CIVL4170-2025-S1-Week02-_Lecture_3_4_-_The_Risk_Management_Process_-lecture_slides_1_

CIVL4170: Risk Analysis in Civil Engineering

Lecture Overview

Lecturers: A/Prof Ilje Pikaar

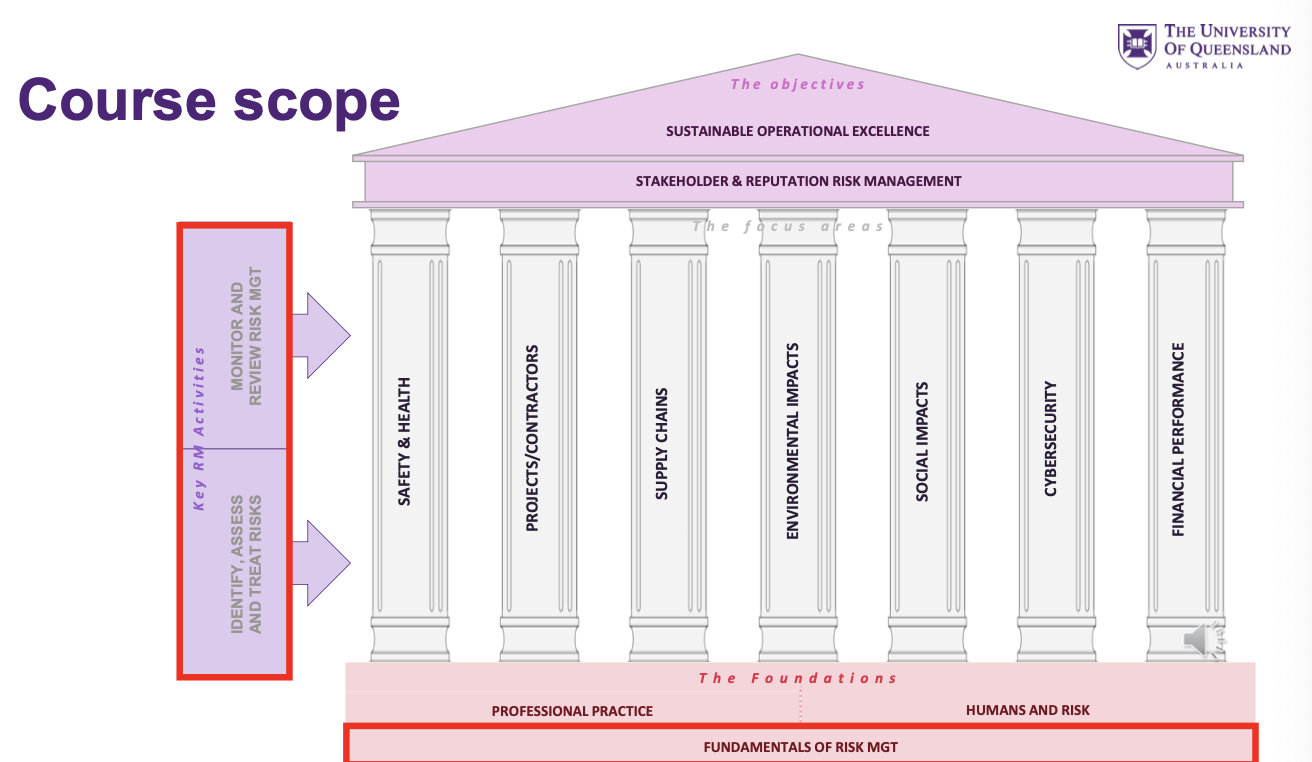

Course Structure:

Week 2 - Semester 1, 2025

Risk Management Process

$

Overview of ISO 31000 Risk Management Framework

Step 1: Establish the Scope

Define objectives and stakeholders

Clarify the scope of risk management activities

Document context to ensure common understanding

Step 2: Risk Identification

Identify, recognize, and describe risks

Utilize team of experts from various engineering disciplines

Step 3: Risk Analysis

Evaluate the probability and consequences of risks using qualitative and quantitative methods

Step 4: Risk Evaluation

Assess whether risks are acceptable or require treatment

ALARP - As Low As Reasonably Practicable

Step 5: Risk Treatment

Determine controls needed to mitigate risks

Step 6: Monitoring and Reviewing Risks

Keep the risk register up-to-date and evaluate the effectiveness of controls

Importance of Risk Management for Civil Engineers

Engineers design processes and structures involving hazards such as height, speed, and hazardous substances.

