Business GCSE topic 2.3 - Making operational decisions

1/44

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

45 Terms

Purposes for business operations

To provide services

To produce goods

Types of production processes

Job

Flow

Batch

Job Production

Single product is made at a time

Products made for specific client and is high quality

Higher prices can be charged

Advantages of Job Production

Unique → Tailored to customers measurements and specifications

Less absenteeism → More motivated workers who are more productive

Higher prices charged

Disadvantages of Job Production

High labour costs → Skilled labour are expensive

Expensive to buy necessary equipment → Increase cost of products

No economies of scale → One person making that product

Economies of scale

Cost advantages that a business can exploit by expanding their scale of production

Batch Production

Small quantities of identical products are made

Used when business wants to make more than one item (ie → Bread factory makes crumpets and tortillas)

Advantages of Batch Production

Flexible → Production can change to meet customer needs or fluctuation in demand

Less labour involved → Due to the standard production of items through machines

Specialisation → Employees specialise in their areas to become good at their job

Disadvantages of Batch Production

Repetitive → Monotonous work so workers may be demotivated leading to inefficient productivity

If one batch takes too long, other batches will all be held up

Idle time between batches need to be managed as this is wastage as work stops while machines are changed to make the next product

Flow Production

Continuous movement of items through the production process.

Large numbers of the same goods are produced continuously in this production process.

Often an opportunity for a high level of automation on a flow production assembly line.

Advantages of flow production

Economies of scale can be achieved as cost per unit will be low

Automated assembly lines save time and money

Quality systems can be built into the production at each stage

Disadvantages of flow production

Standardised product produced

High initial set-up costs of automated assembly lines

Workers find work repetitive and boring

Logistics

Commercial activity of transporting goods to customers

Stocks

A share in the ownership of a company

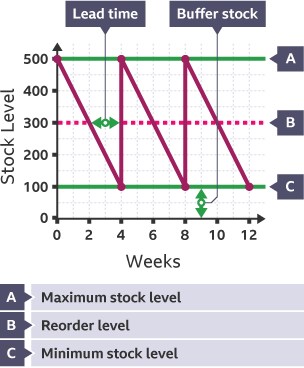

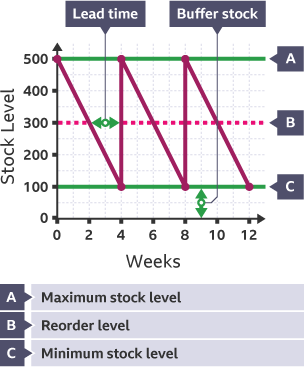

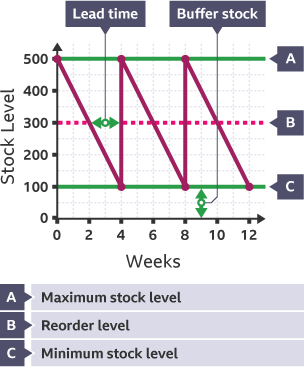

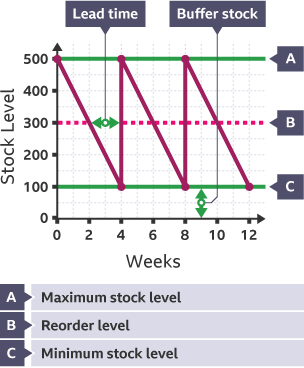

Bar gate stock graph

Graph which gives a business a plan to make sure they do not run out of stock to sell

Diagram helps business to plan when to order more stock

High stock holding

Massive storage space and huge insurance along with a larger amount of manpower and warehouse maintenance cost.

Problems with high stock holding

Expensive and adds cost to business reducing profits

Business can be left with unwanted stock making it hard to compete on price due to stock holding costs

Parts of a bar gate stock graph

Max Stock Level

Re order Level

Min Stock Level

Lead time

Max Stock Level

Most a business can store in a shop or warehouse and business can’t share more stock as they don’t have space and will go out of date

Reorder Level

Level of stock in a business that should signal when it is time to reorder

Min Stock Level (Buffer Stock)

Least a business should store, any less and they will run out and won’t keep up with demand

Lead time (Delivery time)

How long it takes from ordering stock for it to arrive

Just in time stock control

Business doesn’t keep stocks of parts in a warehouse but instead they order the parts and get them delivered the same day from the supplier

How to make JIT to work

Manufacturer needs to have great relationships with their smaller parts supplier

Times when JIT doesn’t work

Quality issues

Delivery issues

Advantages of JIT

Parts are ordered when needed so no wastage

Parts aren’t warehoused so costs are saved

Stocks less likely to be out of date

Business cash flow will improve

Disadvantages of JIT

Unable to meet unpredicted surges in demand

Unable to replace damaged parts quickly

Late delivery stops whole production line

Procurement

Where business buys raw materials, components, products, services from suppliers to make their own products/services

Relationships with suppliers on quality

Business wants its suppliers to sell them the best possible quality products for the price

Relationships with suppliers on delivery

Some businesses may wish to enter into JIT agreement with a supplier involving number of deliveries being made a day

Relationships with suppliers on availability

There’ll be problems if the stock isn’t available which may stop production entirely and if products are still out of stock, customers will shop elsewhere

Relationships with suppliers on cost

Both sides want deal to last a long time to reduce costs of having to find another supplier or customer or renegotiate another deal

There’ll be initial costs in setting up agreements such as administration

Relationships with suppliers on trust

Important for joint problem solving and open communication between the businesses which is what makes a great relationship.

Trust is built through reliable deliveries and quality products/services

Quality

Measure of excellence or a state of being free from defects, deficiencies and significant variations

Ways to preserve quality

Quality Control

Quality Assurance

Quality Control

Inspectors check standards have been met at end of production process:

Standards consistent ensuring quality standards are met

Customer doesn’t receive a sub-standard product

Advantages of Quality Control

Controlling quality means less wastage

Less wastage means lower cost of production

Disadvantages of Quality Control

Faulty goods means costly wasted resources/materials

Could be a lot of waste as the fault is only identified at end of production process

Quality Assurance

Building quality into every stage of production process and isn’t left until the end

When product is sold, business can assure customer it’s a quality product

Each worker is responsible for making sure that the work they do meets quality standards

Advantages of high quality products

Differentiate products from competition increasing product range → Bring more customers → Increase brand awareness → Brand loyalty → Charge premium price for product → Increase sales revenue

Disadvantages of high quality products

Extra quality control checks → Employee specialisation training needed → Cost per unit increases → Reducing profits

Steps of the sales process

Product knowledge

Speed and efficiency of service

Customer engagement

Response to customer feedback

Providing good customer service

Product knowledge

Understanding features allows sales person to present their benefits accurately and persuasively

Customers respond to enthusiastic sales staff who’re passionate about their products and eager to share the benefits with them

Speed and efficiency of service

Customers expect a fast service with the correct order

Customer engagement

An effect, reaction, response, experience of customers with one another, with a company or brand

The initiative for engagement can be either consumer or company led and the medium of engagement can be on or offline