APSC 101 Final Notes

Risk Management

Chapter 11, 18 Sections 18.1-18.3

Risk Factors

Severity: Maximum harm that could come from an incident

Likelihood: The probability of a harm causing accident

Hazard: Capacity to cause harm (in terms of safety)

Risk = Severity x Likelihood

What is Risk?

Possibility of harm occurring, determined from severity and likelihood.

Risk Sources:

Preventable

Risks that teams can manage and control

Strategic

Risks knowingly taken for potential rewards

External

Outside of the teams control, must be considered

Risk Types:

Safety

Related to health and wellbeing of people and environment

Technical

Design and manufacture, ensuring the solution works as intended

Project Management

Completion of project on time and with budget

Operational

Decision making on the operation and use of the device

Risk Categorization Table

Horizontal categories: Risk Sources (external, preventable, strategic)

Vertical categories: Risk Types (safety, technical… etc)

Use of Risk Categorization Table:

Documents and captures important risks

Focuses on different risk sources and categories

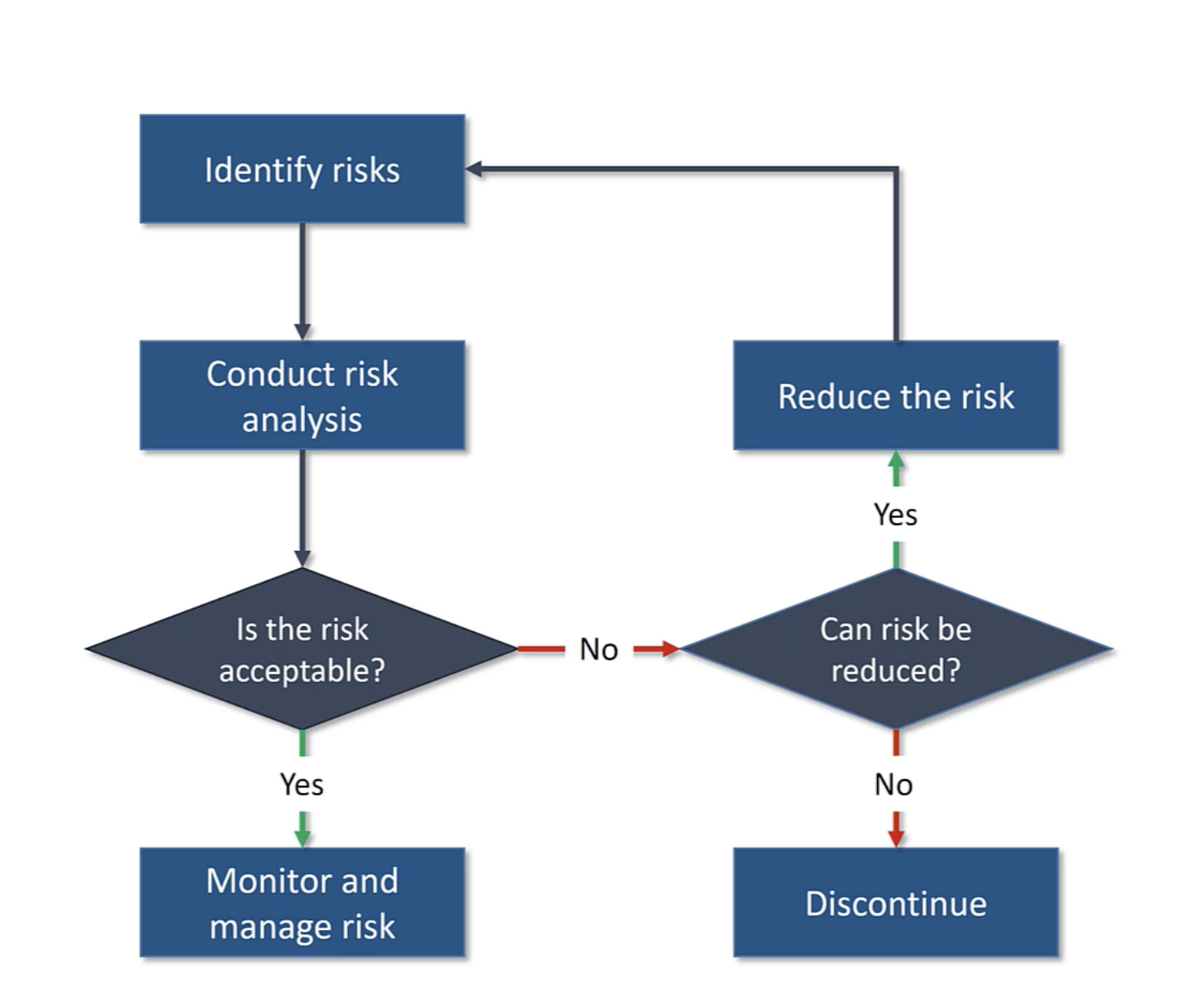

Risk Management Approaches:

Avoid

Change what you are doing to remove the risk entirely

Ex. Stopping the project, changing ideas

Mitigate

Try to minimize likelihood, severity or both

Ex. Changing certain aspects of your design

Transfer

Pass the risk to someone else

Ex. Insurance

Accept

Be willing to live with the consequences of your risk

Ex. Doing nothing

Risk Matrix

A tool for quantifying risk based on the product of likelihood and severity.

Vertical column: Likelihood increasing

Horizontal column: Severity increasing

Risk Analysis Chart

Team Development

Sections 17.2 and 17.4 ("Managing Conflict").

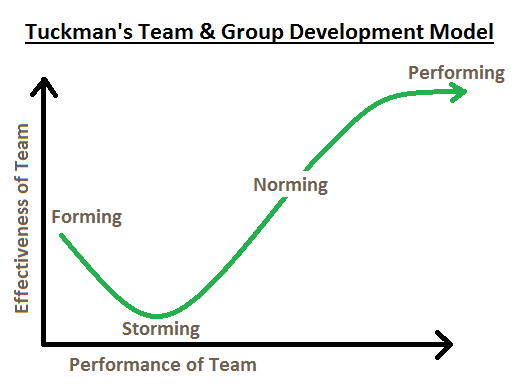

Tuckman’s Stages Chart

Team Completion and Team Relationship

Tuckman’s Stages of Team Development

Forming

Everyone is polite, tries to contribute, minimizing controversy

Not well coordinated: strengths of team aren’t well utilized

Storming

More willingness to speak, however tension and disagreements are created

Quantity and quality of work decreases

Norming

Good Norming:

Mutual understanding of roles, goals and standards.

Bad Norming:

Dysfunctional, worried about awkwardness instead of resolving issues

Performing:

Strong group identity, healthy and supportive relationships, high value work

When does conflict occur?

Throughout all stages.

Forming: avoiding conflict

Storming: conflict in the open, stressful

Performing: dealing with conflict quickly and smoothly

Conflict ensures all opinions and voices are heard.

Transitioning through stages:

F→S

Time spent working together, leadership

S → N

Open Communication, real friendships, desire to improve

N → P

Willingness to face conflict

Valuing team relationships and accomplishments

Bad Norming → Good Norming

Courage to speak up against unfairness

Conflict Management Chart

Co-operativeness

Seeking to meet the other parties goals

Assertiveness

Seeking to meet our goals

Vertical: Assertiveness Horizontal: Co-Operativeness

Conflict Management Styles

Avoiding

Ignoring the conflict, removing yourself from the situation

No one gets what they want

Accommodating

Being flexible to give up what you want for others

Competing

Pushing to achieve what you want, even if it upsets the others

Quick

Compromising

Meeting the other party in the middle

Both get what they want

Quick

Collaborating

Taking the time to listen and work together to come up with a solution everyone likes

Takes time and effort

Engineering Drawings

Sections 10.1, 10.2, and 10.3.

Projection

View used to represent a 3d object in a 2d space

Perspective Projection

Realistic perspective where closer features are larger, further are smaller

Principal View Projection

View from main sides: top, front, end

Multiview Orthographic

Multiple principle projection views

Pictorial Drawings

Look 3d but use parallel lines

Starting line is typically 30 degrees to 45 degrees to the horizontal

Isometric Projection

Pictorial drawing

Starting line 30 degrees from horizontal

Circular features are elliptical

Distances from axis are proportional to IRL

Vertical and Parallel lines match IRL

Uses reference lines

Hidden Lines Orthographic

Dashed lines used to show un-visible features

Orthographic Drawings

If you stood directly in front of a specific side, you see the face (view)

Third Angle Projection

Top view above front view, right view to the right of front view

Dimensioning Guidelines

Sufficient dimensions to describe the object

Dimension the view that shows features clearly

Diameter of circle: on the view that shows it

Diameter of cylinder: dimensioned from the side, cylinder appears a rectangle

Don’t dimension hidden lines

Dimensioning

Dimension Line

Line with arrows on the ends to show size or location of a feature

Don’t cross dimensions lines with each other

Shouldn’t be in the object

Extension Line

Straight reference line to identify features on an object and to which a dimension line points

Can cross with other extension lines if necessary

Centre mark

“+” symbol identifies the centre of a circular feature

Dashed line with a long-short pattern identifies centre of cylinder

2 Types of Dimensioning

Chain dimensioning

Style of dimensioning where a new dimension starts where a previous ends

Datum Dimensioning

Multiple dimensions start from the same datum

Title Block

Section used on an engineering drawing with critical information

What does a Title Block Contain?

