Sustainability management Test 2 Slides C3 and C4

1/74

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

75 Terms

Supply Chain

includes all parties involved in fulfilling a customer request, such as manufacturers, suppliers, transporters, warehouses, and retailers.

Charactertization of supply chain management and the focal firm

•Purpose: Coordinate relationships to:

Boost competitive advantage (e.g., faster delivery).

Maximize total surplus (profit + social/environmental value).

focal firm

Central company shaping the supply chain through decisions, selecting suppliers and distributors, and interacting with consumers. It designs key product aspects, influencing characteristics and sustainability impacts, but may not produce the product (e.g., outsourcing).

Sustainable supply chain management (SSCM)

•Integrates triple-bottom-line goals:

•Economic (profit)

•Environmental (planet)

•Social (people)

Manages material, information, and capital flows while considering sustainability goals from all three dimensions: economic, environmental, and social

Challaneges for sustainable supply chain management

strutural challenges

multi-tier netowrks

transparency gaps

Dynamic pressures

External forces

governments

Customers

NGOs

Multi-tier netwoks

3+ supplier tiers (e.g., raw materials → parts → assembly)

Example: Apple works with ~2,000 suppliers across 43 countries

Transparency Gaps

Critical data (e.g., labor conditions, emissions) lost across tiers

Only limited number of firms track Tier 3+ suppliers

External Forces

Governments: Weak enforcement (e.g., <30% of ESG fines collected in EU)

Customers: 68% demand sustainability but reject price hikes

NGOs: Targeted campaigns (e.g., Greenpeace vs. fast fashion) often lack public traction

Two prototypical strategies to increase sustainability in supply chains

Supplier Management (Risk-Focused)

Sustainable Product Supply Chain Managment (innovation focused)

Supplier Management Goal

Mitigate risks in existing supply chains

Supplier Management Approach

•Screen suppliers using sustainability criteria (e.g., carbon footprint, labor practices)

•Reactive: Address issues post-identification (e.g., audits, corrective action plans)

Supplier Management is best for

Compliance-driven industries (e.g., electronics, apparel)

Sustainable Product SCM Goal

Design greener products through supply chains

Sustainable Product SCM Approach

Proactive: partner with suppliers on eco-design (ex. recycled materials)

Embed sustainability in product lifecycle (ex. from sourcing to disposal)

Sustainable Product SCM is Best for

Differentiated brands (ex. Patagonia, IKEA)

Core steps in supplier management for risk and performances

Commit, Evalute, Control, Develop

Commit

Commit suppliers to sustainability related minimum standards

Evaluate

Evaluate suppliers based on sustainability criteria

Control

Control suppliers via audits

Develop

Develop suppleirs to improve practices and performance

Commit suppliers to uphold certain sustainability-related minimum standards

Ex. supplier codes of conduct:

Form of voluntary commitment Content, form, and implementation not regulated

Can provide recommendations for behavior of suppliers or their employees, suggested courses of action, or certain measures which should be taken

Company-own or external code of conduct

Commit suppliers to have certain sustainability-related certificates

Provide incentives such as price premiums for suppliers with sustainability-related certificates

Very common for quality and environmental management systems standards

Social standards less widespread

Evaluate sustainability-related information as part of risk management

Self-asessments, Risks

Self-assessments

suppliers provide inforamtion usually though one-time or epriodic questionnaires

Self-assessments benefits

Relatively inexpensive → Can be used even with limited financial or human resources

Indicate areas where audits or supplier development measures might be necessary

Risks

•Prone to social desirability bias

•Widespread adaptation of self-assessments may lead to evaluation fatigue

Industry standards, software solutions, and platforms for supplier assessments aim

