QMS Module 1

RAN OUT OF PRACTICE TESTS, SORRY :(

Introduction to Quality Management and Improvement

Quality

relating to one or more desirable characteristics that a product or service should have

an important consumer decision factor in selecting competing products and services

understanding it is the key to business success, growth, and enhanced competitiveness

increased quality provides a substantial return on investment

Garvin’s Dimensions of Quality

Performance

Reliability

Durability

Serviceability

Aesthetics

Features

Perceived Quality

Conformance to Standards

Dimensions of Service Quality

Responsiveness

Professionalism

Attentiveness

Quality’s Traditional Meaning: Fitness for use; focuses on products/services meeting user requirements

Two Aspects of Quality

Quality of design - how a product is planned and made to stand out.

Quality of conformance - how well the product matches its original design.

Quality’s Modern Meaning: It is inversely proportional to variability; quality improves when there is less unwanted variability in the product’s key characteristics.

Quality Engineering Terminology

Critical-to-Quality (CTQ) Characteristics: Elements of a product that determine how well it meets user or consumer expectations.

Types of Quality Characteristics

Physical

Sensory

Time Orientation

Quality Engineering: involves operational, managerial, and engineering activities designed to ensure that the quality characteristics of a product meet the required levels and that variability is minimized.

Statistical methods are essential for describing and managing variability in quality improvement efforts.

Types of data:

Variable data - discrete data

Attribute data - continuous measurements

Specifications: these define the desired measurements and performance levels for a specific quality characteristic of a product or service.

Nominal or Target value: The ideal or desired value for a quality characteristic set by design engineers.

Specification Limits:

Upper Specification Limit

Lower Specification Limit

Over-the-wall approach: A traditional design method where engineers set specifications without fully considering manufacturing processes or variability.

Concurrent Engineering: A team approach to design, with specialists in manufacturing, quality engineering, and other disciplines working together with the product designer at the earliest stages of the product design process.

A Brief History of Quality Control and Improvement

Early Development in Quality (Pre-1900s)

Fredrick W. Taylor

Introduced scientific management principles.

Focused on task division, enhancing productivity and quality.

Impact: Standardization of work methods.

Frank and Lillian Gilbreth

Extended work on motion study and work design.

Issue: Early emphasis was more on productivity than quality.

Walter A. Shewhart (1924)

Developed the statistical control chart.

Significance: Marked the formal beginning of statistical quality control.

Harold F. Dodge and Harry G. Romig (Late 1920s)

Developed acceptance sampling as an alternative to 100% inspection.

Widespread use in Western Electric by the 1930s.

Growth During WWII

Expanded use of statistical quality control in manufacturing

The American Society for Quality Control was created in 1949

They promoted quality improvement techniques in various industries

Advancements in the 50s-60s

The emergence of reliability engineering

The introduction of designed experiments in the 1950s, these were initially applied in the chemical industry and strengthened the US chemical industry’s competitiveness

Global Influence and Japanese Methods

1970s-1980s

Western companies realized Japanese competitors used designed experiments since the 1960s.

Applications in process improvement, new product design, and reliability enhancement

These resulted in those methods being adopted in the West

Global Influence and Japanese Methods

Post-1980s Growth

There was a profound increase in the use of statistical methods for quality and business improvement in the US, which helped their automobile industry from the brink of collapse

Management frameworks began to emerge for implementing quality improvement

Statistical Methods for Quality Control and Improvement

Process as a System

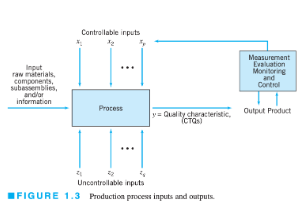

Inputs: Controllable factors (x1, x2, ... xp): Process variables (e.g., temperatures, pressures, feed rates).

Uncontrollable factors (z1, z2, ... zq): Environmental factors, raw material properties.

Output: Quality characteristic (y) – A measure of process and product quality.

Control Charts

Control charts are used as a primary SPC technique

They plot the averages of measurements of a quality characteristic in samples taken from the process vs. time or sample number

Components include:

Center line (CL): represents the expected average value of the quality characteristic

Upper control limit (UCL) and lower control limit (LCL): these define the boundaries within which the process should operate if there are no unusual variations

Designed experiments

Designed experiments systematically vary controllable input factors to understand their impact on output quality characteristics. This helps in identifying key variables affecting process performance and product quality.

