Ch. 8: Process management

0.0(0)

Card Sorting

1/25

Earn XP

Description and Tags

Last updated 4:23 AM on 2/20/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

26 Terms

1

New cards

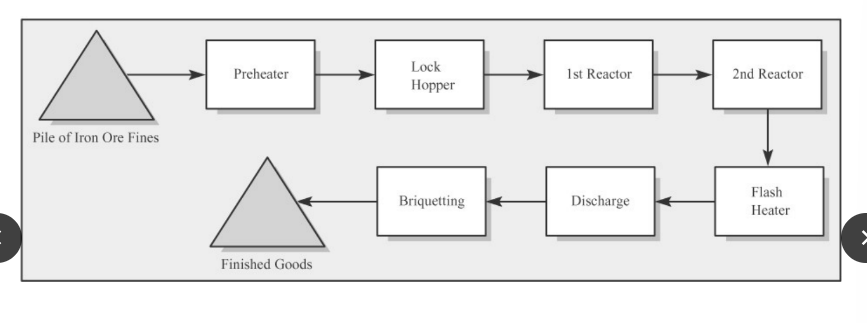

What is the process view of a visitor on making iron

The input would be seen as a rock, the process would be the factory, and the output would be the iron blocks creates

2

New cards

What is the process view of an engineers view of making iron

They would be seen as the machines processing the material to create the output of the iron

3

New cards

What is the process flow diagram

It has activities (as rectangles), arrows (as arrows), and buffers (as triangle)

4

New cards

Process - Activates

This is the simplest form of transformation carried out by resources. It is the building block of a process

5

New cards

Process - Arrows

It indicates the flow of the unit. The direction to the next step

6

New cards

Process - Buffers

They are like inventory. It stores flow units that finished & is waiting for the next activity to start

7

New cards

Process down in different industries

The process is not the same for every job. They have a different system they need to follow and how they operate

8

New cards

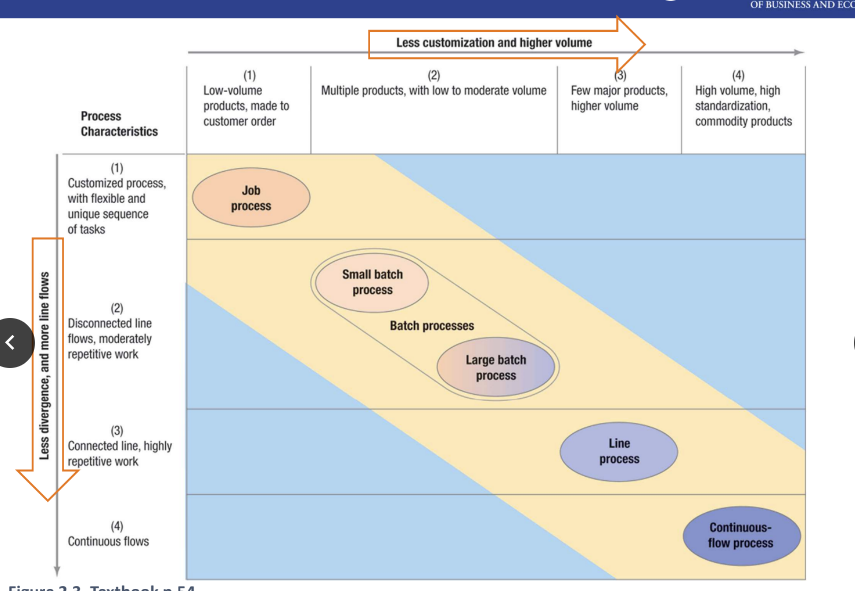

Process selection

It is a way of structuring the process by organizing resources around the process or vis versa. The questions to ask are: variety, flexibility, volume. It is demand driven

9

New cards

Process selection - Variety

How much from the product or services will the system need to handle

10

New cards

Process selection - Flexibility

To what degree does the equipment need to adopt

11

New cards

Process selection - Volume

What is the expected amount of output needed

12

New cards

What are the different types of manufacturing process

There is: job shop process, batch process, assembly line process, and continuous process

13

New cards

What is the process of job shop

It is small scale. Used for low volume (speed) with high variety of good or services. The flow is intermittent & is high flexibility of the equipment and skills. It can have more than one input and can have more than one output

\

ex.) auto repair shop, vet, high end cars

\

ex.) auto repair shop, vet, high end cars

14

New cards

What is the process of batch

This is moderate scale. Used for moderate volume (mid speed) with moderate variety of goods and services. The flow is intermittent flow. The equipment has more volume and the worker skills has less variety than the job shop. It can have more than one input, but comes out to one output

\

Ex.) Bakeries, movie theater, high end resurant

\

Ex.) Bakeries, movie theater, high end resurant

15

New cards

What is the process of a line

It is moderate to high scale. The volume is high (speed) with low variety b/c of having more standard goods and services. It is repetitive process with increased efficiency. The equipment has slight flexibility & the worker skills is low. It can have more than one input, but need to come out in the same output

\

ex.) auto assembly, subway, McDonalds

\

ex.) auto assembly, subway, McDonalds

16

New cards

Worker paced assembly line

Each person is able to work at their own pace. Inventory various due to the capacity the workers have. Has more triangles between each process. Only has one inout and one output

\

ex.) Bugatti assembly line

\

ex.) Bugatti assembly line

17

New cards

Machine paced assembly line

All the workstations need to be worked at the same speed. If one stations stops, then the whole production stops.

\

ex.) Prius assembly line, Pizza topping

\

ex.) Prius assembly line, Pizza topping

18

New cards

What is the process with continuous

It is high scale. Very high volume (speed) with very low variety. The output is highly standardized. The flow is always flowing. The equipment has not flexibility & workers skills is low to high demand depending on the task

\

ex.) steel, sugar

\

ex.) steel, sugar

19

New cards

What is the characteristics of job shop

* Product variety: high

* Process flexibility: high

* Output volume: low

* Process flexibility: high

* Output volume: low

20

New cards

What is the characteristics of batch

* Product variety: moderate

* Process flexibility: moderate

* Output volume: moderate

* Process flexibility: moderate

* Output volume: moderate

21

New cards

What is the characteristics of line

* Product variety: low

* Process flexibility: low

* Output volume: high

* Process flexibility: low

* Output volume: high

22

New cards

What is the characteristics of continuous

* Product variety: very low

* Process flexibility: very low

* Output volume: very high

* Process flexibility: very low

* Output volume: very high

23

New cards

Design to order

This is a strategy that designs new product from scratch. Job process is considered this.

24

New cards

Make to order

It is also called pull strategy. Used by manufacturer that make small amounts according to customers specifications. It allows high degree of customization and used under job and small batch processes.

25

New cards

Assemble to order

Strategy used for producing wide variety of product from few subassemblies and components. It is mainly on line process and batch process. Used for mass customization

26

New cards

Make to stock

This is also called push strategy. It involves holding items in stock for fast delivery. the product is made ahead of time for customer demand. Used in line and continuous flow processes