FINALS-HFASAFETY

PRELIMS

TOPIC 1

Aviation Quality: Determining gaps based on non-compliance with regulatory or organizational requirements. Focuses on identifying areas of non-compliance and implementing measures to address them.

Aviation Safety: The state in which the possibility of harm to persons or property damage is reduced and maintained at or below an acceptable level. Involves a continuous process of hazard identification and safety risk management.

Concept of Safety:

Zero accidents

Freedom from danger or risks

Attitude towards unsafe acts and conditions by employees

Acceptability of inherent risks in aviation

Process of hazard identification and risk management

Control of accidental loss of persons, property, and damage to the environment

Safety Programme: Integrated set of regulations and activities aimed at improving safety.

Safety Management System: Organized approach to managing safety, including organization structures, accountabilities, policies, and procedures.

Difference between ICAO and CAA:

ICAO: Provides procedures and guidance for safe international aircraft operations.

CAA: State body responsible for implementing legislative and regulatory provisions for aviation safety.

Difference between Accident and Incident:

Accident: Involves fatality or serious injury, substantial damage to the aircraft, or aircraft being missing or inaccessible.

Incident: Affects or could affect the safety of operation, but does not meet the criteria of an accident.

Management's Special Responsibility for Safety:

Clear direction through credible policies, objectives, goals, and standards.

Adequate resources, including time, to fulfill tasks safely and efficiently.

Access to expertise through safety literature, trainings, seminars, etc.

Terminologies to Remember in HFASafety:

Slip: Action not carried out as planned.

Hazard: Condition, object, or activity with potential to cause harm or damage.

Mitigation: Measures to eliminate or reduce risk probability or severity.

Probability: Likelihood of a dangerous situation occurring.

Safety Assessment: Process of hazard identification and risk analysis.

Severity: Consequences of a dangerous situation.

Risk Index: Combined value of risk probability and severity.

Risk: Potential chance of loss or injury.

ALARP: As Low As Reasonably Practicable.

Human Error: Primary cause contributing factor in disasters and accidents.

BIAS

TOPIC 2

Introduction to Safety Management System

The regulation specifies the requirement for service providers in the aviation industry to implement a safety management system (SMS) in accordance with various annexes of the International Civil Aviation Organization (ICAO). The term "service provider" refers to approved/certificated organizations providing aviation services, including training organizations, aircraft operators, maintenance organizations, type design/manufacturing organizations, air traffic service providers, and certified aerodromes. The regulation focuses on aviation safety-related processes, procedures, and activities of the service provider. It establishes the minimum SMS framework requirements, but the service provider can establish more stringent internal requirements.

Swiss Cheese Model

The Swiss Cheese Model illustrates the multiple layers of defense in the aviation system to protect against fluctuations in human performance or decisions at all levels. It highlights that no single defense is perfect, but by having multiple layers, the likelihood of an error leading to a safety incident is reduced.

Relation of Aviation Quality to Aviation Safety

Aviation quality and aviation safety are distinct concepts. Quality, as defined by ISO standard 9000:2005, refers to the degree to which a group of inherent characteristics fulfills requirements. Safety, as defined by ICAO, is the state in which the likelihood of harm to persons or property damage is reduced and maintained at an appropriate level through hazard identification and safety risk management. While meeting safety requirements is essential for an air operator, quality goes beyond regulatory compliance and focuses on meeting customer requirements and improving customer satisfaction.

SMS Quality Principles

SMS (Safety Management System) and QMS (Quality Management System) share commonalities but have distinct characteristics. SMS promotes a hazard identification/risk management-based approach to safety management, considering the human dimension organization-wide. QMS focuses on fulfilling requirements and providing confidence that quality requirements are met. SMS is more proactive and developed with safety in mind, while QMS aims to improve customer satisfaction. Both systems strive for continuous improvement and involve every function, process, and person within the organization.

Total Quality Management

Total Quality Management (TQM) is an advanced form of quality management that goes beyond satisfying customers or offering quality products. It is a management approach in which all members of an organization participate in improving processes, products, services, and the organizational culture. TQM emphasizes eradicating defects and waste, reducing costs, and setting quantified goals and benchmarks. Airlines can benefit from TQM by achieving cost reduction and control while maintaining product safety.

What is Quality Auditing

Quality Auditing is a systematic and independent examination of processes, activities, and systems within an organization to ensure compliance with regulatory requirements, industry standards, and internal policies. The main goal of auditing is to identify any gaps in regulatory or organizational compliance and generate findings that lead to corrective and preventive actions, ultimately improving overall efficiency and effectiveness.

The 5 Audit Elements:

The Finding: Clearly state the problem and ensure it is understood in detail. Repeated findings may indicate failure to address root causes effectively.

Why It's a Problem: Identify the standard that has not been met and determine whether it is an internal or external requirement.

Root Cause Analysis: Uncover why the problem occurred, addressing the root cause behind the finding.

Consequences and Moving Forward: Assess the consequences of the finding and determine how to proceed, taking auditee responsibility into account.

Corrective Action Disposition: Clearly specify who is responsible for implementing corrective actions, what actions should be taken, and when they should be completed. Ensure the root cause assessment is properly validated by the auditor.

Root Cause - 5 Whys Analysis:

The 5 Whys Analysis is a powerful technique used in quality auditing to delve deeper into the root causes of problems. It involves repeatedly asking "Why" to trace the issue back to its fundamental source. This technique can help auditors and organizations gain a more comprehensive understanding of the problems they encounter.

TOPIC 3

Aviation Safety

Process of identifying and managing hazards within an aviation organization to ensure the safety of flight operations, personnel, and the public.

Key Points:

Involves both reactive and proactive hazard identification.

Safety reports should not be limited to incidents; hazards should also be included.

Data from safety reports helps in mitigation, defining intervention strategies, and verifying the effectiveness of measures.

Safety Reporting System

Proactive and reactive approach for reporting incidents, accidents, and hazards to facilitate safety improvements and prevent future occurrences.

Key Points:

Voluntary reporting includes hazards and near misses, complementing reactive reporting.

Importance of reporting hazards threatening organizational viability for timely safety improvements.

Confidential incident reporting fosters a culture of learning and continuous improvement.

Safety hazard reports reviewed by the Safety Management Department Head, analyzed by the Safety Action Group.

