310 Final Exam.docx

Exam Date: Monday 12/9 10:30 - 12:30

What to study:

Equations and units

Define the units if there are similarities

If there is math associated it will appear in that section

Lighting, turbines, PV cells

Types

Which to use if there are varieties/options

How they work

The parts that make it up

Advantages and Disadvantages

Understand and explain scientific concepts

Sections and possible points

1. Heat Pumps (20 points) (needs to be finished)

A heat pump function:

Summer: pumps heat from inside to outside

Winter: pumps heat from outside to inside, heat is extracted from the air outside

Energy Balance:

Qh = WNET + Qc

∴WNET = Qh - Qc

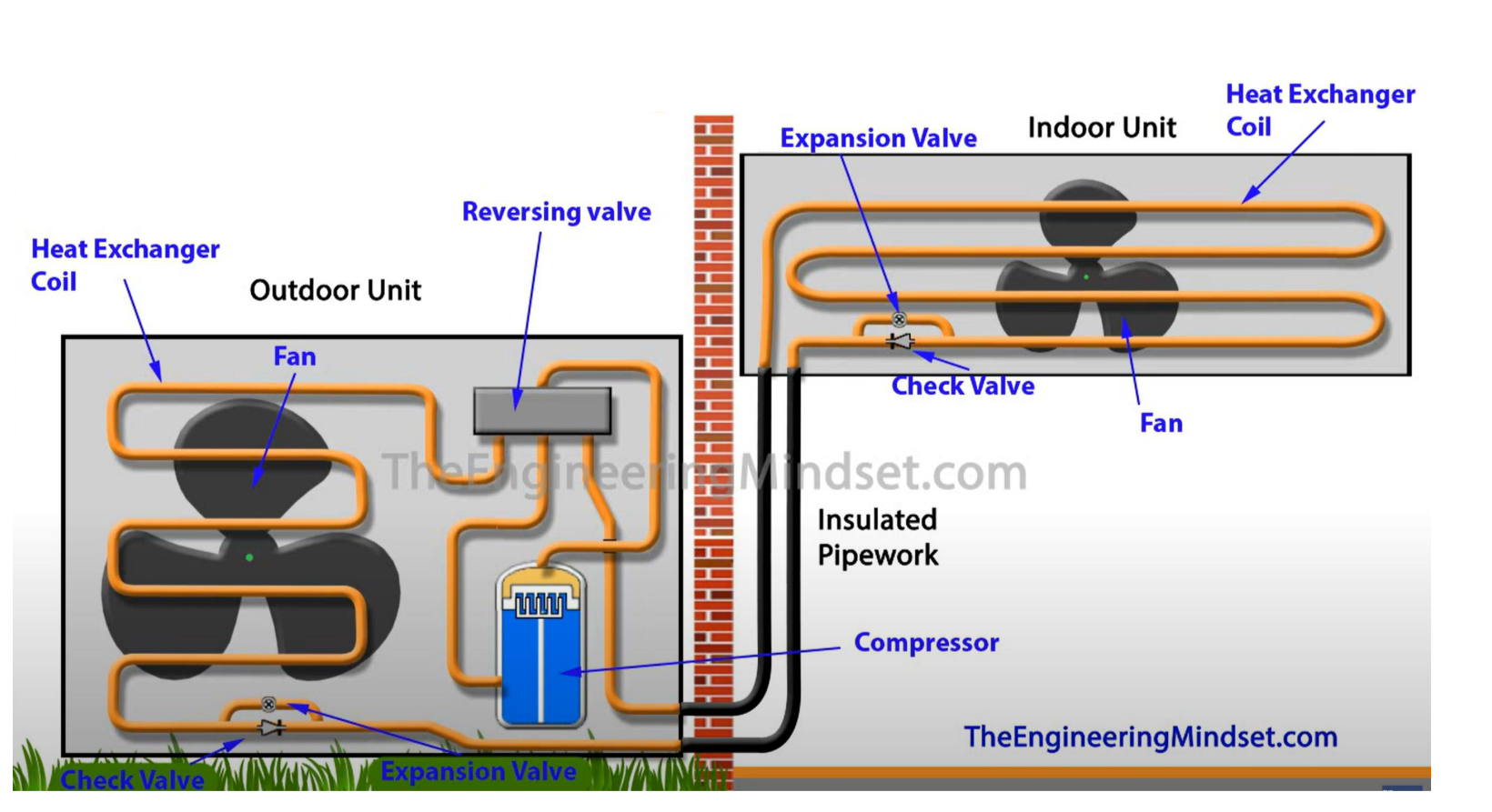

Key Components of a heat pump system

Compressor: Compresses refrigerant to raise temp and pressure

Reversing valve: Directs refrigerant flow to indoor or outdoor unit for depending if heating or cooling mode in use

