Topic 10: Polymers

1/52

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

53 Terms

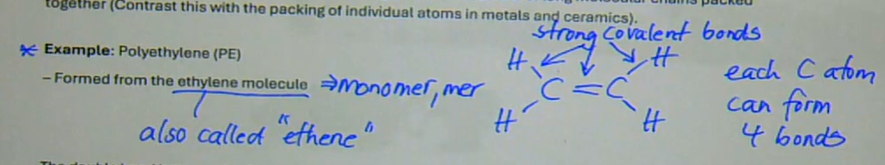

polymers are materials with structures made up of repeating molecular units, often based on carbon

each repeating unit is called a monomer

the small molecules or monomers are covalently bonded together to form long molecular chains

what are polymers

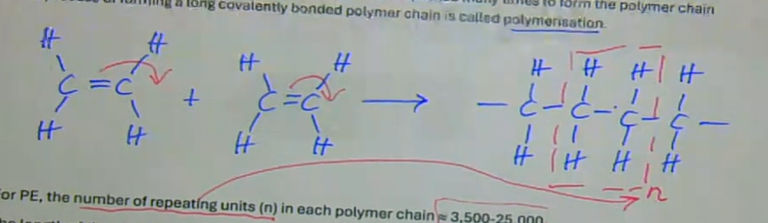

the double bond between the C atoms is ‘opened up’ and replaced by a single covalent bond allowing each C atom to bond to another molecule

this process is repeated many times to form the polymer chain — this process of forming a long covalently bonded polymer is called polymerisation

for PE, the number of repeating units (n) in each polymer chain is ~3500 to 25000

how are polymers formed

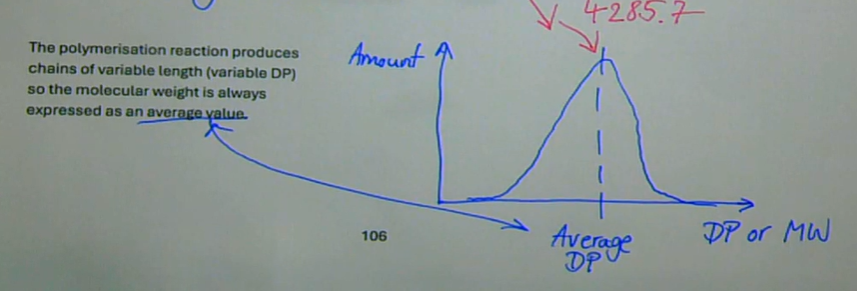

measure of the average number of repeating units/monomers in each polymer chain

calculated by:

DP = average molecular weight of chains in the polymer (g/mol)/molecular weight of the repeating unit (g/mol)

what is the degree of polymerisation (DP)

because the polymerisation reaction produces chains of variable length (variable DP)

why is the molecular weight always expressed as an average value

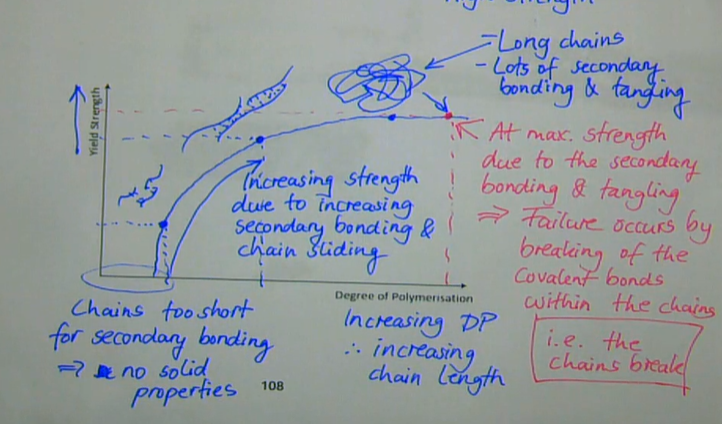

what does the DP graph look like

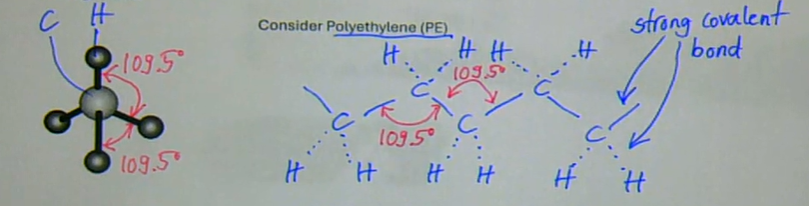

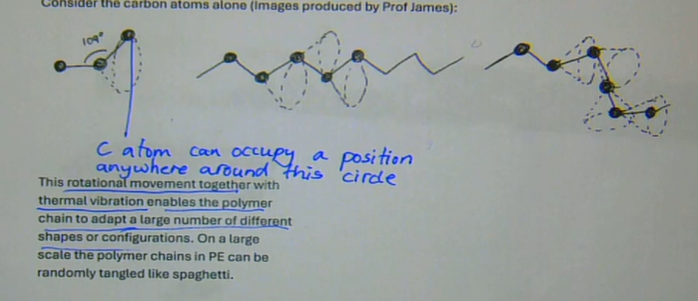

polymer molecules are not straight, as drawn in the previous section, but assume a zigzag configuration along the -C-C-C-C- backbone

this is because carbon is tetravalent → surrounded by four atoms in an equally spaced tetrahedral arrangement

describe the shape of a polymer molecule

the C-C bond has a fixed bond angle of 109.5 degrees, BUT rotation is possible about the C-C bond

the C-C bond is a covalent bond

this bond is strong and highly directional

describe the bond angle of C-C in terms of angle and strength

rotational movement together with thermal vibration enables the polymer chain to adapt a large number of different shapes or configurations

on a large scale the polymer chains in PE can be randomly tangled

how does rotational movement affect the shape of a polymer

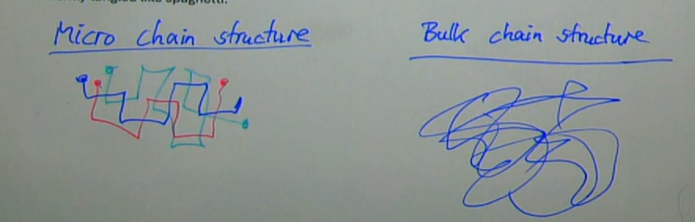

what does the micro chain and bulk chain structure look like

strong covalent bonds within atoms in the chain

weaker secondary bonds between separate PE chains in the bulk polymer (Van der Waal’s forces)

tangling between chains

the degree of tangling increases with the length of the polymer chains and therefore with increasing DP

what are the three interactions that contribute to the mechanical strength of polymers

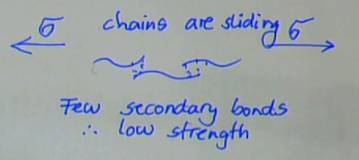

few secondary bonds

easy to break these and get chains to slide past each other under → low strength

describe short chain (low DP) polymers

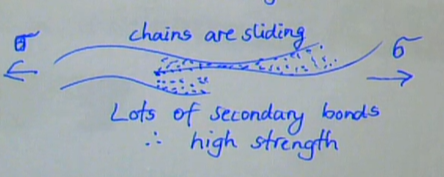

lots of secondary bonds

difficult to break all of these to get chains to slide past each other → high strength

also more strength from chain tangling

describe long chain (high DP) polymers

how does the graph of yield strength against degree of polymerisation look like

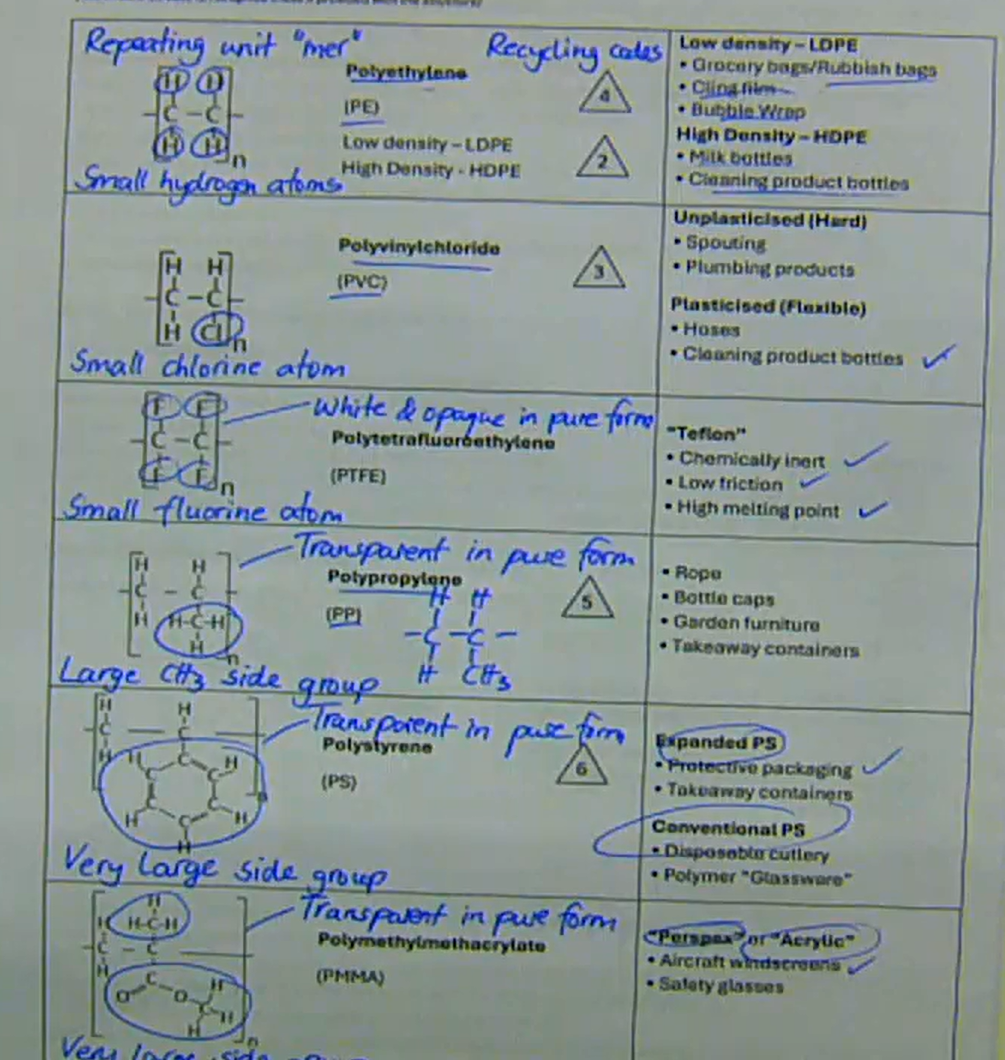

what are common polymers and their monomers

the same monomer repeating along the chain, e.g. -A-A-A-A-

what are homopolymers

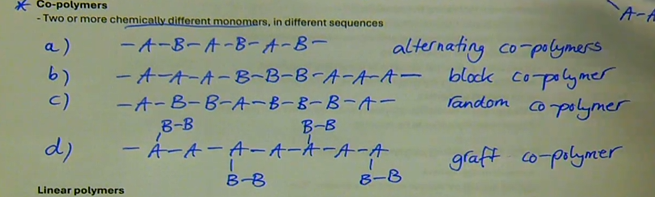

two or more chemically different monomers, in different sequences

→ -A-B-A-B-A-B- → alternating copolymer

→ -A-A-A-B-B-B-A-A-A- → block copolymer

→ -A-BB-A-B-B-B-A- → random copolymer

→ -A/B-B-A/B-B-A-A-A/B-B-A-A/B-B → graft copolymer

what are copolymers

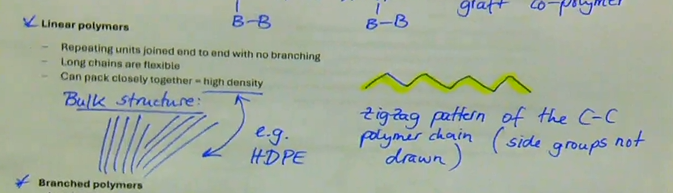

repeating units joined end to end with no branching

long chains are flexible

can pack closely together → high density

forms zigzag pattern of the C-C polymer chain

e.g. HDPE

what are linear atoms

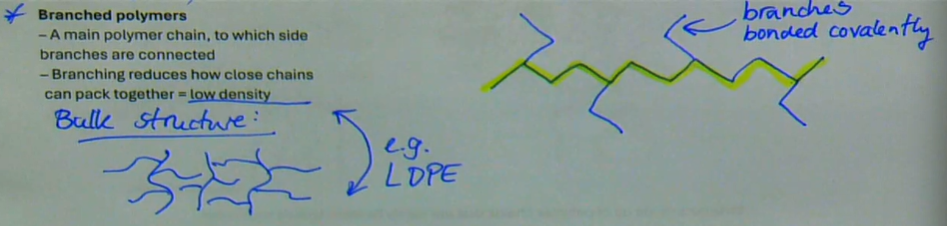

a main polymer chain, to which side branches are connected

branching reduces how close chains can pack together → low density

branches are bonded covalently

e.g. LDPE

what are branched polymers

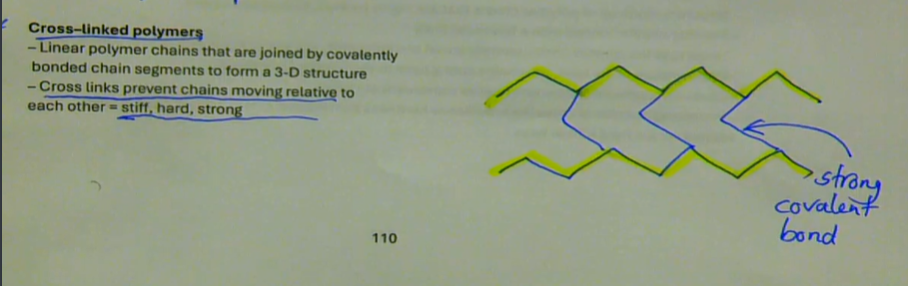

linear polymer chains that are joined by covalently bonded chain segments to form a 3-D structure

cross links prevents chains moving relative to each other → stiff, hard, strong

what are cross-linked polymers

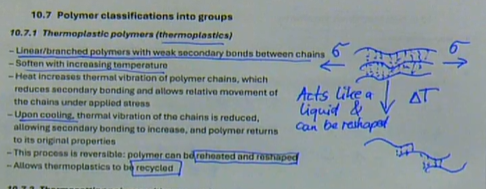

linear/branched polymers with weak secondary bonds between chains

softens with increasing temperature

heat increases thermal vibration of polymer chains, which reduces secondary bonding and allows relative movement of the chains under applied stress

upon cooling, thermal vibration of the chains is reduced, allowing secondary bonding to increase, and polymer returns to its original properties

this process is reversible: polymer can be reheated and reshaped

allows thermoplastics to be recycled

what are thermoplastic polymers (thermoplsatics)

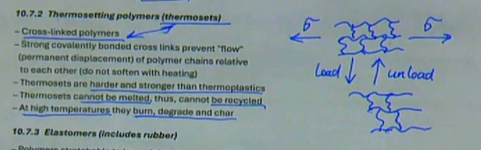

cross-linked polymers

strong covalently bonded cross links prevent ‘flow’ (permanent displacement) of polymer chains relative to each (do not soften with heating)

thermosets are harder and stronger than thermoplastics

thermosets cannot be melted, thus, cannot be recycled

at high temperatures they burn, degrade, and char

what are thermosetting polymers (thermosets)

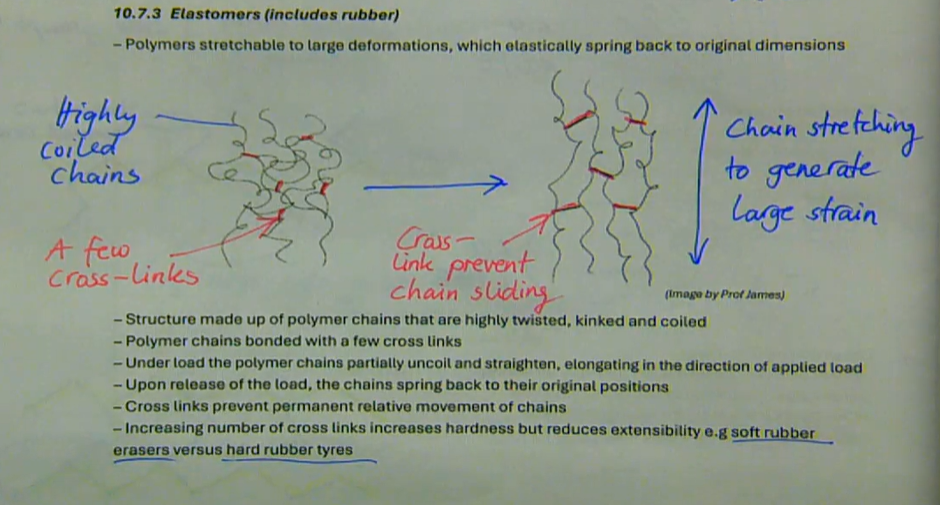

polymers stretchable to large deformations, which elastically spring back to original dimensions

structure made up of polymer chains that are highly twisted, kinked, and coiled

polymer chains bonded with a few cross links

under load the polymer chains partially uncoil and straighten, elongating in the direction of applied load

upon release of the load, the chains spring back to their original positions

cross links prevent permanent relative movement of chains

increasing number of cross links increases hardness but reduces extensibility, e.g. soft rubber erasers vs hard rubber tyres