Analysis includes Hazard Identification and Risk Assessment (HIRA), outcomes disseminated through toolbox briefings or notice boards.

Hazard Identification and Risk Assessment (HIRA)

Systematic and documented process to identify hazards and assess risks in an organization's operations.

Methods of Hazard Identification:

Reactive: Responds to past events like incidents and accidents.

Proactive: Actively seeks hazards through analysis of activities, mandatory reports, safety surveillance, and safety reporting.

Predictive: Aggressively seeks information from various sources to identify emerging risks.

Examples of Aviation Hazards:

Fuel vapor from open wing tanks, discrepant test equipment, inadequate training, etc.

Sources of Hazard Identification: Safety evaluation, safety surveillance, safety reporting, and accident/incident investigations.

Safety Evaluation

Process performed by the Safety Management Department to identify safety, health, and/or environmental hazards and assess the risk involved in newly proposed or modified processes or facilities.

Key Points:

Performed to identify safety, health, and environmental hazards in new or modified processes/facilities.

Part of proactive hazard identification process.

Safety Surveillance

Observation activity performed, usually at random, by the Safety Management Department to identify unsafe conditions and practices.

Key Points:

Involves random observation to identify unsafe conditions and practices.

High-risk areas or operations are inspected more frequently.

Concerned sections take action to address hazards and document such actions.

Safety Reporting

Reporting process performed by any personnel to report any accidents, incidents, near-miss, maintenance error, or hazardous events.

Key Points:

Involves reporting of accidents, incidents, near-misses, maintenance errors, or hazardous events.

Part of both proactive and reactive hazard identification.

Accident/Incident Investigation

Process performed by the Safety Management Department to analyze the circumstances and identify the root cause/s, including the contributing factors that led to an accident or incident.

Key Points:

Performed to analyze circumstances and identify root causes of accidents or incidents.

Part of reactive hazard identification.

Risk Management

Identification, analysis, and mitigation of risks associated with the hazards of an organization's operations.

Key Points:

Aims to allocate resources effectively and prioritize activities based on the risk index.

Key component of the Safety Management System (SMS).

Risk Assessment

Process of assessing the risks associated with each of the hazards identified to understand the nature of the risk.

Key Points:

Involves assessing the likelihood of occurrence and the severity of the consequences.

Various ways of performing risk assessments, ranging from subjective to analytical.

Risk Probability

: Likelihood that a situation of danger might occur.

Key Points:

Questions may guide the assessment of probability, such as history of occurrences, equipment usage frequency, etc.

Risk Severity

Possible consequences of a situation of danger, looking at the worst-case scenario.

Key Points:

Measures severity in terms of property, health, finance, liability, environment, reputation, etc.

Risk Index

Values assigned to numerically weigh the relative importance of each level of severity and probability.

Key Points:

Composite assessment of risk derived by multiplying severity and probability values, represented by the Risk Index Matrix.

Risk Level

High- stop. unacceptable until new measures are introduced

Moderate- existing control measures have to be revised and monitored

Low- existing control measures shall continue to be monitored and shall be reevaluated as necessary.

HIRA Eligible Operations/Processes

All operations/processes with the potential to harbor or generate hazards/risks to aviation safety should be eligible for HIRA accountability.

Key Points:

Includes high-risk or complex aircraft maintenance operations, workshop maintenance, and other priority areas.

HIRA should also be performed under specific conditions, such as unexplained increase in safety-related events or major operational changes.

TOPIC 4

Quality and Its Importance:

Definition of Quality:

Quality refers to the excellence or standard of a product or service.

It can also be a distinctive attribute possessed by something or someone.

ISO 8402-1986 Standard:

Quality is the totality of features and characteristics satisfying needs.

Importance of Quality:

Vital for competitiveness, customer satisfaction, and regulatory compliance.

Regulatory Requirements and Industry Standards:

Operators must establish a quality system and designate a quality manager for safe practices and airworthy aircraft.

Maintenance systems ensure aircraft airworthiness and serviceability.

Quality assurance program audits and evaluates management and operational functions.

Organizational Structure:

PAL express follows an organizational structure with the Accountable Manager overseeing quality, maintenance, and operations.

Duties of Accountable Manager:

Defines quality policy, manages quality evaluation, and provides necessary resources.

Roles, Accountabilities & Measures:

Adhere to PAL express quality standards, ensure quality of work, strive for improvement.

Quality Management System:

Follows PDCA cycle, includes resource management, measurement, product realization, and management responsibility.

IATA Operational Safety Audit (IOSA):

Assesses airline operational management and control systems.

Mandatory for IATA-member airlines.

Quality Assurance Program:

Includes audit planning, notification, preparation, proper, risk assessment, review, corrective/preventive actions.

Conduct of Audit:

Audits monitor compliance, scheduled and unscheduled, for various offices and operations.

Quality Inspection:

Inspections cover flight operations, maintenance, technical and training standards.

PAL express Service Providers:

List of service providers including Philippine Airlines, Petron, Macroasia Corporation, etc.

Recording:

Quality Assurance Program results are stored in Aviation Quality Database (AQD).

Root Cause - 5 Whys Analysis:

Identifies root cause for effective corrective/preventive actions.

Feedback System:

Periodic reports and management reviews for improvement insights.

Management Review:

Conducted every four months to evaluate and support QMS.

Safety Performance Monitoring:

Crucial for risk identification and accident prevention.

The Quality Assurance Manual

outlines the Quality Assurance Program of PAL express.

Summary

PCAR 9.2.2.3 (d) mandates the inclusion of a description of the quality system in documentation.

Airlines are required by PCAR and IOSA Standards to establish a Quality Management System (QMS).

The Quality Department is responsible for implementing the QMS in accordance with PCAR and IOSA standards.

Audits of the QMS are conducted by the PAL Quality Department.

Auditees identify root cause and provide corrective/preventive actions.

Permit-Required Confined Spaces - 29 CFR 1910.146

Confined Space:

A space where employees can enter and perform work.

Limited means for entry or exit.

Not designed for continuous occupancy.

Permit-Required Confined Space:

A confined space with hazardous conditions, including:

Hazardous atmosphere.

Potential for engulfment.

Characteristics:

Internal Configuration: Open (no obstacles) or Obstructed (obstacles present).