at reducing transaction costs for both sides

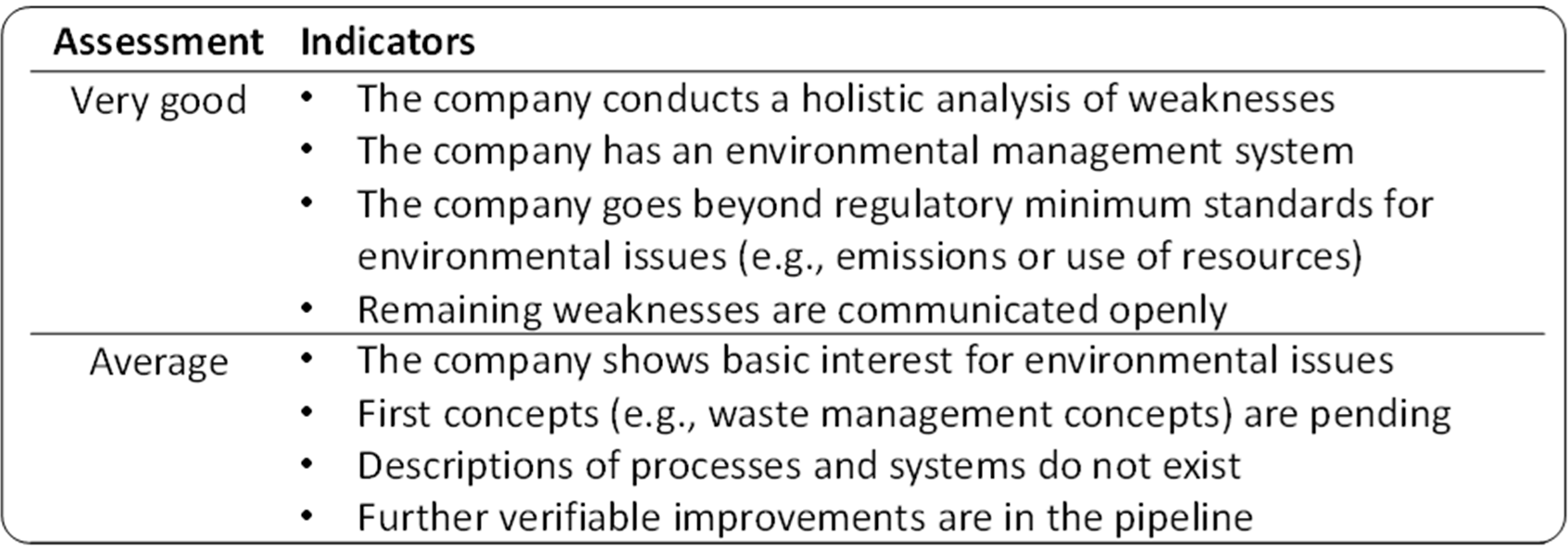

Exemplary criteria for an ecological supplier evaluation

assesment and indicatiors

Audits in a sustainable supply chain management

Focus on environmental and social issues, unlike regular audits, which focus on quality

they can cover products, processes, or verify enviormental/social management systems

Types of Audits

First, Second, and Third party

First-party audit

Internal audit by employees or paid individuals to uncover weaknesses, with no personal interest in results.

ex. A food processing company conducts an internal hygiene audit at its own plant. Their quality assurance team inspects cleanliness, checks if protocols are being followed, and identifies gaps in procedure.

Second-party audit

External audit by a company at its suppliers, more formal and impactful on relationships.

ex. A large retail chain like Walmart audits a supplier’s warehouse to ensure it meets the company’s standards for safety, labor practices, and delivery reliability.

Third-party audit

Independent external audit, initiated and paid by the company, to check compliance and issue certification if requirements are met.

ex. A bakery hires a health inspector from a certified agency to check if the kitchen is clean enough to get an official hygiene certificate.

Decommoditizing

Treating a supplier or supply chain of a commodity as if it provides a rare, strategic input

Byproducts

secondary products from primary production (ex, buttermilk, sawdust, waste heat).

Eco-efficiency

improve process efficiency, reduce by-products

Eco-effectiveness

reuse by-products within the company or for others (ex. waste heat for energy, sawdust for oriented strand boards).

Reduction

is the top choice: minimizes waste and harmful substnaces, only provide necessary goods

How is reduction achieved?

by reducing input (e.g., less offcuts, thinner materials) or substituting harmful substances.

no further processing needed later in the product life cycle.

Reuse

Second-best option: give products a second life through refurbishing.

Common in households (e.g., buying used goods), but less common in production.

Parts can be reused in new products or repairs.