Units of dimensions

Uncertainties of dimensions

Symmetric symbol: 3rd angle projection

Who created and checking the drawing and when

Material and quality of surface finish of item

Drawing Scale (1:1)

Name and number of drawing

Current drawing version

Feedback

Section 17.4 ("Giving and Receiving Feedback") and Section 15.2.

Equity Diversity and Inclusion

Equity:

Everyone has the same opportunities for success

Diversity:

Differences in background and identities allowing for more creativity and better performance

Inclusion:

Addressing inequities between people of different backgrounds and working towards a respectful community

Intersectionality

Overall experiences of discrimination or privilege based on dimensions of diversity

Biases

Implicit Biases:

Subconscious stereotypes about groups, learned through seen patterns

Microaggressions:

Small, subtle or indirect discriminatory actions or statements

Stereotype Threat:

When people feel concerned about conforming to a stereotype for a group they belong to

Allyship:

Acting to support individuals facing discrimination

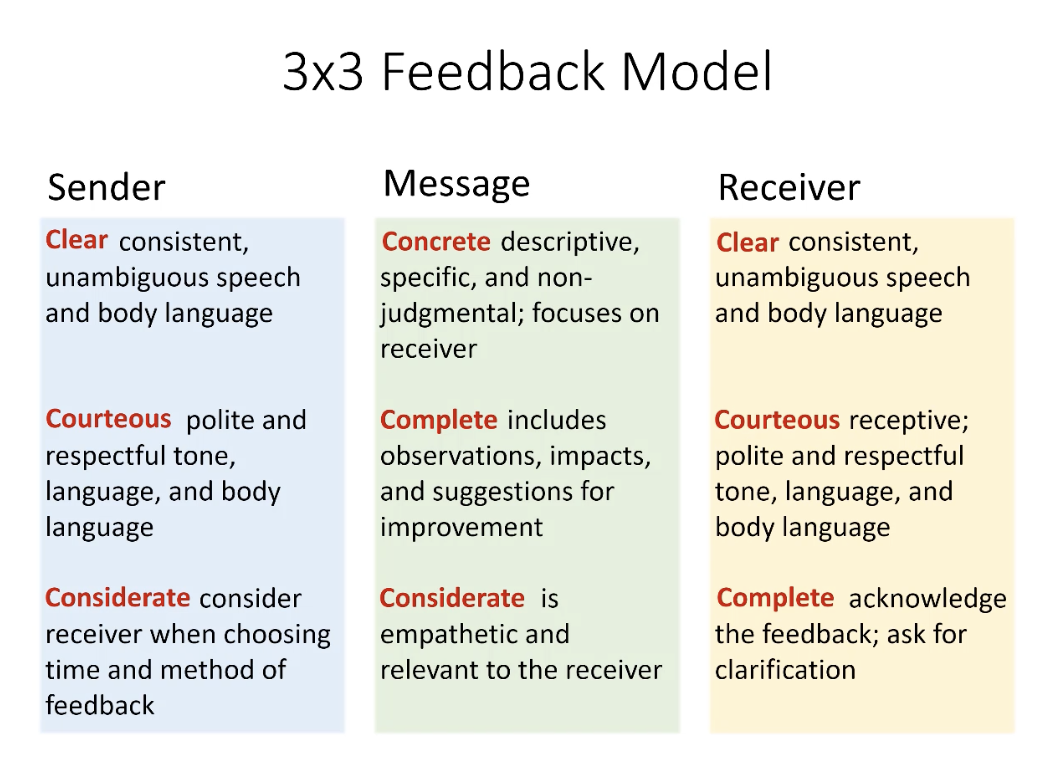

7 C’s of Communication

Clear

Easy to follow, direct, appropriate structure

Correct

Factually correct, free of errors

Concise

Brief and to the point without losing meaning

Concrete

Detailed, specific, intended message evident

Complete

Information the audience needs and what is expected

Courteous

Polite, friendly, sincere, appropriate honorific

Considerate

Empathetic and mindful

Takes into account audience and reaction (impact)