Elevation: Elevated (entrance above 4 ft) or Non-elevated (entrance ≤ 4 ft).

Portal Size: Restricted (≤ 24” portal) or Unrestricted (≥ 24” portal).

Space Access: Horizontal (side entrance) or Vertical (top or bottom entrance).

Definitions:

Attendant: Monitors entrants and performs assigned duties.

Authorized Entrant: Employee allowed to enter permit space.

Entry Supervisor: Responsible for permitting, overseeing, and terminating entry.

Duties:

Attendant: Knows hazards, monitors entrants, and maintains count.

Authorized Entrant: Knows hazards, uses equipment, communicates, exits when needed.

a. Authorized entrants must:

-Be aware of the hazards that could be encountered during entry, including understanding the signs, symptoms, and consequences of exposure.

-Properly use the required equipment as outlined in the relevant regulations or guidelines.

-Maintain communication with the attendant as needed, allowing the attendant to monitor their status and receive alerts if evacuation is necessary.

b. Authorized entrants must alert the attendant whenever they:

-Recognize any warning sign or symptom indicating exposure to a dangerous situation.

-Detect a prohibited condition that could jeopardize safety.

c. Authorized entrants must exit the permit space promptly whenever:

-They receive an order to evacuate from the attendant or entry supervisor.

-They recognize any warning sign or symptom indicating exposure to a dangerous situation.

-They detect a prohibited condition.

-The evacuation alarm is activated.

Entry Supervisor: Verifies conditions, terminates entry, ensures rescue availability.

Terminology:

Hazardous Atmosphere: Atmosphere with risk of death or injury.

IDLH: Conditions immediately dangerous to life and health.

Isolation: Process of removing space from service and protecting against energy release.

Line Breaking: Opening pipes containing hazardous materials.

Rescue Service: Personnel designated for rescues.

Testing:

Testing Protocol: Tests for oxygen content, flammable gases, vapors, and potential toxic air contaminants.

Purpose of Testing: Identify and evaluate hazards, implement control measures.

Other Hazards:

Unstable surfaces

falling objects

insects or animals

biological hazards.

TOPIC 6: Basic Electrical Safety

Introduction:

Electrical shocks and burns can result in serious injuries, with hundreds of workers dying every year from electrical shock incidents.

Even low levels of current can be lethal.

Voltage, Current, Resistance:

Voltage- is the force that drives the current through a circuit.

Current- is the amount of electricity flowing through a circuit.

Resistance- hinders the flow of electricity.

Factors Affecting Conductivity:

The condition of the skin (wet, dry, greasy) can influence electrical conductivity.

An individual's health, the duration of contact with electricity, and the specific body part in contact also affect conductivity.

Safety Do's and Don'ts:

Keep electrical equipment away from water sources.

Use a C-rated fire extinguisher on electrical fires and turn off the power source.

Remove frayed or damaged equipment and cords from service.

When unplugging, pull the plug, not the cord.

Grounding Electrical Equipment:

Grounding channels current leaks to the earth or ground.

A grounded cord has a 3-wire plug and requires a 3-way receptacle.

Double-insulated equipment doesn't need grounding.

Electrical Shock Injury (Amps and Milliamps):

1 Amp (1000 Milliamps) can cause severe burns.

0.1 Amp (100 Milliamps) may lead to an irregular heartbeat.

0.01 Amp (10 Milliamps) can prevent releasing one's grip.

0.001 Amp (1 Milliamp) is the threshold of sensation.

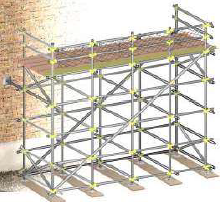

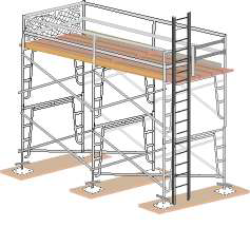

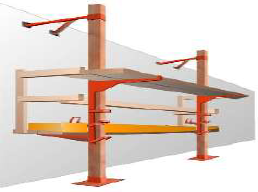

TOPIC 7: SCAFOLDING

Scaffolding refers to temporary elevated platforms and their supporting structures used to support employees or materials.

Competent Person:

A competent person must inspect scaffolding and its components before each work shift.

Capacity:

Non-Adjustable Scaffolds: Should support its own weight and 4 times the maximum intended load. Suspension rope and connecting hardware should support 6 times the maximum intended load.

Adjustable Scaffolds: The stall load of the scaffold hoist must not exceed 3 times the rated load. Must be designed by a qualified person and constructed according to loaded design.

Protection from Falling Objects:

Employees are required to wear hardhats.

Measures to protect employees below from falling objects include:

Installing toe-boards to prevent objects from falling off elevated platforms.

Using canopies to shield employees from objects falling from above.

Setting up barricades to prevent unauthorized access to areas where falling objects are a concern.

Suspension Scaffolds:

Suspension scaffolds are supported by support devices that must be capable of supporting four times the imposed load.

Outrigger beams, made of metal or equivalent material, must be used and restrained.

Outrigger beams must be stabilized to the floor or roof deck.

Direct connections must be evaluated by a competent person.

Supported Scaffolds:

Consist of platforms supported by outrigger beams, brackets, poles, legs, uprights, frames, or similar rigid support.

Poles must be restricted until bearers are set and braced.

Couplers should be made of structural steel, and the use of gray cast iron couplers is prohibited.

Designs over 125 feet require a Professional Engineer (P.E.).

Transverse bracing forming an "X" across the scaffold width must be installed at scaffold ends.

Tube and Coupler: Existing platforms must remain until new bearers are set and braced. Couplers must be made of structural metal.

Fabricated Frame: Existing platforms remain until frames are set and braced. Designed by an engineer for over 125 ft.

Mobile: Plumb, level, and squared. Braced to prevent collapse. Casters and wheels must be locked when stationary. Platforms shouldn't extend beyond base supports unless stability is ensured.

Pump Jack: Brackets and braces must be made from metal plates and angles. Each bracket must have two positive gripping mechanisms. Workbench can be used as top-rail if guardrails used for fall protection.

Ladder Jack: Must meet subpart "X" requirements. Ladder jacks designed to bear on side rails and ladder rungs. Ladders used to support ladder jacks must be securely fastened.