Indoor heat exchanger: Transfer heat between refrigerant and indoor air

Outdoor heat exchanger: Transfer heat between refrigerant and outdoor air

Expansion valves: Control refrigerant flow and reduces temp and pressure

Check valves aka non-return valves: prevent reverse flow of refrigerant

Filter Drier: removes moisture and contaminants form refrigerant

Sight glass: allows for visual inspection

Temperature and pressure sensors: monitor system operation

Refrigeration cycle basics:

Evaporation: Refrigerant absorbs heat and turns into gas

Compression: Refrigerant pressure is increased therefore increasing temperature

Condensation: Refrigerant releases heat and condenses back to liquid

Expansion: refrigerant passes through expansion valve to reduce pressure and temp

Heating mode process:

Refrigerant compression

Starts as low pressure and temp vapor

Refrigerant compress to be high temp high pressure vapor

Flow directed by reverse valve

Reversing valve directs hot refrigerant to indoor heat exchanger

Heat transfer to indoor air

At indoor heat exchanger fan blows cool air over coil

Heat from refrigerant transfer to indoor air

Refrigerant cools and compresses

Flow through expansion valve

Flow to expansion valve, in heating process by passes this first valve to bypass and non-return valve

Passes through filter drier and sight glass

Expansion and cooling

Pressure and temperature is reduced making a mix of liquid and vapor in second expansion valve

Heat absorption in outdoor heat expansion

Cold refrigerant flow to outdoor heat exchanger

Fan blows outdoor air over coil transferring thermal energy to refrigerant

Refrigerant absorbs heat and evaporates

Cycle repeats

Warmed vapor returns to reversing valve and goes back to compressor

Cooling mode process:

Switch to cooling mode

Reverse valve changes position direction vapor to outdoor heat exchangers

Heat transfer to outdoor air

Outdoor exchanger blow cooler air over coil, carrying heat away from refrigerant and it cools and condenses

Flow through expansion valve

Refrigerant flows toward the second expansion valve, the first one is closed so it passes through the non-return valve and goes through the filter drier and sight glass

Cooling process

Goes through a second expansion valve where it expands and lowers pressure and temperature

Heat absorption in indoor heat exchanger

Cooled refrigerant flows into indoor heat exchanger

Fan blows warm hard over coil and transfers heat from air to refrigerant cooling the space

Refrigerant absorbs heat and evaporates becoming a low-pressure, low temperature vapor

Cycle repeats

Cooled vapor flows back into reserve valve which directs to compressor and continues the cycle

2. Compressors (15 points) (done)

Convert mechanical power into fluid air power

Compressed air produced can be stored

Critical components in industries and systems that rely on pneumatic tools, air-driven machinery, and industrial air systems

2 major designs

Positive displacement

Pressure is increased by decreasing volume

Types:

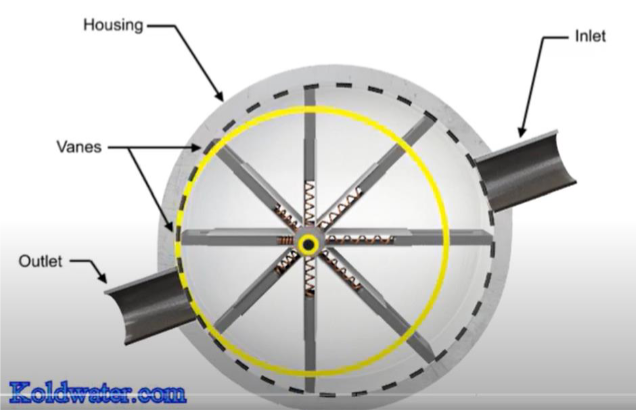

Rotary:

Vane: cylindrical housing with an off-center drive shaft and adjustable vanes

Smooth and free of vibrations

Screw: ambient air intake -> cleans the air

Scroll: used in refrigeration

Reciprocal

Cylindrical housing with piston connected to crankshaft

Piston moves up and down

Single stage: air becomes hot and makes compressor less efficient

Multi-stage: avoids overheating and increases pressure

Dynamic compressor

Use rotating elements to accelerate the gas by diffusing action, velocity is converted into static pressure

Total energy in flowing gas is constant

Entering an enlarged section, flow speed is reduced and some velocity turns into pressure energy -> static pressure is higher in enlarged section

Centrifugal compressor

Converts kinetic energy into potential energy

Bernoulli’s principle

Radial acceleration

Efficiency and safety concerns:

Heat can reduce efficiency or even blow up

Cooling system is essential

Air or water cooled

Applications:

Industrial and commercial

Pneumatic tools, air systems in factories, transportation

Chemical manufacturing, HVAC, and energy production

Displacement -> quiet and smooth

Reciprocating -> high compression ratios

3. Chillers (15 points) (done)

Used to generate cool water for AC

Normally on roof or basement

Closed-loop system

Remove heat from building

Can come from: people, lighting, plug loads, solar radiation

Basic operation:

Chilled water circuit: water leaves evaporator, circulates through the building, and absorbs heat

Heat rejection: heat is transferred from chilled water to refrigerant

Key components:

Evaporator: cools water

Compressor: drives refrigerant through system

Condenser: transfer heat from refrigerant to condenser water loop

Expansion valve: expands refrigerant, lowering pressure and temp

Cycles:

1. Refrigeration circuit: transfers heat from evaporator to condenser

Loop: evaporator -> compressor -> condenser -> expansion valve -> evaporator

2. Chilled water circuit: absorbed heat from building via AHU (air handling unit)

Loop: AHUs -> evaporator -> AHUs

3. Condenser water circuit: rejects heat to cooling tower

Loop: condenser -> cooling tower -> condenser

Step-by-step process

1. Evaporator: starting point where chilled water is produced

chilled water circulates through the building, absorbing heat and returning to the evaporator for heat transfer

refrigerant within the evaporator absorbs this heat, causing it to vaporize

evaporator is insulated to minimize energy losses and maintain efficiency

2. Compressor: refrigerant, now a low-pressure, low-temperature vapor, enters the compressor through suction line

the refrigerant is compressed, increasing its pressure and temperature

process transforms the refrigerant into a high-pressure, high-temperature superheated vapor

compressor is the driving force of the system

3. Condenser: from the compressor, the refrigerant flows into the condenser

it releases the heat absorbed in the evaporator

Cooling water from the cooling tower circulates through the condenser, removing this heat

water always inside the pipe, refrigerant and water ever actually meet

refrigerant condenses into a high-pressure liquid

4. Expansion valve: high-pressure liquid refrigerant moves to the expansion valve, where it experiences a dramatic pressure drop

process causes a portion of the refrigerant to vaporize, creating a low-pressure, low-temperature liquid-vapor mixture

expansion valve regulates the flow of refrigerant into the evaporator, ensuring efficient operation

Prepares refrigerant to re-enter evaporator for heat absorption

Chiller load:

= water flow rate

= water density

= water specific heat capacity

Types:

Water-cooled: use a water loop and cooling towers

Advantages: efficiency, temp stability, scalability

Disadvantages: high initial costs, maintenance requirement, water dependency

Installation considerations: installed on roof or ground level -> structural requirement; maintenance

Air-cooled: use fans to dissipate heat directly into the air

Advantages: ease of installation, lower maintenance, suitable for dry climates

Disadvantages: low efficiency, affected by ambient air, noise levels

Installation considerations: pipe routing, aesthetics, space

Applications:

Commercial and institutional: buildings and data centers

Industrial: manufacturing, power generation

4. Resistive Heat and Boilers (6 points) (done)

Resistive heat (joule heating) is when an electric current passes through a conductor and encounters resistance. Converts electrical energy into heat

Equations

P = I2R

Q = Pt

R =

Types

Direct: the material to be heated carried the current and heat is developed within material. Basically the heat goes straight to workpiece

Ex. electric kettle: heating element is in contact with water

Others: toasters and electric underfloor heating

Indirect: heat is developed in separate conductor or heating element and the workpiece receives energy by a combination of conduction, convection, and radiation. Basically there is a middle man to get the heat to workpiece

Ex. ovens: resistive heat element heats the air and then the air cooks the food

Others: boilers and furnaces

Heat distribution can be enhanced with fans as it forces air over the element. It can also push heat further into a room

Safety: enclosed elements and design

Materials used:

Nichrome: combo of nickel and chromium. Most common due to high resistivity and melting point of 1400 C

Kanthal: used in high temperature applications

Ceramic: used in some space heaters

Boilers: A closed vessel or system of vessels and tubs where steam or hot water is generated by applying heat to water

Convert energy stored in fuels to generate heat

How it works:

Fuel combustion: burns fuels like natural gas, oil, or biomass in the combustion chamber. Fuel reacts with oxygen to make heat

Heat transfer to water or steam: heat is transferred to water through heat exchanger which raises temp

Circulation: heated water circulates through a network of pipes. In a steam boiler steam is transported to required areas

Exhaust: by produced such as CO2 and water vapor are expelled through pipe or flue

Steam contains significant energy and is high efficient at powering turbines

Heating boilers (hot water boilers) used for heating in domestic or commercial purposes and provide steam or hot water

Power boilers (steam boilers) used for power plants or industrial application by generating steam or high temp hot water

