12.2 - Critical Path Analysis, SCRUM, Six Sigma

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

Critical Path Analysis

Project managment method used to make projects as efficient as possible

How CPA works

Allows thungs to be done at the same time

Works well for time sensitivity

Calcuates the shorttres time a product could take to make

Advantages of CPA

Cuts down uncessary waiting

Parallel processes

Efficient resource planning

Disadvantages of CPA

May be difficult to accurately represent complex activity

External factors may change and require intervention

Relies on possibly inaccurate estimates

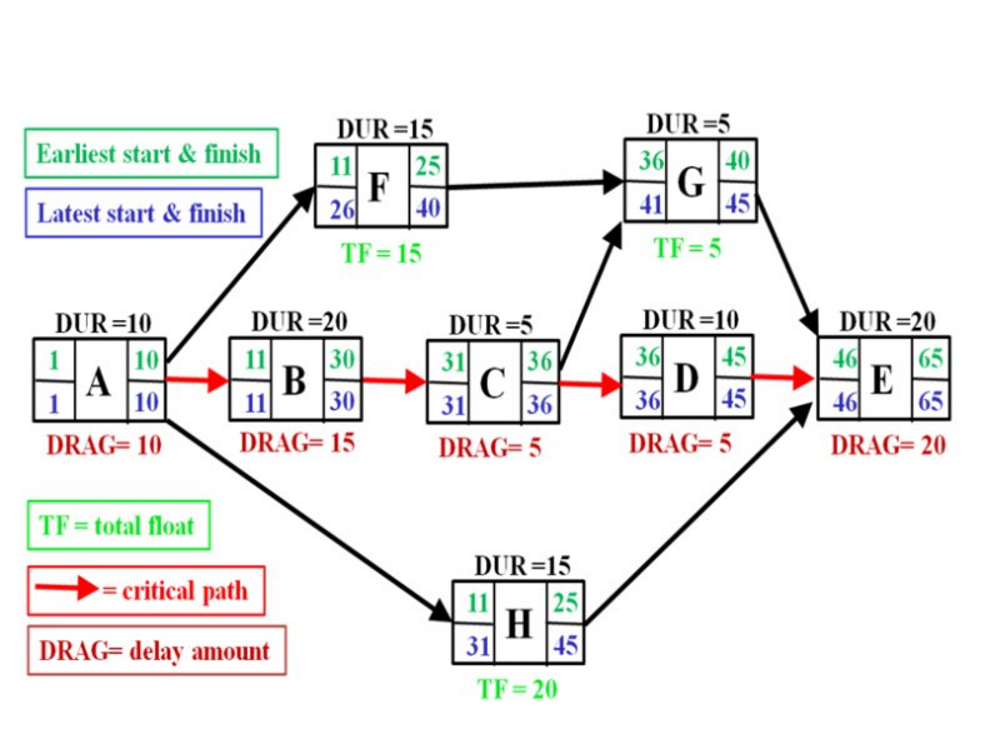

Illustratuion of CPA

Red line is critical path

Illustrates how multiple jobs are being done at once

Scrum

Focusses on flexible and holisitic product development

Scrum in practice

Teams have multiple different skill sets

They work in short sprints

Allows for adaptation and fast iteration

Designers and engineers - make it look good and make sure it will actually work

Short and long term goals established

Advantages of Scrum

Time and money used effectively

Projects move quickly

Allows for customer feedback

Allows for testing

Disadvantages of Scrum

Lack of definitive completion date

Success is reliant on cooperation and commitment

Large groups can decrease productivity

Losing team members can be very detrimental

Six Sigma

A method to improve processes - DMAIC (5 stages NOT 6)

It puts numers to targets

Reducing process cycle time

Reducing pollution

Reducing Cost

Increasing customer satisfaction

Increasing profit

Redesigining

Poka-Yoke method

Makes it impossible to carry out processes incorrectly

Stage 1 - Define

Set goals and objectives:

Staff, skills and processes required

Stage 2 - Measure

Look at estimates or existing data and consider the cost/ quality/ schedule to develop the team

Stage 3 - Analyse

Identify which processes actually add value to the project

Consider which will need more time or funding and justify why

Stage 4 - Improvements

Reduces stakes and improves effiiciency

Implamentation needs verification

Stage 5 - Control

Ensures new processes become standard practice

If new errors arise, changes are made and the process repeats

Advantages of six sigma

Direct impact on profitability

Improves overall quality through quality assurance

Increases customer satisfaction

Prevents losses rather than waiting for them to happen

Disadvantages of six sigma

Expensive processes increase costs

Huge amounts of data - analysis needs time and resources

Training can be expensive

Can prevent innovation for being risky

SS improves quality

Focussing of quality control and reducing the number of defects

SS reduces process cycle time

Removes errors and unncessary stages

SS reduces pollution

Reduces transportation, travel and waste from faulty products

SS reduces costs

Simplifies processes and steps required by using common processes across products

SS makes processes consistent

Streamlines processes to reduce the possibility of defects

SS improves efficiency/productivity

DMAIC improves results and streamlines resource use

SS is a managment tool/methodology

Employees become involved in quality assurance and reducing defects as they understand the processes involved