Suspended Scaffolds:

Platforms suspended by ropes or non-rigid means from an overhead structure.

Two-Point Swing Stage: Platform limited to 36". Must be securely fastened to hangers. Ladder, plank, or beam type platforms. No bridging unless appropriately sized.

Single-Point Adjustable: Support rope between scaffold and suspension device kept vertical unless designed otherwise by a qualified person.

Multi-Level: Must have additional independent support lines equal in strength to suspension ropes.

Aerial Lifts: Must meet ANSI criteria. Must be secured in lower traveling position. Proper fall protection including guardrails required.

Training and Retraining:

Employees must receive training covering hazards, scaffold use, load capacities, setup, dismantling, and more.

Retraining required when employee lacks skills or understanding, new hazards arise, or changes occur in scaffold type or fall protection.

This summary emphasizes the different types of scaffolding, their components, and the importance of proper training and retraining for safe scaffold use.

Supported scaffolds:

Pole:

Tube and Coupler:

Fabricated frame:

Mobile:

Pump jack:

Ladder jack:

Suspended scaffolds:

Two point swing stage:

Single-point adjustable:

Multi-level:

Aerial lifts:

MIDTERMS

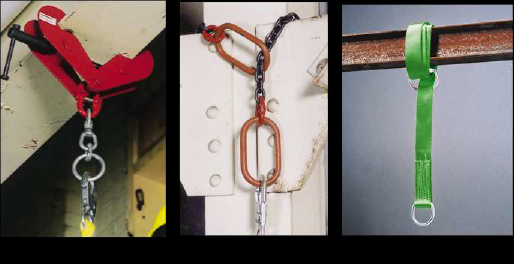

TOPIC 8: Fall Protection

Introduction:

Falls are a significant cause of accidents in general industry, second only to motor vehicle crashes.

OSHA requires fall protection when exposed to a 4-foot fall or greater, unless working on ladders, scaffolds, or scissor lifts.

Common Fall Hazards:

Overhead platforms

runways

elevated workstations.

Stationary storage tanks

tanker trucks

industrial production units.

Floor openings

pits

wall openings

shelving units.

Fall Hazard Controls - Hierarchy:

First line of defense – Eliminate the fall hazard.

Second line of defense – Prevent the fall.

Third and last resort – Control the fall.

Eliminate Fall Hazards:

Examples include moving gauges to ground level and using drones for inspections at heights.

Hole covers/grates are an effective way to eliminate fall hazards when properly designed and secured.

Eliminate fall hazards – hole covers/grates

Very effective way to eliminate a fall hazard.

Designed to withstand intended load.

Secured-bolted, hinged, latched, locked

Prevent the fall – guardrails

Standard railing

Top rail, mid rail, and posts

The height from upper surface of top rail to floor level is 42” (+/− 3”)

Mid-rail height is 21”

Standard toeboard

Not more than ¼” clearance above the floor

3.5” high

Prevent the fall – fences and barricades

Prevents unauthorized employee exposure to fall hazard

Employer authorizes access

Authorized personnel must then be protected from the fall hazards within

Prevent the fall –personal all restraint

Prevent falls by keeping worker from reaching fall hazard

Comprised of a body belt or body harness, an anchorage, connectors

Often used when section of guardrail or hole cover is temporarily removed

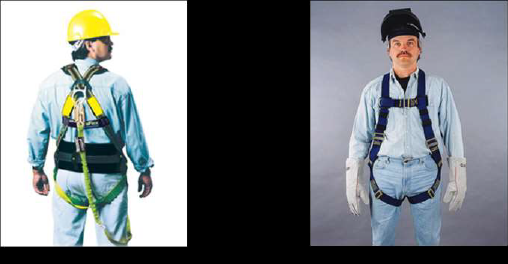

Know the A, B, Cs of Personal Fall Arrest Systems

Anchorages- must handle 5000 pounds.

Body harness

Components

PFAS – temporary anchorage

PFAS – permanent anchorage

PFAS – full-body harness

PFAS – connecting components

Control the Fall:

Positioning devices consist of body belts and connecting devices, allowing workers to have their hands free for work.

Safety net systems include mesh nets, panels, and connecting components, requiring proper design and maintenance.

Employer Requirements

Training – your employer must train you on the following:

Fall hazards associated with your facility and your work

Methods used to protect you from those hazards

Proper and safe use of any personal fall arrest, positioning, or fall restraint systems

Applicable OSHA standards

Inspection

Your employer must inspect the:

workplace for existing and potential fall hazards

fall hazard controls used; such as guardrails, covers, grates, and anchorage points

You must inspect your PFAS, Positioning and Fall Restraint hardware before each use.

Rescue

Personal Fall Arrest Systems require a rescue plan

Employer must develop and communicate the rescue plan to all involved

TOPIC 9: Fire Safety and Fire Code

Bureau of Fire Protection (BFP):

Established through RA 6975 in 1991.

Responsibilities: Prevent and suppress fires, conduct investigations, provide emergency medical and rescue services, enforce Republic Act 9514.

Republic Act 9514 (The Revised Fire Code of the Philippines):

Governs fire safety in the Philippines.

Covers fire safety inspections, seminars, fire drills, and fire brigades.

Fire and Its Stages

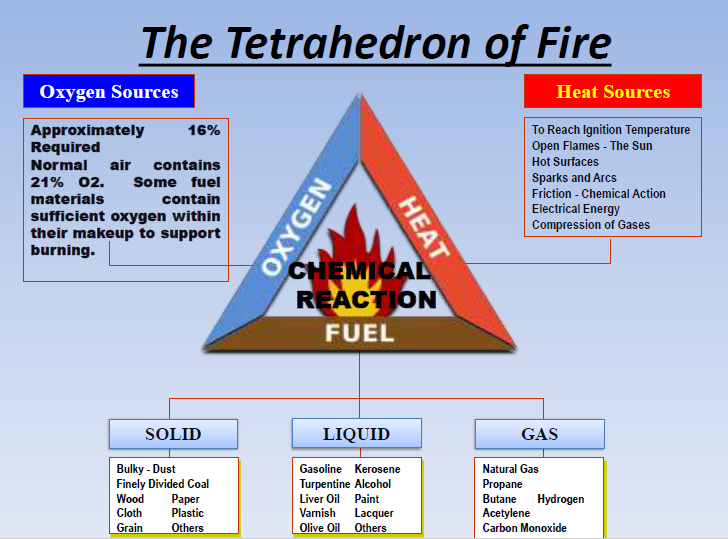

Fire is the active principle of burning characterized by heat and light (RA 9514).