Types of designed experiments:

Factorial Design Types

Two-Factor Example (2^2): Four combinations of low and high levels for two factors.

Three-Factor Example (2^3): Eight combinations for three factors, arranged in a cube.

Benefits:

Reducing variability

Improving quality

May lead to performance breakthroughs

Acceptance Sampling

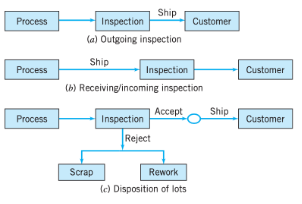

The inspection and classification samples from a larger batch to decide if the whole lot should be accepted or rejected

Types of acceptance sampling:

Outgoing: Conducted post-production, before shipping.

Incoming: Applied to batches received from suppliers.

Rectifying: Involves scrapping, recycling, reworking, or replacing rejected units.

Evolution of Quality Techniques

Early Stage: Reliance on acceptance sampling and inspection.

Intermediate Stage: Increased use of sampling inspection with the realization that quality can’t be solely inspected into products.

Advanced Stage: Emphasis on process improvement through Statistical Process Control (SPC) and designed experiments.

Management Aspects of Quality Improvement

3 Main Activities of QMS

Quality Planning

Involves identifying customers, both internal and external, and identifying their needs

Products or services that meet or exceed customer expectations must be developed

It prevents wasted resources on defects, complaints, and failures

Quality Assurance

The set of activities that ensures the quality levels of products and services are properly maintained and that supplier and customer quality issues are properly resolved

Key components include:

Documentation:

Policy

Procedures

Work instructions and specifications

Records

Document control

Quality Control and improvement

SPC and designed experiments are major tools of this

Quality Philosophy and Management Strategies

Key Figures in Quality Management

W. Edwards Deming (1900-1993)

Background: Educated in engineering and physics at the University of Wyoming and Yale University.

Influences: Greatly influenced by Walter A. Shewhart, known for developing the control chart.

Career: Worked at Western Electric, held government positions, and contributed significantly during WWII.

Impact on Japan: Post-war consultant to Japanese industries, advocating for statistical methods, which fueled Japan’s industrial growth. The Deming Prize was established in his honor.

Philosophy: Emphasized that quality improvement is primarily the responsibility of management, not the workforce; critiqued traditional American management practices.

Deming’s 14 Points (Summarized, sir’s PowerPoint as reference)

Long term focus

Commit to quality

Prevent problems; don’t rely on mass inspections

Choose suppliers over quality, not price

Focus on continuous improvement

Train your people

Help, don’t micromanage

Create a safe environment for your employees; drive out fear

Encourage teamwork; break down barriers between departments

Avoid empty slogans

Stop using quotas

Remove obstacles

Educate everyone

Leadership should commit to the past 13 points

Deming’s 7 Deadly Diseases of Management

Lack of constancy of purpose

Emphasis on short-term profits

Performance evaluation issues

Management mobility

Running a company of visible figures alone

Excessive medical costs

Excessive legal damage rewards

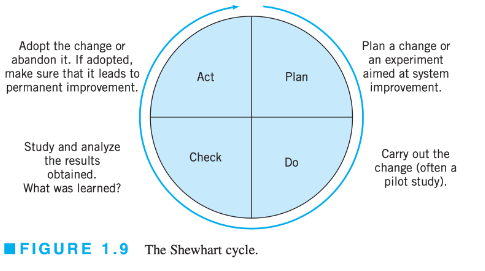

The Shewhart Cycle (PDCA)

Deming’s Obstacles

Automation as a solution

Copying existing solutions

“Our problems are different”; ignoring universal principles

Outdated education

Poor use of statistics

Relying on inspection

Quality as a departmental task

Blaming workers

False starts

The fallacy of zero defects

Inadequate Prototype Testing

External Help Misconception

Joseph M. Juran (1904-2008)

Pioneer in Quality Management: Key figure in the development of quality control and improvement, influenced by Walter A. Shewhart.

