Design - timber all you need to know

1/47

Earn XP

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

48 Terms

(START OF TIMBER) Hardwood

from trees with broad leaves

Softwood

from trees with needle-like leaves

Manufactured Boards

made in a factory

Examples of hardwood

oak, black walnut, beech, ash

Softwood examples

pine, spruce, cedar

Manufactured board - plywood

made from veneers stuck together with the grain at 90 degrease, this adds strength

Manufactured board - MDF

made from sawdust glued together under compression, It is also available in low and high density’s

Manufactured board -

From tree to timber - felling

trees are cut down and the branches and bark are removed

From tree to timber - Sawing

the logs are cut into rectangular planks

From tree to timber - Seasoning

the logs are dried either in air or a kiln

Stock forms - rough sawn

the timber has rough edges, which might not necessarily be square

Stock forms - Planned all round or PAR

This will be smooth on all sides, with all edges square

Stock forms - Dowell

Timber with has a circular cross section

Stock forms - Planned square edge or PSE

this has one corner that is at 90 degrease to be used as a start point for your manufacture

Warping

Warping is when planks bend over time, to prevent this we place planks opposite grains to one another this means that the warping cancels out

Marking out - name all the utensils shown (down left to right)

Sharp pencil - steel rule - try square - marking gauge - marking knife - centre punch - sliding bevel gauge

Cutting - name all the tools shown

Tennon saw - coping saw - panel saw - band saw - circular saw - bevel edge chisel - router - drill

Name and explain this plane

Smoothing plane - used for flattening surfaces and removing excess material

Name and explain this plane

Jack plane - used for smoothing flat boards, To tell the difference between a jack plane and a smoothing plane, pay attention to the size of the base and the location of the handles

Name and explain this plane

Rebate plane - a very thin blade used to cut rebates (before routers were invented). Usually has a guide rail to ensure a straight cut

Name and explain this plane

Compass plane - used for planning along curves

Name and explain this plane

Spokeshave - used for shaping timber into curves

Name and explain this plane

Draw knife - not technically a plane but does the same job

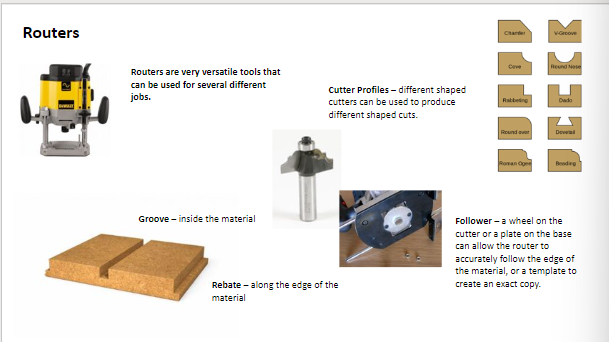

Explain a router

Name and explain this cramp

Sash cramp - used for holding long, flat boards together.

Name and explain this cramp

Sped cramp - also known as a quick cramp or trigger cramp. Good for apply quickly , less good for applying pressure

Name and explain this cramp

G cramp - good for applying pressure but limited in size sometimes called a C cramp

Name and explain these two cramps

Rachet strap - used to squeeze products together

Rubber bands - for small or awkwardly shaped items, you may end up using rubber bands, or even masking tape.

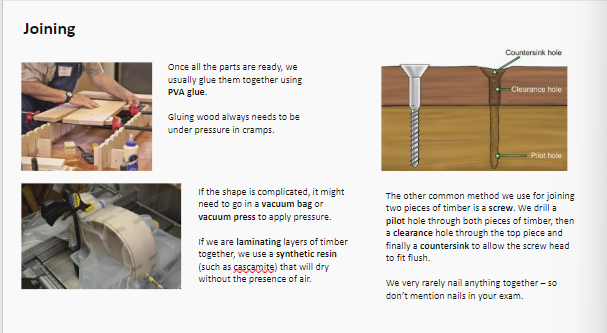

Joining

Shaping - laminating

Laminating is a process where several thin and flexible strips of wood are glued together and then bend into a shape. Once the glue has dried, the laminated timber will stay in the shape it was bent into

Shaping - steam bending

steam bending involves softening the fibres in timber with we heat (steam). This makes the timber flexible. The flexible wood is then bend into a shape and held into place whilst it cools. As the fibres cool, they harden and the timer will retain its shape.

Draw Mortise and tenon joint

Draw a Dovetail joint

Draw a finger joint

Draw a lap joint

Draw a dowel joint

Draw a mitre joint

Draw a biscuit joint

Draw a housing joint

Finishing - abrasive paper

Used for smoothing timber and removing marks. Abrasive paper comes in different ‘grits’ - the higher the number the finer the grit and the smoother the surface is

Finishing - Danish oil

used to provide a waterproof barrier to the top of the timber, along with a slight shine and colour. often when covered with a layer of wax to create a shine

finishing - paint

used to add a protective coating and usually to change te colour of timber. The grain will usually be hidden, so we do not usually pain hardwoods

Finishing - varnish

used to provide a strong waterproof barrier and semi-gloss to the timber. Lacquer gives a deeper shine and is also more resistant to abrasion and corrosion

Finishing - stain

Adds a colour to the timber, but allows the grain pattern to show through

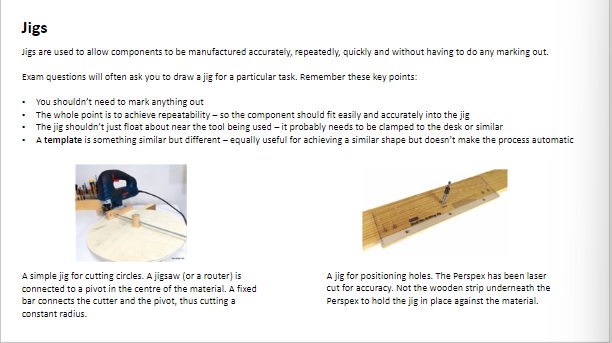

Jigs

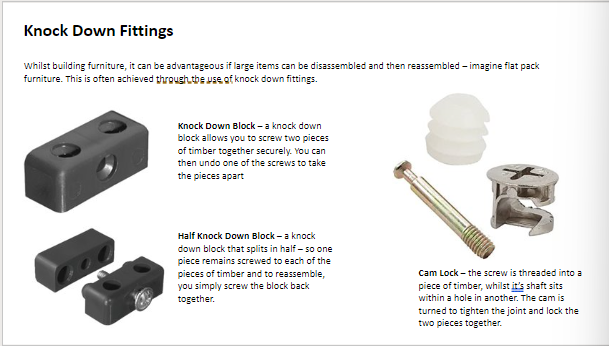

Knockdown fittings

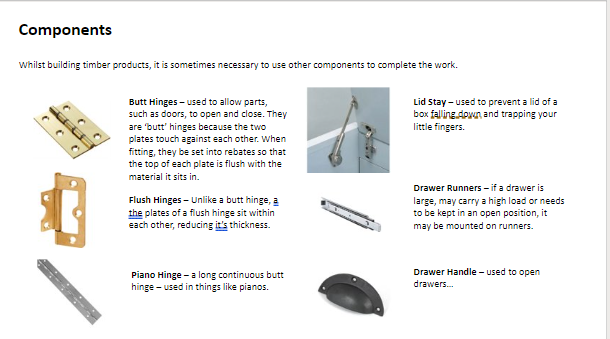

Components (list and explain)