Exam 3 Supply Chain

Chapter 7-9

The Essence of Demand Management

To estimate and manage customer demand and use this

information to make operating decisions.To further the ability of firms throughout the supply chain to

collaborate on activities related to the flow of products, services,

information, and capital

Desired end result:

Greater value for the end user or consumer

Common Problems in Demand Management

Lack of coordination between departments

Too much emphasis placed on forecasts of

demand, with less attention on the

collaborative efforts and plans needed to be

developed from the forecastsNon-strategic uses of demand information

Effective Demand Management

unifies channel members with the

common goals of satisfying customers and solving customer problems.Gather & analyze knowledge about consumers, their

problems, and their unmet needs.Identify partners to perform functions needed in

demand chain.Move functions to the channel member that can perform

them most effectively and efficiently.Share with other supply chain members knowledge

about customers, technology, and logistics challenges

and opportunities.Developing products and services that solve customers’

problems.Develop & execute best methods to deliver products &

services to consumers in the desired format.

Demand Forecasting

Foundation of many SC manager decisions

How to balance supply and demand

All forecasts will be wrong

Select the forecasting technique with the lowest forecast error

Two Types of Demand Forecasting

Forecasts serve as a plan for both marketing and operations to set goals

and develop execution strategies

Independent Demand

demand for the primary item, known as base

demand

Dependent Demand

demand directly influenced by demand for an

independent item

All Demand is Subject to Fluctuations

Random fluctuation – cannot be

anticipated & is usually the cause to hold

safety stocks to avoid stockoutsTrend fluctuation – gradual increase or

decrease in demand over time for an

organizationSeasonal fluctuation – patterns will

normally repeat themselves during a year

for most organizations

common forecasting techniques

simple moving average

weighted moving average

exponential smoothing

weighted moving average

assigns a weight to each previous period with higher weights usually given to the more recent demand

pros: allows emphasis on more recent demand as a predictor of future demand

cons: not easily accommodate seasonal demand patterns

Other Quantitative Methods

Regression – based on the assumption that underlying factors influence

what is being forecastedSimulation – can be very sophisticated, often used to compare different

forecasting methods

Common Qualitative Methods

Executive Judgment – expert opinions from different

departments is averagedSales Force Composite – forecast based on the

opinions of salespeopleMarket Research/Survey – directly collecting

information from consumers about purchasesDelphi Method – panels of experts individually

questioned (not as a group); effective for long range

forecasting

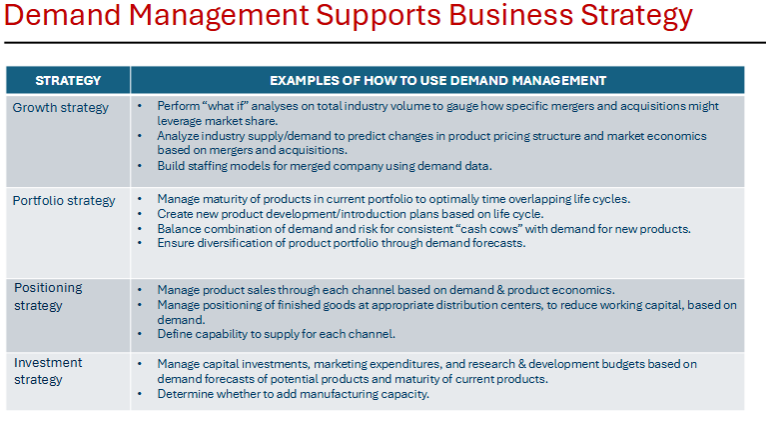

Demand Management Impacts Order Management

Demand Management: How organizations create forecasts that are

used to create marketing, production,

finance, and logistics plans & Align organization resources to strategic

goalsOrder Management & Customer Service: The execution of the plans from demand management & Tactical, day-to-day activities

Order Management

Defines and sets in motion the logistics

infrastructure of the organization

Two Phases:

Phase 1: Influence and Order

Organization attempts to change the manner by which

customer place orders

Phase 2: Execute the Order

Order receipt: electronic vs. manual

Order fulfillment: inventory policy, number and location

of warehousesOrder shipments: transportation mode choice

Customer Service

Anything that touches the customer, including all activities that impact

information flow, product flow, and cash flow between the organization and its

customersCustomer service as a philosophy

Elevated to an organization-wide commitment

Customer service as a performance measure

Assess performance through measures like on-time delivery and percentage of

orders filled complete

Customer service as an activity

A task that an organization must perform to satisfy customers

Order Management: Influencing the Order

Customer Relationship Management (CRM)

Align the supplier’s resources with its customers in a manner that

increases both customer satisfaction and supplier profitsHow? How much? What? When?

