Materials Compiled

Structure of matter

Types of Atomic and Molecular Bonds

Primary atomic bonds

Ionic bonds - Ceramics

B/w + and - ions

Electron transfer

Materials are hard, brittle, electrically, and thermally insulating

Covalent bonds - Polymers and ceramics

Sharing electrons → Directional

Materials are hard, brittle, electrically and thermally insulating

Metallic bonds - Metals

Sea of donated valence electrons

Materials and thermal and electrically conductive, and can readily undergo plastic deformation

Secondary atomic and molecular bonds - weaker than primary bonds

Polar forces (ex/ H-bonds) - Polymers

Covalently bonded atoms have dipole

Van der Waals forces

Properties from Bonding

Ceramics (ionic and covalent)

Large bond energy

Large Tm

Large E (elastic modulus)

Small CTE (coefficient of thermal expension)

Metals (metallic)

Variable bond energy

Variable Tm

Variable E

Moderate CTE

Polymers (covalent and secondary)

Directional properties with secondary bonding dominates

Small Tm

Small E

Large CTE

Structural arrangement of atoms in solids

Crystal Structure

Regular arrangement of atoms and molecules in space for minimal internal energy

Organized in lattice forms (FCC, BCC, HCP)

Polycrystalline structures: aggregates of many single crystals organized in different orientations → Grain boundaries

Noncrystalline Structure

Amorphous materials

Random arrangement of atoms (polymers and some ceramics - porcelain)

Tg vs Tm

Tg = Glass transition temperature (noncrystalline materials)

At Tg, materal is “softer” but not fully a liquid

Tm = Crystalline melting/fusion temperature

Surface energy and wetting

Surface energy is higher than bulk → B/c there are “dangling'“ bonds

A material with a lower surface energy can wet a surface with a higher energy

Elevate surface energy via polishing to make it easier to wet

Wetting in Dentistry

Key for adhesion

Key to take accurate dental impressions

Physical properties of dental materials

Thermal properties

Thermal conductivity: How easily heat transfers through a material

Metals > Non-metals

Large metallic restorations need insulating cement to protect pulp

How insulating the base material is (Lining efficiency) = Thickness / sqrt(thermal diffusivity)

Thermal diffusivity: Rate at which temperature of body changes as heat passes through

Depends on thermal conductivity, density, and specific heat

Inversely proportional to density

Specific heat: quantity of heat to raise temperature of a unit mass of a material by 1 degree C

Thermal expansion: Change in length per unit of the original length when the temperature is raised by 1 degree C

Must know original length

\alpha=\frac{\Delta L}{L\cdot\Delta T}

CTE of dental materials

Clinical consequences: Expansion and contraction of material, leakage around restorations, shrinkage of wax patterns, differential shrinkage of PFM crowns

Biological consequences: Microleakage along tooth/restoration interface, Corrosion products from amalgam reduce microleakage

Rheological properties

Rheology: Study of flow of materials

Viscosity: Resistance to flow of a material under an applied stress

Resistance is due to internal friction

Shear stress = F/A

Shear strain rate = V/d

Viscosity = Shear Stress / Shear Strain

Rheological Behavior of Fluids

Newtonian: Viscosity is constant with respect to stress

Pseudoplastic (shear thinning): Viscosity decreases after initial stress

Dilatant (shear thickening): Viscosity increases with stress

Plastic: Some initial stress needed, then linear (like newtonian)

Optical properties

In dentistry, interaction of light with restorative material must mimic the interaction with teeth

Light and Color in Dentistry

Visible light wavelength: 400-700 nm

Wavelength of max. visual perception: 550 nm (green)

Spectral Distribution of Light

Different light sources have different wavelength distributions

Color measurement system

Munsell system

Hue (wavelength)

Circumference

Chroma (intensity)

Radius

Value (light/dark)

Bottom → Top

CTE

L*, a*, b* systems

L = value

a* = red/green

b* = blue/yellow

Color Perception

Metamerism: Change in color matching of two objects under different light sources (have different wavelength distribution)

Translucency/Opacity: Amount of incident light transmitted by an object that scatters part of the light

Gloss: Proportion of specualr reflection to diffused reflection of light

Gloss = specular / diffused

Fluorescence: 300-400 nm absorbed → 400-450 emitted (blueish)

Near enamel edges - hard to minic

Color Rendering Index

The degree to which a light source can render the color of an object compared to a reference source

CRI: Measurement of how well a light source displaces color compared to a natural light source (ex/ sunlight)

0 - 100

Shade Matching

Light sources (at least 2)

Background color (neural gray)

Tarnish and Corrosion

Tarnish: surface discoloration of a metal

Presence of saliva, bacteria, chemicals

Formation of thin films of oxides, sulfides, and chlorides

Corrsion: reaction of metallic material with environ,ent

Progressive and destructive

Degredation of material and possible by-products

Other properties

Electrical - Galvanism

Can be caused by… opposing metal restorations or be in 1 tooth

Mechanical Properties of Dental Materials

Stress and strain: What are they and why are they used instead of load and deformation

Stress and Strain

Stress: force per unit area (independent on sample size)

Types of stress: Tensile, shear, compressive

Strain: material deformation in response to stress (change in length per initial length)