Career Highlights: Chief industrial engineer at Western Electric, simplified processes during WWII, and led NYU’s Department of Administrative Engineering. A key influencer in Japan's industrial rise.

Major Contributions: Co-authored the Quality Control Handbook and founded the Juran Institute.

Juran Trilogy: Focuses on three pillars—Planning, Control, and Improvement—emphasizing project-based quality improvement, either through continuous or breakthrough efforts.

Armand V. Feigenbaum (1920-2014)

Concept of Total Quality Control: Introduced in his 1951 book Total Quality Control, which greatly influenced early quality management practices in Japan.

Three-Step Approach: Emphasized quality leadership, quality technology (statistical methods and technical tools), and organizational commitment.

Organizational Focus: Advocated for a systems approach to quality improvement, highlighting the importance of management commitment and a structured process for successful implementation.

19-Step Improvement Process: Proposed a detailed framework for quality improvement, with statistical methods as a key component. Initially suggested centralizing technical expertise in a specialized department.

Total Quality Management (TQM)

A strategy for implementing and managing quality improvement activities on an organizational basis

Began in the 1980s with Deming and Juran’s philosophies as a focal point

Key elements of TQM include:

Customer focus

Workforce engagement

Supplier Improvement

Integration with business goals

Quality Systems and Standards

The International Standards Organization (ISO)

Founded in 1946 in Geneva, Switzerland

They establish standards for quality systems; the ISO 9000 series is their most widely adapted, it includes:

ISO 9000: Fundamentals and Vocabulary

ISO 9001: Quality Management System Requirements

ISO 9004: Quality Management System - Guidelines for performance improvement

The ISO 9000 series is also an American National Standards Institute and an ASQ Standard

The ISO Certification Process involves selecting a registrar, preparing for audits, and ensuring compliance with the standard’s clauses (e.g., management responsibility, resource management)

Challenges of ISO Certificatio:

Heavy emphasis on paperwork and documentation

Lack of emphasis on variability reduction and process improvement

Other ISO certified organizations have still faced challenges despite being certified

ISO certification has been criticized for being costly without much actual impact on quality improvement, which suggests that companies might benefit more from focusing on internal quality standards

Malcolm Balridge National Quality Award (MBNQA)

Established by the US Congress is 1987

Given annually to recognize US organizations for performance excellence

Administered by the National Institute of Standards and Technology (NIST)

Categories of award:

Manufacturing

Service

Small Business

Healthcare

Education

Six Sigma

A quality methodology developed by Motorola in the 1980s as a response to customer demand

Focuses on reducing variability in key product quality characteristics to the level where failure or defects are extremely unlikely

Three Sigma Quality

Specification limits are three standard deviations from the mean; probability of producing a product within specifications is 0.9973, which corresponds to 2,700 ppm defective

Six Sigma Quality

The probability that any specific unit of a hypothetical product is non-defective is 0.2 ppm

However, predictions can only be made of process performance when the process is stable or mean and standard

The Link Between Quality and Productivity

Producing high-quality products is challenging in today’s rapidly evolving industrial environment. Technology advances in fields like electronics, metallurgy, and biotechnology complicate product design and manufacturing.

Challenges in Balancing Quality and Productivity

Rapid technological advancements require:

the quick integration of new technologies for competitive advantage

the optimization of processes for economy, efficiency, productivity, and quality

Without focusing on all dimensions, companies face higher costs and reduced productivity

Quality Costs

Financial controls in business management often overlook quality costs.

Why do quality costs matter?

Products are becoming more complex because of technological advances

There is more awareness of life-cycle costs (maintenance, spare parts, failures)

Quality engineers can communicate better with management using cost metrics

Categories of quality cost:

Prevention costs: costs associated with avoiding defects

New products review

Product or process design

Process control

Burn-in

Training

Quality data acquisition

Appraisal costs

Inspection or testing of incoming materials

Product inspections throughout production

Calibration and maintenance of testing equipment

Internal failure costs

Scrap

Rework

Retesting

Downtime

Yield Losses

External failure costs

Complaint adjustments

Returned products

Warranty changes

Liability costs

Indirect costs

Quality costs can range from 4% to 40% of sales depending on the

industry.

Prevention and appraisal investments reduce internal/external failure

costs.

Pareto analysis can be used to identify key areas for quality improvement.