• Maximize efficiencies of the shipping organizations logistics

network

4 Basics Steps in the Implementation of the CRM Process

1. Segment the Customer Base by Profitability

2. Identify the Product/Service Package for Each Customer

Segment3. Develop and Execute the Best Processes

Measure Performance and Continuously Improve

CRM: product/service package example Option #1, Most Commonly Used

Offer the same product/service to each customer segment, while varying the product quality or

service levels.Pro: easy for the supplier to manage

Con: Assumes that all customer segments value the same types of supplier offerings.

CRM Product/Service Package Example, Option#2

Vary the service offerings for each customer segment

Pro: meet the needs of each segment

Con: difficult for the supplier to manage

What is Activity Based Costing?

“A methodology that measures the cost and performance of activities, resources, and cost

objects. Resources are assigned to activities, then activities are assigned to cost objects based

on their use. ABC recognizes the causal relationships of cost drivers to activities”

Customer Segmentation

Danger zone segment strategies are: (1) Change the manner in which the customer interacts with the shipper to

move the customer to another segment; (2) Charge the customer the actual cost of doing; or (3) Switch the customer to an alternative distribution channel.Build segment strategies aim to maintain the cost to serve but build net sales value to help drive the customer into the “Protect” segment.

Cost engineer segment strategies aim to find more efficient ways for the customer to interact with the shipper.

Protect segment: most profitable, provide shipper with the most cost efficiencies

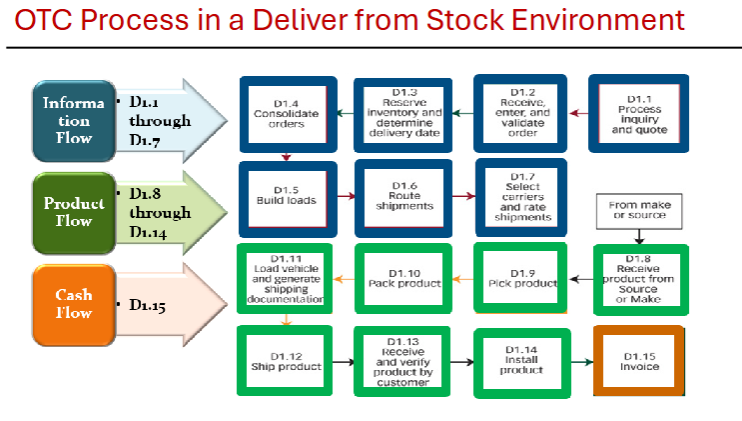

OTC: refer to outbound-to-customer shipments. The order to cash (or order cycle) is all of the activities that occur when an order is received by a seller until the product is received by the buyer, plus the flow of funds back to the seller based on the invoice.

Replenishment Cycle: The term replenishment cycle is used more frequently when referring to the acquisition of additional inventory as in materials management.

Customer Service

Output of logistics activities

Right product, right place, right time…lead to good

customer service

Today’s consumers:

Time conscious

Demand flexibility

High standards for quality

Not always brand loyal

Desire products at the best price, best service, with times that are convenient for their schedules

Companies build today’s customer service strategies on speed, flexibility, customization, and reliability

Customer Service: The Logistics/Marketing Interface

Marketing Objective: Allocate resources to the marketing mix to maximize long-term profitability of the firm

Logistics Objective: Minimize total costs, given customer service

objective, where: Total cost = Transportation costs + Warehousing costs + Order processing & Information costs + Lot quantity costs + Inventory carrying costs

4 Elements of Customer Service

Time – absolute length of lead time

Sellers – order to cash

Buyers – order cycle time, lead time, replenishment

time

Dependability – consistent lead time, safe delivery,

correct ordersCommunications – pre-transaction, transaction, post

transactionConvenience – flexible logistics service level

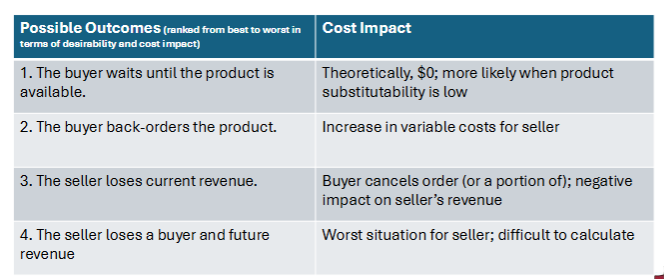

stockout- occurs when desired quantities of finished goods are not available when or where a customer needs them.

Item- a case, an inner-pack, or an “each” on an order

Line- a single product on a multiple product order

Item fill rate- the percentage of items in stock available to fill an order

Line fill rate- the percentage of total lines filled complete on an order

Order fill rate- the percentage of orders filled complete

Perfect order rate- the percentage of orders filled completely, received on time, billed accurately, etc

Metrics

Internal

Item fill rate

Line fill rate

External Metrics

Order fill rate

Perfect order

Financial Impact of Order Fill Rate: Improvement in order fill results in improvement in cash flow but might require some type of investment in inventories and/or technology

Service Recovery

Requires an organization to realize that mistakes will occur and to have plans in place to fix them.