It's a rapid oxidation process with heat and light evolution.

Stages of fire: Ignition, Growth, Flash Over, Fully Developed, and Decay.

Ignition Stage

Fire initiation point.

Abundant oxygen, little heat, and smoke.

Fire is small and confined to the initial fuel source.

Growth Stage

Temperature and smoke increase.

Oxygen decreases, fuel dries out.

Hot gases rise, spread to walls.

Can continue with enough fuel and oxygen.

Smoke thickens, fire spreads to nearby items.

Flash Over

Transition between growth and fully developed.

Huge smoke presence indicates rapid change.

May involve exposed combustibles.

Increased smoke, reduced visibility.

Gases generated by heat.

Fully Developed

All combustibles continuously burn.

Maximum heat release.

Fire volume depends on ventilation.

Unburned gases flow to adjacent spaces and ignite with more air.

Decay

Fire intensity decreases due to lack of available fuel.

Most fuel consumed.

Focus on cooling remaining fuel.

Methods of Heat Transfer

Radiation: Heat energy through electromagnetic waves.

Convection: Heat transfer through fluid movement.

Conduction: Heat transmission from one body to another through molecules.

Direct Contact: Heat transfer through physical contact.

Fire Extinguishment Theory

Cooling: Reducing temperature.

Smothering: Diluting oxygen.

Fuel Removal.

Inhibition: Breaking the chemical reaction.

REDUCTION OF HEAT

Use something that absorb heat

Use water being the best cooling agent

Use foam which contains 94% water

EXCLUSION OR DEPRIVATION OF OXYGEN

Secure the door at close position

Displacement or diluting oxygen by means of CO2

Blanketing- using wet blanket as foam

REMOVAL OF FUEL

Shut off fuel supply

Relocate flammable/ combustible materials

INHIBITION OF CHAIN REACTION

breaking the combustion Chain

Classification of Fire

Class A Fire:

Fuel: Ordinary combustibles or fibrous materials.

Examples: Wood, paper, cloth, rubber, some plastics.

Characteristics: Typically, these materials leave behind ashes when burned.

Class B Fire:

Fuel: Flammable or combustible liquids.

Examples: Gasoline, kerosene, paint, paint thinners, propane.

Characteristics: These fires involve liquid fuels that can spread quickly if not controlled.

Class C Fire:

Fuel: Energized electrical equipment.

Examples: Appliances, switches, panel boxes, power tools.

Characteristics: These fires occur when electrical equipment is involved and should be addressed with non-conductive agents.

Class D Fire:

Fuel: Certain combustible metals.

Examples: Magnesium, titanium, potassium, sodium.

Characteristics: Combustible metals that can react violently with water or other chemicals, requiring specialized extinguishing agents.

Class K Fire:

Fuel: Combustible cooking fluids.

Examples: Oils and fats used in cooking.

Characteristics: Typically found in kitchen settings and require specialized extinguishing agents due to the nature of the fuel.

FIRST AID FIRE FIGHTING APPLIANCE

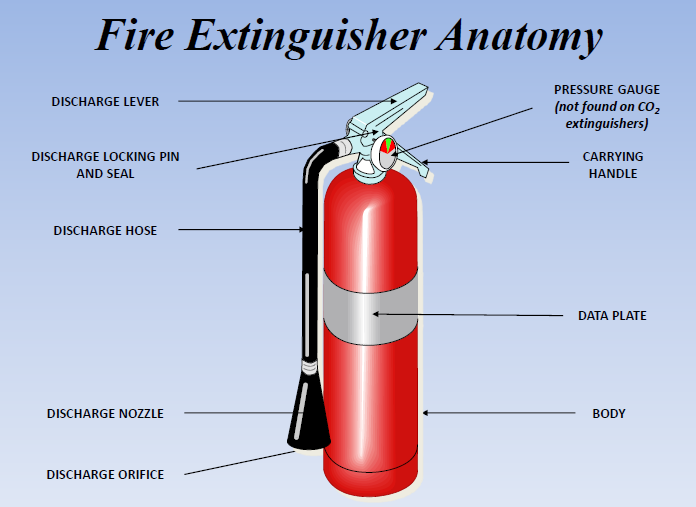

Fire Extinguisher: is a handy, first aid fire fighting equipment

Classifications of Fire Extinguishers

Hexafluoropropane HFC-236FA (FE-36) - Clean Agent:

Environmentally friendly and compliant with regulations.

Effective for A, B, and C types of fires.

Dry Chemical:

Multipurpose agent for A, B, and C fires.

Works by creating a barrier between oxygen and fuel in Class A fires.

Aqueous Film Forming Foam (AFFF):

Removes the heat element of the fire triangle.

Suitable for A fires and can be used on limited Class B fires with caution.

Wet Chemical:

Designed for commercial kitchens.

Extinguishes fires by removing heat and preventing re-ignition.

Effective on Class A and limited Class K fires.

Dry Powder:

Designed for Class D or combustible metal fires only.

Functions by separating the fuel from the oxygen element or removing heat.

FIRE DRILL:

is an exercise or practice that teach the people on how to leave the building safely.

PURPOSE OF FIRE DRILL:

Ensure the efficient and safe of exits

Help prevent panic

Occupants participating in a drill learns to: a. locate the fire exits of the building b. leave the building/house in a smooth, safely, orderly and disciplined manner c. recognize or familiarize the actual sound of the fire alarm system d. assemble at the designated evacuation area

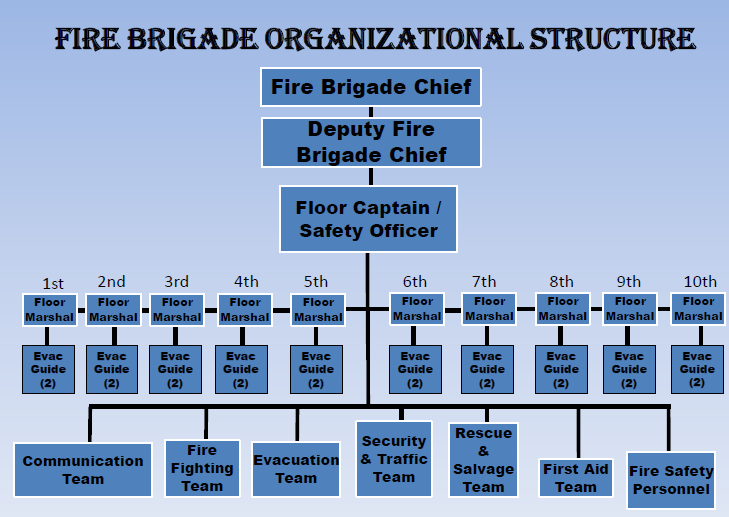

Fire Marshal: Supervises during emergencies, sets up a command post.