Dimensionless

Types of strain: Tensile, shear, compressive

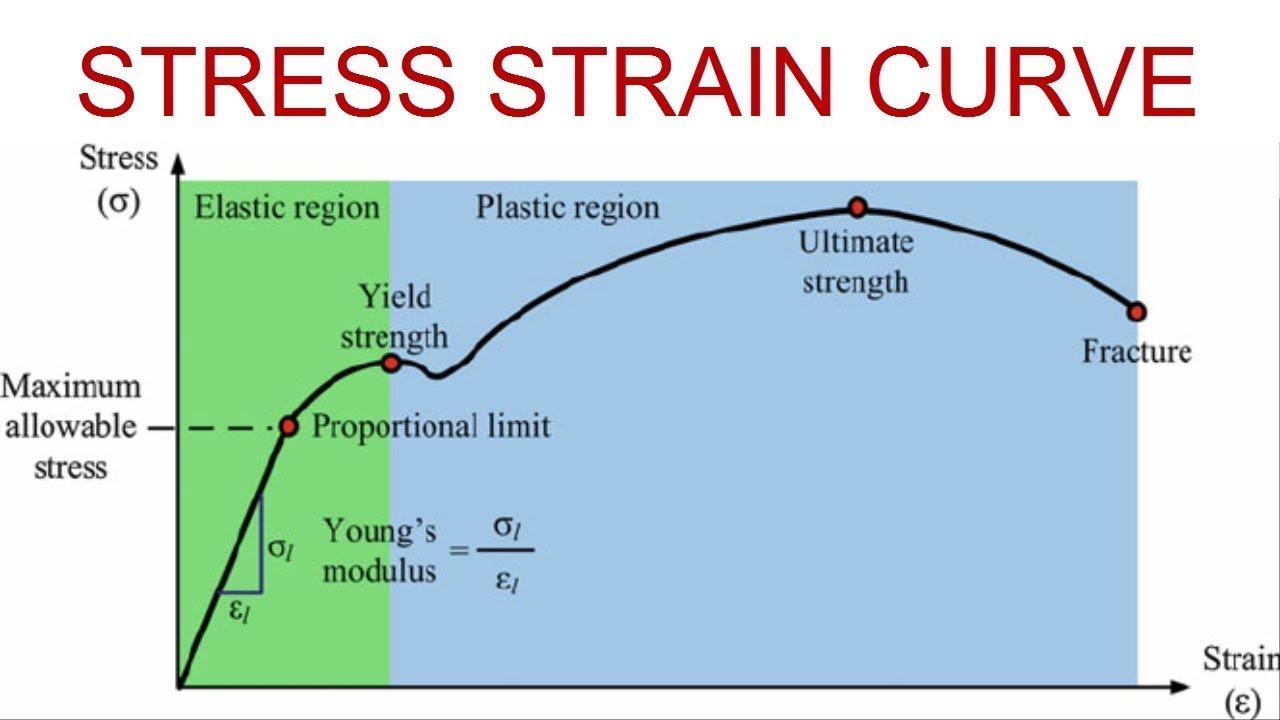

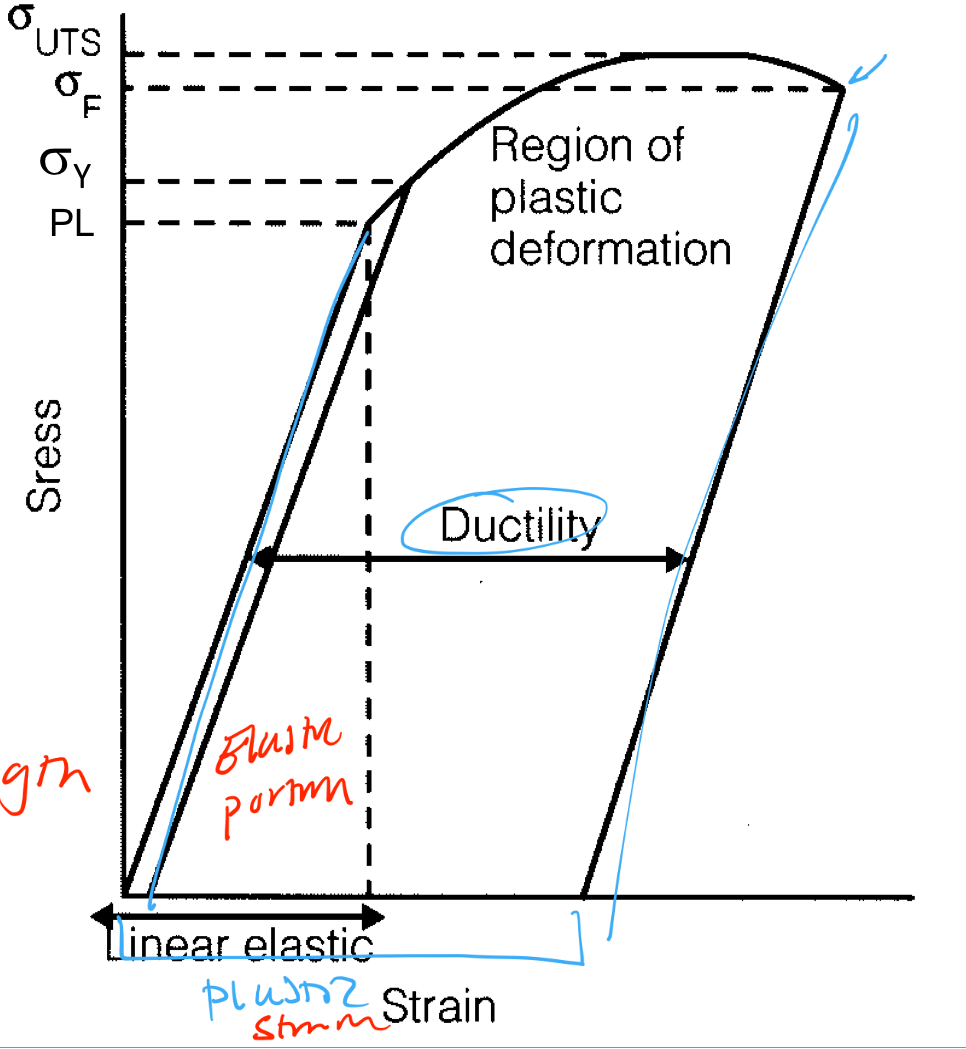

Stress-strain curve

PL = Proportional limit

Value of stress at which the stress/strain curve deviates from the initial linear relation

Elastic limit: Stress corresponding to the 1st measurable permanent deformation

Somewhere between the PL and YS

Yield strength: strength corresponding to a designated amount of permanent strain 0.2%

Ultimate tensile strength: Maximum stress without fracture

Elastic and plastic behaviors: When loads are small, how much deformation occurs?

Elastic strain: Strain which disappears completely when the applied force is removed

Ex/ Pulling on a rubber band

Permanent (plastic strain): Strain which remained permanently after the applied force is removed

Ex/ Bending a metal rod

Elastic modulus and hardness: What are they and how are they determined

Elastic Modulus/Modulus of elasticity/Young's modulus

E = stress/strain (within the elastic range or the linear portion of the curve)

Determined by interatomic and intermolecular forces (the stronger the force, the more rigid the material)

Material dependent

Elastic modulus: resistance to elastic deformation

Important to consider elastic modulus of implants relative to bone.

If elastic modulus of implant much higher than bone, can lead to bone loss

Tooth: Enamel = 70-90 GPa; Dentin = 15-20 GPa

Stiffness and Modulus

Stiffness = force/deflection

Modulus = stress/strain

Higher stiffness = Higher modulus

Steeper slope in elastic region

Yield strength and tensile strength: What are they and how are they determined

Ultimate Strength

UTS: The stress corresponding to the maximum value of applied stress a material can withstand without rupturing

Peak of stress/strain curve

Fracture Strength

Fracture point: The value of stress at which a material ruptures into 2 or more portions

Yield Strength

Yield strength: strength corresponding to a designated amount of permanent strain 0.2%

Toughness, ductility, and resilience: What are they and how do we measure them?

Ductility and Elongation

Ductility: The ability of a material to undergo permanent tensile deformation without fracturing

Elastic + plastic deformation

Plastic tensile strain at failure

The more ductile the material, the more strain it can withstand

Malleability

The ability of a material to undergo permanent compressive deformation without fracture

Brittleness

Material behavior characterized by fracture with little or no prior permanent deformation

