there is too little lubrication?

High friction during compression

Leads to:

Sticking – material sticks to punch faces

Picking – part of the tablet surface is pulled off

Causes defective tablets and equipment issues.

Glidants

Purpose of glidants

Examples

To improve powder flowability

E.g. Colloidal silicon dioxide

Examples of interactions between APIs and excipients

E.g.

Lactose and primary or secondary amines → Maillard reaction

CaHPO, is alkaline, so need to consider pH stability of drug

What must happen to all excipients before direct compression

Must be spray dried to ensure they are spherical, so they mix and flow well

Possible problems after tablet manufacturing

Weight variation

Caused by variation of flow of powder into the die

Leads to variation in drug content

Solution:

Improve flow properties

Reduce compression speed

Possible problems after tablet manufacturing

Segmentation of granules/powder

Leads to variation in drug content

Solution: improve powder flow properties

Possible problems after tablet manufacturing

Capping / Lamination

Caused by excessive elastic recovery

Moisture content may be too high or low

Solution:Add excipients to give more brittle fracture

Possible problems after tablet manufacturing

Sticking

Bits of formulation stick to the punches

Causes by small/irregular particles or high moisture content

Solution: increase the amount of lubricant/lubrication time

Possible problems after tablet manufacturing

Picking

Tablets pick up bits of powder on the surface

Causes by small/irregular particles or high moisture content

Solution: increase the amount of lubricant/lubrication time

Possible problems after tablet manufacturing

Chipping / Cracking

Caused by:

large particle size

high elastic recovery

high humidity

Possible problems after tablet manufacturing

Poor dissolution properties

Caused by:

Particle size

High moisture content

Low binding

Segregation

How are tablets made to be easy to swallow?

To improve swallowability, tablets are often given a special film coating. This coating is formulated to:

Be smooth and slippery

Show low bioadhesion (does not stick to the mouth or throat)

Coating composition

Polymers:

Hydroxypropyl methylcellulose (HPMC)

Polyvinyl alcohol (PVA)

These form a smooth, flexible film with low adhesion

Plasticisers:

Polyethylene glycol (PEG)

Plasticisers increase flexibility and prevent cracking

Colorants:

Improve appearance and aid product identification

2 types of capsules

Hard (shell) capsule

Two piece capsules which include a "body" and "cap"

Capsule materials: Gelatin or Hydroxypropyl methylcellulose (HPMC) or Starch

Contents may be solids or liquids

Three stage manufacturing process: i) shell, ii) contents, ili) filling

Soft (shell) capsule

One piece

Capsule material: Gelatin

Contents are liquids

Two stage manufacturing process: i) contents, ii) shell manufacture and filling combined

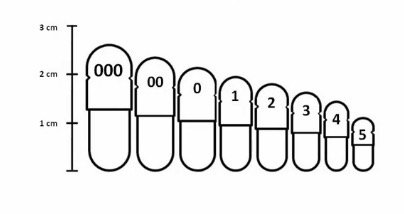

Capsule Sizes

There are 8 standard capsule sizes, ranging from: 000 (largest) → 5 (smallest)

As the capsule size number increases, the capsule volume decreases

How to estimate fill weight for hard capsules

Fill weight ≈ capsule body volume × tapped bulk density

Tapped bulk density is used because it reflects how powder behaves after settling, which is closer to real capsule filling conditions.

How to estimate fill volume for soft capsules

Fill volume depends on the density of the liquid in the capsule

Hard Capsules

How are hard gelatin capsule shells manufactured?

Gelatin dissolved in hot water (60°C to 70°C)

Colour is added as necessary

Stainless steel pins (fingers) dipped into the gelatin solution

the coating on the pins will become one part of the capsule

the pins are rotated to ensure constant thickness of coating

the coating is dried, removed and trimmed

the two halves of the capsules are joined together

Hard Capsules

What is the standard moisture content for hard gelatin capsules?

What is the recommended storage conditions?

Standard moisture content: 13% to 16% w/w

Storage conditions: 50% relative humidity at 21°C

Hard Capsules

Why do we use hard capsules compared to tablets?

No water involved in the dry powder mix → prevent hydrolysis

No heat involved in the dry powder mix → good for heat-sensitive drugs

No compression involved in filling of dry powder mix → avoid possible changes of physical state (amorphous v crystalline, polymorphic changes) → prevent change in dissolution profile

Hard Capsules

Why may HPMC be used as a capsule material instead of gelatin?

Used to improve performance and stability of formulations, especially for:

Poorly soluble APIs » better solubilisation

Aldehyde-containing formulations » avoids gelatin cross-linking and disintegration issues

Modified-release formulations

Moisture-sensitive drugs » lower moisture content than gelatin, better stability)

Soft Capsules

How are soft gelatin capsule shells manufactured?

Preparation of the ribbon

Gelatin dissolved in hot water

Plasticisers added (eg glycerol, sorbitol, PEG, propylene glycol)

Colour is added as necessary

A gel "ribbon" is formed

Preparation and filling of the capsules

Two gel ribbons are placed on the rollers

Ribbons are partially sealed to provide a "cup"

The liquid is added to the cup

The ribbons are sealed above the fill, making an intact capsule

The capsules are dried

Soft Capsules

Why do we use soft shell capsules compared to tablets?

For poorly water soluble drugs

Drug is in solution in the fill

Avoids dissolution step in the gastro-intestinal tract

Promotes bioavailability, especially if in a self-emulsifying formulation

Excipients in a capsule filling

Diluents (filler)

Lubricants, which reduce powder-to-metal adhesion

Glidants, which improve powder flow

Wetting agents, which improve water penetration

Disintegrants, which produce disruption of the powder mass

Hard Capsules

Limitations of filling for hard capsules

React with shell material

Contains high levels of moisture

Volume of unit dose exceeds the capsule size available

Hard Capsules

Different types of fillings for hard capsules

Powders

Granules » improve mixing, reduce segregation

Pellets » enable controlled release and combination drugs

Mini-tablets » different drugs or release rates in one capsule

Non-aqueous liquids » oils or oil/surfactant systems for very poorly water-soluble drugs; may be liquid or molten-filled solids