DT 4.1 Properties of Materials, Study notes

1/73

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

74 Terms

Properties and characteristics of material

- Physical properties

- Mechanical properties

- Aesthetic characteristics

- Properties of smart materials

Physical properties

- Density

- Electrical resistivity

- Thermal conductivity

- Thermal expansion

- Hardness

Density

Mass per unit volume

Important when the weight of a product is a major constraint

E.g. portable, packaging, aircraft, racing cars

Electrical resistance

a measure of a material's ability to conduct electricity

(a material with low resistance will conduct well)

Thermal conductivity

a measure of how fast heat is conducted through a slab of material with a given temperature difference across the slab

Thermal expansion

a measure of the degree of increase in dimensions when an object is heated

Hardness

the resistance a material offers to penetration or scratching

E.g. ceramic floor tiles are extremely hard and resistant to scratching // bearings must be hard to avoid excessive wear

Hardness testing

The Brinell hardness test involves a tungsten carbide sphere indenter being forced into the test surface for 15 seconds; the average diameter of the indentation is then measured

The Vickers and Knopp hardness test uses a square-based diamond pyramid as an indenter, the diagonal length of the indentation being measured

The Rockwell hardness test gives a reading, via a dial, while the specimen is still under load

Mechanical properties

- Tensile and compressive strength

- Stiffness

- Toughness

- Ductility

- Elasticity/plasticity

Tensile strength

The ability of a material to withstand pulling forces

Important in selecting materials for ropes and cables e.g. an elevator

Tensile testing

materials are tested to determine suitability under tensile

E.g. machine pulls the object and elongated length is measured

Stiffness

The ability of a material to resist deflection or bending.

Important when maintaining shape is crucial to performance, e.g. aircraft wings

Toughness testing ??

Usually an impact test where a standard notched bar is fractured by a shock load

The Izod test uses a circular cantilever specimen with a V-notch

The Charpy test uses a simply supported rectangular beam with a similar shaped notch

Ductility

The ability of a material to be drawn or extruded into a wire or other extended shape

Important when metals are extruded (not to be confused with malleability)

Malleability

The ability of a material to be cold worked (i.e. hammered, pressed, folded)

The ability to be shaped plastically

E.g. copper bowl - hammering a disc of sheet copper (raising)

Mild steel is relatively malleable, e.g. car body shells (collection of cold 18 gauge sheet pressings welded together creating a rigid monocoque structure)

Aesthetic characteristics

Beauty or the appreciation of beauty

Characteristics of taste, smell, appearance, texture, and colour

Hedonic properties

Hedonism - the belief that pleasure is the highest good of life.

Taste, smell appearance, texture, feel and colour are hedonic properties humans use to decide of a product, object or place are pleasing to use.

These properties activate people's senses, responses to them vary from one individual to another and are difficult to quantify scientifically.

Hearing

Rely on sound to back up other information.

Feedback is an important part of products and systems

Sight

Reading, working, watching films and television, playing games and countless other activities.

Colour

Can influence mood or feelings

Designers deliberately use colour to make a product easier or safer to use

Switches, controls and handles can be made more obvious if they contrast

Touch

The sense that gives us notice of contact with an object

(aka tactile sense)

We learn the shape, texture and hardness of objects through this sense.

Touching gives rise to feelings of warmth, cold, pain and pressure

Smart materials

Have one or more properties that can be dramatically altered, e.g. viscosity (stickiness), volume, conductivity.

The property that can be altered influences the application of the smart material.

Range of smart materials

One of their properties can be changed by an external condition (e.g. temperature, light, pressure or electricity). This change is reversible and can be repeated many times.

Examples of smart materials

Science and technology develop standard materials (e.g. steel, aluminium, gold)

Some smart materials have the ability to change shape or size by adding a little bit of heat, or to change from liquid to solid almost instantly when near a magnet

Shape-memory alloys (SMA)

Objects that are bent can return to its original shape when heated above a certain temperature (e.g. dipped in hot water)

E.g. spectacle frames, triggers to start the sprinklers in fire alarm systems, controllers for hot water valves in showers or coffee machines

Piezoelectric materials

When squeezed rapidly, it produces a small electrical voltage for a moment. If a voltage is put across the material it makes a tiny change in shape.