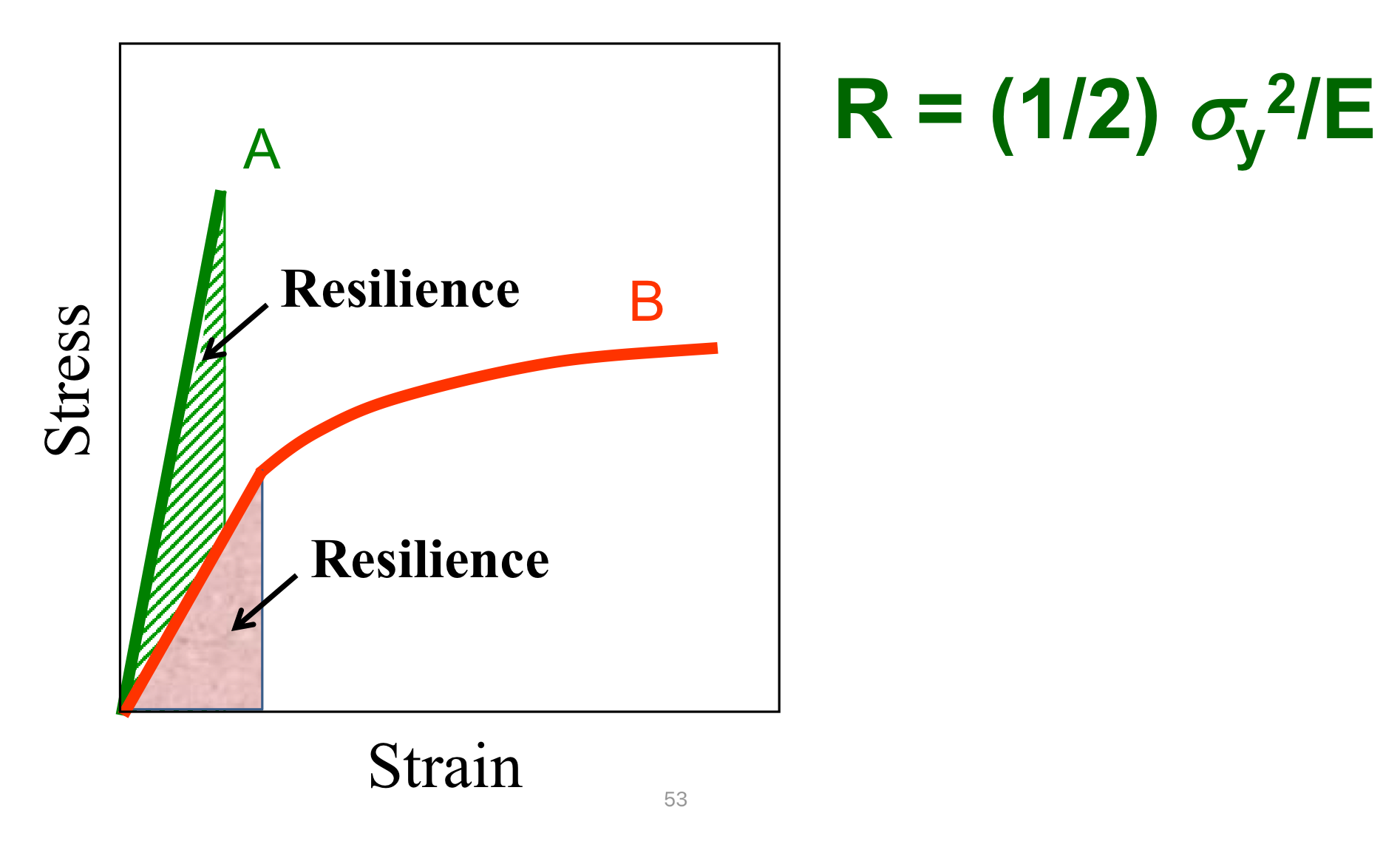

Modulus of Resilience

Resilience: The amount of recoverable energy stored in a material during elastic deformation (material does’t suffer damage)

Area under linear portion of stress/strain curve

The larger the area, the more resilient

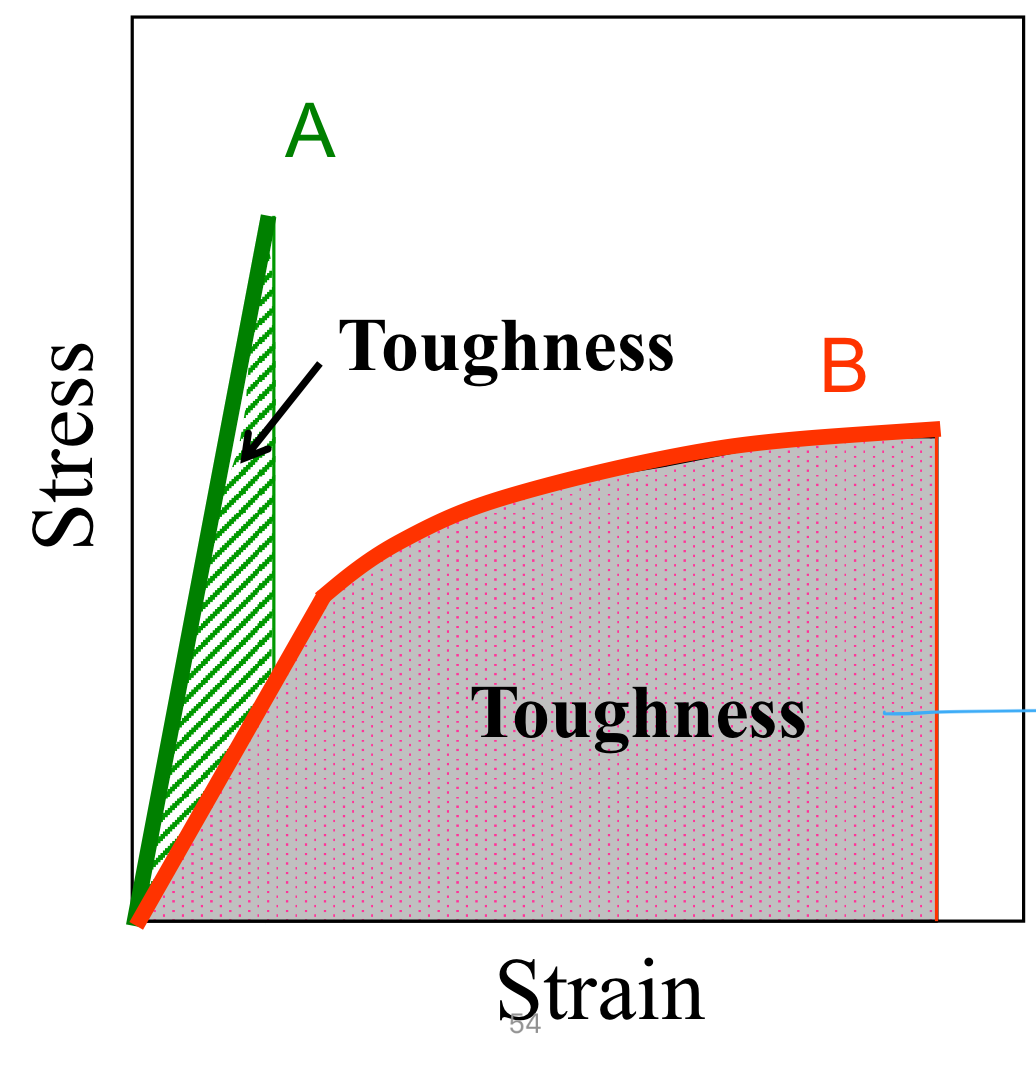

Toughness

Toughness: Energy to break a unit volume of material

Area under the stress/strain curve

Include elastic and plastic regions

Hardness

Resistance of a material to plastic or permanent deformation

In metals, hardness = YS * 3

Determined by the “scratch test”