Technical Memo

Form of concise written communication, shares information (projects)

Structure Technical Memo

Sender’s address

Date

Inside address

Reference line

Salutation

Body

Closing (Signature and Name)

Enclosures

3 Types of Feedback

Appreciation

Acknowledge job well done

Coaching

Help someone improve

Evaluation

Rate someone’s performance against standards

3×3 Feed Back Model

Life Cycles

Sections 13.1, 13.3, and 14.1

3 Scales to Consider

Spatial

Physical largeness of a system

Temporal

Time, looking at now, into the future

Organizational

Based on organizational structures, such as government, schools, etc

Sustainability Venn Diagram

No trade-offs for sustainability

Environment

Clean air, safe environment

Society

Health, safety, human rights

Economy

Employment, business

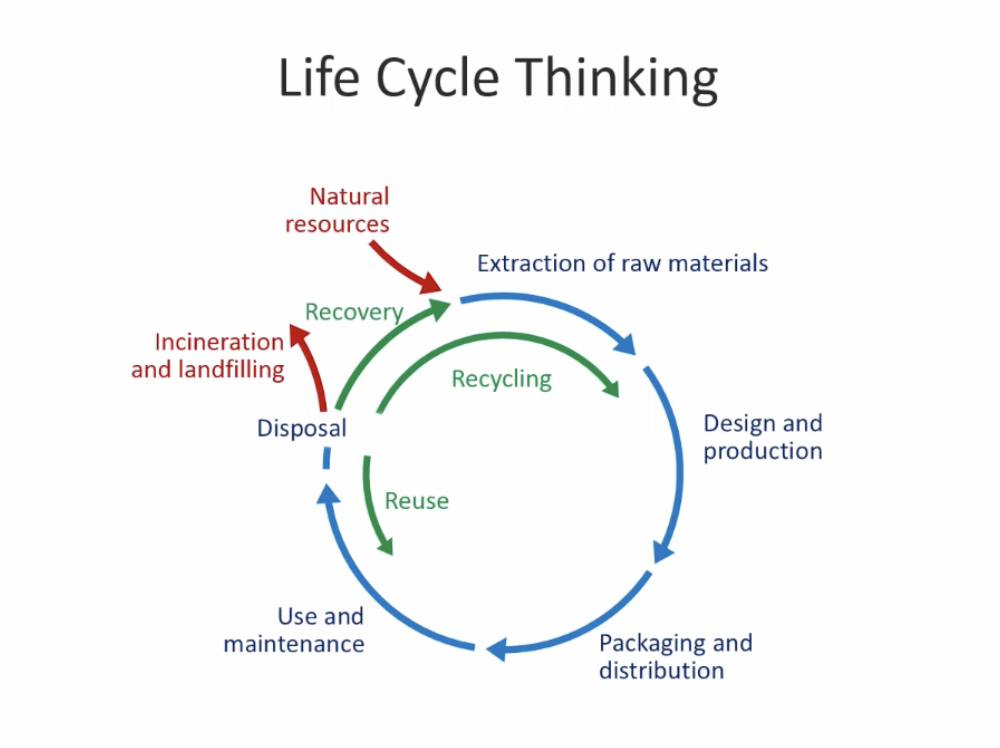

Life Cycle Thinking

Life Cycle Assessment LCA

Systematic Evaluation of the impacts of material and energy inputs and outputs for a product or process across all life cycle stages

Used usually near the end of the design process once everything is known

LCA Main Stages

Goal definition and scope

Defining system boundary, and which life cycle stages are we considering

Inventory Analysis

Tracking material influx and outflux, waste, manufacturing processes, etc.

Impact Assessment

Assessing environmental impacts

Established environmental impact metrics

Interpretation (All throughout)

Displaying our data (bar graph)

Cons of LCA

Detailed knowledge of material and energy flows is required

Impacts must be known and quantified

Focuses on environmental impacts

System Boundary

Description of what elements are included / excluded in an LCA

Ex. Examining a phone, determining if you’re also accounting for the electronics inside, as well as the glass screen… etc

Functional Unit

Reference of performance used to compare things in an LCA

Ex. Comparing emissions from cars vs busses, functional unit: emissions for 120 person-km of city driving

Streamlined Inventory Analysis SLCA

Sees the life cycle of materials as also a life cycle sequence

Used all throughout the design process

Life Cycle Sequence

Raw Materials → Production → Distribution→ Use → End of Life

Categories of an SLCA considered

Resources Used

Waste Generated

Energy Used

Public Health

How to use an SLCA?