Assistant Brigade Marshal: Assists the Fire Marshal.

Communication Team: Notifies authorities.

Firefighting Team: Combats the fire.

Evacuation Team: Ensures safe building evacuation.

Security/Traffic Team: Assists in crowd control.

Rescue Team: Conducts search and rescue.

Salvage Team: Protects property.

First Aid Team: Provides medical assistance.

Fire Safety Personnel: Monitors and inspects fire safety features.

A Fire Brigade must remember to:

Determine the Specific Fire Floor

Begin the Control of Evacuation

Search of the fire floor and all floors above the fire

Gain Control of Building Systems

Confine and Extinguish the Fire

IN CASE OF FIRE

Proceed to the designated evacuation area.

Immediately leave the building by using the nearest available exit.

Notify others as you exit the building.

Do not return to the burning building.

Remain calm, think, and act!

During a Fire Emergency, there should be a:

Command Post (FM, Tech Staff)

White Board

Floor/Key Plan of the building

Radio

First Aid Station

Evacuation Area

Caution Tape

Basic Information for the white board:

Time fire started

Floor/s involved/Location

Time of call to the Fire Dept

Time Evacuation started

Time Responder/s arrived

Time Evacuation ended

Time of fire out

Name of victim/s

Type of injury

Responding Ambulance

Recipient hospital

PERSONAL PROTECTIVE EQUIPMENT

Helmet

Bunker/Fire coat

Trouser

Suspenders

Gloves

Fire Boots

BASIC FIRE SAFETY FEATURES OF A BUILDING

Automatic Fire Suppression System-Sprinkler System

Fire Hose Cabinet

Fire Detection and Alarm System-Smoke detectors

Means of Egress (Emergency Exit)

Portable Fire Extinguishers

Fire Safety Tips

Identify and report fire hazards and unsafe work practices.

Unplug all electrical equipment when not in operation, unless necessary.

Maintain proper housekeeping

Familiarize and keep emergency exits marked, lighted and free from any obstruction.

Familiarize location of fire alarm, fire extinguishers and other fire fighting equipment.

Enforce “No Smoking” policy

Avoid overloading of electrical circuits by plugging many appliances

Do not store large volume of combustible liquids without proper clearance/permit and fire protection

Ensure complete attendance of ALL fire brigade members during Fire Safety Seminars and Drills

Regularly conduct emergency drills (internal)

TOPIC 10: Introduction to Industrial Hygiene

Industrial Hygiene – the science of protecting the health and safety of workers through:

Anticipating: Predicting potential hazards in the workplace.

Recognizing: Identifying existing hazards.

Evaluating: Assessing the risks associated with these hazards.

Controlling: Putting measures in place to prevent worker injuries or illnesses.

Local Effects:

1. Irritation (dryness, redness, cracking) - fiberglass:

- Contact with fiberglass can cause skin irritation.

2. Corrosion (chemical burn) - acid:

- Exposure to acids can lead to chemical burns on the skin.

3. Upper Respiratory Tract Infection – inhaling particles:

- Inhaling particles can cause infections in the respiratory tract.

Systemic Effects:

1. Toxicology - science that studies the poisonous or toxic properties of substances:

- Toxicology studies how substances can be toxic when absorbed into the body.

2. Hepatotoxins - Cause liver damage:

- Hepatotoxins can damage the liver.

3. Nephrotoxins - Cause kidney damage:

- Nephrotoxins can damage the kidneys.

4. Neurotoxins - Cause nerve damage:

- Neurotoxins can harm nerve cells and the nervous system.

5. Hematotoxins - Cause blood system damage:

- Hematotoxins can damage the blood system.

6. Anesthetics - Depress nervous system:

- Anesthetics depress the nervous system, causing a loss of sensation or consciousness.

Types of Health Hazards

1. Common workplace health hazards:

Chemical

Physical

Biological

Ergonomic

2. Chemical Hazards and Controls:

Multiple chemical hazards

Welding fumes

Dust particulates

Spraying mist

Exposure entry routes:

Inhalation

Ingestion

Absorption

Injection

3. Biological Hazards and Controls

Insects

Animals

Contaminated Soil

Poisonous Plants

Water/Sewage

Bloodborne Pathogens

Protection against biological hazards:

Practice universal precaution with:

Blood

Bodily fluids

Practice personal hygiene

Provide proper first aid

Cuts/Scratches

Vaccinations

Wear proper PPE/clothing

Practice precaution with:

Animals

Insects

Use insect repellent

Provide proper ventilation or other appropriate environmental controls

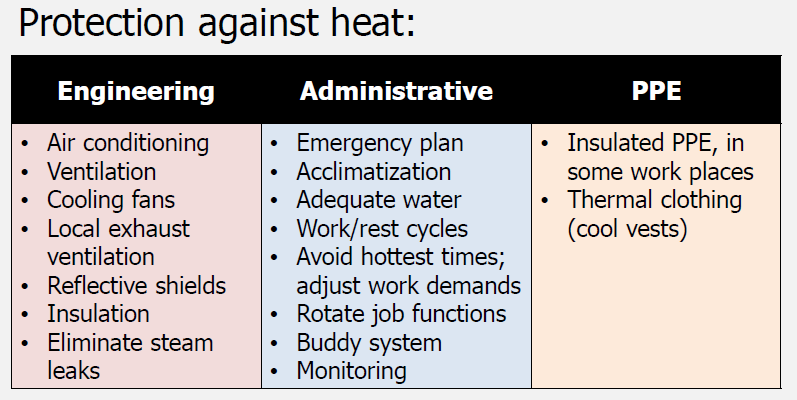

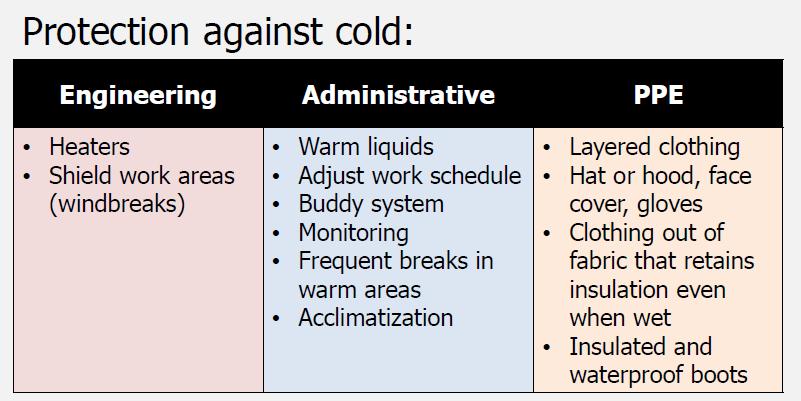

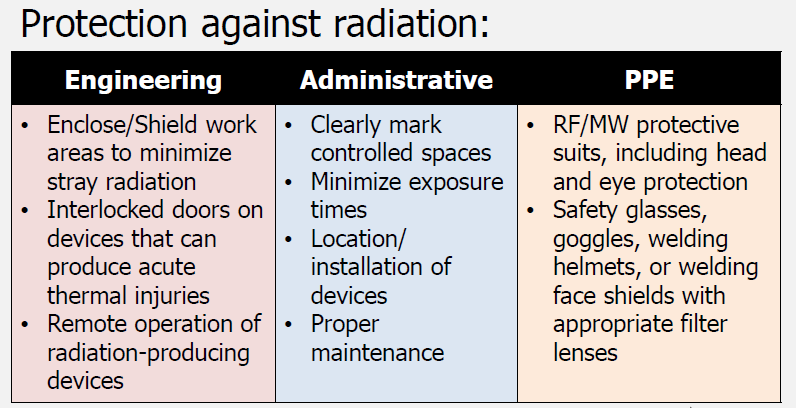

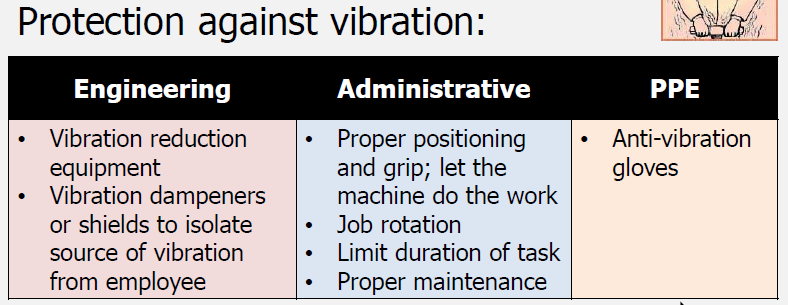

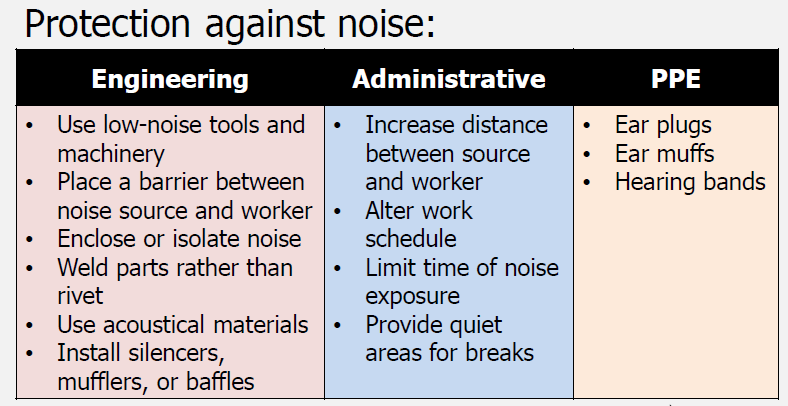

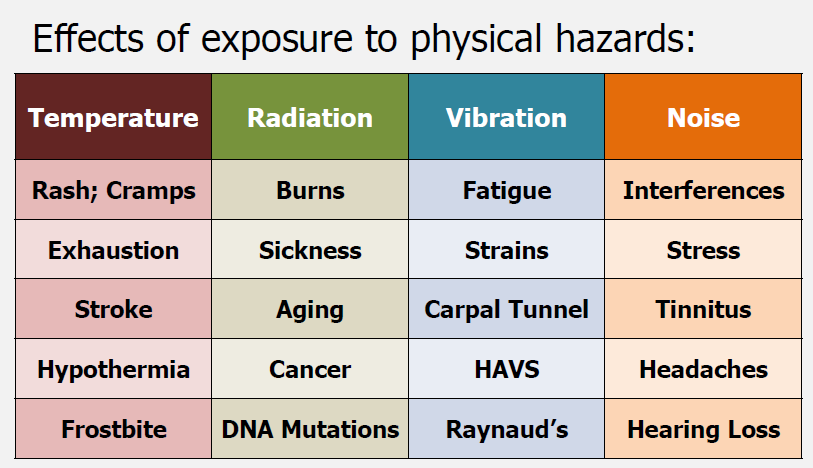

4. Physical Hazards and Controls

Temperature

Radiation

Vibration

Noise- prolonged exposures to 85 dB can lead to hearing loss

5. Ergonomic Hazards and Controls

Musculoskeletal Disorders (MSDs): Exposure to ergonomic risk factors for MSDs increases the risk of injury.

Repetition: Doing the same movements frequently.

High force: Using excessive physical force.

Awkward postures: Maintaining uncomfortable body positions.

TOPIC 11: Emergency Response Plan

Emergency Action Plans

Benefits of an EAP (Emergency Action Plan):

Written Documentation: Provides a structured plan for employers and employees to follow during workplace emergencies.

Injury Reduction: Leads to fewer and less severe injuries among employees.

Structural Damage Reduction: Helps minimize damage to the workplace structure.

