Manufacturing Management

1/231

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

232 Terms

Description of Capital vs return on investment

Assessment of length of time an investment takes to pay back

Trade-off for Capital vs return on investment

Cost vs time and quality

Cycle time

the length of time a part spends at each workstation

Utilisation of a plant

Measurement of proportion of available plant time that is spent generating value - linked to capacity

Trade-off of Utilisation of plant

Time vs cost and quality

Description of Capacity versus responsiveness to demand

Capacity is the theoretical maximum volume of production - spare capacity allows faster response to orders

Trade-off for Capacity versus responsiveness to demand

Time vs Cost

Description of Inventory vs responsiveness to demand

Inventory is the amount of manufacturing material kept on site - more inventory allows faster response to orders

Trade-off of Inventory vs responsiveness to demand

Time vs Cost

Efficient use of resources allows

Simultaneous improvement of cost, time and quality

Effective use of resources allows

Survival and growth of the business

What are the transforming resources in a manufacturing business?

a) Components and raw materials

b) Plant and raw materials

c) Plant and staff

d) Staff and raw materials

c) Plant and staff

low volume processes produce a ______ variety of product

high

High volume processes produce a _____ variety of products

low

The approach to managing an individual process depends where it falls on the _______________ spectrum

Volume-variety

Production process groups examples

Mass production

Batch production

Job production e.g. consultancy companies

Project e.g. buildings, bridges

Project processes

Discrete, highly customised products

Dedicated resources

Long production timescale

e.g. buildings, bridges, large infrastructure

Job shops

Generally similar but may be one-offs

Shared resources

High skill level

e.g. tooling, patterns

Batch production

1+ item at a time produced

Processes repeated

Processes similar to job shop but management is different

Wide range of volumes

e.g. machine tools, automotive components, customised electronics

Mass production

High volume, relatively low variety

Variants possible if do not affect basic process flow

Highly repetitive and predictable

e.g. car factories, consumer electronics

Set up time

time it take to set-up machine so as to switch production from one product to another

e.g. through changing of tooling

Work in Progress (WIP) Inventory

The amount of unfinished product on the shop floor

Control

The ability of management to know and control the state of production at any given moment

Throughput time

The length of time it takes a single product to undergo all stages of production

Utilisation

The proportion of available plant time that is spent generating value

Advantages of Batch manufacturing

Set up time - only needs to be set up once

Flexibility - Wide variety of products and volumes can be handles without changes to the process layout

Disadvantages of Batch manufacturing

High throughput time whole batch processed at each step

High WIP Inventory

Process layouts

Different layouts of machines and staff for the most efficient processing of product depending on the production

3 main types of process layouts

Product Layout

Process Layout

Hybrid Layout

Process layout

Low volume and job shop manufacturing

High flexibility but complex product flow paths

Load distance calcs used to find optimum layout

Advantages of product layout

Smooth product flow

Short throughput

Low WIP inventories

Product layout

Generally used for high volume manufacturing. Has the advantage of simple product flow but is inflexible. Precedence diagrams and line balancing can be used to find the optimum layout.

Disadvantages of product layout

Low flexibility for intro of new product design

Any work interruption stops wholes process

Advantages of Hybrid Layout (Group Technology)

High Utilisation

Short throughput time

Reduced machine set-up time

Low WIP inventories

More flexible than product layout

Hybrid layout

generally used for medium to high volume batch manufacturing

Disadvantages of Hybrid Layout (Group Technology)

Less flexible than process layout

More complex to control than product layout

Group Technology

Grouping together or parts or products into families by processing operations

Influence of group technology on manufacturing industry

Simplifying parts

Standardisation of processes

Visibility of part in flow production

Manufacturing Flexibility

The capability of producing different parts without major retooling

How fast a company can changes its processes from old product to new

Operational Flexibility

Efficiently produce highly customized and unique products

Customer Flexibility

Exploit various dimensions of speed of delivery

Strategic Flexibility

A company to offer a wide variety of products to its customers

Capacity Flexibility

Rapidly increase or decrease production levels or to shift capacity quickly from one product or service to another

Examples of automated operations tasks

Programmed control of manufacturing operations

Storage

Automated transfer of parts between storage and production machines

Identification of parts

Orientation of parts

Loading and unloading of parts

Automated operation cycle

Examples of Automated setup tasks

Changeover of programmes

Tool and fixture storage

Transfer of tools and fixtures between storage and production machines

Automated tool and fixture changeovers

Flexible Manufacturing Systems (FMS)