what are elastomers

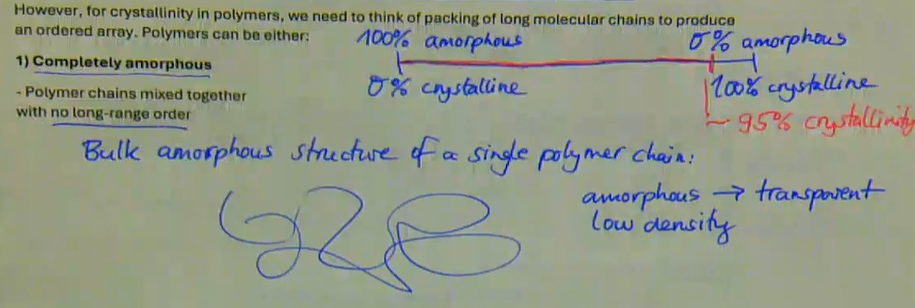

polymer chains mixed together with no long-range order

amorphous → transparent → low density

describe completely amorphous polymers

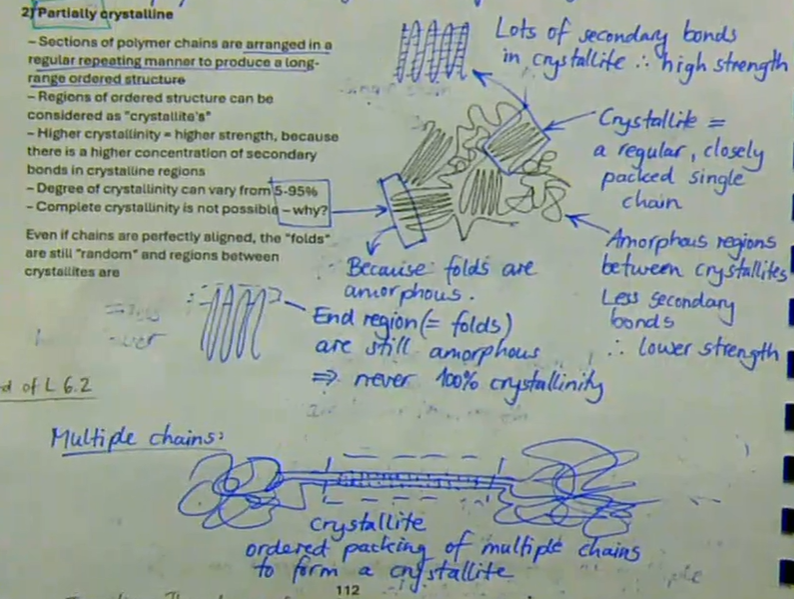

sections of polymer chains are arranged in a regular repeating manner to produce a long-range ordered structure

regions of ordered structure can be considered as ‘crystallites’

higher crystallinity → higher strength, because there is a higher concentration of secondary bonds in crystalline regions

degree of crystallinity can vary from 5 to 95%

complete crystallinity is not possibly → even if chains are perfectly aligned, the ‘folds’ are still ‘random’ and regions between crystallines are

describe partially crystalline polymers

rate of cooling: high rate of cooling from the liquid state → low crystallinity (i.e. amorphous)

→ because long tangled chains need time to move and align themselves in an ordered manner to make crystallites

side groups: large bulky side groups (e.g. PMMA) → low crystallinity (i.e. typically amorphous)

→ because bulky side groups prevent chains from forming regular ordered arrangementarrangement of side groups along the chain: for a fixed polymer composition, the atoms and side groups attached to the main carbon chain can be arranged in different orientations

what are the factors that affect the degree of crystallinity

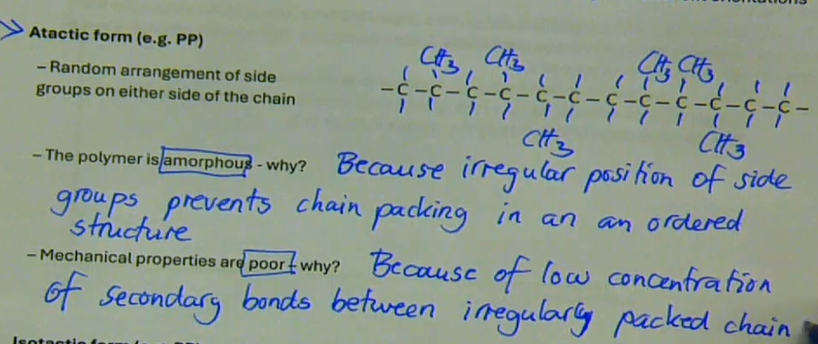

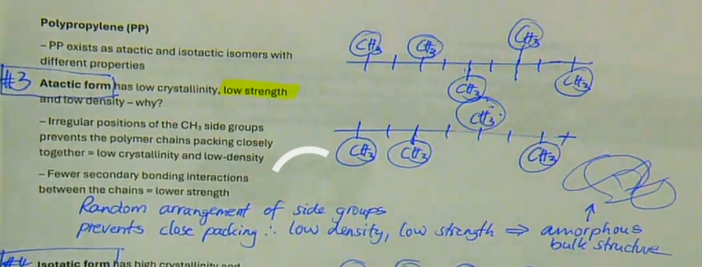

atactic form (e.g. PP)

→ random arrangement of side groups on either side groups on either side of the chain

the polymer is amorphous → because irregular position of side groups prevents chain packed in an ordered structure

mechanical properties are poor → because of low concentration of secondary bonds between irregularly packed chains

describe the atactic form

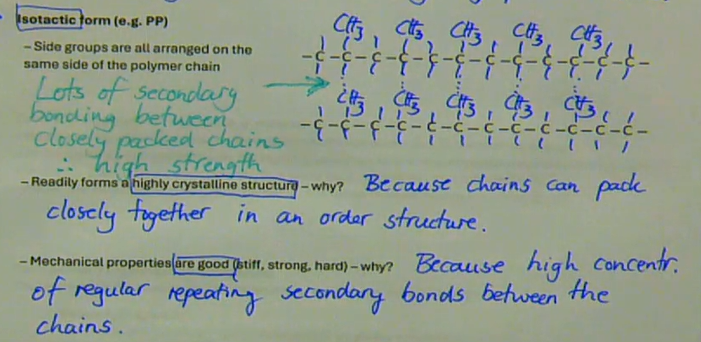

side groups are all arranged on the same side of the polymer chain → lots of secondary bonding between closely packed chains → therefore high strength

readily forms a highly crystalline structure → because chains can pack closely together in an order structure

mechanical properties are good (stiff, strong, hard) → because high concentration of regular repeating secondary bonds between the chains

describe the isotactic form (e.g. PP)

when a thermoplastic polymer is cooked from a flowable liquid state, it may form a completely non-crystalline (amorphous) structure, or it may form a partially or highly crystalline solid structure

what is the influence of temperature on thermoplastics

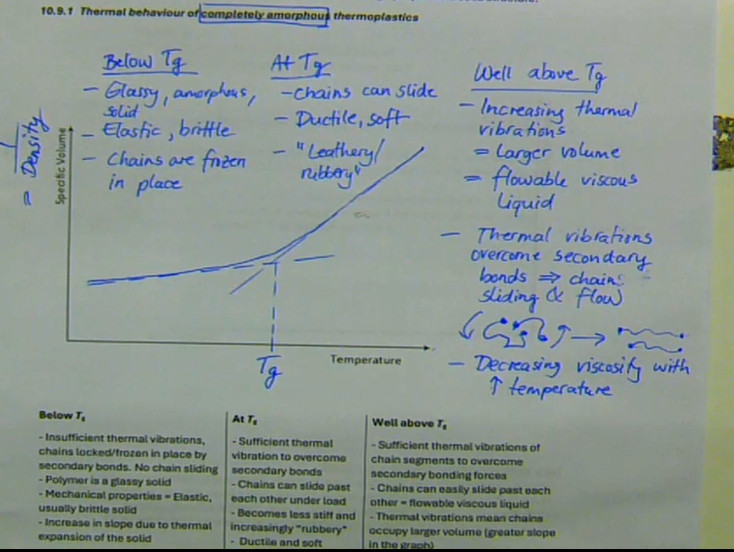

Below Tg:

→ Insufficient thermal vibrations

→ Chains locked/frozen in place by secondary bonds

→ No chain sliding

→ Polymer is a glassy solid

→ Mechanical properties = Elastic, usually brittle solid

→ Increase in slope due to thermal expansion of the solid

At Tg:

→ Sufficient thermal vibration to overcome secondary bonds

→ Chains can slide past each other under load

→ Becomes less stiff and increasingly “rubbery”

→ Ductile and soft

Well above Tg:

→ Sufficient thermal vibrations of chain segments to overcome secondary bonding forces

→ Chains can easily slide past each other = flowable viscous liquid occupy larger volume (greater slope in the graph)

what is the thermal behaviour of an amorphous thermoplastic

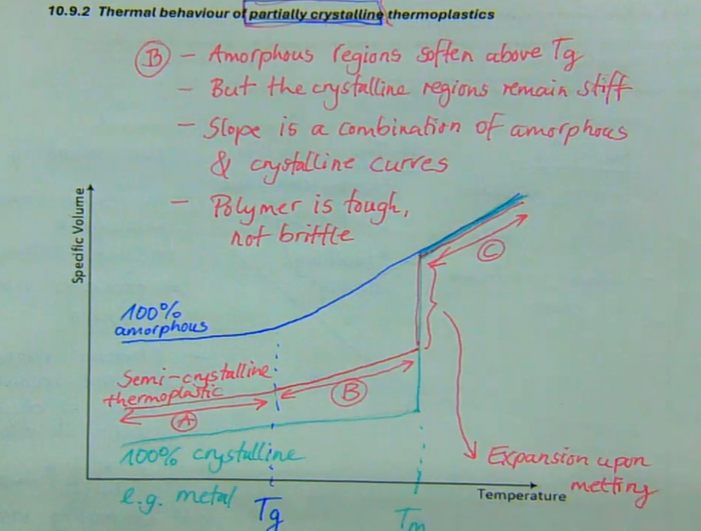

A → hard, brittle, solid

B → amorphous regions soften above Tg, but the crystalline regions remain stiff, slope is a combination of amorphous and crystalline curves, polymer is tough, not brittle

C → at Tmelt, the crystalline regions transform into amorphous material with low viscosity

what is the thermal behaviour of a partially crystalline thermoplastic

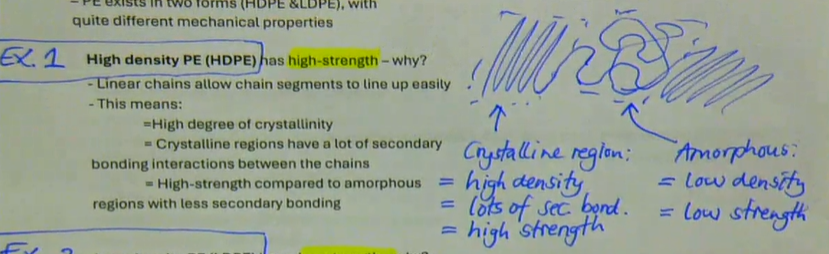

linear chains allow chain segments to line up easily

this means

→ high degree of crystallinity

→ crystalline regions have a lot of secondary bonding interactions between the chains → high-strength compared to amorphous regions with less secondary bonding

why does high density PE (HDPE) have high strength

LDPE has branches of PE grafted onto main PE chain

side branches prevent the polymer chain from packing closely together and generates low density structure

this also makes it difficult for crystallisation to occur

there are fewer secondary bonds between the branched chains compared to the linear HDPE chains and, therefore, it has lower strength

forms amorphous structure

what does low-density PE (LDPE) have low strength

low crystallinity

low strength

low density

→ irregular positions of the CH3 side groups prevents the polymer chains packing closely together = low crystallinity and low-density

→ fewer secondary bonding interactions between the chains = lower strength

random arrangement of side groups prevents close packing therefore low density, low strength → amorphous bulk structure

describe the properties of atactic form

has high crystallinity and therefore high strength and density

→ regular repeated pattern of CH3 side groups allow chains to pack closely together = higher crystallinity and higher density

→ more secondary bonding interactions between the chains = higher strength

regular arrangement of side groups allow close packing therefore high density, high strength → semi-crystalline bulk structure

describe the properties of isotactic form

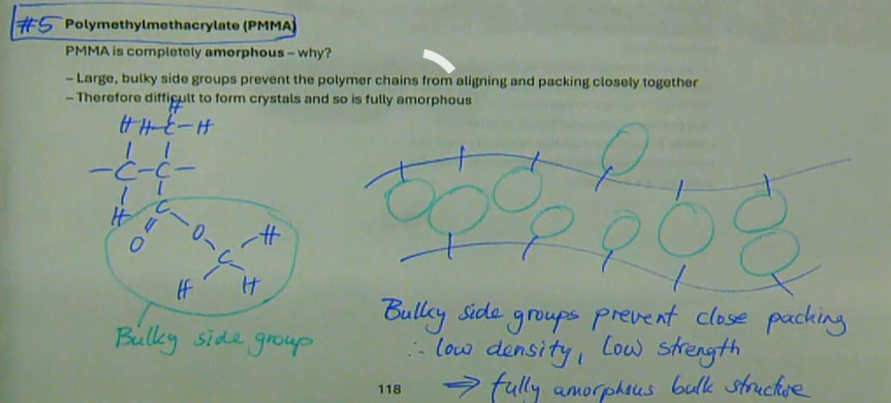

large bulky side groups prevent the polymer chains from aligning and packing closely together

therefore difficult to form crystals and so is fully amorphous

bulky side groups prevent close packing therefore low density, low strength → fully amorphous bulk structure

why is PMMA completely amorphous

if the dimensions of any crystalline regions in a polymer are greater than the wavelength of light, then internal reflection and refraction will occur, resulting in loss of optical transparency

highly amorphous polymers are generally optical transparent

transparency can also be changed by the addition of dyes or pigments, which can reduce transparency or make it opaque (as well as changes its colour)

because PMMA is fully amorphous:no order regions

→ no internal reflection and refraction, light travels through

→ transparent

semi-crystalline structure:if crystallite dimensions are greater than wavelength of light → opaque due to internal reflection and refraction

why is PMMA transparent

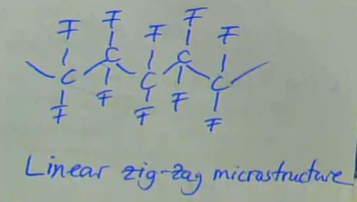

flourine is a very small, reactive atom

forms highly symmetrical chains which enables PTFE to be highly crystalline

→ lots of secondary bonding between the close packed chainshigh degree of secondary bonding = high strength, high density, and high melting point

strong C-F bonds = high chemical in inertness and ‘slipperiness’ (low coefficient of friction)

while it is a thermoplastic, it doesn’t melt normal thermoplastics and, therefore, must be sintered like a ceramic

linear zig-zag microstructure

F = small atom allows close chain packing therefore high density, high crystallinity (→ opaque)

high strength

describe PTFE — ‘Teflon’

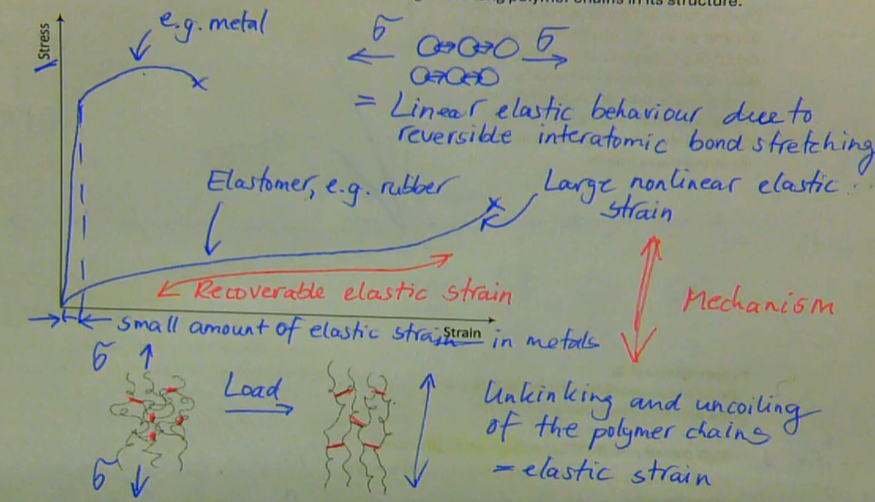

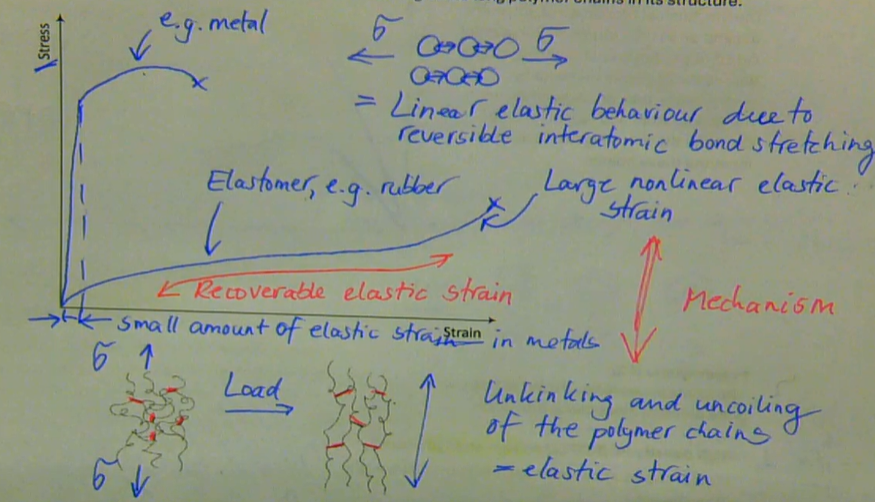

elastomeric polymers (e.g. rubbers) can exhibit very large non-linear tensile elastic strain (500 - 1000%) with full recovery, due to unkinking and rekinking of the long polymer chains in its structure

describe the mechanical response of elastomers

long, linear chains (i.e. high DP)

→ long chains allow high strain when stretchedrandom arrangement of polymer chains (i.e. must have an amorphous structure)

a) limited secondary bonding interactions between chains

b) amorphous structure allows for stretching by chain straighteningSufficient, but not too great, density of cross links between chains

→ cross links prevent irreversible chain sliding, but still allow chain stretchingchain segments must be in a state of constant thermal vibration

→ the elastomer must be above its Tg

→ thermal energy increases chain vibration which helps the chains unkink and slide past each other to generate elastic strain

what are the four structure requirements for large strain elastomeric behaviour

below Tg:

→ brittle solid, only elastic deformationabove Tg:

→ neck forms when yield stress is reached

→ neck becomes longer but not thinner going along stress-strain curve until fracture point is reached — called a travelling neck

→ because the curve gets higher, material becomes stronger due to orientation strengthening

describe the mechanical response of thermoplastics (viscoelasticity)

when load is applied:

→ amorphous chains align

→ becomes more crystalline

→ lots of secondary bonding

→ higher strengthamorphous material is drawn into aligned form in the neck → neck grows due to consumption of amorphous material from ends

why does the neck region in polymers become longer but not thinner

long tangled molecules are pulled into a ‘travelling neck’

chains become more aligned i.e. more crystalline

weaker in direction perpendicular to chains:

→ easy for a crack/tear to propagate along between the chainsstrong in direction along the chains:

→ hard for a crack/tear to grow across aligned chains

what is orientation strengthening

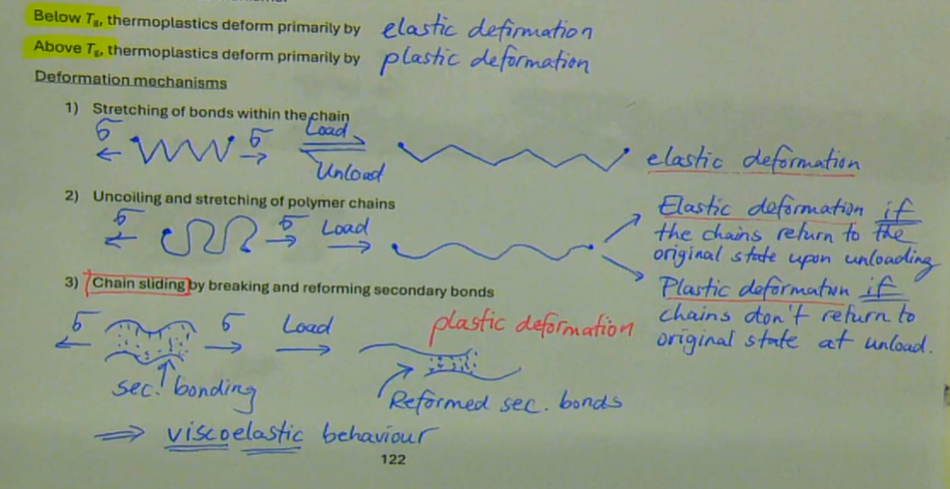

the deformation of thermoplastic materials can be primarily elastic, plastic (permanent) or a combination of both mechanisms

below Tg, thermoplastics deform primary by: elastic deformation

above Tg: thermoplastics deform primarily by: plastic deformation

deformation mechanisms:

1. stretching of bonds within the chain

→ undergoes elastic deformation

2. uncoiling and stretching of polymer chains

→ undergoes elastic deformation if the chains return to the original state upon unloading

→ undergoes plastic deformation if chains don’t return to original state at unload

3. chain sliding by breaking and reforming secondary bonding

→ undergoes plastic deformation

→ displays viscoelastic behaviour

describe the deformation mechanisms in thermoplastics

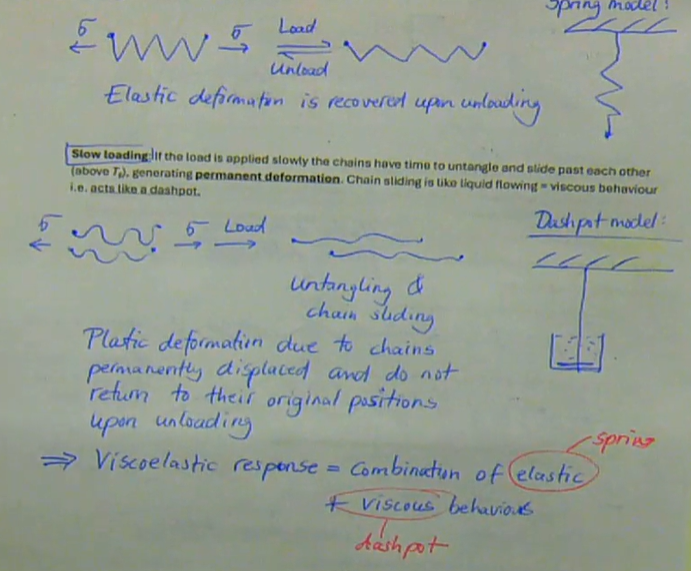

Rate of loading:

→ Fast loading: if the load on a polymer is applied very fast, the chains do not have time to untangle and slide past each other. Elastic deformation occurs by stretching of the bonds in the chain, i.e. acts like a spring. Elastic deformation is recovered upon loading.

→ Slow loading: If the load is applied slowly the chains have time to untangle and slide past each other (above Tg), generating permanent deformation. Chain sliding is liquid liquid flowing = viscous behaviour, i.e. acts like a dashpot. Plastic deformation due to chains permanently displaced and do not return to their original positions upon loading

this demonstrates the viscoelastic response of polymers → combination of elastic + viscous behaviour

what is the effect of loading conditions on polymer mechanical properties of Tg

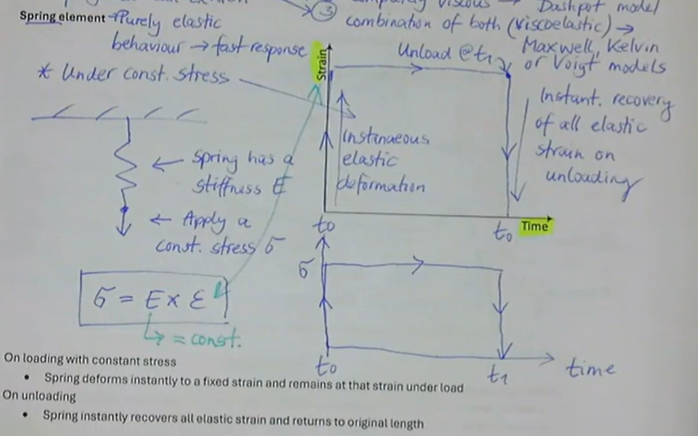

under constant stress, polymers can exhibit

1. completely elastic → spring model

2. completely viscous → dashpot model

3. combination of both (viscoelatic) → Maxwell, Kelvin, or Voigt models

what are the viscoelastic models used to describe polymer behaviour

structure

temperature

rate of loading

time

what are the factors affecting viscoelastic behaviour

purely elastic behaviour → fast response

under constant stress:

stress = E (stiffness) x strain

what is the spring element

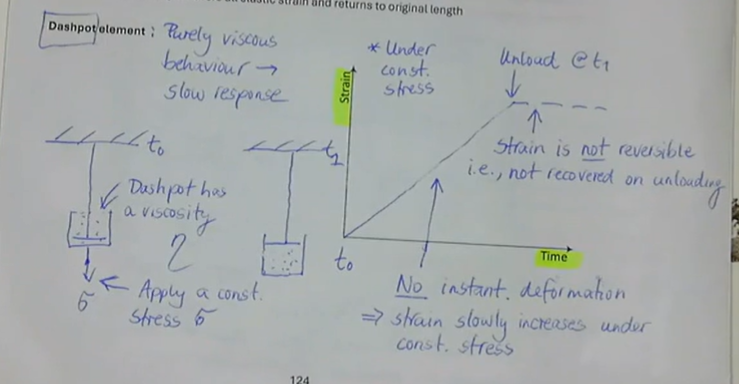

purely viscous behaviour → slow response

under constant stress:

no instant deformation → strain slowly increases

strain is not reversible, i.e., not recovered on unloading

what is the dashpot element

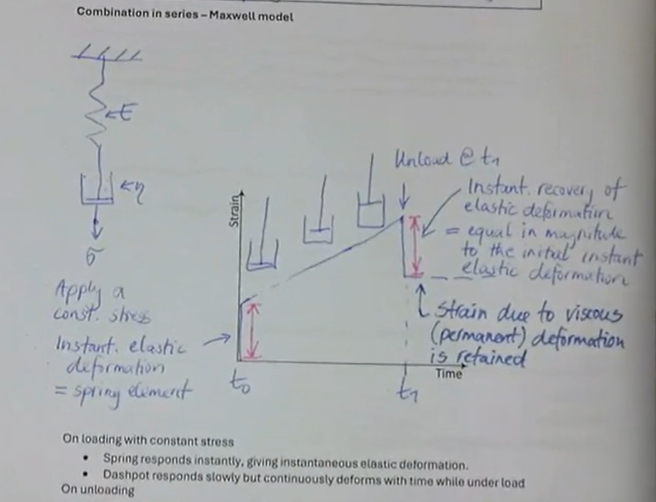

Combination in series → Maxwell model

under constant stress:

instantaneous elastic deformation = spring constant

after unloading there is an instantaneous recovery of elastic deformation → equal in magnitude to the initial elastic deformation

remaining strain is due to viscous (permanent) deformation is retained

what is the Maxwell model

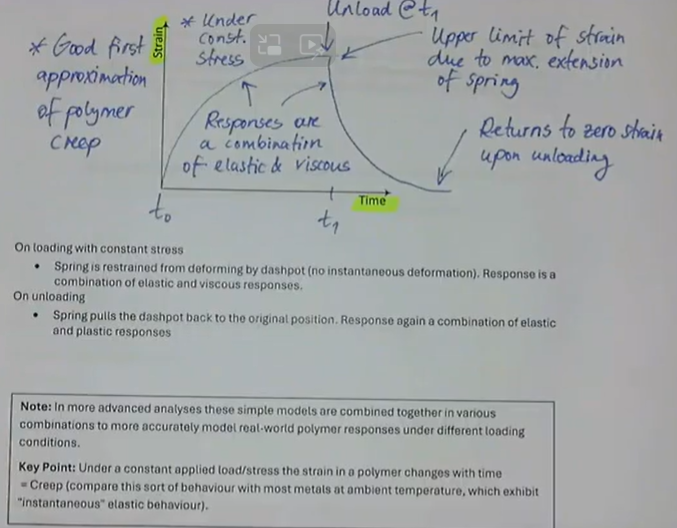

Combination in parallel - Kelvin or Voigt model

under constant stress

spring and dashpot must deform at the same time, i.e., in parallel

responses up to the unloading point are a combination of elastic and viscous

upper limit of strain is due to max extension of spring

returns to zero strain upon unloading

what is the Kelvin/Voigt model

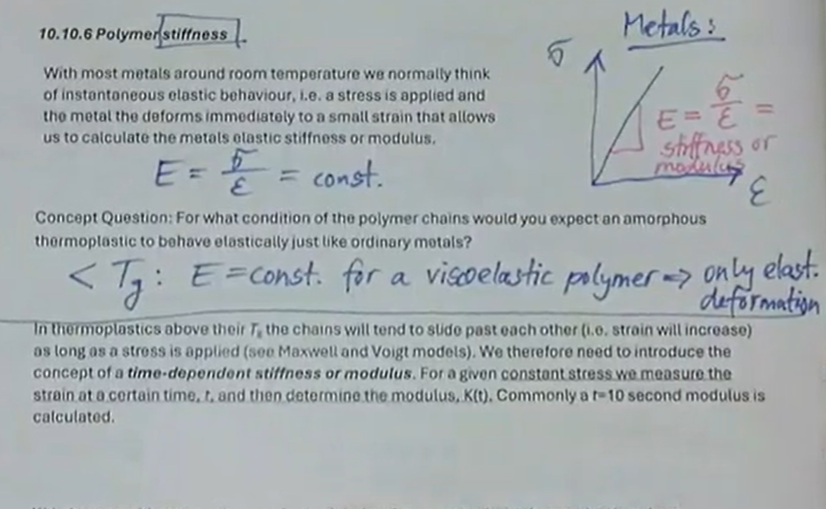

with most metals around room temperature we normally think of instantaneous elastic behaviour, i.e., a stress is applied and the metal deforms immediately to a small strain that allows us to calculate the metals elastic stiffness or modulus

E = stress/strain = constant

when <Tg: E = constant for a viscoelastic polymer → only elastic deformation

under these conditions of polymer chains, amorphous thermoplastics behave elastically just like ordinary metals

when > Tg: E is not constant

time-dependent stiffness/modulus is used

K(t) = constant stress/strain at 10 seconds

K(t) changes with temperature

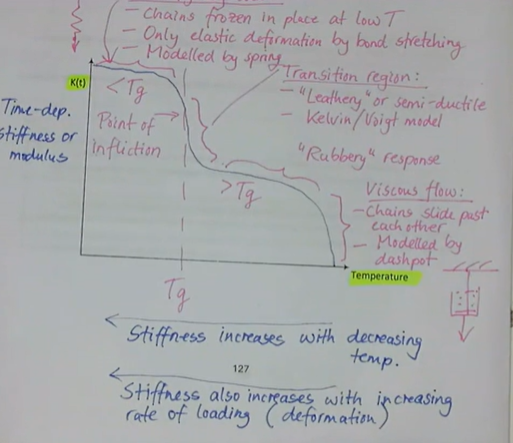

what is polymer stiffness

at high temperature: viscous flow

chains slide past each other

modelled by dashpot

decreasing temperature: ‘rubbery’ response

decreasing temperature towards Tg (point of inflection): Transition region

‘leathery’ or semi-ductile

Kelvin/Voigt model

temperature less than Tg: Brittle, glassy, solid

chains frozen in place at low T

only elastic deformation by bond stretching

modelled by spring

stiffness increases with decreasing temperature

stiffness also increases with increasing rate of loading (deformation)

K(t)-Temperature graph