The harder material can scratch the softer material

Cyclic mechanical properties

Failure of materials due to cyclic loading and unloading

Fails occur at stresses lower than UTS

Growth of small cracks which become larger upon cycling until failure

Fatigue limit

Stress at which material can withstand an unlimited number of cycles

Influenced by how polished the surface is, temperature, and wetness

The more polished, the greater the fatigue resistance

Increase temperature decreases fatigue resistance

Wetness decreases fatigue resistance

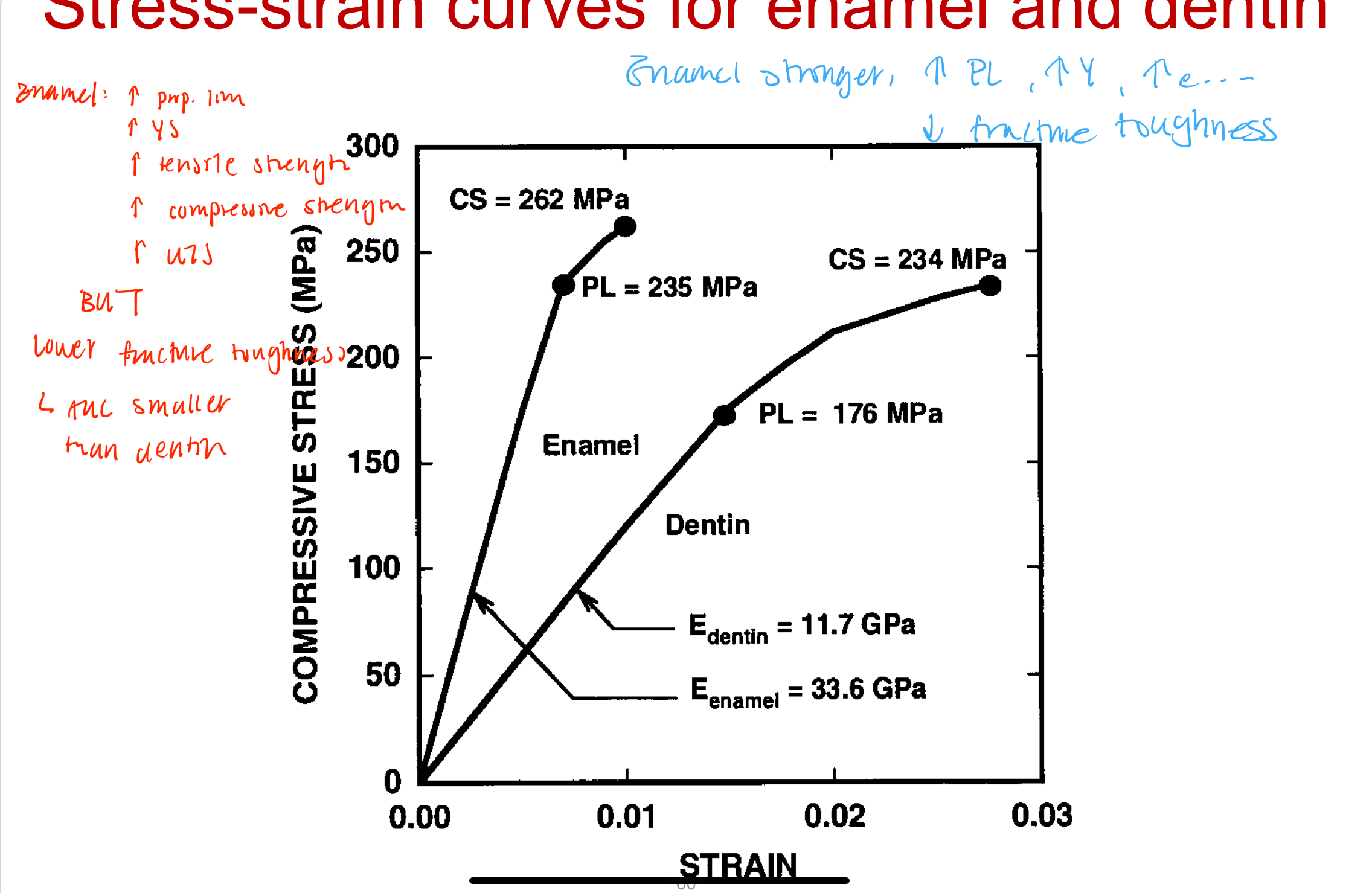

Mechanical properties of enamel and dentin

Enamel compared to dentin

Increase: PL, YS, Tensile strength, Compressive strength, UTS

Decrease: Fracture toughness (AUC smaller than dentin)

Composites

What is the basic composition of dental composites?

Dental Composites

A combination of materials in which each component retains its identity

Composed of…

Matrix (high molecular weight monomers, low molecular weight monomers, polymerization control additioves)

Fillers (particles, fibers, whiskers)

Interfacial coupling agents (organic silanes)

What are the roles of the matrix phases, filler particles, coupling agents, and polymerization control additives?

Matrix (Continuous Phase)

High molecular weight monomers: Increase strength and viscosity, decrease filler loading

Ex/ Bis-GMA, UDMA, Sirolane

Low molecular weight monomers: Decrease viscosity, increase filler loading and polymerization kinetics

Ex/ TEGMA

Polymerization Control Additives

Activators/initiator

Light activation = Camphorquinone

Chemical activation = Organic peroxide

Inhibitor

BHT and Hydroquinone

Fillers (inorganic - Dispersed Phase)

Dental composites primarily have noncrystalline (glassy) silicates

Ex/ borosilicate glass, quartz, zirconia

Can also add radio-opacity

Generally harder and stronger than the matrix

By adding filler to composites….

Decrease CTE

Increase hardness

Decrease shrinkage (fillers physical dimensions won’t change)

Decrease water absorption

Interfacial Coupling Agents - Organic Silanes

Pros…

Silanes are the most effective coupling agent and they work best with filler materials have a lot of Si-O bonds (ex/ silica)

Reduces viscosity and glass hydrophilicity → Chemical bonding from matrix to filler

Raise strength and wear resistance for composites

Cons

Silanation reaction may be reverse in water

Problems such as: multi-layers, bonding (increase vulnerability to break between interfaces)

Other Components

Inorganic pigments for shade development

What are the clinical indications of various composites

Polymerization Shrinkage

Increased filler → Decreased shrinkage

High stress due to high elastic modulus → Stiffer

How to resolve

Increase amount of filler

Add composite in 2mm increments

Use low shrinkage monomers

Working and Setting Time

Light cure: “On demand”

Reaction continues for 24hrs

Chemically cured: 3-5 mins

Depth of Cure

2 mm composite at a time

Mechanical Properties

Abrasion and wear

Toothbrush abrade and wear weak polymers first → rough surface

If inter-particle spacing becomes small, wear is greatly reduced (ex/ use of nanohybrids → highly polished surface)

Occlusal wear resistance

Hybrid composites wear rate similar to dental amalgam

Thermal Properties

Water Sorption

Solubility

Color and Color Stability

Biocompatibility

Translucency

Composites for special application

Multipurpose composites

Microfilled composites

Packable composites

Flowable composites

Laboratory composites

Core composites

Provisional composites

Metals and Alloys

What are pure metals?