E.g. contact sensors for alarm systems, microphones and headphones

Quantum-tunnelling composite (QTC)

A flexible polymer which contains tiny metal particles. It is normally an insulator but if it is squeezed it becomes a conductor

E.g. membrane switches on mobile phones, pressure sensors and speed controllers

Electroluminescent materials

Give out light when an electric current is applied to them

E.g. safety signs, clothing for use at night

Thermochromic materials (colour-change material)

Changes colour as the temperature changes. Used on contact thermometers made from plastic strips and test strips on the side of batteries (where the heat comes from a resistor under a thermochromic film)

E.g. food packaging materials (shows when the product is cooked to the right temperature)

Photochromic materials (colour-change material)

Change colour according to different lighting conditions.

E.g. security markers that can only be seen in UV light

Magnetorheological fluid (MR fluid)

Usually a type of oil

When subjected to a magnetic field, the fluid greatly increases its apparent viscosity.

Yield stress can be controlled very accurately by varying the magnetic field intensity

The fuild's ability to transmit force can be controlled with an electromagnet (gives rise to many possible control-based applications)

Young's modulus

Measure of the stiffness of an elastic material

Can be experimentally determined from the slope of a stress-strain curve created during tensile tests.

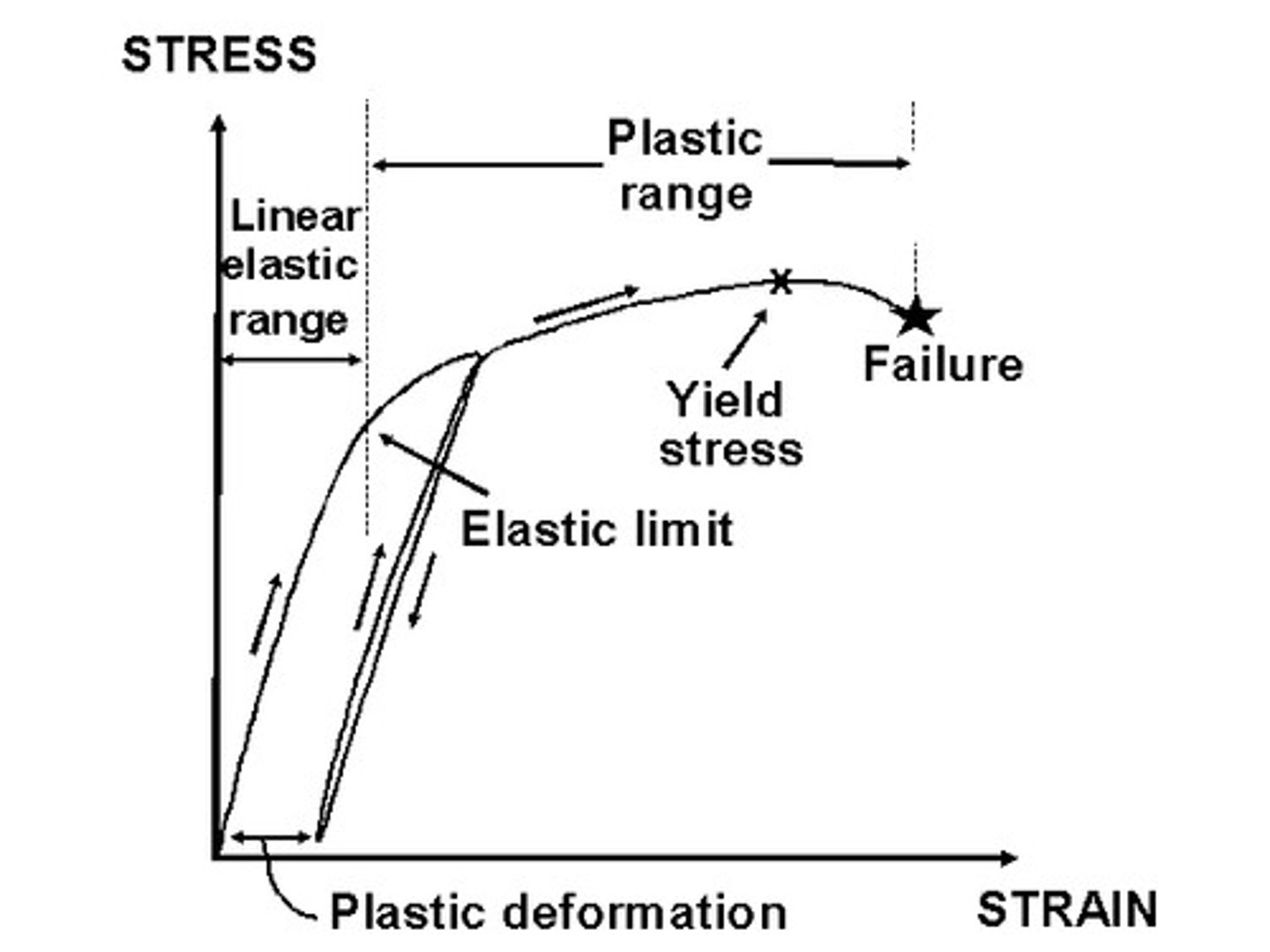

Stress-strain curve

Unique for each material, found by recording the amount of deformation (strain) at distinct intervals of tensile or compressive loading.

