Principles of Business Management Midterm Study Guide

1/51

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

52 Terms

Computer Aided Design (CAD)

Using computers to design products and prepare engineering documentation

Shorter development cycles, improved accuracy, and lower cost

Info and designs can be deployed worldwide

Benefits of CAD/CAM

Product quality

Shorter Design Time

Production cost reductions

Database availability

New range of capabilities

Virtual Reality Technology

A visual form of communication in which images substitute for reality and typically allow the user to respond interactively

Allows people to ‘see’ the finished design before a physical model is built

Very effective in large-scale designs such as plant layout

Product Decision

Develop and implement a product strategy that meets the demands of the marketplace with a competitive advantage

Product Strategy Options

Differentiate

Shouldice Hospital

Low Cost

Taco Bell

Rapid Response

Toyota

Product decisions have major implications throughout the operations function

GM’s steering columns

Tesla Model 3 vs Model Y

Product Life Cycle- Growth Phase

Product design begins to stablize

Effective forecasting of capacity becomes necessary

adding or enhancing capacity may be necessary

Product Life Cycle- Decline Phase

unless the product makes a special contribution to the organization, management must plan to terminate the offering

Social Entrepreneurship

Found its roots in the 1980s when businesses began to realize that their customers care about specific social issues

Social entrepreneurs measure success by the positive impact they have made in the community in the long run