Systematic and transparent risk management is crucial to ensure safety.

Compliance with regulations like the Health and Safety Act (2011) and Environmental Protection Act (1994).

Defining Key Terms

Definition of Risk

Risk: Effect of uncertainty on objectives.

Effect: Deviation from expected outcomes (positive or negative).

Objectives: Can vary across levels (strategic or project-based).

Uncertainty: Lack of information related to events and consequences.

Definition of Hazard

Hazard: A source that can cause injury, illness, or circumstances leading to harm as per ISO 45001.

Importance of Probability and Repetition

Understanding how repetition impacts likelihood.

Example: Dutch dike design assumes flood exposure probability of 1 in 1250 years.

Systematic Risk Analysis Framework

Systematic approach helps choice-making amidst ambiguity in projects.

Risk management framework assists engineers in making organized decisions.

Key Findings from Week 1

Many incidents arise from failure to manage known risks effectively.

Risk management ensures clear stakeholder communication and understanding.

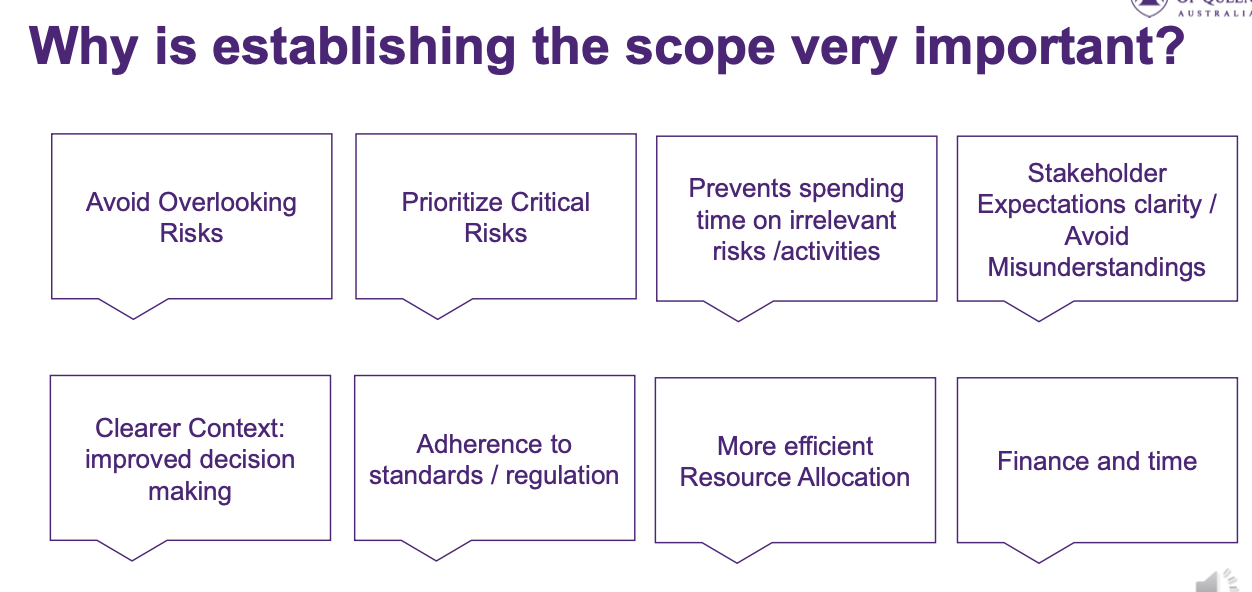

Detailed Steps in Establishing Scope

Importance of scope:

Helps avoid overlooking risks and prioritizing critical risks.