Recycling

Third-best option, reprocessing waste into new products or materials, either for the same or different purposes

Mechanical, Chemical, Biological

Mechanical Recycling

Crushing, melting plastic for reuse

Chemical Recycling

converting plastic into basic chemicals

Biological Recycling

compsoting plastic to biomass using organisms

Recovery and disposal

Least favored

Incineration recovers energy from waste.

Disposal should only be used when no alternatives exist, and done responsibly (e.g., limit wastewater discharge to protect the environment).

Waste Heirarchy

Reduce, reuse, recycle, repair/recover, dispose

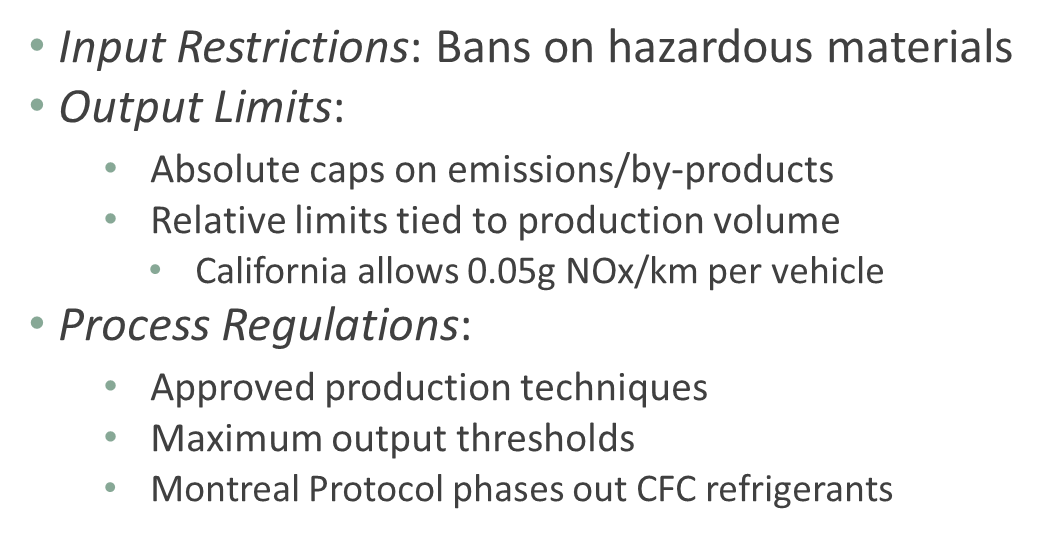

Sustainability in business is increasingly shaped by formal regualtions across two key dimensions.

Social Compliance

Enviormental controls

Social Compliance

Minimum wage requirements

Occupational health & safety standards

Enviormental Controls

Output limits:

Absolute caps on emissions/by-products

Relative limits tied to production volume

California allows 0.05g NOx/km per vehicle

Sustainable product design: Lifecycle approach

Design Phase Decisions

Key considerations

Design Phase Decisions

Most impactful stage

Example: Tesla’s battery design reduces colbat use by 60% from Day 1

Key Considerations

•Customer needs:

Example: Patagonia’s washable wool reduces dry-cleaning waste

•Environmental impact:

Example: IKEA’s flat-pack furniture cuts transport emissions by 30%

Designers can improve sustainability through

Eco-efficiency: using lightweight or energy-efficient materials

Eco-effectiveness: choosing nontoxic, reusable materials

Sufficiency: creating durable products for sharing

Most products’ biggest impacts occur during

USE not production

Example: A washing amchine uses 85% of its totoal energy during laundry cycles not manufacturing

The Lifecycle Blind Spot

•Traditional focus: Optimized factory efficiency (e.g., Toyota’s 10% production waste reduction)

•Missed opportunity:

•Example: Early refrigerators consumed 2x more energy than modern eco-models

Manifold opportunities for implementing idea of sustainability in product design Examples

Lighter vehicle materials reduce energy use.

Better insulation lowers heating/cooling needs.

Durable or modular designs extend product life, reducing new product demand.