Why entrepreneurial ventures fail

lack of effective planning

insufficient capital

poor management

lack of customer interest

obtaining financing

personal funding

family and friends

bank loans

venture capital

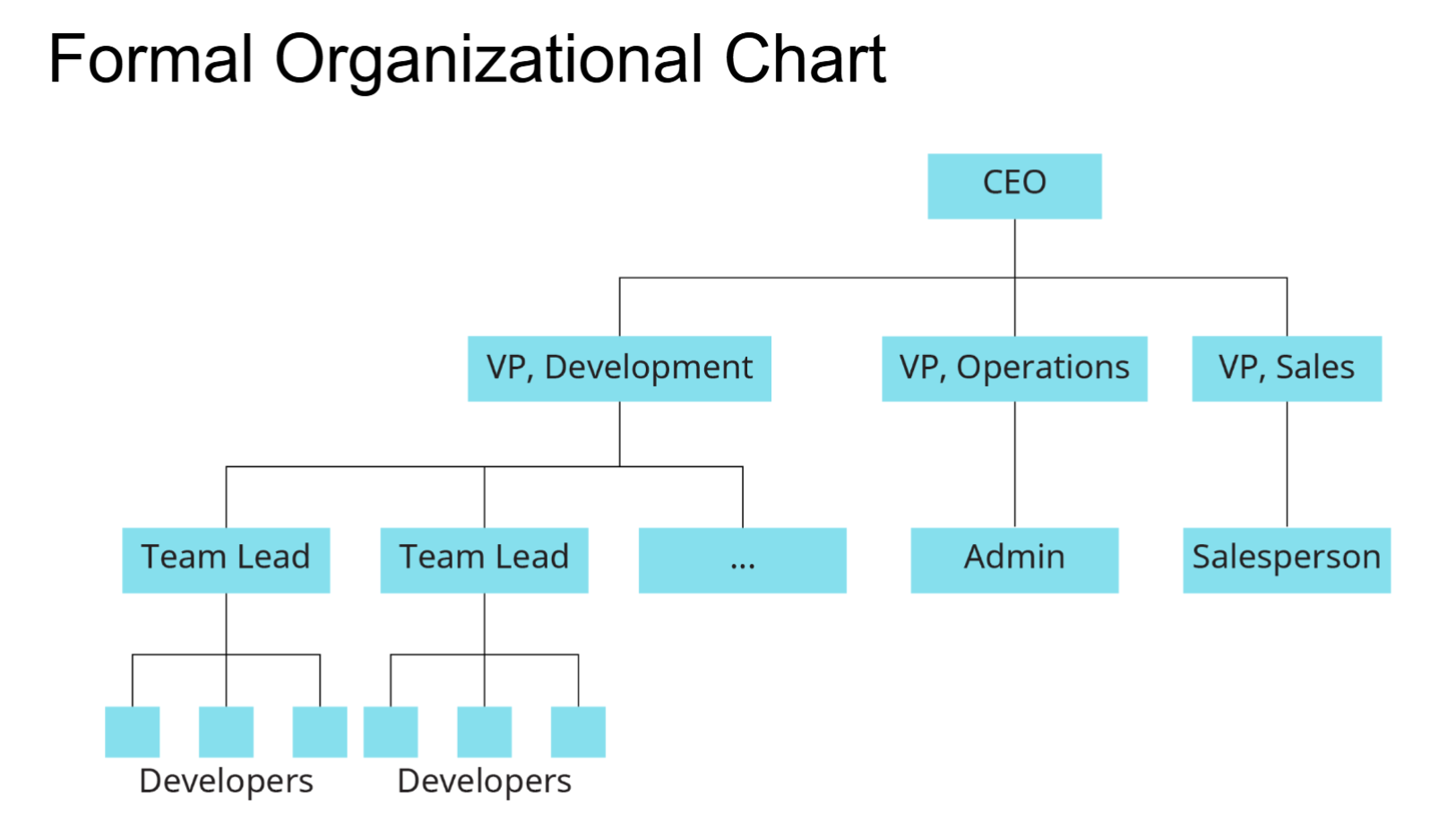

Formal Organizational Chart

How an organization’s culture, structure, and HR practices Support strategic implementation

Organizational Culture

shared assumptions that affect how work gets done

who reports to whom and who does what

HR Practices

How the organization manages its talent

Leadership creates alignment among culture, structure, and HR practices

Business Acumen

The skill to understand and manage business situations for positive outcomes and success

Business Acumen for Students

Helps student interpret data, forsee market trends, and engage in strategic decisions. Increases your potential value to employers if you show an understanding the elements of bus. acumen

Elements of Business Acumen

Strategic thinking, decision making, financial literacy, adaptability, market awareness, leadership, communication skills, problem solving, customer focus, operational understanding

What is Forecasting?

the art and science of predicting future events

underlying basis of all business decisions

production, inventory, personnel, and facilities

Forecasting Time Horizons- Short Range

Up to 1 year

purchasing, job scheduling, workforce levels, job assignments, production levels

Forecasting Time- Medium Range

3 months to 3 years

Sales planning, production planning and budgeting, cash budgeting, and analysis of various operating plans

Forecasting Time- Long range

3+ years

new product planning, facility location or expansion, capital expenditures, research and development

Forecasting Approach- Qualitative methods

used when a situation is vague

new products and technology

involves intuition, emotions, personal experiences, and value systems

Forecasting Approach- Quantitative Methods

Used when the situation is ‘stable’ and historical data exists

Existing products, current tech

involves mathematical techniques

Random Component

“Blips” in data caused by chance and unusual situations

follow no discernible pattern

cannot be predicted

Naive Approach

Assumes demand in next period is the same as demand in most recent period

phone sales in January will be the same in February

Sometimes cost effective and effecient

Can be a good starting point for comparison w/ more sophisticated models

Process Strategy

an organization’s approach to transforming resources into goods and services

The objective is to create a process to produce offerings that meet customer requirements within cost and other managerial constraints

repetitive focus

facilities often organized as assembly lines

characterized by modules with parts and assemblies made previously

modules may be combined for many output options

less flexibility than process-focused facilities but more effecient

product focus

facilities organized by product

high volume but low variety products

long, continuous production runs enable efficient processes

typically high fixed cost but low variable cost

generally skilled labor

benefits of VMI

•Reduced stockouts and overstocking.Improved inventory turnover and cash flow.

•Stronger vendor-customer relationships through collaboration.

•Lower administrative costs for the customer (less need to place frequent orders).

•Common Industries Using VMI:

•Retail (e.g., Walmart pioneered VMI with suppliers like Procter & Gamble).

•Manufacturing, Healthcare, Automotive.

Centralized Purchasing

One department at Corporate purchases for all locations

leverage volume

develop specialized stuff

develop supplier relationships

maintain professional control

maintain professional control

devote resources to selection and negotiation

reduce duplication of tasks

promote standardization

logistics managements

•Objective is to obtain efficient operations through the integration of all material acquisition, movement, and storage activities

•Is a frequent candidate for outsourcing

•Allows competitive advantage to be gained through reduced costs and improved customer service

airfreight

fast and flexible for light loads

may be expensive

uses passenger aircraft

cost and speed of shipments

Faster shipping is generally more expensive than slower shipping

Faster methods tend to involve smaller shipment sizes, while slower methods involve very large shipment sizes

third-party logistics 3PL

•Outsourcing logistics can reduce inventory, costs, and improve delivery reliability and speed