Key Aspects

Measuring the costs of poor service

Anticipating the needs for recovery

Developing employee training and empowerment

Basic Facts About Inventory

Asset on the balance sheet

Variable expense on the income statement, direct impact on COGS

Direct impact on service levels

Part of corporate strategy

Constant balancing of too much vs. too little

Major logistics cost tradeoff is between transportation and inventory

Basics of Inventory Management

A set of techniques used to manage the inventory levels within different companies in a

supply chainGoal is to reduce cost (efficiency) while maintaining service levels customers require

(effectiveness)Forecast + product price = inputs that IM needs to balance

3 Types of Inventory

Cycle Stock – needed to meet demand between normally scheduled orders

Safety Stock – necessary to compensate for demand uncertainty & order lead times

Seasonal – produced and stockpiled in anticipation of future demand

Conflicting Goals of Functional Areas

Marketing- In favor of holding sufficient, or extra, inventory to ensure

product availability to meet customer needs and new

product offerings for continued market growth.Manufacturing- In favor of long production runs of a single product with

minimal changeovers to lower labor and machine costs

per unit, resulting in high inventory levels of the product.Finance- In favor of low inventories to increase inventory turns,

reduce liabilities and assets, and increase cash flow to

the organization

Major Types of Inventory Costs

Inventory Carrying Cost

Incurred by inventory at rest and waiting to be used. Four major components: Capital cost, Storage space cost, inventory service cost, & Inventory risk cost.

Ordering and Setup Cost

Refers to the expense of placing an order, excluding the cost of the product itself. Setup cost refers to the expense of changing/modifying a production/assembly process to facilitate line changeovers.

Expected Stockout Cost

Cost associated with not having a product/materials available to meet customer/production demand. Most organizations hold safety stock or buffer stock, to minimize the possibility of a stockout and costs of lost sales.

In-transit Inventory Carrying Cost

Generally, carrying inventory in transit costs less than in warehouses. However, in-transit inventory carrying cost becomes especially important on global moves since both distance & time increase.

4 Fundamental Questions of Inventory Management

How much should inventory be ordered?

When should inventory be ordered?

Where should inventory be held?

What specific line items should be available at specific

locations?

3 Key Factors of Inventory Management Strategies

1. Dependent vs. Independent demand- Independent demand is unrelated to

the demand for other items, while dependent demand is directly related to,

or derives from, the demand for another inventory item or product.

2. Pull vs. Push- The “pull” approach relies on customer orders to move

product through a logistics system, while the “push” approach uses

inventory replenishment techniques in anticipation of demand to move

products.

3. System-wide vs. Single-facility solutions- A system-wide approach plans

and executes inventory decisions across multiple nodes in the logistics

system. A single-facility approach does so for shipments and receipts

between a single shipping and receiving point.

Inventory Management Approaches

Economic Order Quantity (EOQ)

Just-in-time (JIT)

Materials Requirement Planning (MRP)

Manufacturing Resource Planning (MRP II)

Distribution Requirements Planning (DRP)

Vendor Managed Inventory (VMI)

Economic Order Quantity (EOQ)

Most cost-effective amount to purchase at a time

Order a fixed amount each time reordering takes place

Limitation – assumes consumer demand is constant

fixed order quantity EOQ model: inventory is reordered when the amount on hand reaches the reorder point. The reorder point quantity depends on the time it takes to get the new order and on the demand for the item during this lead time.

Just in Time (JIT) Approach

JIT is an operating concept based on delivering materials in exact amounts and at the precise times that organizations need them—thus minimizing inventory costs.

Designed to manage lead times and eliminate waste

Ideally, product should arrive exactly when an organization needs it, with no tolerance for late or early deliveries

High priority on short, consistent lead times but reliability is also important

4 Major Elements of JIT Concept

Zero inventories

Short, consistent lead times

Small, frequent replenishment quantities

High quality (zero defects)

Materials Requirements Planning (MRP)

Begins by determining how much end products (independent demand

items) customers desire and when they are neededTiming and component needs based on end-product demand are disaggregated

Objectives similar to JIT

An MRP system is designed to translate a master production schedule into time-phased net inventory requirements and the planned coverage of such requirements for each component item needed to implement this schedule.

Advantages:

Attempt to maintain reasonable safety stock levels and to minimize or eliminate inventories whenever

possible.Can identify process problems and potential supply chain disruptions long before they occur and take the

necessary corrective actions.Production schedules are based on actual demand as well as on forecasts of independent demand items.

They coordinate materials ordering across multiple points in an organization’s logistics network.