Types:

Fire-tube: hot combustion gas pass through tubes surrounded by water, used in low-pressure applications

Operation: furnace heats tubes, transfers heat to water in tank, steam is generated and sent downstream for use

Advantages: cheap and simple to construct

Disadvantages: limited to lower pressures

Water-tube: water flows through tubes surrounded by combustion gases, used in high pressure applications

Operation: fuel source burns in furnace heart water in tubes, when boiling point is reached steam is produced and moved downstream

Advantages: higher thermal efficiency

Disadvantages: more complex and require better water quality

Sectional

Water in sections and fire around them

Boilers classified by: size, fuel type, steam vs water

Boiler efficiency:

Combustion: how efficiently fuel is burned

Heat transfer: How well heat is transferred from gasses to water or steam

AFUE: Condensing have ratings of 90% and up, older boilers have as low as 70%

Boiler safety:

Pressure relief valves

Temperature control

Ventilation

Routine maintenance

Condensing boilers: higher efficiency by condensing water vapor

9-% of energy is converted into sensible heat and 10% is converted into latent heat

Average efficiency is about 80% and can be increase to 86% and 98% when condensing water

Equations:

Energy input = V x energy content of NG

Boiler efficiency = energy output / energy input

Energy required from fuel = energy required to produce / efficiency

Volume of gas required = energy required from fuel / energy content of NG

Q = mcT

Energy output = energy input x efficiency

5. Energy Storage (4 points) (done)

Capture, store, and release energy back to the grid

Pumped hydro storage is 95% of global storage capacity

Pumped hydro for long term and battery storage for day to day

Applications:

Grid stabilization

Frequency regulation

Backup power

Types:

Pumped Hydro Storage: pumps water to an elevated reservoir and releases it to generate energy as needed

Lithium-ion batteries: store energy chemically and widely used in the grid

Compressed air energy: compressed air stored in underground caverns for later use

Flywheels: store kinetic energy and can provide fast-response power

Flow batteries: use liquid electrolytes to store energy and can scale up

Thermal energy storage: stores energy as heat for later use

How each type works:

Pumped storage:

Use water falling to produce energy, after water falls through turbine it is collected in lower reservoir

A reverse turbine can pump the water back up to upper reservoir when energy demand is low

Lithium ion battery:

Anode and cathode store lithium

Electrolyte carry positive charge lithium ions from anode to cathode and vice versa through separator

The movement creates free elections in anode which makes a charge at positive current collector

Electrical current flows from collector through device being powered to negative current collector

Separator blocks flow of electrons inside battery

Characterized by:

Power vs energy: power is rate of discharge, energy is total amount stored

Cycle life: how many charge and discharge cycles a system can endure before degrading