•Coordinate supplier inventory with delivery services

•May provide warehousing, assembly, testing, shipping, customs

establishing sustainability in supply chains

return or reverse logistics

sending returned products back up the supply chain for resale, repair, reuse, remanufacture, recycling, or disposal

closed-loop supply chain

proactive design of a supply chain that tries to optimize all forward and reverse flows

prepares for returns prior to product introductions

sales and operations planning

elements of an aggregate plans

• Coordination of demand forecasts with functional areas and the supply chain

• Typically done by cross-functional teams

• Determine which plans are feasible

• Limitations must be reflected

• Provides warning when resources do not match expectations

the objective of aggregate planning is usually to meet forecast demand while minimizing cost over the planning period

capacity options: changing inventory levels

–Increase inventory in low demand periods to meet high demand in the future

–Increase costs associated with storage, insurance, handling, obsolescence, pilferage, and capital investment

–Shortages may mean lost sales due to long lead times and poor customer service

capactiy options: varying workforce size by hiring or layoffs

Match production rate to demand

Training and separation costs for hiring and laying off workers

New workers may have lower productivity

Laying off workers may lower morale and productivity

capacity options: varying production rates through overtime or idle time

–Allows constant workforce

–May be difficult to meet large increases in demand

–Overtime can be costly and may drive down productivity

–Absorbing idle time may be difficult

capacity options: subcontracting

Temporary measure during periods of peak demand

May be costly

Assuring quality and timely delivery may be difficult

Exposes your customers to a possible competitor

demand options

backordering during high-demand periods

requires customers to wait for an order without the loss of goodwill or the order

backordering during high-demand periods

requires customers to wait for an order without loss of goodwill or the order

most effective when there are few, if any, substitutes for the product or service

Often results in lost sales

revenue management

allocating resources to customers at prices that will maximize revenue or yield

service or product can be sold in advance of consumption, demand fluctuates

relativity fixed resource (capacity)

segmentable demand

low variable costs; high fixed costs

defining quality

build a total quality management system that identifies and satisfies customer needs

costs of quality

prevention costs- reducing the potential for defects

apprasial costs- evaluating products, parts or service before delivery

external failiure costs- defects discovered after delivery

total quality management

•Encompasses entire organization from supplier to customer

•Stresses a commitment by management to have a continuing companywide drive toward excellence in all aspects of products and services that are important to the customer

continuous improvement

•Never-ending process of continuous improvement

•Covers people, equipment, suppliers, materials, procedures

•Every operation can be improved

•End goal is perfection, which is never achieved but always sought.

•Kaizen describes the ongoing process of unending improvement

•T Q M and zero defects also used to describe continuous improvement

six sigma

two meanings

–In a statistical sense, it describes a process, product, or service with an extremely high capability

–A program designed to reduce defects, lower costs, save time, and improve customer satisfaction

•A comprehensive system for achieving and sustaining business success

•Originally developed by Motorola, adopted and enhanced by Honeywell and G E

•Highly structured approach to process improvement

•A strategy

•A discipline – D M A I C

•A set of 7 tools

six sigma 2

•Defines the project’s purpose, scope, and outputs, then identifies the required process information keeping in mind the customer’s definition of quality

•Measures the process and collects data

•Analyzes the data, ensuring repeatability and reproducibility

•Improves, by modifying or redesigning, existing processes and procedures

•Controls the new process to make sure performance levels are maintained

benchmarking

selecting best practices to use as a standard for performance

1.Determine what to benchmark

2.Form a benchmark team

3.Identify benchmarking partners

4.Collect and analyze benchmarking information

5.Take action to match or exceed the benchmark

Just-in-Time (JIT)

•’Pull’ system of production scheduling including supply management

–Production only when signaled

•Allows reduced inventory levels

–Inventory costs money and hides process and material problems

•Encourages improved process and product quality

TQM tools

•Tools for Generating Ideas

Check Sheet

Scatter Diagram

Cause-and-Effect Diagram

Tools to Organize the Data

Pareto Chart

Flowchart (Process Diagram)

Tools for Identifying Problems

Histogram

Statistical Process Control Chart

source inspection

Poka-yoke is the concept of foolproof devices or techniques designed to pass only acceptable products