-two or more cells doing different tasks

Can be thought of as an automated cell

High level of system automation

Wide variety of parts

Simultaneous manufacture of different parts

Flexible

High capital investment

e.g. aerospace industry and machine tool builders

Flexible Manufacturing cells (FMC)

-Two or more CNC machines doing similar tasks

-Multiple machines with similar capability

-Wide variety of parts

-Machines can be reconfigured to manufacture different parts

-High level of automation

-High capital investment

-e.g. repetitive part manufacturing environments

Advantages of FMS

Faster, lower - cost changes,- improved capital utlisation

Lower direct labour cost (reduction in no. of workers)

Reduced inventory (planning and programming precision)

Consistent and better quality (automated control)

Lower cost/ unit of output

Savings from indirect labour (reduced errors)

Disadvantages of FMS

Limited ability to adapt to changes

Substantial pre-planning activity

Expensive, costing millions

Dedicated Transfer Lines (DTL)

e.g. conveyors, robots

High volume of manufacture of a limited range of parts

Low flexibility

High reliability required

Agile systems

High volume of a limited range of parts

Agility in response to part variety changes

Routing flexibility

Breakdowns have limited effect on production

Equation for desired cycle time

C = time period / planned output

Equation for theoretical minimum number of workstations

TM = time for all operations / c

Equation for Utilisation %

(total work content x 100) / (No workstations x cycle time)

Equation for balancing delay%

100 - utilisation

Steps for designing a hybrid layout

Group parts that share common processes

Groups of processes form manufacturing cells

Deal with remaining processes

i. Duplicate process

ii. Use process layout

iii. Allow part to visit more than one cell

What is production planning

Deciding

-What product, amount, when

Scheduling

Planning

Why is a formal planning process needed

Align production activities and business plans

Ensure business plans are realistic

Handle complexities and large amounts of data

Use production resources efficiently while meeting constraints

Ensure resources are available when needed

Provide a plan against which progress can be measured

Aggregate planning is…

The task of identifying plans to produce products, expressed in specific quantities and dates, to fulfil a series of anticipated product demands and customers orders

MPS

Master Product Schedule

A Master Production Schedule is for

planning horizons which contains required production quantities for a specific product type together with the desired completion date

MPS must seek to reconcile the many requirements of the company functions such as

Sale requirements

Financial requirements

Production requirements

Resources and labour requirements

Patricks def of MPS is

Something which is related to time

Time is the key word

Date

Product

Quantity

We will make x many of y products for the zth of month

The production scheduling function is a combination of a number of tasks such as

-lot sizing

-process routing

-dispatch/loading

-sequencing

-works order generation

Common production scheduling constraints are to

Meet delivery dates

Minimise lead times

Reduce overall length of the required production period

Balance workload of resources

Ensure uniform rate of productivity

An MPS is usually in the form of

list of jobs with associated due dates

Lead time is the

time between customer order and order delivery

Production period is the

time between starting work on an order and completion

The major production activity control functions are

Policies for inspection

Support services

Policies for handling the breakdowns

Schedules for maintenance

Procedures for process monitoring

Data collection on production progress

Benefits of a smooth production profile?

Reduces the amount of unused production capacity

Why is inventory planning needed

A buffer between supply and demand

Decouples processes allowing work to continue if there is a problem upstream

Total Carrying cost =

H(Q/2) where,

H = Holding cost

Q = Quantity

Q/2 = Average inventory

Total ordering cost =

S(D/Q) where,

S = Order cost

D = Average annual demand

D/Q = Number of orders

EOQ =

D = average annual demand

S = order cost

H = holding cost

Weeks of supply =

Average inventory value / weekly sales

Inventory Turnover =

Annual sales / average inventory value

Fixed - Order Quantity System is

ordered whenever inventory drops to reorder level (ROL), so reorder date varies

Replenishments System is when

Reorder date is fixed and order quantity (Q) varies according to inventory level to fulfil the replenishment level