Efficiency: how much energy can be extracted compare to how much is put in

Footprint: the physical space required for installation

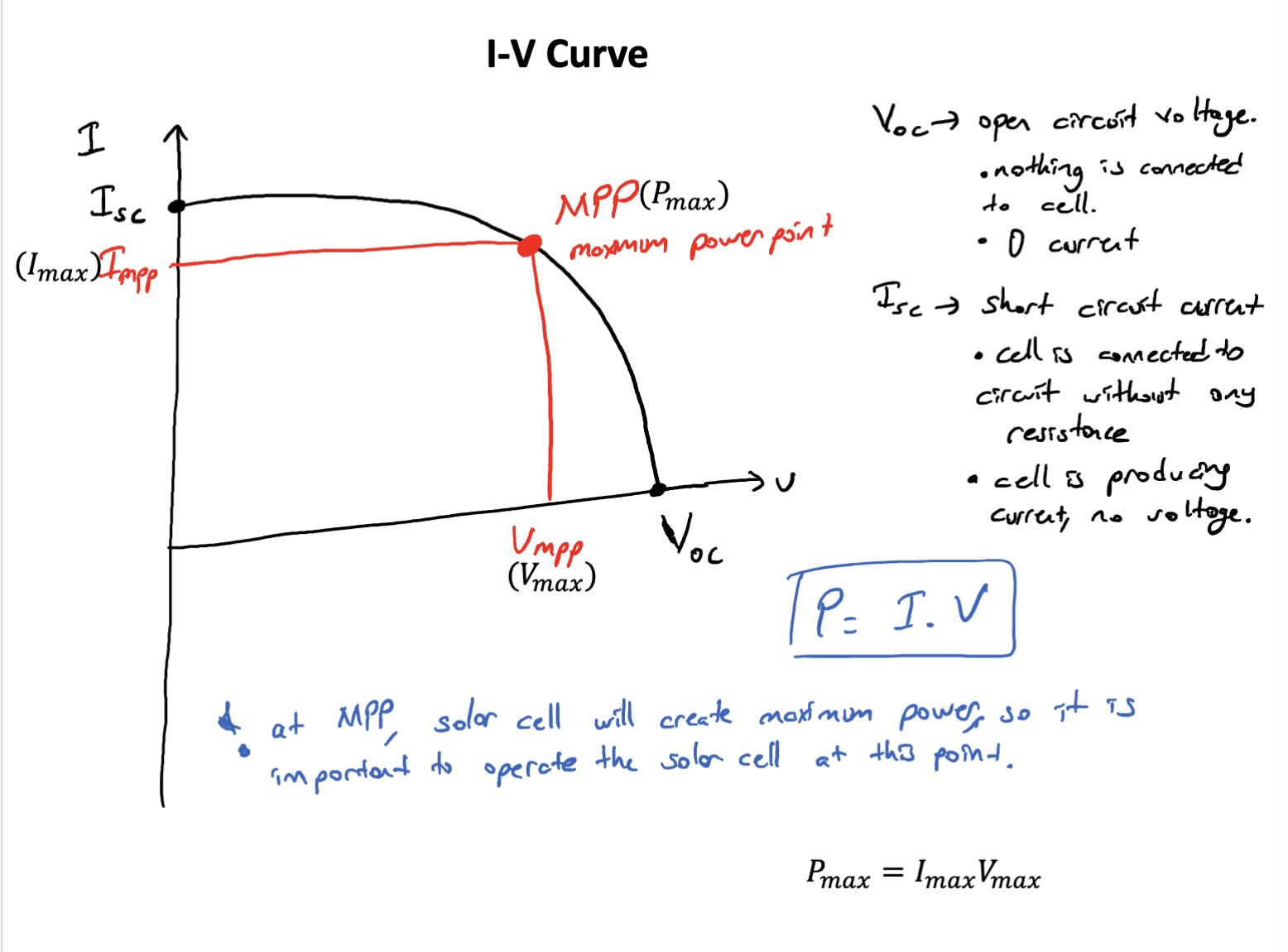

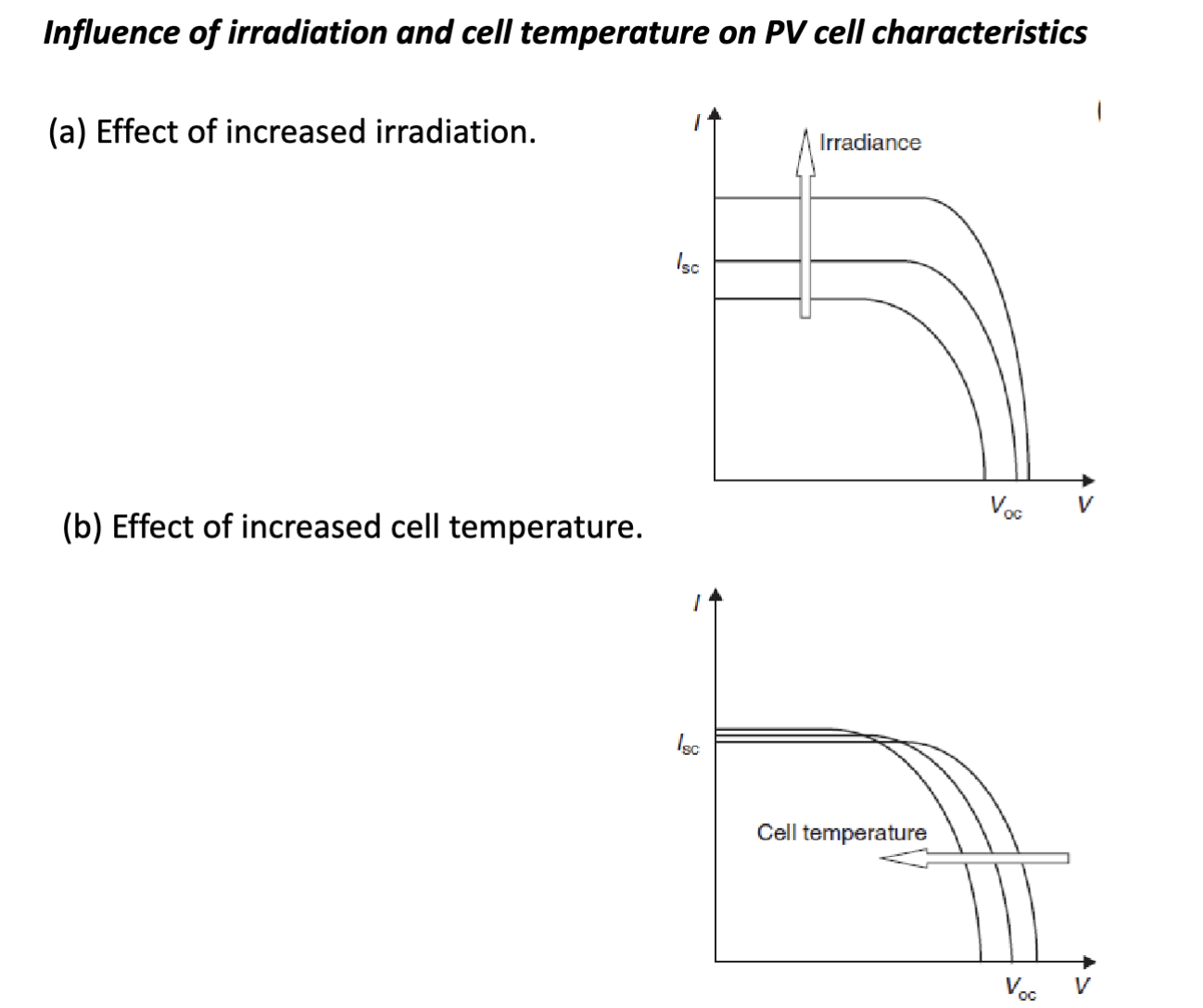

6. PV and Fuel Cell (6 points) (done)

When a photon enter a PV cell it can be reflected, absorbed, or transmitted

If photon energy is smaller than the band gap it will not be able to jump into the conduction band. Excess energy is converted into KE so energy is lost as heat

Ep = hc / or Ep = 1239.8 (nm. eV) / (nm)

= Pmax / Pin = ImaxVmax / AIinsolation

Fuel Cell: Electrochemical device that converts chemical energy from fuel into electricity through chemical reactions

Hydrogen-Oxygen Fuel cell:

Key components:

Electrolyte: ions pass through potassium hydroxide solution

Electrodes: sites of chemical reactions

Negative anode: on left, hydrogen is oxidized

Positive cathode: on right, oxygen is reduced

Wire connects anode to allow electron flow

How it works:

Hydrogen gas enters cell at anode and get oxidized

Electrons from oxidation process move through wire to cathode which generates energy

Oxygen enters cathode and reacts with hydrogen and electrons to make water

Equations:

Pcell = VcellIcell for a single cell

Vstack = NVcell for a stack of cells

Pstack = VstackIstack = N VcellIcell

Pactual = Ptheoretical

Advantages:

Abundant fuel sources: only needs hydrogen and oxygen

No pollution: water only byproduct

Durability: last longer than batteries and simpler disposal

Environmental benefits: cleaner energy alternative

Scalability: can be scaled up or down

Quiet operation: no moving parts

Disadvantages:

Cost: Expensive catalyst and components

Hydrogen supply: Hydrogen takes up more space in gas form than batteries and other fuels. It is also explosive when mixed with air

Energy-intensive fuel production: requires energy to produce

Durability: Membranes and catalysts degrade over time

7. Generators and Power (8 points) (done)

Faraday’s Law: States voltage induced in the loop is directly proportional to the change in time of the flux

In simple terms: Over time a voltage will produce a field and when that field changes in a circuit a force is produced that is flux. The voltage is proportional to that of the rate of change for the flux

Generator: How it works

A coil is (the rotor) rotated inside a field. The magnetic flux changes and induces a field (emf) that produces energy. The rotor's mechanical movement is driven by an energy source. The stator (stationary coil) produces a magnetic field and the rotor spins through it to generate a current.

Key components of generator:

Rotor: Moving part in generator

Stator: Stationary part in generator

AC Generator: Current changes direction

Slip rings: Wire connected to this and brush make contact with it

Brushes: Connect current to slip rings for continuous flow of current

How it works:

Turbine spins a coil inside a magnetic field. The coil rotates and the wires inside move through the field causing an induced current. The current reserves every half turn. Think flips

AC generators can be 3 phase, 3 alternating current, to provide a more stable, smoother, and efficient power supply. This means at any given point there is some level of power provided. There is not one peak time and one low time, there is variation.