Noble metals

Elements with good metallic surfaces that retain their luster in clean dry air

Indicate the inertness of the element

Resist oxidation, tarnish, and corrosion during heating, casting, and soldering

Platinum group (6 metals) - include platinum, palladium, iridium, ruthenium

Gold

The term precious metals indicates how expensive a metal is based on supply and demand

Gold content of a dental alloy

Karat/Carat (K): Parts of pure gold per 24

Fineness: Parts of pure gold per 1000 (used for gold solders)

Pennyweight

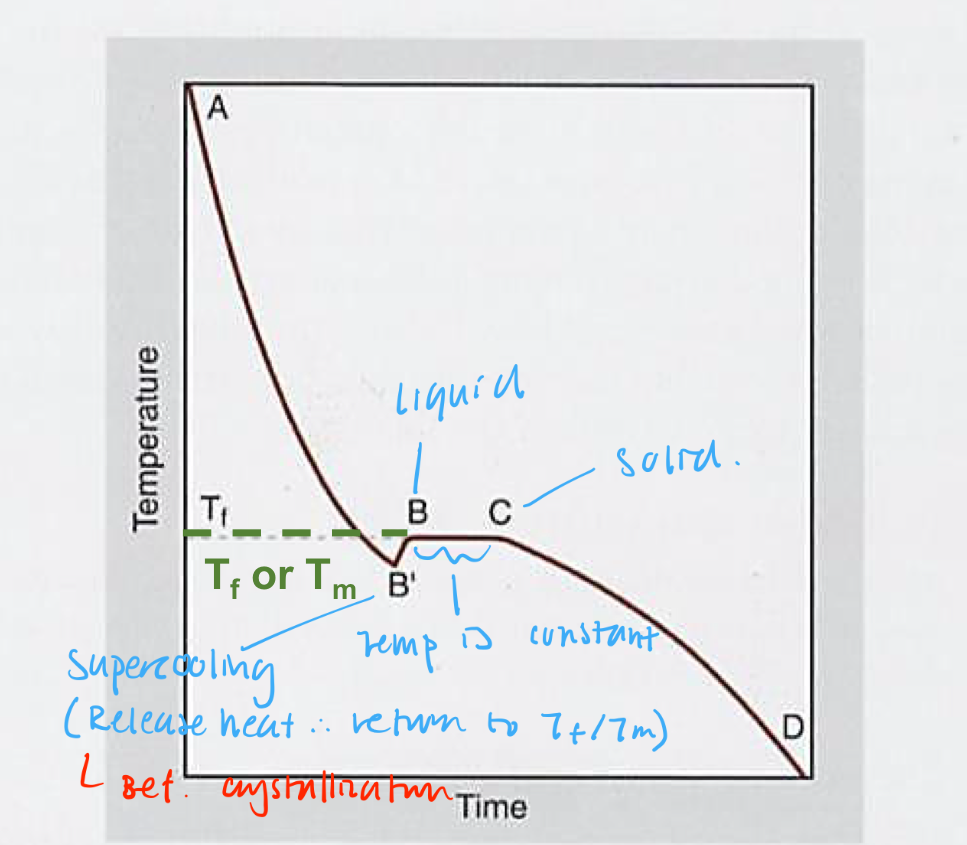

Solidification of pure metals

Have fixed Tm/Tf

Supercooling may occur before crystallization

Formation of grain structures

Stages

Atoms aggregate to form an embryo

Nuclei formation: embryo increases in size

Branch/dendrite formation

Grains become recognizable

Grains are formed

A metal has formed grain structures

Crystal Growth

Homogenous nucleation → Non-uniform grain

From nucleus without external agents

Heterogeneous nucleation → Uniform grain

Discreet particles are used to form nucleus

Grain Boundaries

Junction between grains or crystals

Have higher energy (due to unsatisfied bonds)

Increases strength of material → Cracks don’t propagate as well

Grain morphology and size

Equiaxed grains: Equal in size in all directions

Average size of grains in microstructure

Small grain size → Better physical and mechanical properties

Controlling grain sizes

Rapid cooling

Mold design

Vibration during solidification

High thermal differential between mold wall and alloy

Use of nucleating agents (grain refiner) - best way to do it

What are dental alloys?

Alloy

Mixture of 2 or more metals that are mutually soluble in the molten condition; or a mixture of a metal and a non-metal

Improves physical and mechanical properties

Categorizing Alloys

ADA specification #5: Gold-based alloys

Can have any composition so long they pass the tests for toxicity, tarnish, yield strength, and percent elongation

I → IV (soft → extra-hard)

ADA classification

High noble: >40 wt% Au and >60 wt% of the noble metal elements

Noble: > 25 wt% of the noble metal elements (Au, Pd, Pt)

(Predominantly) Base metal (PB): < 25 wt% pf the noble metal

Principle element: Listed in declining order of composition (highest to lowest)

Except certain elements that affect physical properties or represent potential biocompatibility concerns

Descriptive classification

Normal-fusing alloys (good for all-metal restorations)

Ex/ Silver-palladium

High-fusing alloys (mostly for PFM)