Confusion Reduction: Reduces confusion by outlining clear procedures and responsibilities.

Purpose of an EAP:

Employee Safety: Describes actions to ensure employee safety during emergencies.

Emergency Escape Routes: Utilizes floor plans and maps to illustrate escape routes.

Employee Guidance: Informs employees about specific actions to take during emergencies.

Coverage: Addresses a range of reasonably expected emergencies.

Required elements of plan:

Means of reporting

Evacuation procedures and emergency escape routes

Procedures for critical operations

Accounting of employees

Rescue and medical duties

Contact persons

Training employees on the EAP

General training

Fire Prevention Plan

(FPP) Requirements:

Must be in writing.

Kept in the workplace.

Available to employees for review.

Employer must inform employees of fire hazards when initially assigned to a job.

Review applicable FPP parts with each employee.

Included in FPP:

Lists of all major fire hazards, proper handling and storage of hazardous materials, ignition sources/controls, and fire protection equipment.

Procedures to control flammable/combustible wastes.

Procedures for maintenance of safeguards on heat-producing equipment.

Name/job titles of employees with responsibilities for maintenance of equipment and control of hazards.

Preventing Fire Hazards:

Understanding fires: A rapid chemical reaction between oxygen and a combustible material that results in the release of heat, light, flames, and smoke. It requires four elements: oxygen, ignition source (heat), fuel, and a chemical reaction.

Ignition sources: These can include open flames, smoking, static electricity, hot work, hot surfaces, electrical and mechanical sparks, and lightning.

Tasks that require fire protection and examples of hazards.

Handling of flammable hazards.

Fire protection equipment.

Conditions Requiring Evacuation

1. Man-made emergencies

Fires

Explosions

Toxic material releases

Radiological/biological incidents

Civil disturbances

Workplace violence

2. Natural emergencies

Floods

Earthquakes

Hurricanes

Tornadoes

Wildfires

Winter weather

Factors affecting response to emergencies:

Type/extent of emergency

Location of emergency

Type of building in which workplace is located

Shutting down critical operations

Fire emergencies: Fight or Flee?

Options for evacuation

Performing a risk assessment

Evacuation maps show:

Exits: to, thru, and away

At least two ways out

Primary exit

Secondary exit

Assembly area

Location on the map

Additional information

Location of fire extinguishers

Evacuation actions:

Alerting employees to evacuate

Accounting for who has exited

Keeping employees informed

Incidents that may require shelter-in-place:

Release of chemical, biological, or radiological contaminants

Severe weather - tornadoes

Other situations occurring outside the workplace

Shelter-in-place:

Means taking refuge in interior room(s) with no/few windows

Local authorities often issue shelter-in-place advice via TV or radio

Procedures specific to worksite

Planning shelter-in-place actions:

Alerting employees - shelter-in-place

Accounting for who is in refuge

Keeping employees informed

Exit routes:

Continuous and unobstructed path of exit travel from any place in the workplace to safety

Exit access, exit, exit discharge

Should be:

Clearly marked

Well-lit

Appropriate width

Unobstructed/clear

Basic exit route requirements:

Permanent

Separated by fire-resistant materials

Limited openings

Adequate number of exit routes

Discharge leading directly outside or to a place with access to outside

Exit door unlocked from inside and side-hinged

Adequate capacity

Minimum height and width

Clearly communicate 3 elements of escape route:

Exit access pathway

Nearest exits from all points of the building

Pathway away from the building structure

Extinguishing Fires

Methods of fire protection:

Fixed extinguishing systems

Portable fire extinguisher training and education

Fire brigades

Fire extinguishers

Classes of fires:

Class A – ordinary combustibles

Class B – flammable liquids and gases

Class C – energized electrical equipment

Class D – combustible metals

Class K – cooking oils and greases

How fire extinguishers work:

Remove heat

Displace/remove oxygen

Stop chemical reaction

Types of extinguishers:

Water

Carbon Dioxide

Dry Chemical

Water or Air-Pressurized Water (APW) Extinguishers:

For: Ordinary combustibles (Class A fires).

Using water and air, cools the fire.

Carbon Dioxide (CO2) Extinguishers:

For: Flammable liquids (Class B) and electrical fires (Class C).

Contain high-pressure CO2 to smother the fire.

Dry Chemical Extinguishers (Multi-purpose):

For: Common fires (Class A, B, C).

Contain fire-retardant powder to interrupt the fire's chemistry**.**

Class K Extinguishers:

For: Kitchen fires involving oils and fats.

Contain electrically conductive agents for safe use in kitchens.

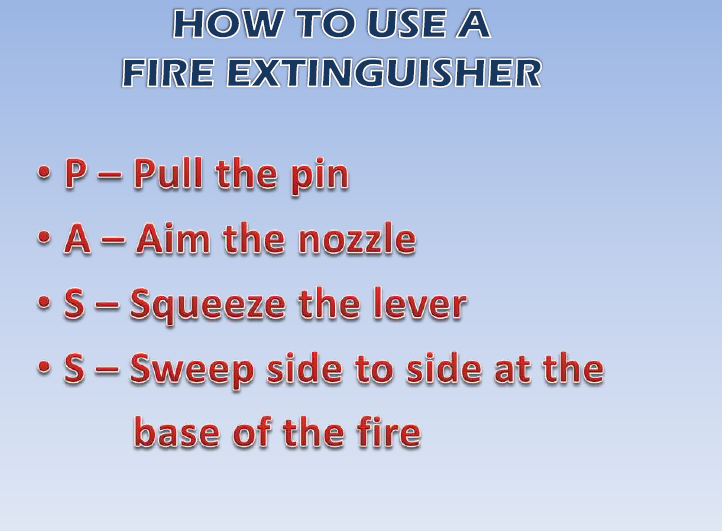

Using a fire extinguisher:

Sound alarm; call fire department

Identify safe evacuation path

Select appropriate fire extinguisher

Discharge extinguisher using P.A.S.S. technique

Back away once extinguished

Evacuate immediately if necessary

Elements of inspection:

Inspect bottle, handle, hose, and gauge for proper working order

Inspection tag:

Month and Year put in service current (annual)

Monthly visual inspections completed (monthly)

Extinguisher product still free-flowing inside bottle (turn upside down and/or shake)