Consider the life cycle sequence:

Raw Materials → Production → Distribution→ Use → End of Life

In each part of the sequence, rank on a scale of 1-5 for each category

Resources Used

Waste Generated

Energy Used

Public Health

Put data into an SLCA matrix and sum the values

SLCA vs LCA

SLCA is faster

SLCA is qualitative, better for difficult to quantify data

Suitable all throughout the design process

Technology

Section 12.3 ("Appropriate Technology")

Appropriate Technology: Meaning

Design solution considers key stakeholders across all lifecycle stages of that solution

Solution is appropriate for the context

Sustainability Venn Diagram

Sustainability: Context

Relevant factors in a problem that influence stakeholder consultation and the sustainability of a solution

Ex. Context needed for maintenance nearby, use after novelty wears off, interactions for citizens

Stakeholder Engagement

All throughout design process

Engage

Design, implement, and commit to processes of engagements that give stakeholders to opportunity to change their future

Learn

Understand and hear all perspectives

Synthesize

Integrate new stakeholder input in decisions, and tweak the project to suit them longterm

Business Letters

Format

Sender Address

Date

Inside Address

Salutation

Purpose

Details

Restate Purpose

Closing

Satisfaction Curves

Section 5.4 ("Evaluation Criteria")

Target Design Specifications

Requirements

Necessary components of a solution

Evaluation Criteria

Distinguish between different degrees of satisfaction

Design Parameters and Attributes

Parameters:

Inputs of a system

Ex. Battery capacity

Attributes:

Outputs

Ex. Cost of the battery capacity implementation

Satisfaction Curves:

Only looks at satisfaction for a certain aspect.

X Axis: Attribute

Something of importance to the stakeholder

Y Axis: Satisfaction

We are trying to maximize

Minimum should be at zero (The minimum required)

In between should be what they want/need

Maximum should be more than needed

Water Treatment

Chapter 18 introduction and Section 18.1

Water Stress

Sufficient quality and quantity of water available

Centralized Water Treatment Systems

Found in large cities

Small number of water treatment plants produce water for the city

Easier to maintain, lower costs for water

Needs large infrastructure, costs a lot

Decentralized Water Treatment Systems

More smaller plants for a city

Per smaller plant, serves small portion of city

RWH System

Schematic:

Catchment

Collection Tank

Pump

Check Valve

Prevents flowing backwards

Filter

Storage

Placement of Filter

Anywhere before UV treatment

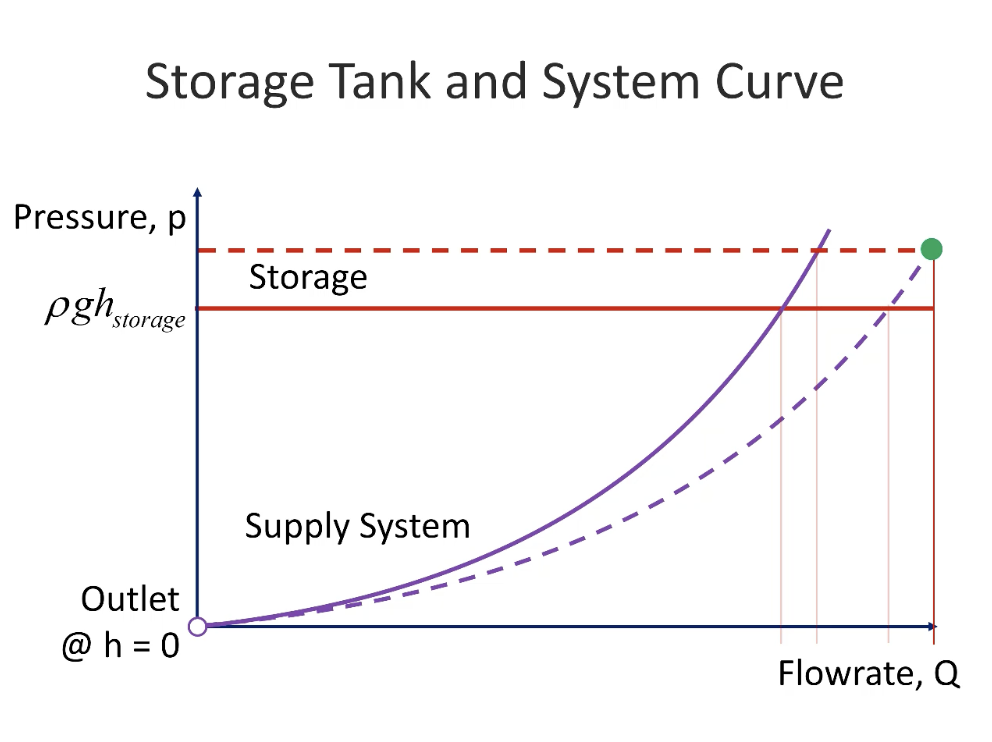

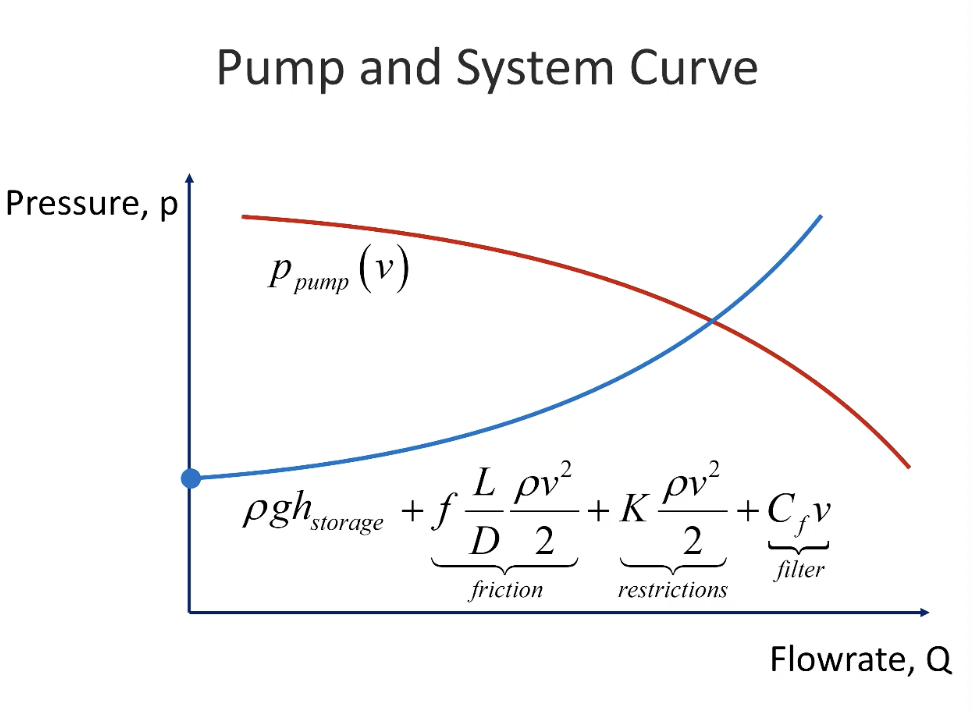

Pump Curves Graph

The system operates at the intersection of system and pump curve

Reducing losses, reducing height of storage tank

Vertical: Pump Pressure

Horizontal: Flowrate

System curve y int: ρgh

On-Demand Flow-Rate Graph

Graph Types

Pump Supply Pressure

Curves downwards

Line to storage tank

Upwards with positive offset (due to elevation gain)

Storage tank

Constant

Line to house

Curves upwards starting from origin

Formulas

Pressure Screencast

Pressure = ρgh, where ρ is water density, g is acceleration due to gravity, and h is height underwater.

Volume and Area don’t affect this.

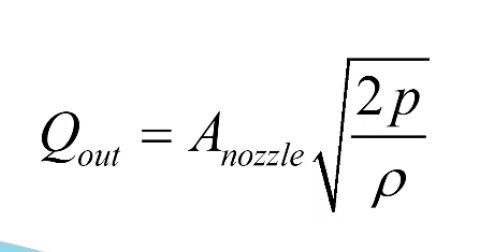

Qout Formula in a Discharge Tank

p = pressure right before the nozzle

ρ = density

Diameter doesn’t matter

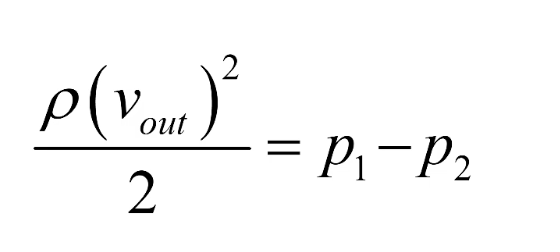

Pressure Flow in Discharging Tank

Calculating Qin

Multiply the daily rainfall with the catchment area

Losses through piping

Shortens with shorter pipe

More elbows, more losses