Distillation

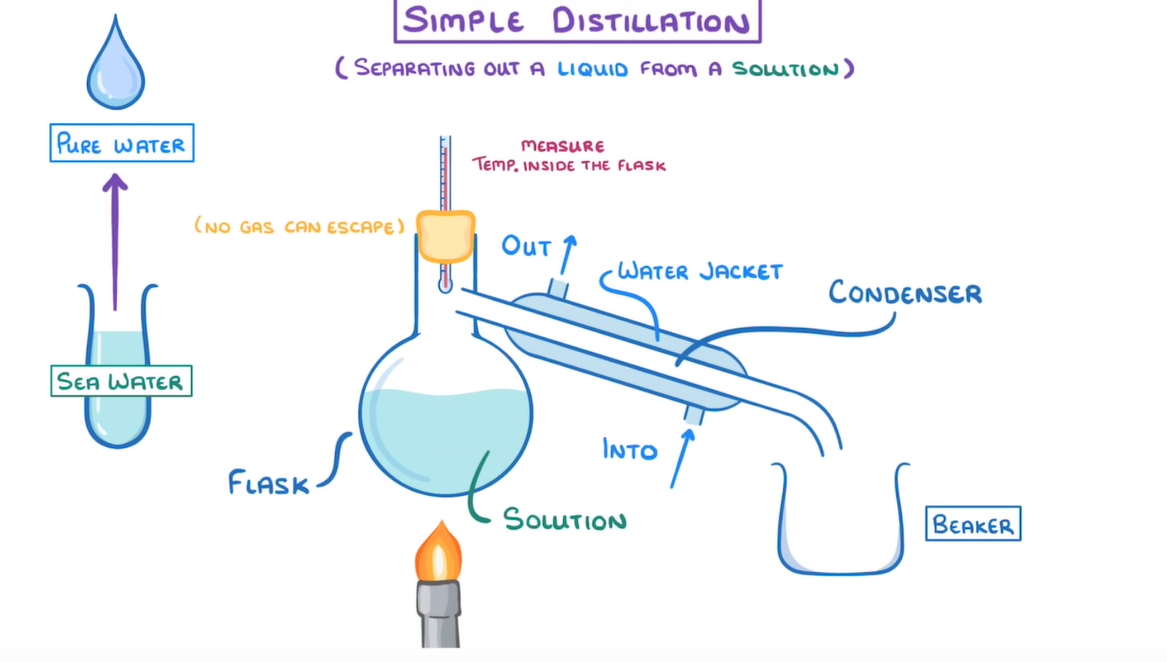

Simple

Setup

- Flask - contains liquid solution

- Bun - seals flask so no gasses can escape

- Thermometer - placed through bun to measure temp inside the flask

- Condenser - attached to a water jacket to provide a stream of continuously flowing cold water

- Beaker - at the end of the condenser to capture pure liquid

- Bunsen burner - placed beneath the flask to heat the solution

Process

- Heat the mixture using a Bunsen burner so that desired liquid evaporates

- As the gas rises to the top of the flask, the pressure will force it into the condenser

- Because their is a continuous flow of cool water, the gas will condense back into liquid where it is collected in the beaker.

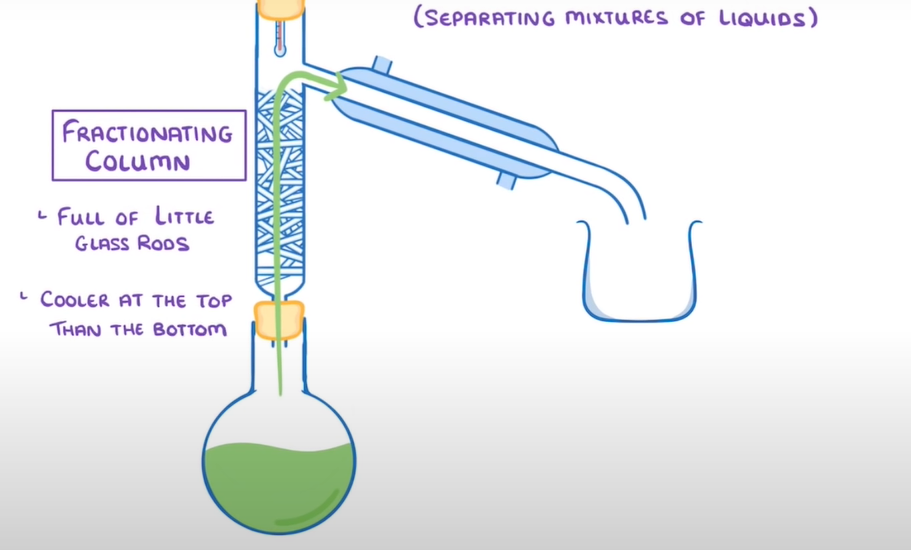

Fractional

Setup

- Flask - contains mixture

- Bun - seals beaker to prevent gasses escaping

- Fractioning column - filled with tiny glass tods to maximise surface area and cooler at the top then the bottom to prevent unwanted gasses evaporating

- Condenser - attached to water jacket to provide a continuous flow of cool water

- beaker - collects pure liquid provided by the condenser

- Bunsen burner - heats mixture in flask

Process

- Flask filled with a mixture containing different liquids of different boiling points

- Flask is heated by Bunsen burner at temperature of the liquid with the lowest boiling point

- This liquid then travels through the fractioning column and is forced into the condenser due to the pressure

- Due to continuous flow of cool water provided by the water jacket the gas condenses back to water and is collected in the beaker

- If any of the other liquids somehow evaporate, the fractioning column condenses them back to liquid as the glass rods are cooler than their boiling points

- Process is repeated at the temperature of each mixtures individual boiling points.