Ex/ Palladium-silver

Why are pure metals not useful for most dental applications

Alloys have better physical and mechanical properties than pure metals

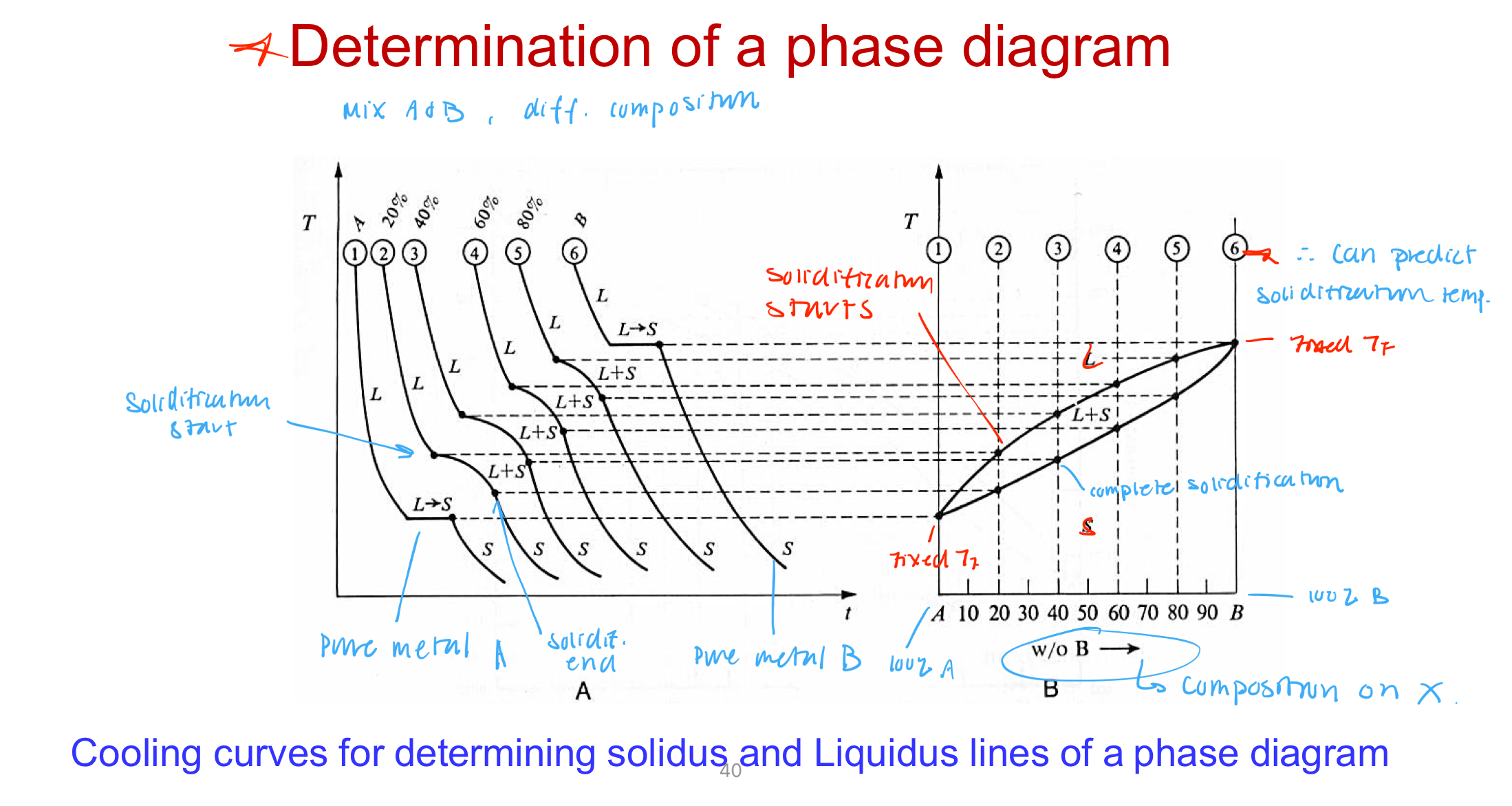

Understand phase diagrams for dental alloys

Definitions/Characteristics

Phase: A physically distinct, homogenous, and mechanically separable portion of a system

Alloys solidify over a range of temperatures

Exist as solid and liquid

No one Tm

Solid solutions

Substitutional: Have similar properties therefore can replace to form alloy

Atomic size - variation within 15%

Valence - behaves the same with other elements

Chemical affinity

Lattice type (FCC, BCC, HCP)

Interstitial: Have different sizes

Can distort lattice and make dislocation movement difficult

Increase strength, hardness, and proportional limit

Decrease ductility and resistance to corrosion

Liquidus curve: Above line, all liquid (solidification begins once you hit the curve)

Solidus curve: Below the line, all solid

Know the role of each element in dental alloy

Gold (Au)

Soft, (most) malleable and ductile

Relatively low strength

Tarnish resistant in air and water at any temp

Insoluble in sulfuric, nitric, or hydrochloric acids

Soluble in a combination of nitric and sulfuric acids (aqua-regia)

Physical properties:

E: low (weak bonds)

Tm: low (weak bonds)

CTE: large (weak bonds)

Platinum (Pt)

Tough, malleable, and ductile

Very high cost (usually replaced by Pd)

High corrosion resistance

Higher melting temp than porcelain

Physical properties:

E: higher than gold → Higher Tm and lower CTE

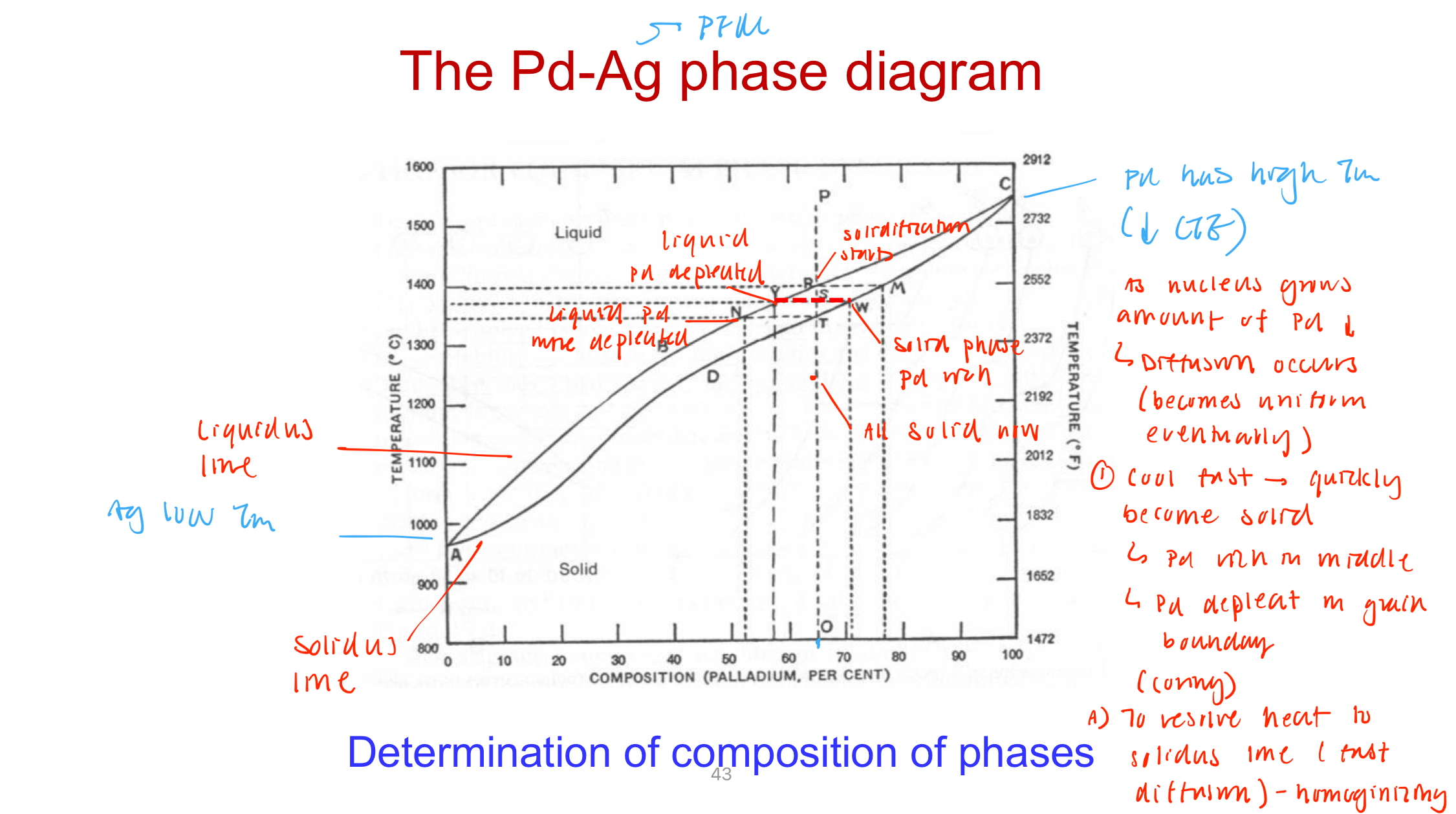

Palladium (Pd)

