Metal Alloys

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

17 Terms

Thermal, Electrical Conduction, Ductilibility/Malleability of Metal Alloys

Conducts both heat and electricity

Lusters due to inability od electromagnetic radiation to penetrate

Ductile and Malleable due to to non-directional bonding and atomic nuclei being physically moved

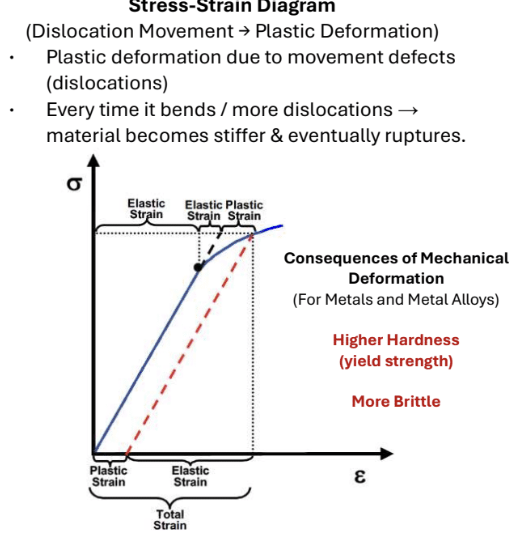

Elastic Limit of Metal Alloys

= Proportional limit = yield strength → indicates onset of plastic deformation

Strain hardening increases work hardening and thus raises elastic limit

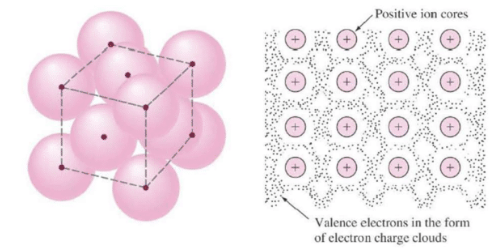

Define Metallic Bonding

Large interatomic forces are created by the sharing of electrons in a delocalized manner to form non-directional bonding

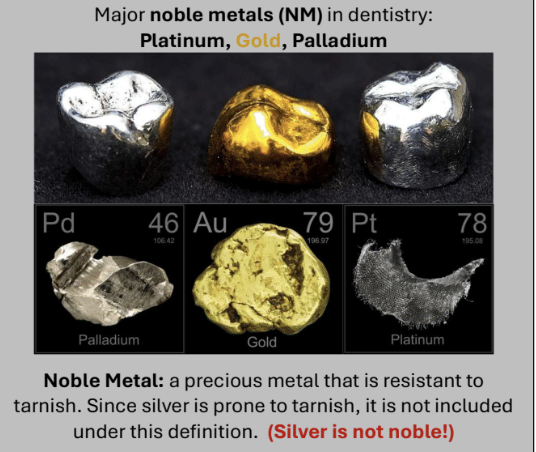

What are the major noble metals used in dentistry

Gold, Platinum an Palladium

Precious metal resistant to tarnish

Silver is not noble, prone to tarnishing

Explain Cast Metal Alloys

Formed into desired shapes by casting in a liquid state or by physically shaping (wrought)

CTE should match or be slightly higher than the material of the veneer porcelain

If CTE is matched appropriately, cooling should not produce fractures

New current ADA Casting Alloy classification

High Noble (HN)

Noble (N)

Predominantly Base Metal (PB)

Base Metal Alloys

High Noble (HN) > must be 40% or more Au and 60% or more total noble metal

TARNISH RESISTANT, corrosion resistant

Noble (N) → must be more or equal to 35% noble

Most common, most common is Ag-Pd (gold substitute) to save money

Predominantly Base Metal (PB) → less than 25% noble

Base Metal Alloys → more than 75% base metal and less than 25% noble

Low cost, oxide formation for bonding porcelain, better for thin casting, high hardness, low ductilibility, low reactivity to oxygen

