process improvement practice

1/27

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

28 Terms

Achieve no more than 3.4 defects per million opportunities (DPMO) by reducing variation and eliminating process defects.

What is the goal of Six Sigma?

six sigma

A data-driven, statistically based approach that uses the DMAIC method to improve processes, eliminate defects, and produce measurable financial returns.

Motorola

Who pioneered and popularized Six Sigma?

key players in six sigma

champions

master black belts

black belts

green belts

yellow belts

yellow belts

entry-level

produce empirical results or effective information collectors

report issues to upper-level experts

beginners w/ some general six sigma knowledge

basic principles, fundamental quality tools

green belts

in less critical projects, they can be group leaders

trained in basic quality tools and work in teams

knowledgeable within the problem-solving model of DMAIC

obtain empirical results and make actual transformation

process mapping, hypothesis testing

black belts

full time project leaders on six sigma project

spend about two years as a black belt

significant and statistics training accomplished

project review measurement, multiple regression

master black belts

full-time, cross-functional, in-house six sigma

experts / consultants / coaches

identified by champions

experienced black belts serve as mentors and trainers

optimization experiments, advanced regression methods

champions

senior level or executive managers

establish six sigma vision

work with black belts to identify possible projects

provides continuing support for the project and validates the results at end of project

cultivate six sigma culture

DMAIC methodology

define

measure

analyze

improve

control

define

project selection

validate problem statement

business impact and goal statement with key metrics

measure

understand the current process status

measure current performance

assess process capability for baselines

analyze

analyze the process flow data and identify bottleneck points with problems

generate theories to explain potential causes, focusing on why defects, errors, or excessive variation occur

experimentation and verification of root causes

improve

generate potential solutions to address the root causes

evaluate solutions

develop a “to be” value stream map of the redesigned process

implement pilot solutions and compare results to baseline

develop and execute a full-scale implementation plan

control

complete the project and hand off the improved process to process owner

finalize the control system with revised procedures

maintain improvements

Maximize customer value by eliminating waste and improving process flow.

What is the goal of Lean?

Just-In-Time System (JIT)

Producing and delivering goods only when needed, in exact quantities, to reduce inventory and expose system problems.

T ransportation

I nventory

M otion

W aiting

O verproduction

O ver-processing

D efects

S kills (under-utilized talent)

What are the eight wastes (TIMWOODS) in Lean?

specify value in the eyes of the customer

identify the value stream and eliminate waste

use a pull system that is triggered by the customer

involve and empower employees

pursue continuously improve (Kaizen & 5S — short, straighten, stnadardize, and sustain)

Steps to Create a Lean Enterprise

Sort, Straighten, Shine, Standardize, Sustain

What is 5S in Lean?

kanban

Japanese word meaning “card” or “visible record” that refers to cards used to control the flow of production through a factory and to ensure just-in-time

Visual Management

The use of visual cues (colors, markings, charts) to monitor process status, manage flow, and ensure transparency.

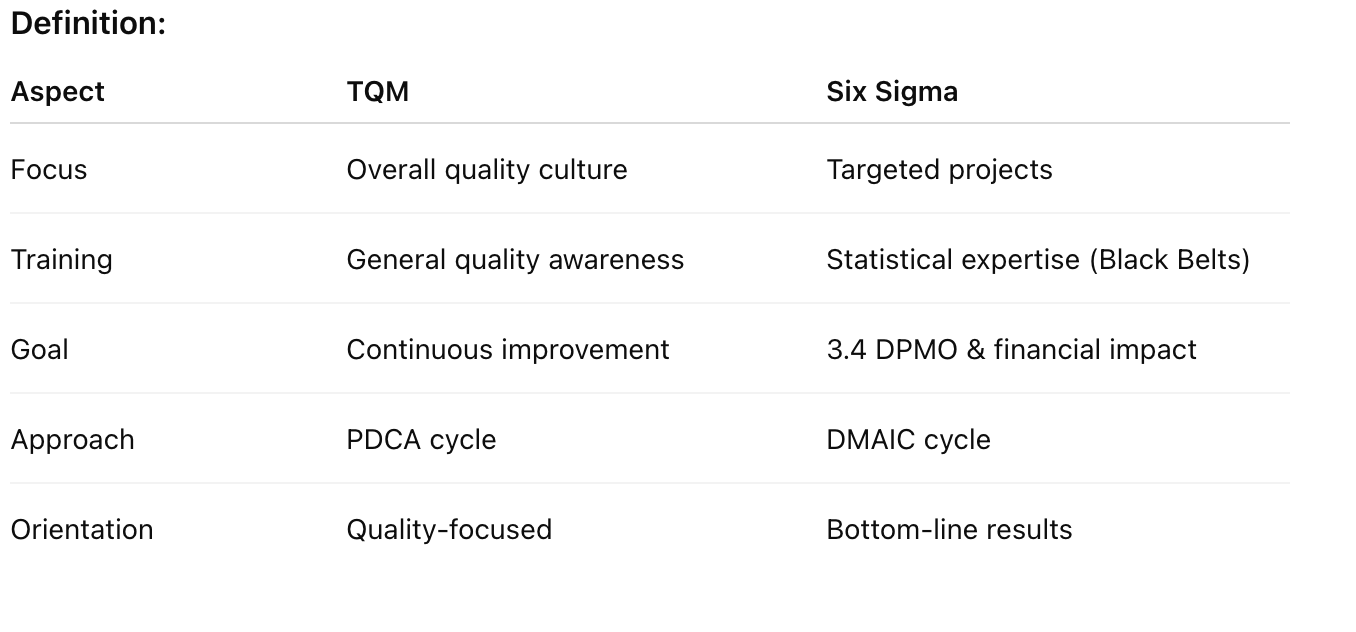

Lean Vs. Six Sigma

Lean: Removes waste, improves flow, and shortens lead time

Six Sigma: Reduces variation and defects through data analysis

Lean Six Sigma

Combines Lean’s waste elimination with Six Sigma’s data-driven problem solving for a comprehensive improvement approach.

Lean: Visible process issues (inventory, flow, safety)

Six Sigma: invisible issues (variation, inconsistency)

What does Lean address vs Six Sigma?

Lean: PDCA cycle, value-stream analysis, pull system

Six Sigma: DMAIC framework

What tool or philosophy guides each?

PDCA cycle

continuous improvement

more flexible and adaptable

faster and simpler

relies on trial and error

less data-driven

DMAIC

data-driven analysis and rigorous planning

more rigorous and structured

root-cause analysis

through and complex

require more resources and time

too complex for smaller-scale improvements