Great for long distance transmission

DC Generator: Current direction remains the same

Commuter (split rings): rotates with coil to keep flow of current in one direction

Brushes: connect current to commuter

How it works:

Similar to ac generator but the current only flows in one direction. Think a turn

Equations

P =

P = power output in watts

= emf or voltage in volts

I = current amps

P = Vrms x Irms x pf

Pf = power factor between 0 and 1 and accounts for the phase change difference as there is energy lost

Pout = Pmechanical

= a decimal between 0 and 1

Key components

8. ICE (4 points) (done)

Convert chemical fuel into mechanical work

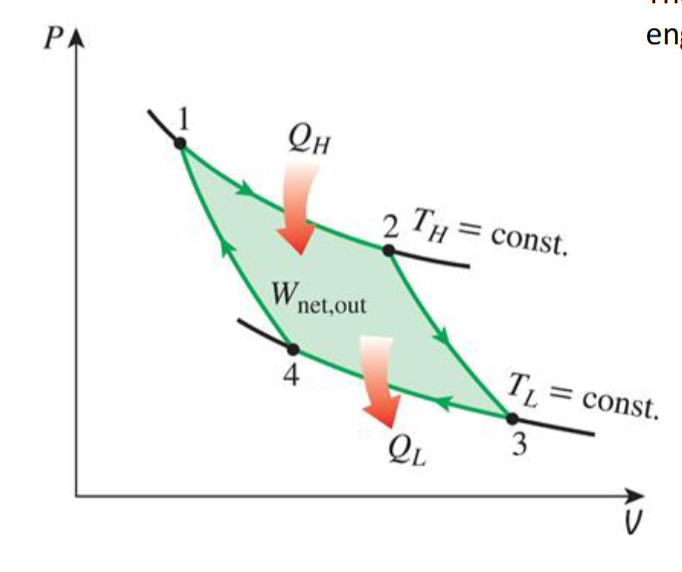

Carnot cycle: most efficient

Applications:

Transportation: cars, trucks, motorcycles, and airplanes

Industrial machines: generators, pumps

Marine engine: boats and ships used diesel-based ICEs

Steps of 4 cycle (in own words):

1. air/fuel mixture gets injected

2. air/fuel mixture gets compressed

3. air/fuel mixture gets ignited, pushing the piston down

4. Piston moves up to push exhaust out

Otto cycle: ideal cycle for spark-ignition engines

Diesel cycle: ideal cycle for compression-ignition engines

V is engine displacement

B is bore

L is stroke length

N is number of cylinders

9. Motors (4 points) (done)

Electric motors

Convert electrical energy into mechanical motion

Electromagnetic induction: moving magnet creates an electric field

Application: spinning motion for fans

AC motor: alternating current, changes direction periodically

AC vs DC: AC is more efficient, smoother, and easier to maintain. DC is simplier

10. Turbines (10 points) (done)

Kinetic energy from moving fluid into mechanical energy

Types: hydraulic, steam, gas, and wind

Bernoulli’s Principle: At points along a horizontal streamline, higher pressure regions have lower fluid speed and lower pressure regions have higher fluid speed.

In own words: pressure differences cause the blade to spin to try and even it out

Hydraulic turbine

Impulse turbine: only kinetic energy; blades in air

Reaction turbine: kinetic and pressure energy; blades fully submerged

Gas turbine: basically an ICE, but continuous

Open-cycle: air is exhausted

Closed-cycle: exhaust is used again and again

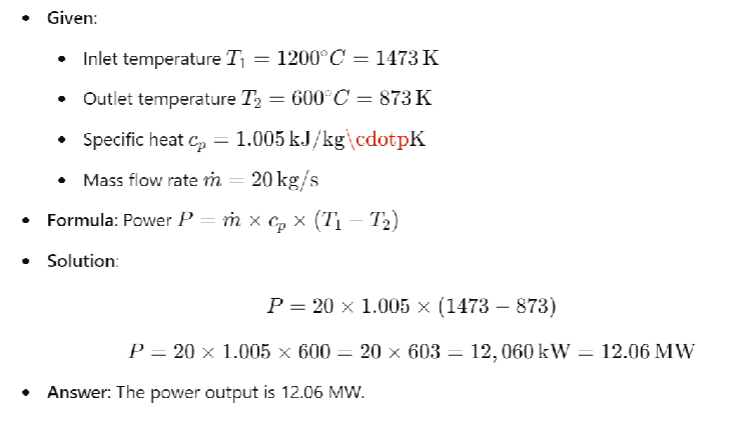

Power output = mass flow rate of a liquid x specific heat capacity of a gas x (initial temp - final temp) x efficiency

ṁ

Steam turbine: thermal energy into mechanical energy

Rotors and stators

Energy forms in steam: kinetic, pressure, and thermal

Power from wind: A= area, v = velocity, = air density

Betz limit: 16/27, actual power

EXAMPLES:

A gas turbine operates with an inlet temperature of 1200°C and an outlet temperature of 600°C. If the specific heat capacity of the gas is 1.005 kJ/kg·K and the mass flow rate is 20 kg/s, calculate the power output of the turbine. Assume no mechanical losses

