5. Life Cycle Analysis

What is LCA?

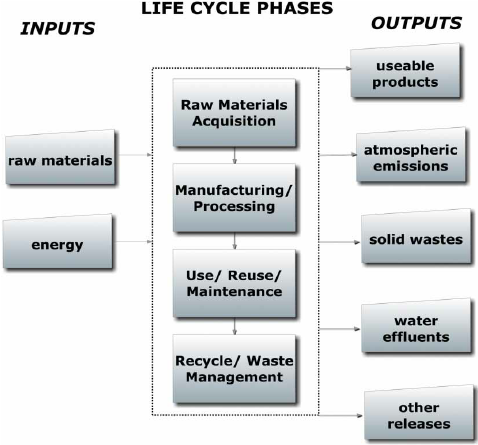

LCA is the process of evaluating the environmental aspects and potential impacts that a product has on the environment over the entire period of its life cycle:

- Extraction and processing

- Manufacture

- Transport and distribution

- Use, re-use and maintenance

- Recycling and final disposal

Carbon footprint is an LCA with Global Warming Potential being the only environmental impact category.

The process includes:

Compiling an inventory of inputs and outputs

Evaluating the potential environmental impacts of the inputs and outputs (e.g. water consumption, waste production, CO2 emissions)

Interpreting the results in relation to the objective of the study

| System Boundary | Life Cycle Stages |

|---|---|

| Cradle to Gate | Raw materials to Manufacturing |

| Cradle to Laid / Made | Raw materials to Construction |

| Cradle to Grave | Raw materials to Demolition (even if not used) |

| Cradle to Cradle | Raw materials to re-use and recycle (stay within the system - in line with a circular economy) |

Why use LCA?

Use LCA because it includes future impacts and allows for long-term planning.

Can compare different products with the same function.

Gives a whole picture of the impacts for a client or designer to make decisions.

Benchmarking and target setting.

Marketing and Labelling of LCA - good to communicate the sustainability of a project to people.

Methodology

Guidelines (PAS 2050 from the BSI website) are available which describe the methodology required by standards ISO14040/4.

Goal and Scope

This should state the intended application, the reasons for the study and the intended audience.

The scope should state:

- Function and functional unit (functional unit is the unit that values will be calculated from, e.g. a specific length of track for a rail)

- System boundaries (elements of life cycle and inventory)

- Data quality requirements

- Any comparisons between products

- Critical review considerations (audit and transparency) but this depends on the audience

Inventory Analysis

This is the data collection and calculations to determine the inputs and outputs of a product system, e.g. quantify resource inputs, emissions, etc.

This is an iterative process with the goal and scope, as data gaps are identified and system boundaries are redefined. Data gaps as collecting data can be very expensive or difficult.

Impact Assessment

The environmental impacts associated with inventory data are determined using databases (tell us CO2 emissions for different materials).

The detail, choice of impacts and methods depend on the Goal and Scope.

This is iterative with the Goal and Scope, as the goal might change as the impacts are assessed.

Impact categories can include:

- Climate change

- Fossil fuel depletion

- Acid deposition

- Ozone depletion

- Water extraction

- Waste disposal

Interpretation

This is the inventory analysis and impact assessment combined, to reach conclusions and recommendations, bearing in mind the goals, scope and audience.

Interpretation stage is iterative with Scope and Inventory data, as more inventory can be collected to reach better conclusions and recommendations.

It is very important to state assumptions, so we know what is being ignored.

Goal and scope definition is important because different impact categories can lead to different interpretations.

Case Study

Does reusing bricks reduce the carbon footprint or would an alternative to bricks be a better option? LCA for both options is carried out and results are compared.

Environmental Product Declarations (EPDs)

An EPD communicates verifiable, accurate, non-misleading environmental information for products and their applications to support scientifically based, fair choices, and to stimulate environmental improvement.

EPD information is expressed as information modules, allowing for easy organisation and expression of data packages.

The approach requires underlying data to be consistent, reproducible and comparable.

The EPD can be aggregated to provide complete information for projects.

Product Category Rules (PCR)

The European Standard BS EN 15804 provides core PCRs for all construction products and services and a structure to ensure EPDs of products, services and processes are derived, verified and presented well.

The core PCR:

- Defines the indicators to be declared, information to be provided and the way that they should be collated and reported

- Describes which stages of the product’s life cycle are considered in the EPD and which processes should be included in the life cycle stages

- Defines rules for the development of scenarios

- Includes rules for calculating the inventory and the impact assessment underlying the EPD, including the specification of the data quality

- Includes rules for reporting information that is not covered by LCA for a product, process or service

- Defines the conditions under which products can be compared based on the information provided by EPD

Given in a table, depending on system boundaries, and the module being looked at (depending on process or data types).

LCAs produce a lot of information based on a lot of assumptions.

BRE Green Guide to Specification

Communicates the results of an LCA to those who need it. Provides an LCA and certification of construction products.

Based on a 60-year lifetime and 13 environmental impact categories which are normalised and weighted into Ecopoints, to give an A+ to E rating.

Different construction components considered in different building types.

Advantages of BRE guide:

- Ease of use of rating system

- Experience and acceptance

Disadvantages of BRE guide:

- Non-compliant with standards

- Limited range of construction products

- Weighting is subjective

- Hides information - can’t see what the issue is caused by looking at only one letter (oversimplification)

- As for all LCA, there is no comparison to environmental limits

Case Study: Embodied Energy of Alternative Rail Track Bed

Comparing ballasted track and concrete track beds.

- Goals listed

- Audience listed

- Scope: Functional unit = 10km straight, high speed, passenger only twin track; Impact assessment = energy use, greenhouse has emissions, solid waste, water pollution; Lifetime sensitivity analysis; data sensitivity analysis (how accuracy and quality of data impacts analysis).

- Assumptions described, e.g. no impacts associated with the manufacture of machinery.

- Inventory: Materials, Machinery, Sensitivity Analysis (min. and max. life expectancy)

- Impact Assessment: Embodied Energy (as a range), Energy Sources, Energy Emissions converted to CO2e

- Results: Given as a graph of min and max lifetimes of components from different rail options against CO2e.

- Conclusions: made based on results and link back to the goals listed. Dynamic LCA required for long lived systems.

- Limitations: list problems with the analysis, e.g. lack of data, if more detail was required anywhere.