A1 - Food production and processing

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

20 Terms

Three types of food industry

Fresh food production

Ingredient production

Product assembly

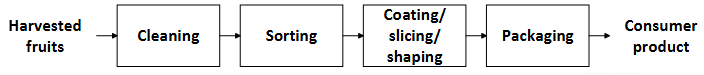

What is Fresh Food production?

The converting of freshly harvested products into consumer products

Steps of fresh food production

Harvested fruits

Cleaning

Sorting

Coating/slicing/shaping

Coating with wax for example. This prevents moisture from diffusing out of the apple.

Also relevant for amount of Kg in supermarkets.

Packaging

Consumer product

Steps of fresh food production (canning)

Fruits

Cutting

Packaging

Heating

Canned product

Can be kept for a long time

What is ingredient production?

The converting of freshly harvested products into ingredients.

Ingredients = not directly consumed

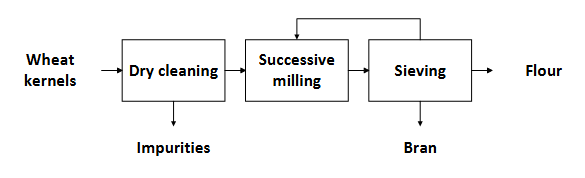

Steps of ingredient production

Example of wheat kernels → flour

Milling is for separating bran (hard part of wheat) from the rest.

General steps of ingredient production

Cleaning or purification of raw material

Preparation for fractionation (e.g. peeling)

Fractionation (sometimes by using sifting, often by dissolution)

Purification (separation from contaminants) and concentration)

Stabilization

Waste steam/side stream

Waste that is not used for further production. Often used for cattle feed.

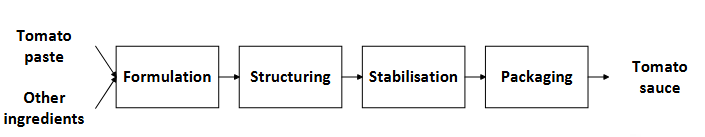

What is product assembly?

Purchasing ingredients to assemble it into consumer products

Example steps of product assembly

The four types of unit operations

Separation - into 2 or more streams

Conversion - changing the composition

Structuring - changing the way that ingredients are positioned

Stabilization - preservation and packaging

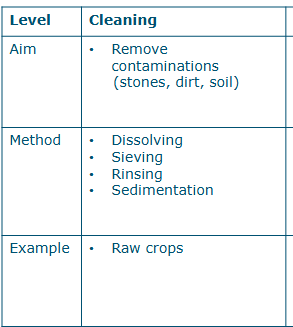

Aim, method and example of cleaning in separation (unit operations)

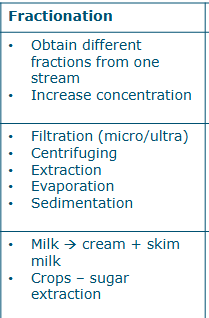

Aim, method and example of fractionation in separation (unit operations)

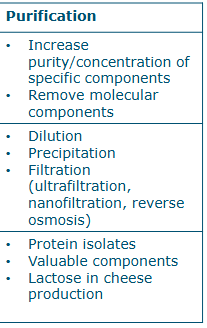

Aim, method and example of purification in separation (unit operations)

Conversion (unit operations)

Changing molecular composition

Fermentation

Acidification/neutralization (pH change)

Reactions (enzyme, heating, gelatinization)

Inactivation (microbial, enzyme)

Structuring (unit operations)

Changing the way that ingredients are positioned

mixing ingredients to the right formulation

Baking bread, cake, cookies

Emulsification (homogenization)

Crystallization

Freezing

Drying

Lots of phase changes

Don’t have to remember all this, just recognize that it has something to do with structure

Food stabilization/food preservation (unit operations)

Reduction of water activity, antimicrobial composition

salting, sugar addition

Drying

Fermentation, acidulation, causticity

Hurdle technology

Thermal preservation

Heating: pasteurization, sterilization, UHP

Cooling: chilling, chilled chain

Freezing: related to lower aw

Non-thermal preservation

high hydrostatic pressure

Pulsed electric fields

Magnetic fields, UV, light pulses

Block chart

Process: rectangle represents a process

Arrow: line that connects material flows between processes

Text: Shows input and output material

Blanching

When fruits and vegetables are heated to 100C for a few minutes. This will inactivate enzymes and micro-organisms on the outside of the product.

Production chain of meat

Animals are slaughtered

Meat is aged for a few days at lower temperature allowing glycogen to be metabolized into lactic acid.

Proteolytic enzymes partially break down the cellular structure, which allows the meat to become tender.

Waste meat is turned into sausages, canned meat or processed into ground meat

Bones are used for broths

Meat is frozen after processing