SRT153 - Building Materials Science Class (On-line)_default (1)

Introduction to Wood and Timber Products

Overview of class focus on wood and timber products following prior introductory session on building material properties.

Outline of Today's Class

Examination of wood structures and types.

Discussion of moisture content as a key property.

Exploration of defects in wood and timber products.

Overview of timber members and products.

Reference materials for visual aid and supplementary information on Australian timber.

Recap of Previous Class

Covered general properties of materials including:

Mechanical properties: compression, tension, shear, ductility, plasticity, elasticity.

Acoustic performances and building movements.

Key deteriorations in building materials.

Environmental properties, sustainability, and toxicity discussed briefly.

Major Building Materials in Australia

Four primary materials include:

Timber

Brick

Concrete

Steel

Importance of timber as a building material:

High strength-to-weight ratio compared to other materials (e.g., timber: 400 kg/m³ vs. stone: 2000 kg/m³).

Suitable for bending, compression, and tension forces.

Bio-based material that absorbs carbon, beneficial for global warming mitigation.

Mechanical Properties of Timber

Timber exhibits non-elastic behavior, specifically creep (long-term deformation under stress).

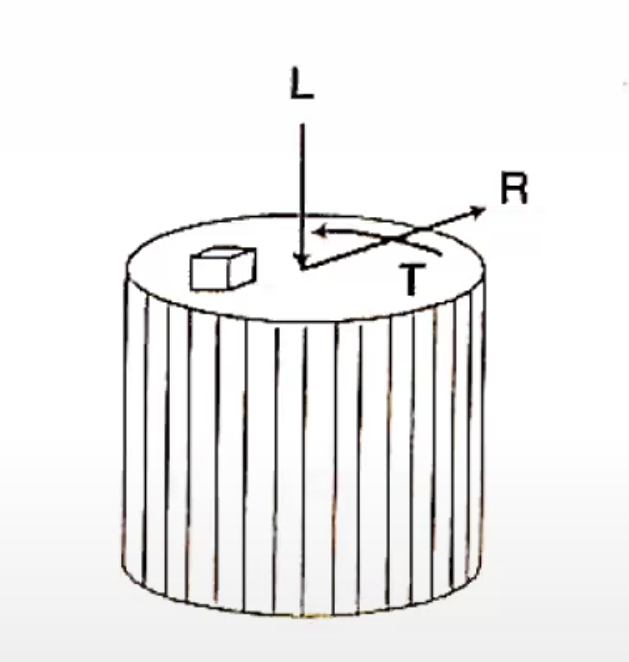

Strength characteristics:

Strongest longitudinally (along growth direction).

Weaker in radial and tangential directions.

Timber is an excellent insulator.

Microstructure of Wood

Composed of longitudinal cells called tracheids and fewer radial cells called rays.

Tracheids conduct nutrients; rays store and transfer nutrients.

Living bark (conducts nutrients) lies beneath protective bark.

Cambium layer generates new cells and growth.

Sapwood stores nutrients; heartwood provides structural strength but is non-living.

Types of Wood

Two broad categories:

Softwoods: Simpler microstructure, large tracheids, small rays, derived from coniferous trees.

Hardwoods: More complex microstructure with larger number of radial cells (rays) and two types of longitudinal cells (fibers and larger vessels) from broadleaf trees.

Common softwoods: Radiata pine, cypress pine, spruce.

Common hardwoods: Oak, mahogany, maple.

Importance of Moisture Content in Timber

Moisture varies from 30% to 300% relative to oven-dried weight.

After cutting, free water evaporates first, followed by moisture held in cellulose (fiber saturation point).

Shrinkage occurs as moisture decreases, affecting stiffness and strength:

10% shrinkage in tangentially oriented wood vs. 5% in radially oriented wood.

Effects of Moisture on Timber

Moisture influences biological susceptibility (fungal and insect attacks).

Low moisture in timber promotes durability.

High moisture leads to increased creep and potential damage to coatings.

Defects and Distortions in Timber

Common defects include:

Knots: Uneven wear, tension, reduce strength.

Gum veins: Impact shear strength and appearance.

Checks, splits, shakes: Distortions causing structural issues.

Geometric distortions: Copying, bowing, springing, and twisting due to uneven moisture shrinkage.

Hazardous Conditions Affecting Timber

Weathering leads to degradation, resulting in uniform gray color and change in appearance.

Insect attacks (termite and beetle) and fungal growth require conditions like moisture and warmth.

Termites cause significant structural damage.

Fungi require moisture (20%) and oxygen.

Chemical degradation occurs from acidic conditions or metal fastener corrosion due to chemical interactions with timber.

Treatment of Wood

Treatment is crucial for preventing hazards affecting wood, involving strategies that consider:

Intended use of facilities (human or animal).

Required structural reliability and aesthetics.

Microstructure of wood influencing treatment types.

Statutory Labels for Commercial Timber

Important information on wood labeling includes:

Grade (F-rating for strength).

Method of grading (Visual Stress Grading, VSG).

Moisture content and species.

Producer information and compliance with national standards.

Timber Members in Construction

Common timber members include lintels, noggings, beams, top/bottom plates.

Understanding timber's structural efficiency contributes to its continued use in construction.

Engineered Wood Products

Types include:

Cross Laminated Timber (CLT): Sustainable, good fire resistance, suitable for mid-rise buildings.

Laminated Veneer Lumber (LVL): Used for straight lengths.

Glued Laminated Timber (Glulam): Attractive architectural designs using laminated sections.

Circular Economy in Timber Use

Potential for wood reuse and remanufacturing to support sustainability goals.

Conclusion

Wood as a versatile, environmentally friendly material, crucial for construction.

Importance of understanding wood types, properties, moisture content, and treatment.

Next class will cover cement, concrete, and related materials.

Reminder for students to engage with seminars and quizzes.