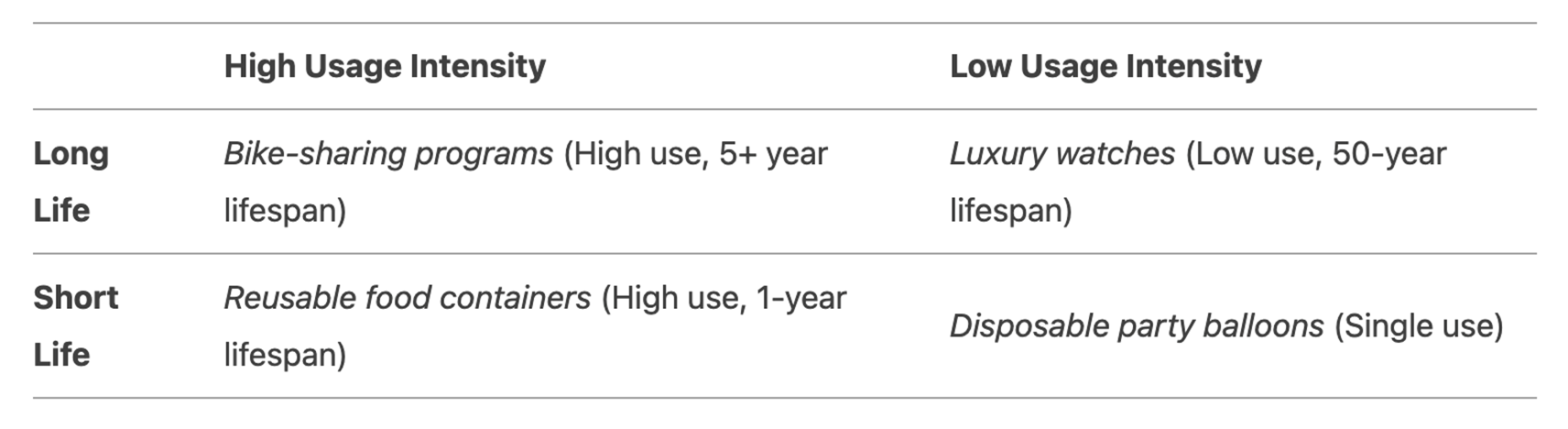

Usage Intensity

High Intensity: Frequent or shared use → Maximizes utility per unit produced

•Examples:

Car-sharing (Zipcar): 1 vehicle serves 10+ users daily

Low Intensity: Infrequent or single-user use → Often leads to underutilization

•Examples:

Formal suits: Worn 5x/year but require dry-cleaning resources

Produt Lifespan

Long Life: Durable, repairable, or upgradable designs

•Examples:

Solid wood furniture: Generational use (30+ years)

Short Life: Disposable or rapidly obsolete products

•Examples:

Single-use coffee pods: Used once, non-recyclable materials

Usage Intensity and Lifespan Crossover

Scenarios of reduction-oriented product use concepts

First Scenario, Second Scenario, Third Scenario, Fourth Scenario

First Scenario

Extending product life by reducing wear using durable materials, gentler use, or encouraging proper usage. It fails if customers don't use products longer, even when still functional.

Second Scenario

Extending product use by ensuring they last until the end of their technical life. Strategies include timeless designs, modular designs for updates, or extended software updates for smartphones.

Third Scenario

Increasing product usage over its lifetime: Scenario 3.1, 3.2

Scenario 3.1

Running production lines continuously for better eco-efficiency.

Scenario 3.2

Car-sharing or rentals to increase vehicle utilization.

More frequent use benefits more people, reducing the need for new products.

Fourth Scenario

Increasing product use intensity at any given time:

Ex. adding capacity to public transport (e.g., double-decker buses) or carpooling.

If we can increase usage intensity

We can create a good impact on the enviorment

Sustainability applies to all production stages:

Input, transformation, output

Input

reduce raw materials, use recycled materials, minimize harmful substances

Transformation

cut energy/ consumable use, ensure safety and decent working conditions

Output

reduce waste, produce energy-efficient products, minimize unused by-products, extend product life

Enviormental focus:

input and output

Social focus:

transformation

Examples of Operational Optimization

•Product level: product miniaturization, redesign of packaging, reduction of hazardous materials

•Organizational level: more resource-efficient processes, improved waste management

Examples of Organizational transforamtion

•Sharing economy

•Services that otherwise change consumption habits such as replacing physical with electronic services

•Products specifically designed to cater to need of poor populations