(5 - 6) microstructures qwq

Chapter 5 microstructures introduction (point defects, diffusion)

3 Types of Bonds:

Metallic: sea of electrons + metallic cations (two metals)

Covalent: sharing electron (two nonmetals)

Ionic: transfer of electrons (nonmetal + metal)

Rare Crystal Structure:

Simple Cubic: atom at each corner of a cube → repeating square lattice

Common Crystal Structures:

fcc (face centered cubic) → corners + faces (highly packed)

HCP (hexagonal close packed) → hexagon top + bottom + 4 faces (highly packed)

bcc (body centered cubic) —> corners + center

bct (body centered tetragonal) → corners + center (elongated)

Microstructure Approximate Size:

Atoms: 10-9

Microstructure: 10-4

Processing → Microstructure → Properties

Defects in crystals

Phases

Defects:

Point Defects

Vacancy (gone) → Schottky

Self interstitial atom (displaced same) → Frenkel

Interstitial impurity atom (small foreign squeezes itself in)

Substitutional impurity atom (foreign replaces)

Dislocations (line defects)

Edge

Screw

Grain Boundaries (plane defects)

What do defects do to the material?

Elastic stress

Increase free energy (unstable)

favorable to REMOVE defects but requires thermal activation (slow)

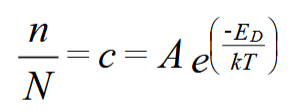

n is number of defects, N is number of atoms, A is a constant, k is Boltzmann’s constant

k = 1.38 × 10-23 J / K

ED is energy of formation for defect

Self Diffusion: only one component due to movement of vacancies

Chemical Diffusion: more than one chemical species (high concentration to low)

Chapter 6: Line Defects (Dislocation) and Planar Defects

Burger’s Vector: vector of lattice distortion bc of dislocation

Glide (slip) bc of sheer stress ALONG slip plane

Climb bc of atomic diffusion PERPENDICULAR slip plane

no equilibrium concentration

due to plastic deformation

How to get rid of line defects:

Recovery

Recrystallisation

Mixed Dislocation (screw + edge): Loops

Types of Planar Defects:

Surfaces (different phases)

Boundaries between solids

Grain boundary: same phase, different orientation due to angle

Interface (same phase, but aligned either perfectly, messy, not not at all)

Coherent

Semicoherent

Incoherent

Twin boundaries (reflection in hcp metals)

Breaking or distorting atomic bonds → energy increase + inc in reactivity

Calculations:

Light Equations:

E = hv

c = λv

c = 3 × 10^8

h = 6.626 × 10^-34

1 Amstrong = 10-10 m

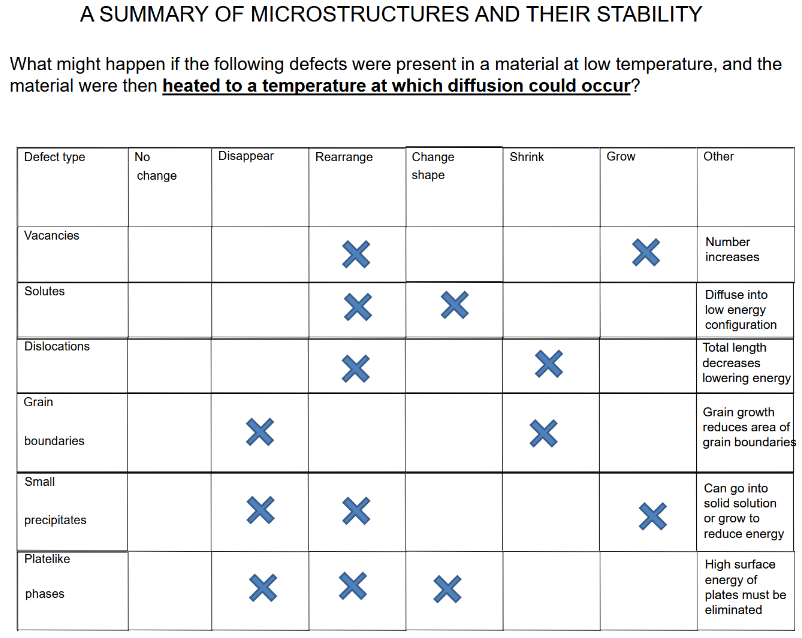

Know this silly chart: