OMIS MODULE 08

understanding capacity

capacity can be viewed either as…

the rate of production output per unit of time

units of resources availability

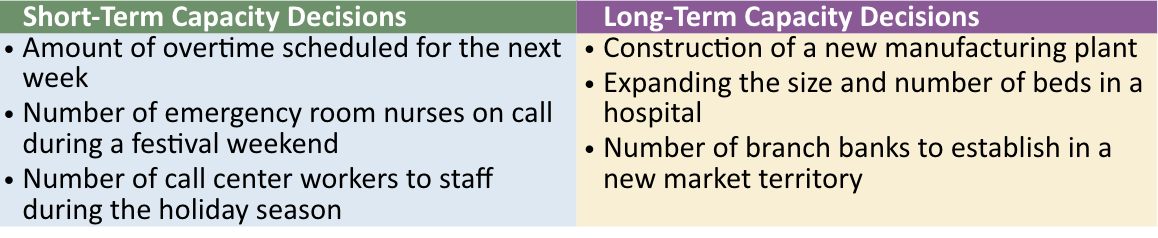

operation managers must decide on the appropriate levels of capacity to meet current (short-term) and future (long-term) demand.

capacity decisions and economies of scale

capacity decisions can be influenced by economies and diseconomies of scale

— suggests that some optimal amount of capacity exists where costs are at a minimum.

focused factory

as a single facility adds more and more goods and/or services to its portfolio,

the facility can become too large and “unfocused.”

as a consequence, diseconomies of scale arise and unit costs increase

theoretical and effective capacity

characteristics of theoretical capacity…

cannot always be achieved

preventative maintenance or unanticipated events will reduce the theoretical capacity

as for effective capacity, short setup times increase capacity and improve flexibility by allowing…

rapid changeovers to different models

products on manufacturing or assembly lines

capacity planning

capacity-planning decisions should be based on effective capacity as ideal

operating conditions are nearly impossible to sustain.

to satisfy customers in the long run, effective capacity must be at least as large as the average demand

demands for many goods and services typically varies over time

— sometimes, a process may not be capable of meeting peak demand, resulting in lost sales or long service wait times

— at other times, capacity may exceed demand, resulting in idle processes or facilities or buildups in physical inventories

safety capacity

safety capacity might be computed over a year for a factory or monthly for a workstation.

safety capacity for flowshops and assembly lines is normally in the 1 to 10 percent range

long-term capacity strategies

long-term capacity strategies address the trade-off between the cost of capacity and the opportunities cost of not having adequate capacity.

complementary goods and services compensate for the unused capacity during the off-season due to the seasonality of many goods and services.

capacity expansion

there are four main basic strategies for expanding capacity over some fixed time horizon...

one large capacity increase

small capacity increases that match demand

small capacity increases that lead demand

small capacity increases that lag demand

these strategies can be applied to capacity reduction too.

short-term capacity management options

managing capacity by adjusting short-term capacity levels…

add or share equipment

sell unused capacity

change labor capacity and schedules

change labor skill mix

shift work to slack periods

managing capacity by shifting and stimulating demand…

vary the price of goods or services

provide customers with information

advertising and promotion

add peripheral goods and services

provide reservations

revenue management system

consists of four dynamic methods to…

forecast demand

allocate perishable assets across market segments

overbook when necessary and by how much

price different customer classes

! the four components of RMS must work in unison if the objective is to

maximize the revenue generated by a perishable asset

experience curve

a broader extension of the learning curve is the experience curve

the idea is that each time experience doubles, costs decline by 10-30 percent

Knowt

Knowt