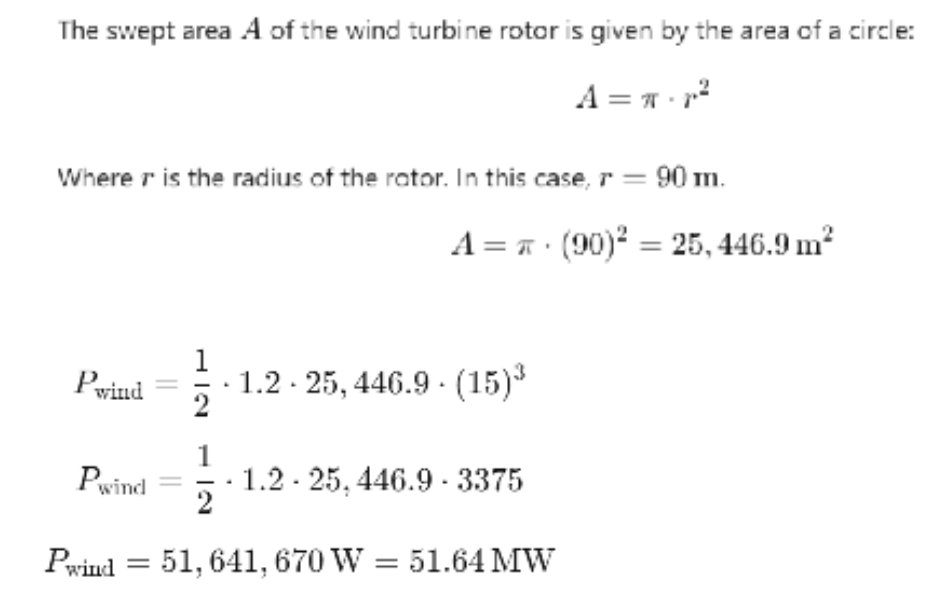

A wind turbine with a rotor radius of 90 m operates in an area with an air density of 1.2 kg/m3 and a wind speed of 15 m/s. Calculate:

a. The total power in the wind approaching the turbine.

b. The theoretical maximum power that the wind turbine can extract from the wind.

A steam turbine operates with an inlet steam temperature of 500°C and an exhaust steam temperature of 100°C. Using Carnot's theorem, calculate the maximum possible efficiency of the turbine

11. Lighting (8 points) (done)

Lumen: light output

Efficacy =

Incandescent:

Electricity heats a filament, which produces light

Advantages: high CRI values (excellent color rendering), cheap, and available in different sizes

Disadvantages: waste energy by consuming the same amount of energy for less lighting and making the cooling system work harder to off-put the heat; limited operation life; tungsten deposits reduce aesthetics and brightness

Fluorescent

Glass tube with inert gas and electrodes that light up

High efficacies

Long lifetime

Emit more UV light than incandescent

LED lamps

Semiconductor diodes emit light

Any range of colors

N-type: doped to have more electrons

P-type: doped to have more holes

Most energy efficient

Long life

High intensity discharge

Similar to fluorescent

High power output

Advantages: long life, high lumen output, small

Disadvantages: require time to warm up

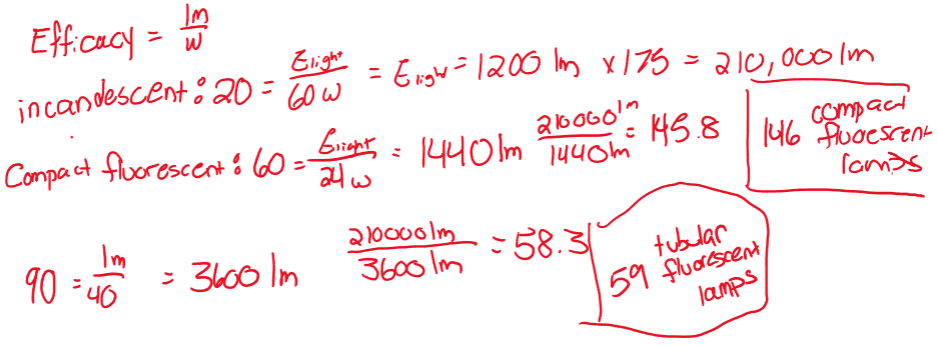

EXAMPLES:

Given the list of materials and their bandgaps below, determine whether each material can be used for LEDs. If applicable, specify the color of light produced by each material

Bandgap of 2.9 eV

A large space is currently illuminated by 175 incandescent lamps, each with a rating of 60 W. How many (a) 24-W fluorescent lamps or (b) 40-W tubular fluorescent lamps are needed to supply the same level of lighting to the space? The efficacies of incandescent, compact fluorescent, and tubular fluorescent lamps are 20, 60, and 90 lm/W, respectively. Please neglect the power consumed by ballasts in fluorescent lamps