Ch 12.1 warehouse management

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

warehouse

essential component of any supply chain

increasingly outsourced to logistic service providers

SKU (stock keeping unit) = a specific item at a particular geographical location

SKU

stock keeping unit

= a specific item at a particular geographical location

roles of a warehouse

storing/ buffering products between points of origin and points of consumption

consolidation and product mixing

crossdocking

value added services, including reverse logistics

meaning crossdocking

a logistics strategy where goods from suppliers are directly transferred to outbound trucks for delivery to customers, bypassing traditional warehouse storage to speed up delivery and cut costs

warehouse function : storing/ buffering

allows different parts of the supplu chain to operate independently

increase operational flexibility (eg impact of seasonal demand, batch production, uncertainties)

reduce customer lead times

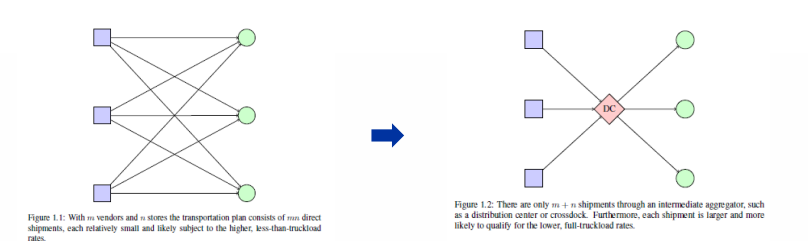

warehouse function : consolidation

allows product mixing and reduces transport costs

combines shipments from a number of sources in the same geographic area into larger, more economical shipping loads,

distribution center (warehouse function)

received large incoming shipments and splits them up into smaller outgoing shipments to demand points in a geographical area

warehouse function : crossdocking

allows to consolidate and transfer products directly without storage/ picking, customer is known

warehouse function : value added logistics

allow to meet specific customer demands, especially when a postponement strategy is adopted

warehouse benefits

achieving transportation economies (eg combined shipments)

achieving production economies (eg make-to stock polocy)

taking advantage of quantity discounts and forwards buys

meeting changing market conditions and uncertaunties (eg seasonality, demand fluctuations

overcoming time and space differences between producers and customers

providing temporary storage of material to be disposed or recycled (reverse logistics)

forward buys

you buy something now but only receive it later on

reverse logistics

the process of moving goods backward through the supply chain, from the customer back to the retailer, distributor, manufacturer, to recapture value through returns, repairs, recycling, refurbishment or disposal, effectively manageing the ‘after-sale’ life of a product

challenges related to warehouses

smaller orders, shorter response time, larger product variety

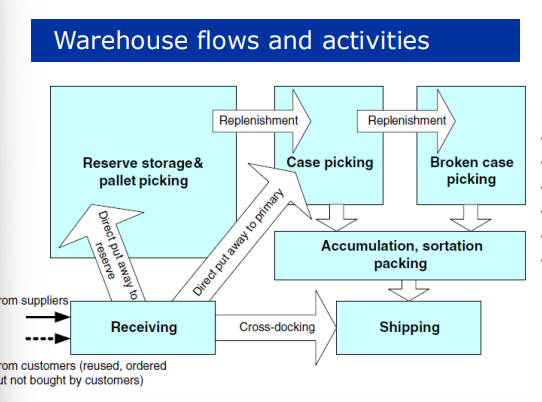

main warehousing activities

receiving

storage (transfer and put away)

order picking

accumulation/ sortation

crossdocking

shipping

warehouse management ≠ inventory management

warehouse activities : receiving

unloading products from transport carrier (typically truck)

updating inventory records

inspecting quantity / quality inconsistencies

warehouse activities : storage (transfer and put away)

transfer incoming products to storage

possibly repackaging (eg full pallets to cases or standardized bins)

warehouse activities : order picking

most labor-intensive activity in many warehouses

obtaining the right amount of the right products for a set of customer orders → many different strategies

customer orders consist of one or more order lines (= SKU in specific quantity)

warehouse activities : shipping

accumulating picked orders into individual customer orders

performing value-added services (pricing, labelling, kitting)

packing and stacking customer orders on the right unit load

operations strategy

decisions related to operations, but not likely to be changed frequently

two aspects of operations strategy

storage strategy ; where to store each SKU (stock keeping unit)

order picking strategy : how to retrieve an SKU when ordered

obective : maximize service level subject to available resources (labor, machines, capital)

what are typical measures of service level

order delivery time

order integrity

order accuracy

storage assignment : forward-reserve allocation

large reserve area (bulk stock) and small forward area (pick stock)

advantage : picking efficiency through reduced distances

disadvantage : frequent replenishment from reserve area

all SKU’s in forward area ?

how many units per SKU in forward area

storage assignment : storage location assignment policies

a set of rules which can be used to assign SKUs to storage locations

random : assign SKUs randomly to eligible empty locations

dedicated : assign SKUs to a fixed location

full-turnover storage : assign SKUs generating the highest sales closest to the depot

class-based storage : combination of turnover and random strategy

family grouping : related SKUs should be stored closed to each other

class-based storage assignment :

apply pareto’s law to devide SKU s in three classes (ABC)

dedicated storage areas for each class, but random assignment within classes

order picking systems : picker to parts :zoning

picking area divided into zones → each order picker assigned to a single zone

order picker travel smaller distances and become familiar with locations

but : different SKUs of the same order may be in different zones → split orders shoudl be consolidated before shipping

order picking systems : picker to parts zoning: consolidation strategies

progressive zoning (pick and pass) → order is picked zone by zone : it goes to the next zone when completed in previous zone

synchronized zoning → order is picked in parallel : it is merged after picking has been done in all zones

order picking systems : picker to parts : batching

in the case of small orders (few order linesà, single-order picking is ineffcient

→ order batching reduces travel distances by picking a set of orders in a single picking tour

sorting needs to be done either during or after picking tour

criteria to decide which orders are batched

proximity of pick location (eg identical pick locations, distance between pick locations)

time windows : order due time must be respected

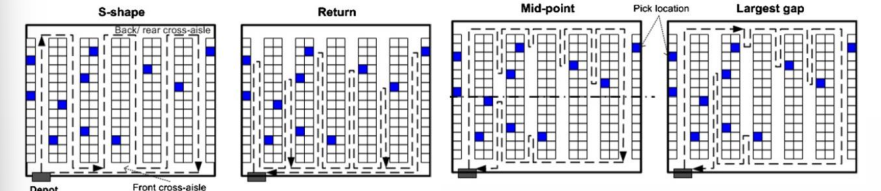

order picking systems : picker to parts : routing

pick list : list of SKUs (and their quantities) to be picked in a single order picking tour

assigned to a specific order picker

results of zoning and batching decisions

routing decisions

sequencing the items on the pick list to ensure a short route through the warehouse for the order picker

order picking systems : picker to parts : routing (different types)

s-shaped routing : works well in combination with within aisle storage

return routing works well in combination with across aisle storage or diagonal storage

mid-point routing and largest gap routing work well in combination with perimeter storage

picker-to-parts : technology

technology to support manual order picking

capital investment vs accuracy and or productivity improvements

eg scanning, voice picking, pick to light ext