Stress-strain curve

(image)

Stress-strain curve typical of...

- ultimate strength

- yield strength

- rupture

- strain hardening region

- necking region

A: apparent stress

B: actual stress

Yield stress

The stress at the yield point on the stress/strain graph

Beyond the yield point, the material undergoes plastic deformation.

Mass (pp)

the amount of matter in an object

Weight (pp)

the force of gravity on an object

weight = mass x acc. of gravity

Volume (pp)

the amount of dimensional space an object occupies

Density (pp)

the mass per unit volume of a material

density = mass x volume

--> important in relation to product weight and size eg. food packaging

Electrical Resistivity (pp)

a measure of a materials ability to conduct electricity

--> low resistivity will conduct electricity well

--> conductors or insulators eg. copper

Thermal Conductivity (pp)

a measure of how fast heat is conducted through a slab of material with a given temperature difference across the slab

eg. cooking utensils

Thermal Expansion (pp)

a measure of the fractional increase in dimensions when an object is heated

eg. oven doors

Hardness (pp)

the resistance a material offers to scratching, cutting, denting or penetration

Strength (mp)

ability of a material to resist an applied force and it is identified as either tensile or compressive strength

Tensile Strength (mp)

the ability of a material to withstand pulling forces

Compressive Strength (mp)

the ability of a material to withstand pushing forces

Stiffness (mp)

the ability of a material to resist a bending deformation

Toughness (mp)

the ability of a material to resist a propagation of cracks

Ductility (mp)

the ability of a material to be drawn or extruded into a wire or other extended shape

Elasticity (mp)

the ability of a material to be deformed and return to its original size and shape

Plasticity (mp)

the ability of a material to undergo permanent deformation

Young's Modulus (mp)

youngs modulus = stress/strain

Aesthetic Characteristics

smell, appearance, taste, texture

Smart Materials

have properties that react and respond to changes in their environment, meaning that one of their properties can be changed by an external condition eg. temp or light, the change is reversible.

1. Piezoelectricity

2. Shape Memory Alloys

3. Magneto-Rheostatic & Electro-Rheostatic

4. Photochromicity

5. Thermoelectricity

Piezoelectricity

when a piezoelectric material is deformed, it gives a small but measurable electrical discharge, contrastingly, when an electrical current is passed through a piezoelectric material it experiences a significant increase in size

eg. sensors/airbags

Shape Memory Alloys

alloys that return to their programmed shape, they exhibit pseudoelasticity and shape memory effect due to the rearrangement of molecules in the material

pseudoelastic springs back to its original shape, eg. eye glass frames

shape memory effect needs a change in temperature eg. robotic limbs

Magneto-Rheostatic & Electro-Rheostatic

MR and ER materials are fluids that , undergo a dramatic change in viscosity

they can change from a fluid to a solid in seconds depending on the magnetic or electric field, and the effect is reversed when the field is removed

mr - car shock absorbers, prosthetic limbs

er - clutches and valves

Photochromicity

react reversibly to light by changing their color eg. color changing lenses

Thermoelectricity

electricity produced directly from heat

Density

Object's mass per unit volume as a property

Electrical Resistivity

How strongly a material reduces the flow of an electrical current. Low resistivity indicates a material easily allows the movement of an electric charge

Thermal Conductivity

K, the property of a material that indicates its ability to conduct heat

Thermal Expansion

Tendency of matter to change in volume in response to a temperature change. Constituent particles move around once heated and the more the motion, the more it maintains greater average separation

Hardness

Resistance of metal to plastic deformation, usually by indentation. Also refers to stiffness or temper, or to resistance to scratching, abrasion, or cutting

Tensile Strength

Resistance of a material to a force without tearing

Stiffness

Resistance of an elastic body to deformation by an applied force

Toughness

Resistance to fracture of a material when stressed

Ductility

The extent to which materials can be deformed plastically without fracture

Taste

Ability to detect the flavor of substances

Smell

Ability to perceive odours

Appearance

Visual appearance of objects by the way in which they reflect and transmit light

Texture

Properties held and sensations caused by external surface of objects registered by sense of touch

Colour

Visual perceptual property determined by the parts of the spectrum of light reflected or transmitted without being absorbed