Disadvantages:

Application is computer intensive, and making changes is sometimes difficult once the system is in operation.

Both ordering and transportation costs might rise as an organization reduces inventory levels and possibly moves toward a more coordinated system of ordering product in smaller amounts to arrive when the organization needs it.

Not usually as sensitive to short-term fluctuations in demand as are order point approaches (although they are not as inventory intensive, either).

Frequently become quite complex and sometimes do not work exactly as intended.

Manufacturing Resource Planning (MRP2)

More comprehensive set of tools than MRP alone

Allows the integration of financial planning and operations/logistics

Helps an organization conduct “what if” analyses to determine appropriate product movement and storage strategies

Distribution Requirements Planning (DRP)

DRP systems accomplish for outbound shipments what MRP

accomplishes for inbound shipments.Determines replenishment schedules between a firm’s manufacturing

facilities and its distribution centers.Usually coupled with MRP systems to manage the flow and timing of both inbound materials and outbound finished goods.

Underlying rationale is to more accurately forecast demand and the

share that information for use in developing production schedules

Vendor Managed Inventory (VMI)

Vendor-managed inventory manages inventories OUTSIDE a

firm’s logistics network, specifically inventories held in its

customer’s distribution centers.How it works:

1. The supplier and its customer agree on which products are to be managed using VMI in the customer’s distribution centers.

2. An agreement is made on reorder points and economic order quantities for each of these products.

3. As these products are shipped from the customer’s distribution center, the

customer notifies the supplier, by SKU, of the volumes shipped on a real- time basis.4. The supplier monitors on-hand inventories in the customer’s distribution center, and when the on-hand inventory reaches the agreed-upon reorder point, the supplier creates an order for replenishment, notifies the customer’s distribution center of the quantity and time of arrival, and ships the order to replenish the distribution center

Principal advantages of VMI systems

The knowledge gained by the supplier of real-time inventory levels of its products at its customer locations allows the shipper more time to react to sudden swings in demand to assure that stockouts do not occur.

Principal shortcomings of VMI systems

Suppliers’ uses of VMI to push excess inventory to a customer distribution center at the end of the month in order to meet monthly sales quotas, resulting in the customer holding extra inventory, adding costs to its operations

Inventory Classification Techniques

Multiple product lines and inventory control require organizations to focus on more important inventory items and use more sophisticated and effective approaches to inventory management.

ABC Analysis

ABC classification technique assigns inventory items to one of three groups according to the relative impact or value of the items that make up the group. A items are considered to be the most important, B items lesser importance, and C items least important.

Pareto’s Law (The “80–20” Rule)

Pareto’s Law “80–20” rule suggests that a relatively small percentage of inventory might account for a large percentage of the overall impact or value.

Quadrant Model

Quadrant model classifies finished goods inventories using value and risk to the firm as the criteria. Value is measured as the value contribution to profit; risk is the negative impact of not having the product available when it is needed.

ABC Classification

In many ABC analyses, a common mistake is to think of the B and C items as being far less important than the A items. However, all items in the A, B, and C categories are important to some extent and each category deserves its own strategy to assure availability at an appropriate level of cost (stockout cost vs. inventory carrying cost).

Quadrant Model

Items with high value and high risk (critical items) need to be managed carefully to ensure adequate supply. Items with low risk and low value (generic or routine items) can be managed much less carefully.

Full Exam review

demand management

essence of demand management “slide”

demand forecasting “slide”

all demand is subject to fluctuation “slide” know the differences in fluctuations

common forecasting techniques- simple moving average & weighted moving average- know the difference between the two types; when it comes to “weighting”

common qualitative methods “slides” know what each is and difference between them

sales and operations

CPFR

difference between them

know the acronyms

Order management & customer service

order management “slide”

influencing order how and why companies do that

section about how companies “tender” orders

customer service “slide”

understand the difference between what customer service is

order management influencing the order “slide”

customer relationship management

4 steps of the relationship process

what is activity based costing- principle behind why companies use this

customer segmentation

profitable customers, change customers, danger zone customers; know the customer in each

order to cash cycle

customer service in logistics “slide”; what marketing org does v logistics org does

dreaded stockout

know what a stockout is and potential outcomes

terminology

financial impact on product availability “slide”; understand the breakeven point

Inventory management

basic facts about inventory

COGS

basics of inventory management “slide”

3 types of inventories; know which one which is

rational behind different types of inventories

seasonality, procurement, emergency or unusual need

inventory carrying cost “slide”; know the cost categories

what is not a part of inventory carrying cost?

inventory carrying cost vs. ordering cost

economic order quality “slide”

know reorder point vs safety stock

all things “just in time” JIT

requirement planning, basics on “planning”

all the acronyms with planning

vendor management

advantages and disadvantages

inventory classification techniques

ABC Vs. Quadrant models