Passivated with addition of Al, Cr and Ti

Characteristics of HN and N alloys for metal-ceramic prostheses

Can bond to ceramics

CTE matches to ceramic

High melting point for use with low-fusing porcelains

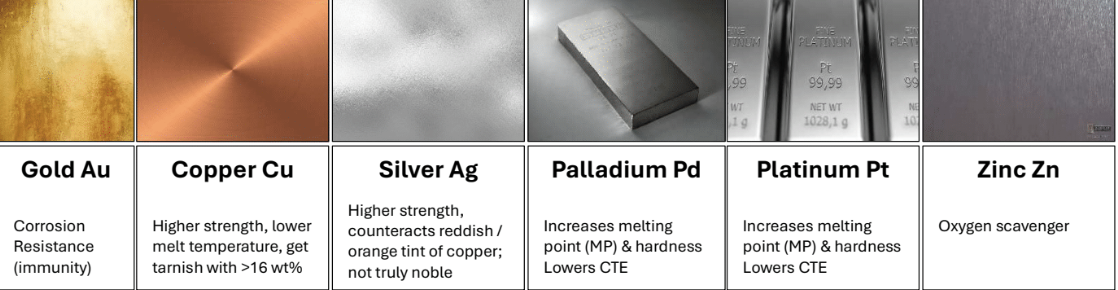

Characteristics of metals

Gold (Au)

Copper (Cu)

Silver (Ag)

Palladium (Pd)

Platinum (Pt)

Zinc (Zn)

Gold (Au): corrosion resistant

Copper (Cu): Higher strength, lower MT, gets tarnished with >16%wt

Responsible for yellow color in yellow gold

Silver (Ag): Higher strength, counteracts reddish tint of copper; not truly a noble metal and tarnishes

Palladium (Pd) and Platinum (Pt): Increases MT, lowers CTE, increases hardness

Responsible for white color of white gold

Zinc (Zn): Oxygen scavenger

Thermal mismatch stresses, what are they and what causes them

Metal and porcelain must have matched LCTE to avoid fractures upon cooling and multiple porcelain applications

No thermal stress issues

Large mismatch can cause fracture, small mismatch compresses porcelain and increases strength

Metal is sandblasted so it mechanically lock into porcelain

PFM vs ceramic preparations are different

Where do errors come from in the fit of indirect cast restorations

The key issue is error propagation due to multiple “hands on” manufacturing steps

Dimensional errors in the impression can worsen as each step is completed

Describe the process of passivation

Oxide layer formed by some elements in base allows which inhibits further oxidation → aluminum, chromium or titanium

Wrought alloys

Rolling or forging an alloy through physical force at levels above yield strength

Facilitated by dislocation movement which increases elastic limit

Displays better properties than cast alloys

Most metal alloys used in dentistry, implants

Define Strain Hardening, cold/hot working, hardening and hardness

Describe the strain-stress curve after work hardening

Strain Hardening: the process of strengthening a metal through deformation due to increasing difficulty for dislocation motion

Done through stamping, drawing, rolling, pounding, bending

Hardening: Increasing the elastic limit of a material

Hardness: Resistance of a material to penetration by an indenter or stylus

Curve: stronger but more brittle, ductility decreased

Hot/Cold- working: work hardening at high or low temp respectively

Re- crystallization

After cold working, the grain of the metals are very disordered, at ½ the MT, re-crystallization occurs and re-precipitates crystals which makes the metal soft and ductile again

Re-crystallization time decreases as the amount of cold working increases

Examples of uses of wrought alloys

Hand instruments: 316L Stainless Steel (S), low carbon, hardened during manufacturing

Clasps for RPDs: made of high noble alloys, clasps must not be too stiff or hard but must be durable

Endo files: SS or NiTi; Nitinol shape memory alloy

Ortho wires and bands: SS, Co-Cr-Ni, NiTi

Composition of Steel, composition of stainless steel and 316L

Steel = Iron + Carbon

Stainless steel = Steel + Chromium

316L = Stainless Steel + 16% Cr + low Chromium

Metal Alloys related to Implants

Almost all implants currently are made of commercially pure titanium (cp-Ti) and special instruments of the same material must be used when placing them as well as cleaning them or they may be scratched and left with iron residue from 316L instruments