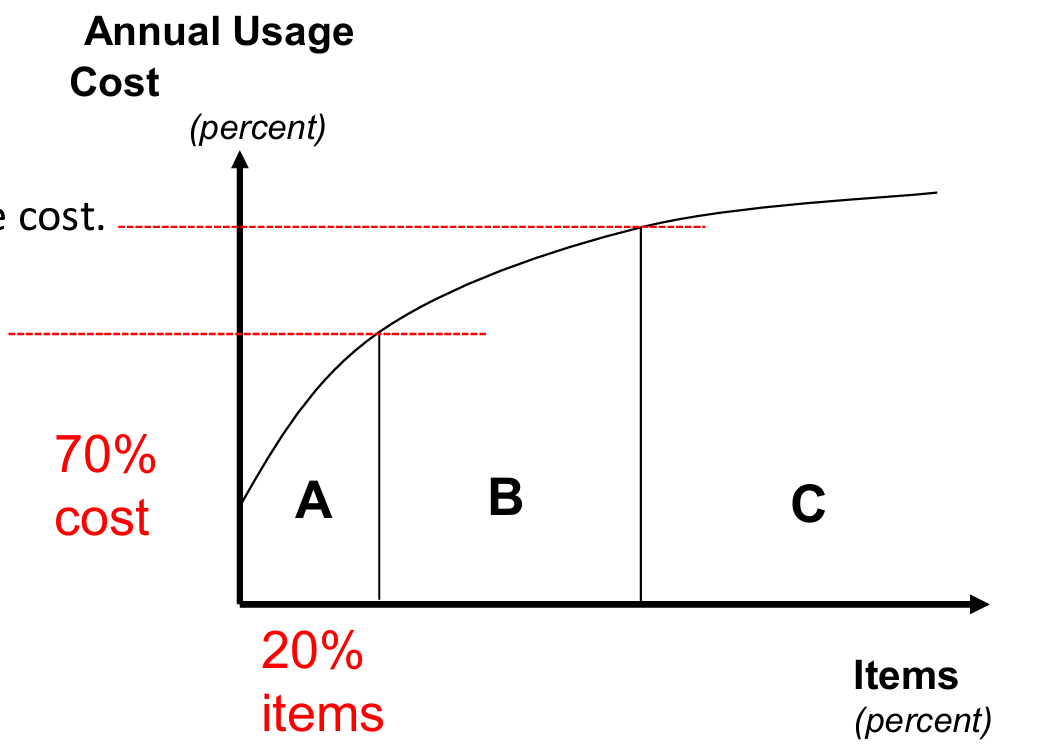

A-items

5-20% of inventory items incurring 50-70% of expenses.

High cost items that are vigorously controlled

B-items

30-50% of inventory items incurring 20-30% of expenses

Moderate costs items that are accurately controlled

C-items

40-70% of inventory items incurring less than 10-20% of expenses

Low cost items that their control are more relaxed

Pareto Analysis is used to

Separate the vital few from the trivial many, and often utilises a Pareto chart as a visual tool to identify the few problems that causes the greatest lost

Pareto chart used to generate ABC inventory classification by

Calculate annual usage cost

(unit cost x annual usage)

Rank items in descending order based usage cost

Find cumulative percentage of usage cost

Find cumulative percentages of total items

Plot results

Divide into ABC categories

What is the main reasons a company would try to identify an economic order quantity for a stock item

In order to reduce the costs of holding stock

What does MRP stand for

Materials Requirements planning

MRP is

planning to have the correct quantities of components and materials available at the correct time in order to fulfil the Master Production Schedule

Some MRP characteristics are…

Product Oriented using a BOM

Future Oriented uses info from the master production schedule to calculate future component requirements

Priority Planning determines the production requirements to meet the master schedule

LT stands for

Lead Time (days)

TYP - M vs TYP-B

M is manufacture

B is bought

What is a Business Plan?

sets out the long term future of a company as series of financial statements and targets

What is a Marketing Plan?

gives in general terms what is to be sold and what income will be derived to meet the figures in the business plan

What is a Production Plan?

sets out what is to be produced, what resources will be needed and what this will cost

Resources Requirements Plan

Identifies the loads on the resources imposed by production plan and to compare this with theoretical capacity

In a JIT approach it is wasteful to

Store large amounts of anything

Produce more goods than immediately required

Move in-process materials and goods around

Product scrap

Carry out unnecessary work

JIT aims to…

Reduce waste in all forms, where waste is defined as everything that adds to the cost but not to the value

A Kanban system is designed to…

Minimise WIP quantities

It is a pull system

OPT stands for

Optimised production technology

OPT defined ten rules for planning and controlling production…

-Utilisation of a non-bottleneck resource system not determined by its own capacity

-Activation of a resource not the same as utilisation

-Time lost at a bottleneck operation is time lost for the total production system

-Time saved at non-bottleneck operation is an illusion

-Transfer between operations may not and often should not equal process batches

-Process batch sizes should be variable

-Capacity and priority should be considered simultaneously, not sequentially

-The unexpected is not unknown, it can be isolated and minimised

-Plant capacity should not be balanced, flow should be

-Sum of local optimisation factors is not equal to the optimisation of the whole system