Not used in pure state

Replaced Pt in dental casting alloys

Cheaper than Pt

Helps prevent corrosion of silver in the oral environment

Physical propertiesL

E: higher than gold → Higher Tm and lower CTE

Silver (Ag) - NOT A NOBLE METAL

Malleable and ductile

Best known conductor of heat and electricity

Harder than gold

Unaltered in clean dry air

Severe tarnishing in the oral environment → Pits and porosities

Recognize the importance of some properties of the alloys

Coring: inhomogenous alloy composition because of non-equilibrium cooling rates

Happens during solidification (one element in higher concentration in the center) → can lead to corrosion

Homogenizing with heat treatment can undo the coring

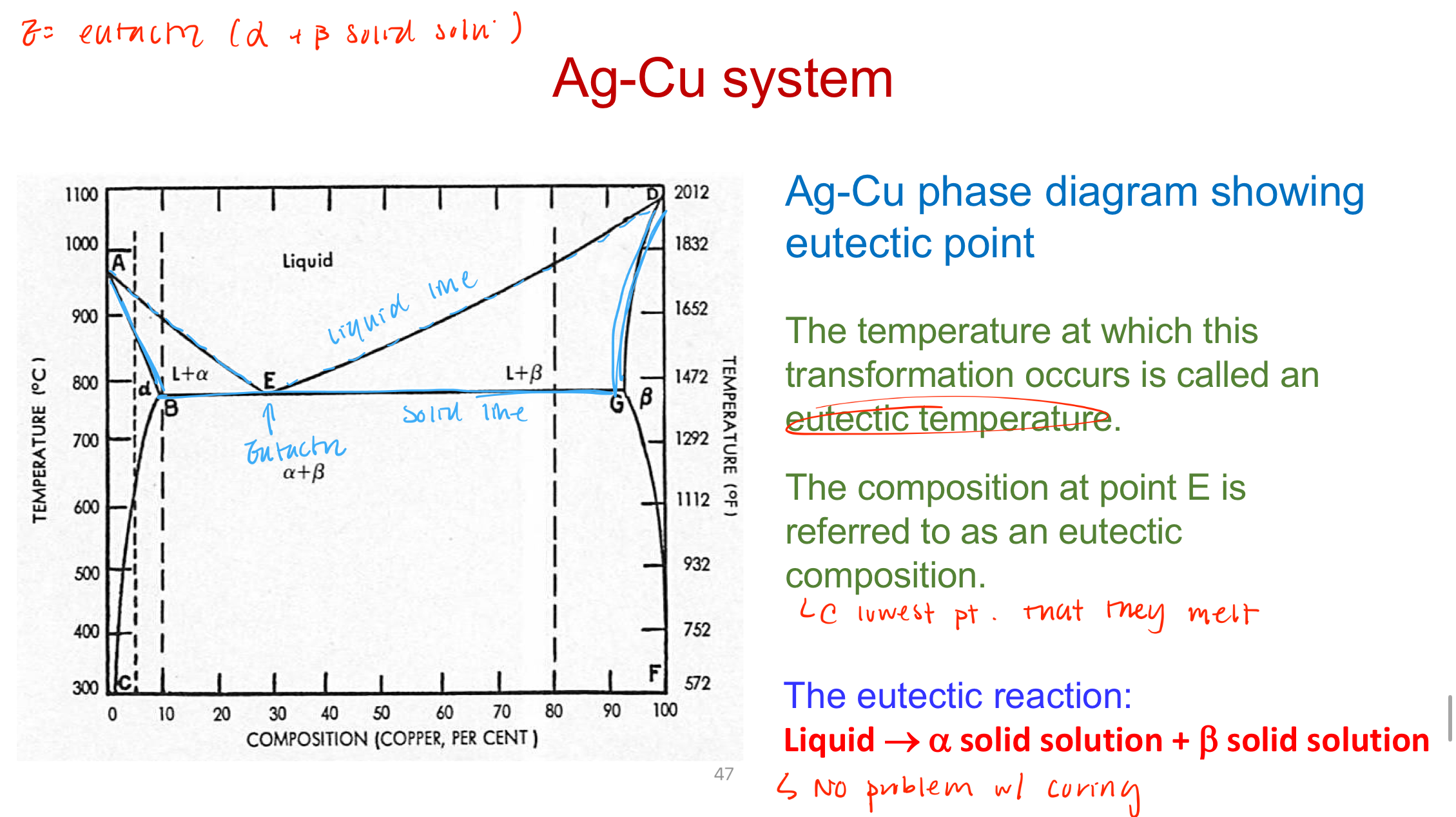

Eutectic system

Liquid freezes and forms 2 different phases (alpha and beta) - point is known as the eutectic temperaure

Alloys in eutectic systems are…

Brittle, high hardness and strength, poor tarnish and corrosion resistance

Peritectic Alloys

Takes place between a previously precipitated phase and the liquid to produce a new solid

Liquid + Beta solid solution → alpha solid solution (susceptible to coring)

Alloys in pertectic systems are…

Susceptible to coring

Brittle

Boor corrosion resistance

Intermetallic compounds

An alloy with definite (fixed) proportions of 2 or more metals (elements in clearly defined atomic ratios)

Clearly defined stoichometry

Properties of Metals and Alloys

Cast metals and alloys = Not deformed

Wrought metals and alloys = Plastically deformed

Have changes in microstructure and physical properties

Ex/ direct filling gold, orthodontic wires, titanium dental implantss

Is deformation good or bad?

Mechanism of Deformation

Deformation occurs when bonds between atoms are ruptured

Stress needed = E/15

Large stresses required to produce slip in a perfect lattice

E/15 » YS (through experimentation) because all metals have impurities and defects

What is the reason for deformation?

What types of defects arise in solids?

Types of Imperfections

Point defects

Vacancy atoms: Distorts plane → Collapse

Interstitial atoms

Self-interstitial: Distorts plane → Extra atoms bulges lattice

Interstitial atoms: Typically smaller

Substitutional atoms

Line defects

Dislocation: “extra” half plane of atoms → Edge dislocation

Atomic arrangement next to a dislocation line is strained

Dislocation slips to proceed at stresses lower than predicted yield stress

Only need to break one bond at a time (propagates)

Movement of dislocation → slip → plastic deformation

Stops once reaches the edge of the crystal

Area defects

Grain boundaries: Impedes dislocation motion

Need more energy to overcome boundary

Volume defects

Cracks, pores, inclusions

How do defects affect material properties

Wrought

T/S: high

Ductility: low

Corrosion resistance: low

Cast

T/S: low

Ductility: high

Corrosion resistance: high

Are defects undesirable?

Not necessarily, can strengthen material

What are the methods for strengthening metals and alloys?

Strengthening Strategies

Decrease grain size: Add grain refiners

In metals… increase number of nucleation sites or pin grain boundaries by fine particles

Solid solution strengthening

Substitutional solid solution: Adds local stresses → Increase strength (stress spots making it more difficult to dislocate)

Interstitial solid solution: Interstitial strengthening can lock planes from shearing and pit the surface in compression

Precipitate strengthening

Hard precipitates are difficult to shear

Ex/ alpha titanium precip. into beta titanium → Locks up beta titanium while maintaining ductility

The closer the precipitates are, the more difficult it is to shear

Cold work: Physically plastic deforming (but becomes more brittle)

Dislocation becomes more difficult (trapped by the dislocation that happens during cold-working)

Increase YS and tensile strength

Decrease ductility (fractures more easily)

Annealing

Annealing can reduce dislocation density and increase grain size

Reverse effects of cold work

Heat metal to half its fusion temperature

Stages: recovery, recrystallization, grain growth

Application: Implants

Modern titanium implants are stronger than those from 30 years ago

Use CP4 Ti → strengthened via cold working (480 → 760)

Can return to 480 after annealing

Introduction to Dental Polymers

Uses in Dentistry

Impression materials

Denture base materials: PMMA/acrylic

Composite resin restorative materials: Bos-GMA, UDMA, Sirolane

What is a monomer?

Resins: monomer - nonmetallic materials synthesized from organic compounds that can be molded when soft and hardened for use

Plasticizers

Added to monomers to increase solubility and decrease brittleness of a polymer

Facilitates slipping of polymer chains along each other

Effects:

Reduce strength

Decrease hardness

Lower Tg

What is a polymer?

Long chain molecules consisting of many repeating units

Classification Based on Origin

Natural: Proteins and nucleic acids, polyisoprenes, polysaccharides

Synthetic: PMMA, Nylon, Teflon

Classification based on thermal behavior

Thermoplastic resins: Soften under heat and pressure and harden when cooled

No chemical reaction

Generally soluble in organic solvents

Ex/ PMMA, waxes

Thermoset resins: Harden by a chemical reaction and generally insoluble in organic solvents

Ex. Alginates, epoxy, Bis-BMA

Cross-linking

Formation of bridges between chains of polymers to form a 3D network

Effects:

Increase Tg

Increase strength

Decrease solubility

Decrease water-sorption

Physical Properties of Polymers

Degree of polymerization (DP): Average number of repeating monomeric units in a polymer molecule

Large polymer = Large DP = Increase strength

Degree of conversion: Fraction of DB converted to single bonds after polymerization

Increase degree of conversion = Increase strength

Strength Properties

Strong influence of temperature on strength

As temperature increases…

Physical properties decrease

Strength decrease

Ductility increase

Other influences: Composition, molecular weight, structure, residual monomer (conversion rate)

Biological Properties

Taste, smell, toxicity, soft tissue irritation influenced by…

Water uptake (will structurally change dimensions)

Solubility

Residual monomer (no less than 25%)

Bond to tooth structure

What is the difference between condensation polymerization and addition polymerization?

Polymerization: A series of chemical reactions by which a macromolecule is formed from a single monomer

Condensation Polymerization (step-growth)

Repeating units are joined by functional groups

Reaction is slow (hard to make large molecules)

Results in a by-product and is exothermic

Ex/ Mercaptan + lead dioxide → polysulfide rubber + lead oxide + water

Lead dioxide = catalyst (survives entire reaction)

Addition Polymerization

General steps: initiator + monomer → activated monomer → Propagation → Termination

Successive reactions between monomer molecules to form a polymer without formation of volatile by-products

Features: the presence of an unsaturated group, readily form giant molecules, chain growth can continue indefinitely, exothermic reaction

Ex/ polymerization of MMA → PMMA

Initiated by benzoyl peroxide

Activators and Inhibitors

Activators of addition polymerization: Heat, tertiary amine, light (UV, visible), Microwave energy

Inhibitors of polymerization: Impurities, hydroquinone (esp in composites), oxygen

Structure of Polymers

Linear

Branched

Copolymerization

Polymerization of 2 or more monomers to form a polymor

Dental Ceramics

Define ceramic in general terms and give examples of ceramics and their applications in dentistry

Ceramics: Solid material composed of inorganic nonmetallic compounds (ex/ pottery, clay, cements, glass)

Key characteristic - Brittle (stress concentrations at surface imperfections lead to crack initiation, propagation, and failure)

Dental ceramics

Gypsum products

Cement powders (ZnO, MgO)

Orthodontic bracket

Fillings,

Veneers

Crows and fixed pros.

Implants and abutments

Differentiate the composition and structure of crystalline and non-crystalline ceramics

Crystalline vs Non-Crystalline Ceramics

Crystalline (Ex/ Quartz, cristobalite, tridymite)

Non-Crystalline (Ex/ Amorphous SiO2 glass, fused silica)

Classes of Dental Ceramics

Silicate ceramics

Porcelain: Mimics optical properties of enamel and dentin

Feldspathic ceramics, leucite ceramics, fluor-apatite ceramics

Glass ceramics: Add crystallites to strengthen and toughen material

Leucite, lithia

Glass-Infiltrate (no longer used)

Oxide ceramics

Polycrystalline

Aluminum oxide (no longer used)

Zirconia

Non-Crystalline: Dental Porcelains

Feldspathic ceramics: Best mimics optical properties of enamel and dentin

Predominantly glassy material

Mainly feldspar, minimal clay and quartz components

Other porcelains: feldspathic porcelain, feldspar, aluminosilicate glass

Potash (with K2O) and soda (with Na2O) feldspar

Always use oxides in porcelains

By adding K2O and Na2O → Lower Tm and Increase CTE (glass modifier)

Characteristics…

Amorphous - non-crystalline

Highly translucent

Easy to make tooth shades

BRITTLE

Structure and properties of feldspathic ceramics

Low strength: Low resistance to crack initiation

Low toughness: Low resistance to crack propagation

Glass Ceramics

Leucite glass-ceramic

Add leucite to add strength and toughness

Dispersion strengthening

Lithia glass-ceramics

Lithium disilicate (has a higher crystalline content - “log” shaped)

By compressing, can force crystals to be perpendicular to applied stress

Stronger and tougher than leucite glass-ceramics but still relatively low

Best used for anterior bridge and single tooth restorations

Oxide Ceramics - Zirconia (Polycrystalline ceramic - glass free)

Much higher strength (harder to initiate crack)

Very strong, but highly opaque

Describe methods of strengthening ceramics for dental application

Leucite Reinforced Feldspar

Has a similar refractive index to porcelain

Increases strength

Faster acid etch rate → Increase mechanical interlocking with cement

Role of Components

Feldspar

SiO2 (glass network)

Oxides of potassium, sodium and calcium (glass network modifier)

Alumina

Increase strength and viscosity (glass network intermediate)

Leucite crystal formation

Metal oxides (opacity) and pigments

Fracture of Porcelain Crowns

Feldspathic ceramic crowns

Reinforcement with crystals can make it harder

Strengthening Porcelain Restorations

Strong core materials: zirconia, glass ceramics, and metals

Ex/ Porcelain veneered glass-ceramic, PFM

Strengthen via having a strong framework

List the advantages and disadvantages of ceramic material

Advantages

Natural appearance

High resistance to wear and distortion

Excellent biocompatibility (chemically inert)

Low or no corrosion

Considerably less expensive

Disadvantages

Brittle

Tensile stresses can cause crack propagation and fracture

High compressive strength (10x the tensile strength)

No dislocation motion (slip) - Ionic bonding → too much electrostatic repulsion

Hard, difficult to polish

Wear opposing teeth (harder than enamel)

Produce clicking sound on contact (especially zirconia)

Difficult to bond to denture base material