Enhances clarity for stakeholder expectations, leading to improved decision-making.

Scope Table Elements

People: Involved in risk management or impacted by risks.

Locations: Areas affected by risks.

Equipment: Tools and infrastructure involved.

Activities: Operations linked to risks.

Environmental considerations: Climate and weather-related impacts.

Risk Identification Techniques

HAZID/ PHA: Identifying potential hazards.

Job Hazard Analysis (JHA): Analyzing job-specific risks.

HAZOP: Structured examination of processes for hazard identification.

Checklists: Reviewing policies at various design and operational stages.

FMEA: Analyzing potential failure modes in systems and their impacts.

Risk Analysis Methodologies

Common techniques include:

Risk Matrix: Qualitative assessment of risk likelihood and impact.

Quantitative Methods: Conditional probability methods and mathematical modeling.

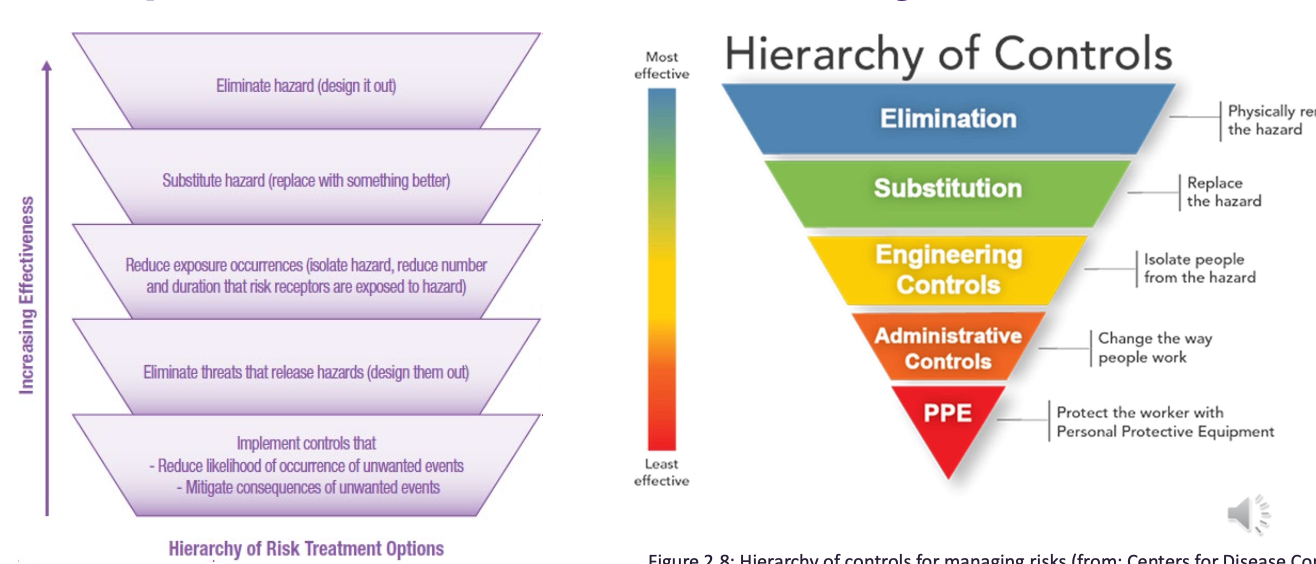

Risk Evaluation and Treatment Essentials

Evaluate risks against acceptable standards (ALARP principle).

Focus on inherently safe designs and layers of protection.

Monitoring and reviewing existing controls to ensure effectiveness and compliance.

Concluding Remarks

Important principles: Inherently Safe Design, Defence-in-Depth, and continuous improvement in risk management.

Ongoing communication and documentation are crucial to ensure effective risk management practices.

Knowt

Knowt